Full-automatic detection method for pneumatic valve based on gas turbine purging system

A detection method and pneumatic valve technology, which are applied in mechanical valve testing, electrical program control, program control in sequence/logic controllers, etc., can solve problems such as low work efficiency, large number of personnel, and high operating intensity of maintenance personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]In order to understand the technical features, objects, and effects of the present invention, specific embodiments of the present invention will be described with reference to the drawings.

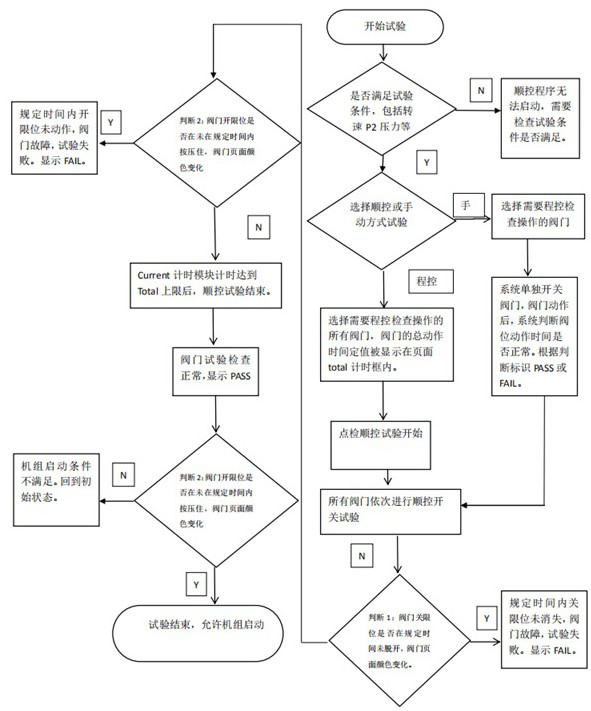

[0030]Such asfigure 1As shown in the present embodiment, a fully automatic detection method based on a pneumatic valve based on a combustion engine cleaning system is included, and the air valve fully automatic detection method includes the following steps:

[0031]S1: With the Mark Vie Control System Control Logic Block, including the air blowing system pneumatic valve that needs to be checked, and performs visual operation;

[0032]S2: combine and select the air-blown system pneumatic valve that needs to be checked;

[0033]S3: Set test conditions and test requirements, the conditions including pre-condition and latching conditions;

[0034]S4: Judging whether the valve test is qualified.

[0035]The step S4 also includes the following sub steps:

[0036]S41: After the unit condition meets the front conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com