Heat preservation and decoration integrated composite plate and production process therefor

A composite board, an integrated technology, applied in the field of composite boards, can solve the problems of poor mechanical properties and insignificant heat removal effect, so as to enhance the ability to resist external force damage, improve thermal insulation performance and mechanical performance, and reduce compressive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

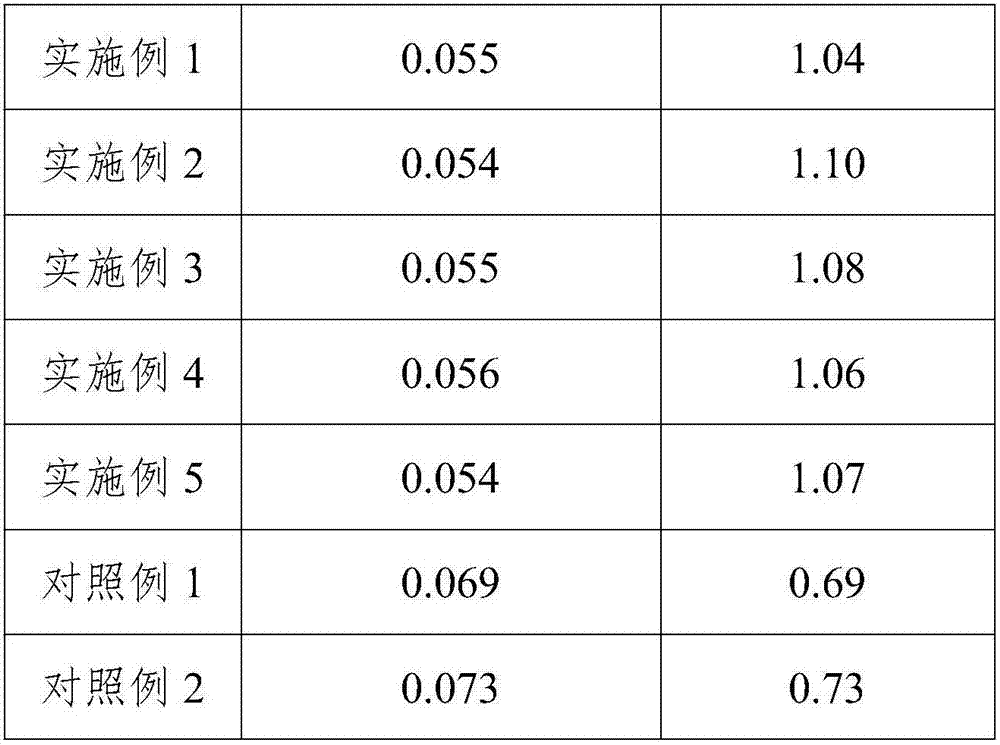

Embodiment 1

[0020] A thermal insulation and decorative integrated composite board, made of the following raw materials in parts by weight: 30 parts of calcium silicate, 2.5 parts of graphite, 1 part of sepiolite powder, 2 parts of vitrified microbeads, 3 parts of admixture, 5 parts of cement, 2 parts of zirconia powder, 1 part of aluminum oxide powder, and 3 parts of silicon rubber.

[0021] A thermal insulation and decoration integrated composite board and its production process, the production process includes the following steps:

[0022] (1) Grind graphite and calcium silicate in a tube mill at 25°C, crush them through a 400-mesh sieve, put the ground powder in the reactor, add water half the mass of graphite and calcium silicate, and Stir mechanically at a speed of 150r / min for 30min, set aside;

[0023] (2) Put the vitrified microspheres and sepiolite powder in the reaction kettle, add water equal to the quality of the two, ultrasonically treat for 20 minutes, add admixtures and ce...

Embodiment 2

[0026] A thermal insulation and decoration integrated composite board, made of the following raw materials in parts by weight: 48 parts of calcium silicate, 4 parts of graphite, 5 parts of sepiolite powder, 6 parts of vitrified microbeads, 8 parts of admixture, 9 parts of cement, 7 parts of zirconia powder, 6 parts of aluminum oxide powder, and 7 parts of silicon rubber.

[0027] A thermal insulation and decoration integrated composite board, the production process of which includes the following steps:

[0028] (1) Grind graphite and calcium silicate in a tube mill at 30°C and pass through a 400-mesh sieve. Put the ground powder into the reactor, add water half the mass of graphite and calcium silicate, and Stir mechanically at a speed of 200r / min for 30min, set aside;

[0029] (2) Put the vitrified microspheres and sepiolite powder in the reaction kettle, add water equal to the quality of the two, ultrasonically treat for 20 minutes, add admixtures and cement, and mechanica...

Embodiment 3

[0032] A thermal insulation and decoration integrated composite board, made of the following raw materials in parts by weight: 36 parts of calcium silicate, 3 parts of graphite, 3 parts of sepiolite powder, 3 parts of vitrified microbeads, 5 parts of admixture, 6 parts of cement, 4 parts of zirconia powder, 3 parts of aluminum oxide powder, and 4 parts of silicon rubber.

[0033] A thermal insulation and decoration integrated composite board, the production process of which includes the following steps:

[0034] (1) Grind graphite and calcium silicate in a tube mill at 26°C, crush them through a 400-mesh sieve, put the ground powder into the reactor, add water half the mass of graphite and calcium silicate, and Stir mechanically at a speed of 160r / min for 30min, set aside;

[0035] (2) Put the vitrified microspheres and sepiolite powder in the reaction kettle, add water equal to the quality of the two, ultrasonically treat for 20 minutes, add admixtures and cement, and mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com