Modified ABS material doped with graphene nanosheet and aluminum nitride nanoparticles for 3D printing and preparation method of modified ABS material

A technology of graphene nanosheets and ABS materials, which is applied in the field of 3D printing, can solve the problems of obvious shrinkage, cracking, and easy warping of materials when they are cold, so as to improve the yellowing phenomenon, enhance the interface adhesion, and reduce the use of materials. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

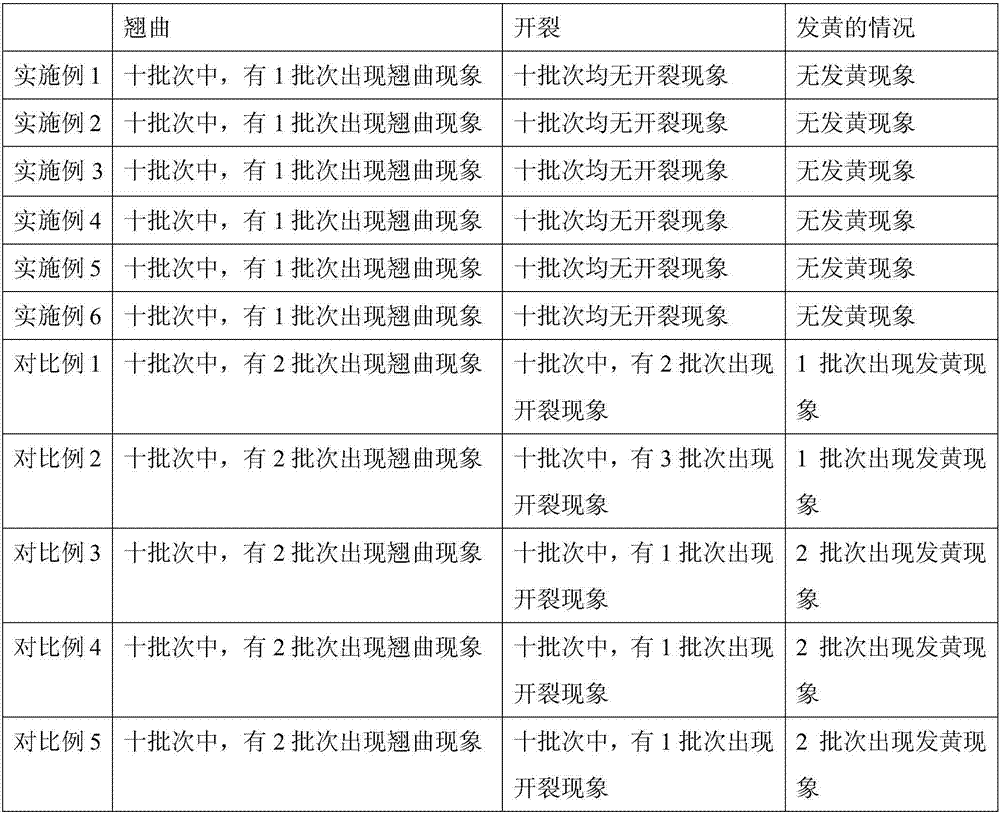

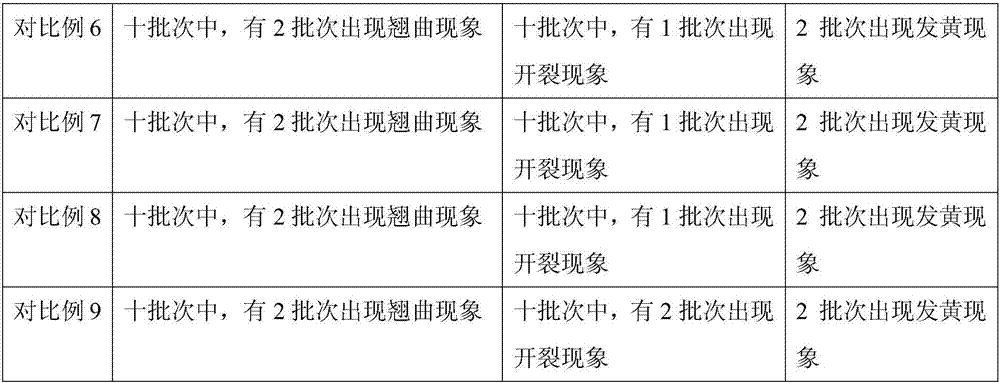

Examples

Embodiment 1

[0028] The SBS and ABS were heated at 65°C, dried in vacuum, and mixed with the surfactant evenly; then glass fibers, graphene nanosheets and aluminum nitride nanoparticles were added, mixed, heated at 200°C, and then extruded through a screw and dried to obtain a modified solution. ABS material after sex.

[0029] in,

[0030] SBS 20kg

[0031] ABS 100kg

[0032] Surfactant 1kg

[0033] Fiberglass 20kg

[0035] Aluminum Nitride Nanoparticles 4kg

Embodiment 2

[0037] The SBS and ABS were heated at 50°C, dried in vacuum, and mixed with the surfactant evenly; then glass fibers, graphene nanosheets and aluminum nitride nanoparticles were added, mixed, heated at 180°C, and then extruded through a screw and dried to obtain a modified solution. ABS material after sex.

[0038] in,

[0039] SBS 40kg

[0040] ABS 100kg

[0041] Surfactant 1kg

[0042] Fiberglass 5kg

[0044] Aluminum Nitride Nanoparticles 2kg

Embodiment 3

[0046] The SBS and ABS were heated at 70°C, dried in vacuum, and mixed with the surfactant evenly; then glass fibers, graphene nanosheets and aluminum nitride nanoparticles were added, mixed, heated at 180°C, extruded through a screw, and dried to obtain a modified solution. ABS material after sex.

[0047] in,

[0048] SBS 50kg

[0049] ABS 100kg

[0050] Surfactant 2kg

[0051] Fiberglass 10kg

[0052] Graphene Nanosheet 3.2kg

[0053] Aluminum Nitride Nanoparticles 3kg

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com