Clamping device

A fastening device and locking clip technology, applied in the direction of threaded fasteners, clothing, connecting components, etc., can solve the problems of low drawing strength, high cost, and great importance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

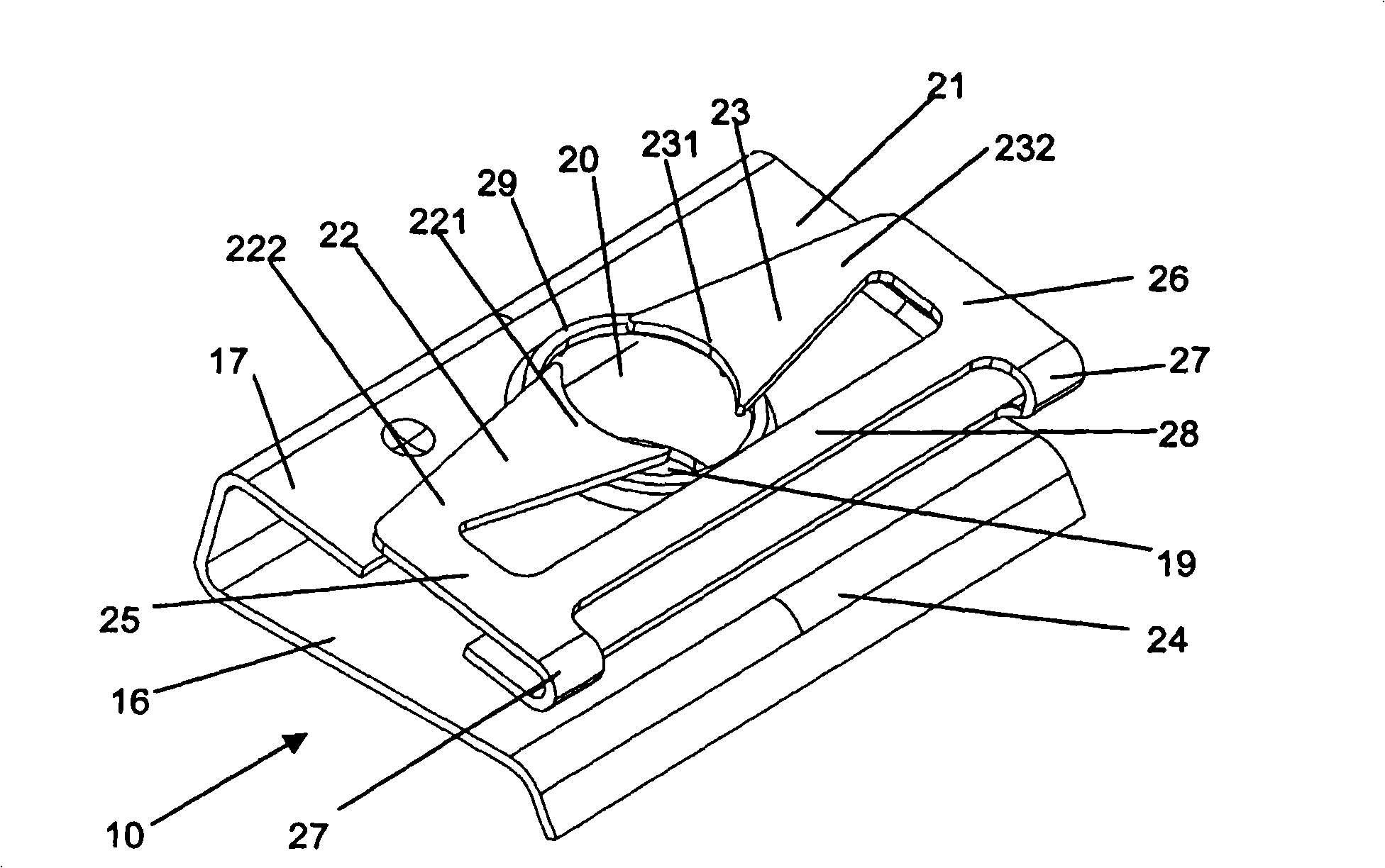

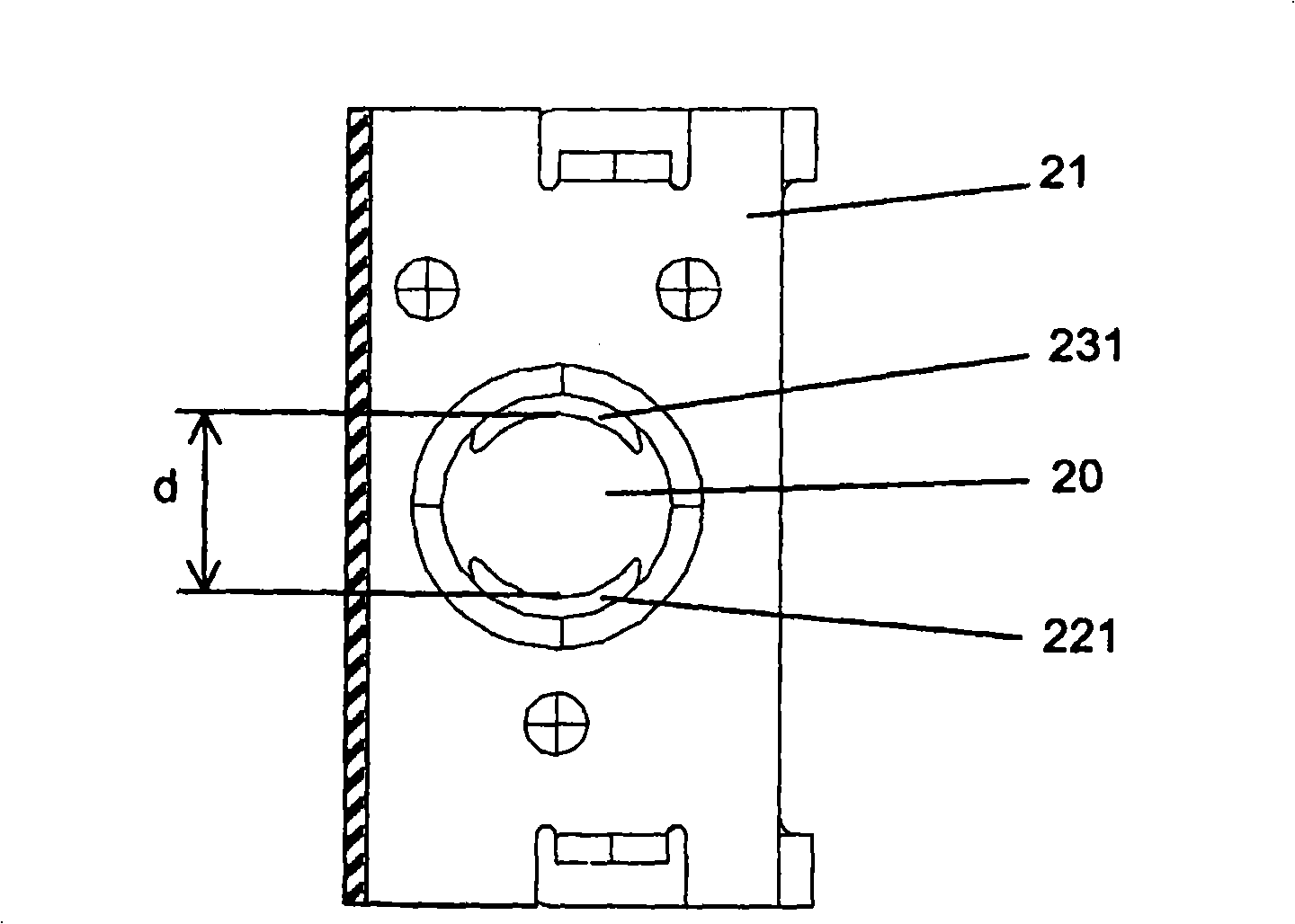

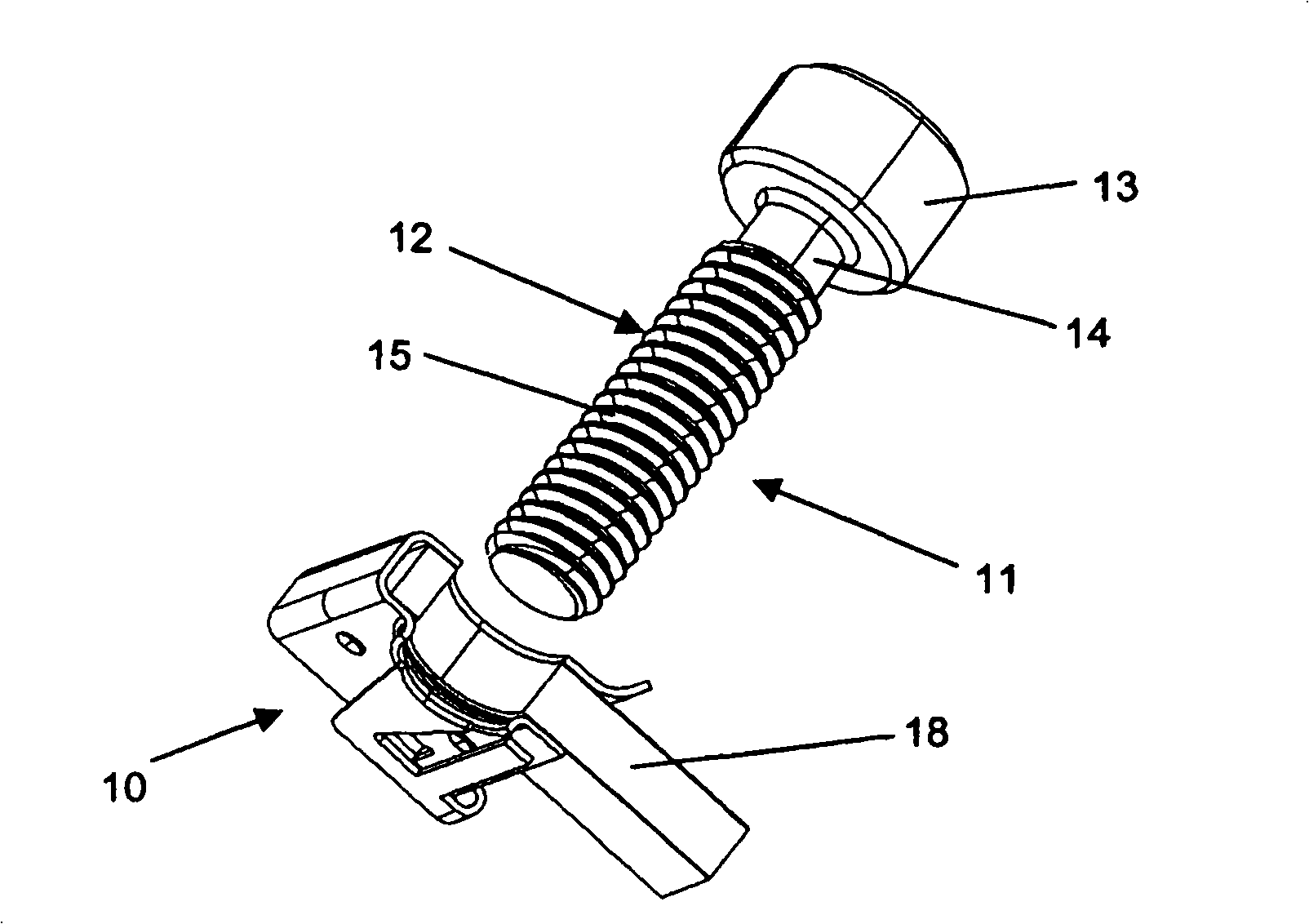

[0018] Figures 1 to 3 A first embodiment of a fastening device according to the invention is shown, comprising a locking clip 10 and a screw part 11 . Bolt member 11 (for example is made of metal, and only in image 3 ) includes a partially threaded rod 12, and a support head 13 at the end called the proximal end. The rod 12 has a smooth upper portion 14 close to the support head 13 and a threaded lower portion 15 extending to the opposite end, referred to as the distal end.

[0019] In this first embodiment, the locking clip 10 is configured as a generally U-shaped cavalier (metal clip) with a first branch 16 and a second branch 17 that are substantially parallel. The locking clip 10 is manufactured by cutting and bending from sheet metal.

[0020] In the following, the fastening device will be described in a specific but non-limiting example of application, such as for assembling planar elements of the type of panels, laths, sheet metal, etc. However, it is obvious that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com