Second-order hot-mixed epoxy tack coat oil and application thereof

A technology of epoxy adhesive layer oil and hot mixing, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

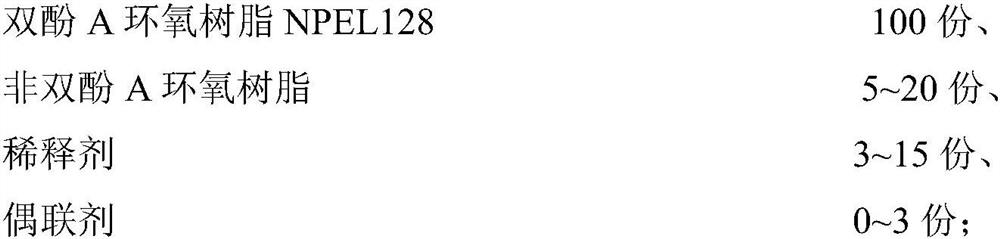

[0023] Described epoxy resin A proportioning:

[0024]

[0025] The resin B component includes the following components by weight

[0026] Octadecylamine 100 parts

[0027] T-99 strong elastic toughness epoxy curing agent 50 parts

[0028] Hot mix epoxy resin preparation:

[0029] Mix the epoxy resin component A and the resin component B according to the above ratio, and mix them according to the mass ratio of the epoxy resin components A and resin B as 3:2, and form the test piece after mixing. Preserve in an oven at 60°C for 4 days, test the basic properties of hot-mix epoxy resin, and the coating amount of epoxy resin is 0.4kg / m 2 .

[0030] Comparative example experimental method:

[0031] The Japanese epoxy resin component A and the resin component B were mixed in a ratio of 1:1, and then mixed to form a specimen. The specimen was cured in an oven at 60°C for 4 days to test the basic properties of the hot-mix epoxy resin.

[0032] Table 1 The main performance par...

Embodiment 2

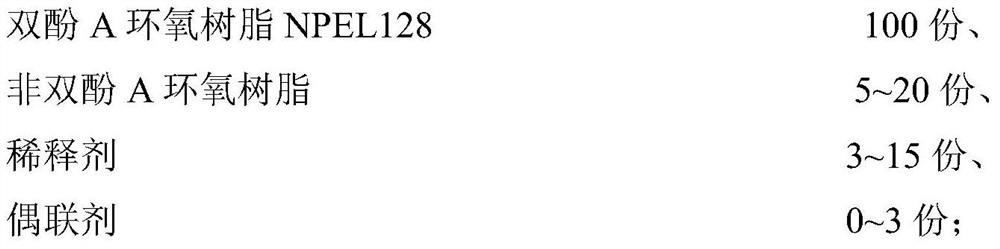

[0035] Described epoxy resin A proportioning:

[0036]

[0037] The resin B component includes the following components by weight

[0038] Oleylamine 120 parts

[0039] Polyetheramine D-230 60 parts

[0040] Hot mix epoxy resin preparation:

[0041] Mix the epoxy resin component A and the resin component B according to the above ratio, and mix them according to the mass ratio of the epoxy resin components A and resin B as 1:1, and form the test piece after mixing. Preserve in an oven at 60°C for 4 days, test the basic properties of hot-mix epoxy resin, and the coating amount of epoxy resin is 0.8kg / m 2 .

[0042] Comparative example experimental method:

[0043] The Japanese epoxy resin component A and the resin component B were mixed in a ratio of 1:1, and then mixed to form a specimen. The specimen was cured in an oven at 60°C for 4 days to test the basic properties of the hot-mix epoxy resin.

[0044] Table 2 The main performance parameters of the second-order hot-...

Embodiment 3

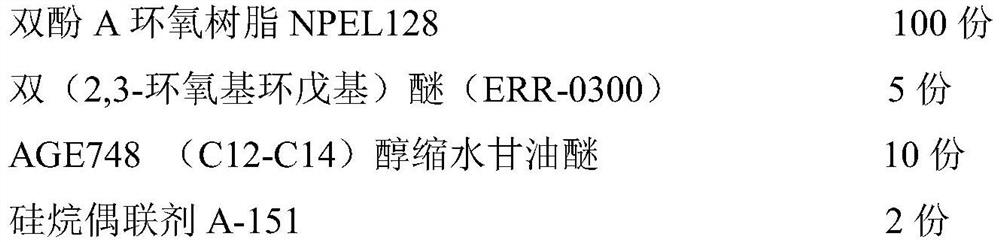

[0047] Described epoxy resin A proportioning:

[0048]

[0049] The resin B component includes the following components by weight

[0050] Hexadecylamine 90 parts

[0051] Polyetheramine D-400 45 parts

[0052] Hot mix epoxy resin preparation:

[0053] Mix the epoxy resin component A and the resin component B according to the above proportions, and mix them according to the mass ratio of the epoxy resin components A and resin B as 56:44, and form the test piece after mixing. Preserve in an oven at 60°C for 4 days, test the basic properties of hot-mix epoxy resin, and the coating amount of epoxy resin is 0.55kg / m 2 .

[0054] Comparative example experimental method:

[0055] The Japanese epoxy resin component A and the resin component B were mixed in a ratio of 1:1, and then mixed to form a specimen. The specimen was cured in an oven at 60°C for 4 days to test the basic properties of the hot-mix epoxy resin.

[0056] Table 3 The main performance parameters of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com