Prefabricated cast-in-place shear wall structure

A shear wall and cast-in-place technology, which is applied to walls, building components, building structures, etc., can solve problems such as difficulty in meeting living requirements, achieve good safety, and reduce the amount of high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

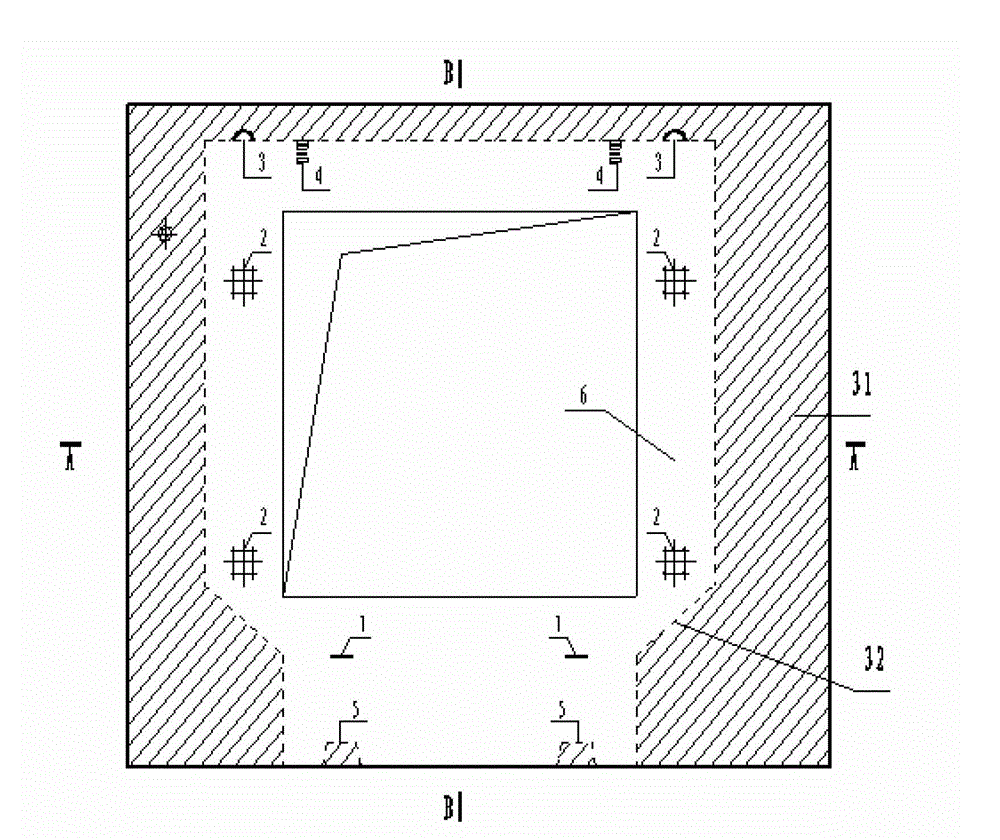

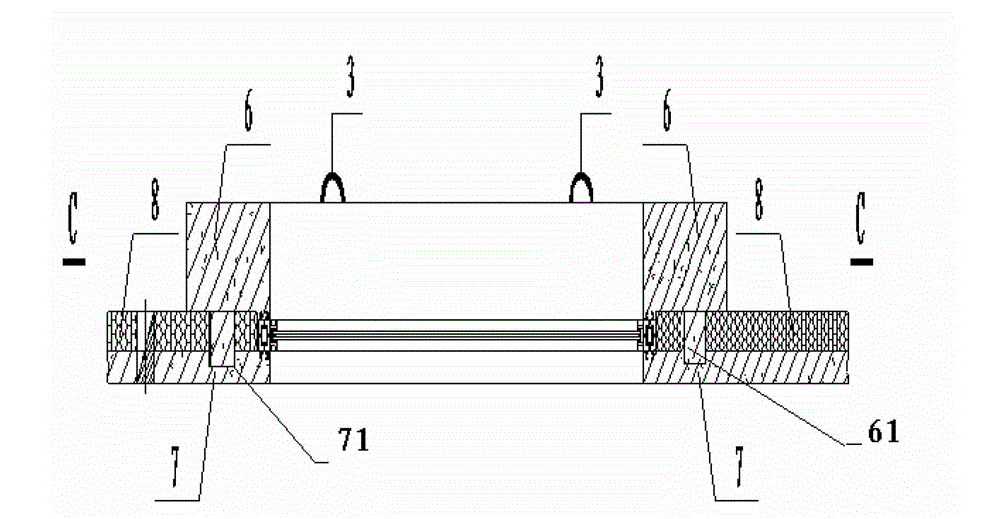

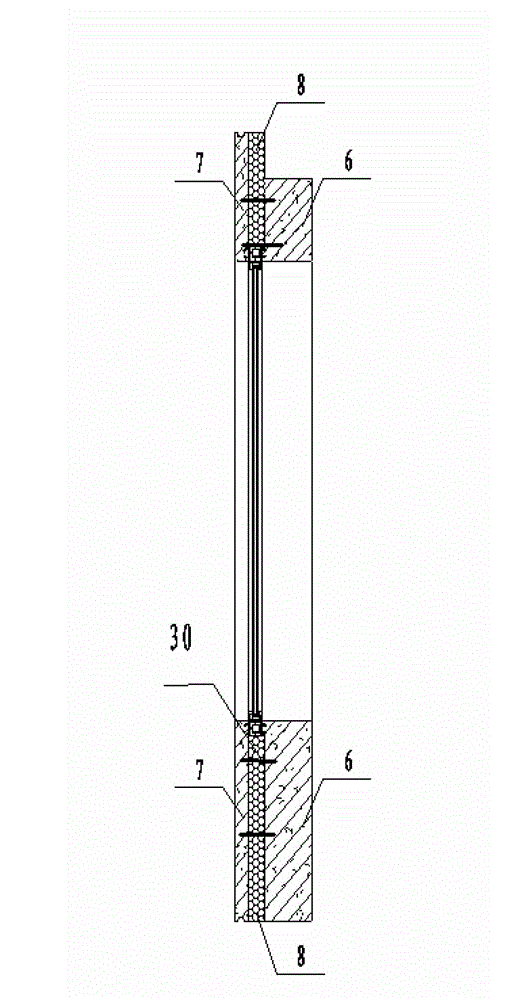

[0041] Such as Figure 1 to Figure 6 Shown is a shear wall structure with a window, including an outer wall 7, an insulating material layer 8, and an inner wall 6, and the insulating material layer 8 is interposed between the outer wall 7 and the inner wall 6 In between, the inner wall 6 is provided with a convex portion 61, and the outer wall 7 is provided with a concave portion 71, and the steel bars exposed by the convex portion 61 and the concave portion 71 are poured with cement so that the outer wall and the inner wall are fixed. become one.

[0042] The other parts between the inner wall 6 and the outer wall 7 are connected by tie bars 30. The inner wall 6 is composed of two parts, one part is a prefabricated part, and the other part is a cast-in-place part 31. The inner wall is prefabricated Some are located in the middle of the outer wall 7, and the area of the prefabricated part of the inner wall is smaller than that of the outer wall 7 to leave space for the cast...

Embodiment 2

[0049] Figure 7 ~ Figure 10 It is another embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that the shear wall does not have reserved holes (windows), but is integral, the same as Embodiment 1, including the outer wall 7, thermal insulation Material layer 8, inner page wall 6, the thermal insulation material layer 8 is interposed between the outer page wall 7 and the inner page wall 6, the inner page wall 6 and the outer page wall 7 are connected by tie bars 30, the The inner wall 6 is made up of two parts, one is a prefabricated part, and the other is a cast-in-place part 31. The prefabricated part of the inner wall is located in the middle of the outer wall 7, and the area of the prefabricated part of the inner wall is smaller than the The outer page wall 7 is to reserve the space of the cast-in-place part, and the inner page wall is also provided with a lifting point 3, a steel bar handle 1, and a position adjustment device;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com