Hoisting method for modular vault-type space tube truss steel structure system building

A hoisting method and a pipe truss technology, which are applied in construction, building structure, processing of building materials, etc., can solve the problems of high safety risk, many high-altitude operations, and many procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

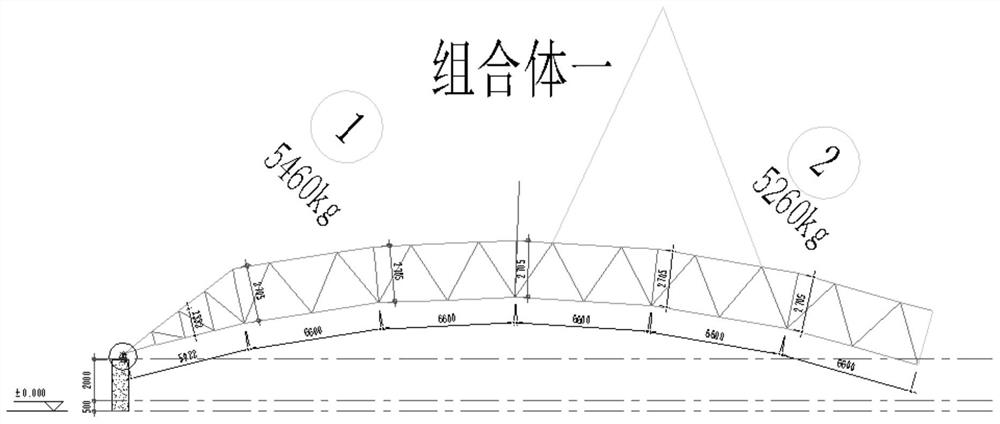

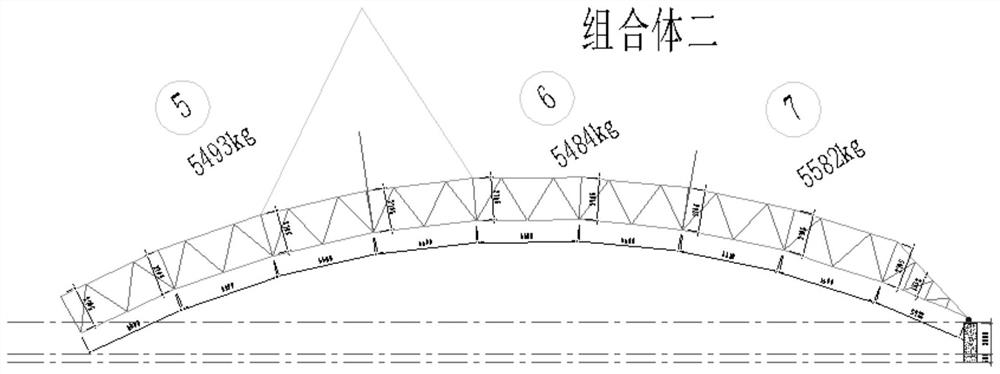

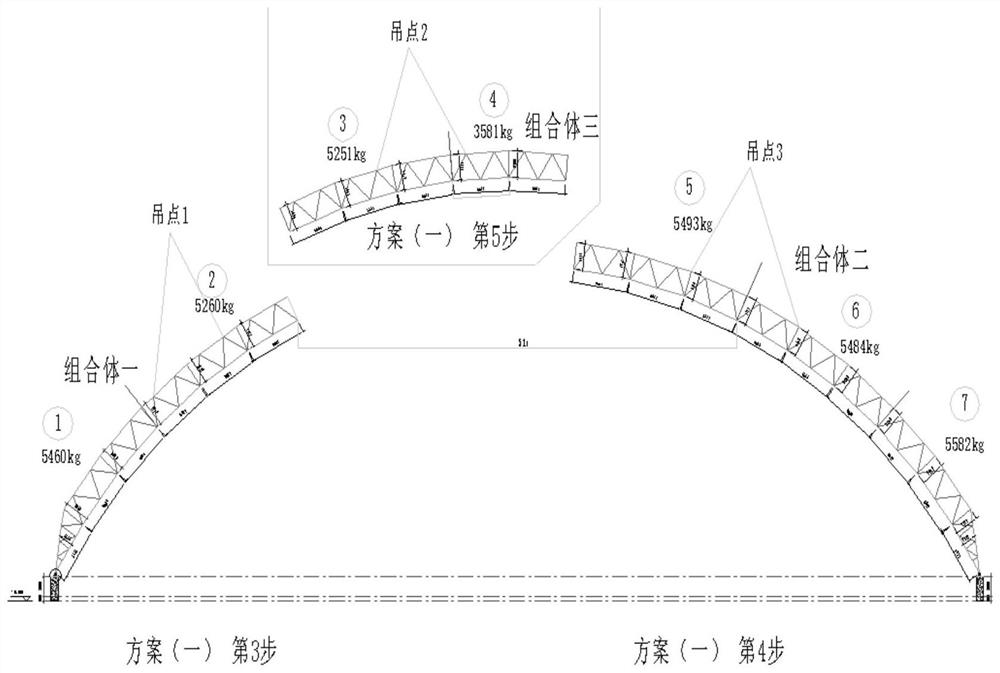

[0037] The 2 steel truss module units are pre-assembled on the ground to form 7 modular units, and then the 7 modular units are assembled on the ground, unit 1 and unit 2 are assembled on the ground to form a module combination 1, Assemble unit body 5, unit body 6, and unit body 7 on the ground into module assembly 2, and assemble unit body 3 and unit 4 on the ground into module assembly 3, using two 80t crawler cranes and one 220t truck crane respectively. Hanging.

[0038] Hanging point setting: 4 hanging points are set on each module combination, and the hanging points are set on the upper chord main pole node of the truss with a vertical pole. In order to ensure that the combination is evenly stressed during hoisting and ascent, the front and rear hoisting points on each truss are dynamically adjusted with a steel wire rope (length 20m) through a fixed pulley set on the balance beam. The wire ropes of the lifting points on the trusses on both sides are connected with the ...

Embodiment 2

[0042] The 2 steel truss module units are pre-assembled on the ground and assembled into 7 module units, and then the 7 module units are assembled on the ground, and the module unit 1, the module unit 2 and the module unit 3 are assembled. Assemble the module assembly 1 on the ground, assemble the module unit body 4, the module unit body 5, the module unit body 6, and the module unit body 7 into the module assembly body 2 on the ground, and use a 160t crawler crane and a 200t truck crane respectively The machine is hoisted.

[0043] Hanging point setting: Set 4 hanging points on the module assembly 1, and the hanging points are set on the upper chord main pole node of the truss with a vertical pole. In order to ensure that the combination is evenly stressed during hoisting and ascent, the front and rear lifting points on each truss are dynamically adjusted with a steel wire rope (20m in length, 25mm in diameter) through a fixed pulley set on the balance beam. The wire ropes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com