Method for preparing polyphenyl particle heat-insulation boards

A technology of polystyrene particles and thermal insulation boards, which is applied in the directions of manufacturing tools, forming indenters, supply devices, etc., can solve the problems of restricting the application of polystyrene particles thermal insulation boards, high thermal conductivity of boards, and large volume water absorption, and achieves porosity. Small, simple process steps, small volume water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

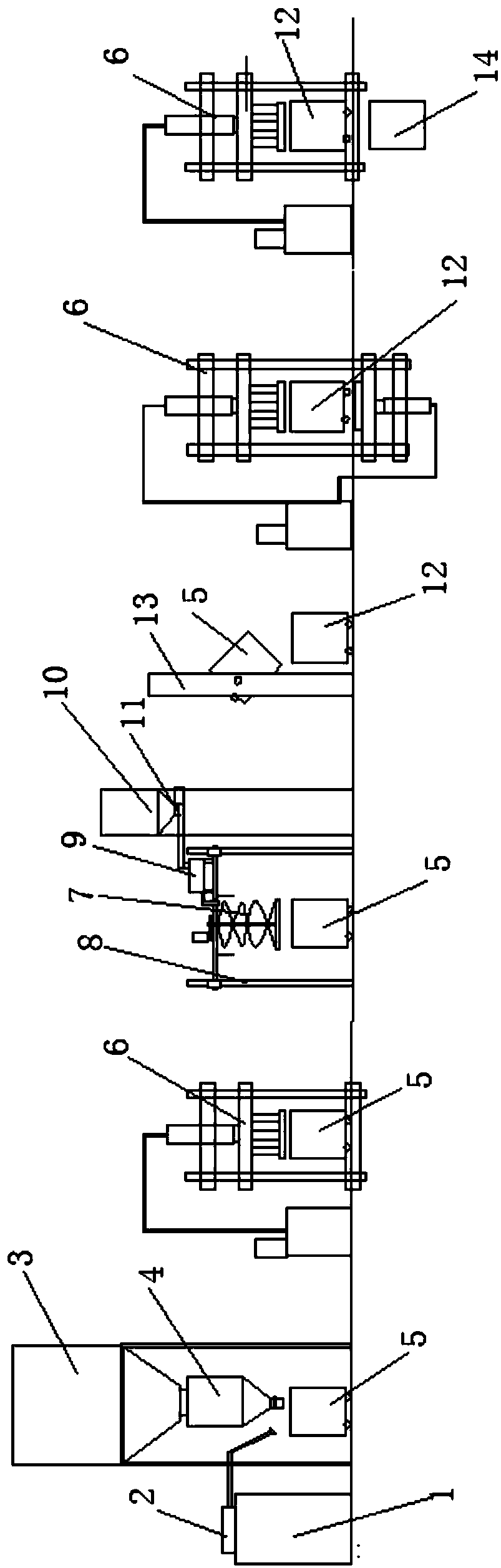

[0027] See attached picture.

[0028] A method for preparing a polystyrene particle insulation board, characterized in that: the raw materials used and the amount per cubic meter are as follows: polystyrene particles 5kg-20kg, cement 80kg-200kg, siliceous mineral powder 5kg-20kg, rubber powder 0.5kg- 8kg, organic emulsion 3kg-20kg, water repellent 3kg-10kg, water 40kg-100kg; during production, the organic emulsion, water repellent and water are stirred evenly to make a mixed liquid, which is mixed with polystyrene particles in a pressing barrel according to a certain proportion Mix evenly, use a hydraulic machine to press repeatedly in the pressing barrel to make the mixed liquid absorb and wrap on the surface and inner shallow layer of the polystyrene particles, use a mixer to break up the pressed polystyrene particles, and then put in cement, siliceous mineral powder and glue The powder material is evenly mixed with powder, and after stirring, it is made into polystyrene gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com