Bridge deck pavement method for orthotropic steel bridge

An orthotropic and bridge deck pavement technology, which is applied in the direction of on-site paved concrete pavement, bridges, bridge parts, etc., can solve the problems of high initial investment, high temperature resistance of waterproof bonding system, and inability to bond firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

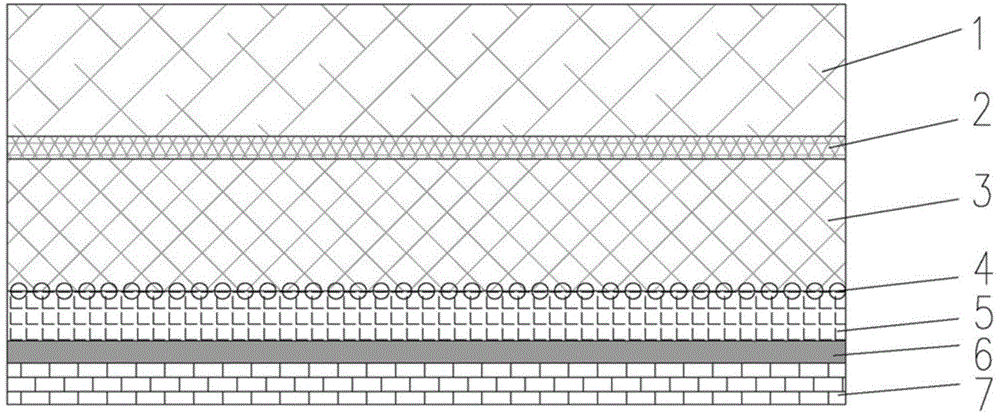

[0055] A pavement method for a deck pavement structure of an orthotropic steel bridge, comprising the steps of:

[0056] (1) Sandblasting and derusting the steel bridge deck to make the cleanliness reach Sa2.5 level and the roughness is 70μm; according to 0.3kg / m 2 The amount of mica-containing epoxy resin used is artificially brushed and rolled to coat a mica-containing epoxy anti-corrosion layer;

[0057] (2) After 24 hours of mica-containing epoxy anti-corrosion coating curing, according to 2.5kg / m 2 The amount of solvent-free epoxy resin is used to scrape a solvent-free epoxy resin waterproof layer;

[0058] (3) Within 30 minutes of completing the solvent-free epoxy resin waterproof layer, according to 0.8kg / m 2 Sprinkle the hot-melt particles with a certain amount, so that half of them are trapped in the solvent-free epoxy resin waterproof layer to form a hot-melt particle bonding layer;

[0059] (4) After 48 hours of curing of the solvent-free epoxy resin waterproof l...

Embodiment 2

[0064] A pavement method for a deck pavement structure of an orthotropic steel bridge, comprising the steps of:

[0065] (1) Sandblasting and derusting the steel bridge deck to make the cleanliness reach Sa2.5 level and the roughness is 80μm; according to 0.3kg / m 2 The amount of mica-containing epoxy resin used is artificially brushed and rolled to coat a mica-containing epoxy anti-corrosion layer;

[0066] (2) After 24 hours of mica-containing epoxy anti-corrosion layer curing, according to 3.0kg / m 2 The amount of solvent-free epoxy resin is used to scrape a solvent-free epoxy resin waterproof layer;

[0067] (3) Within 30 minutes of completing the solvent-free epoxy resin waterproof layer, according to 0.8kg / m 2 Sprinkle the hot-melt particles with a certain amount, so that half of them are trapped in the solvent-free epoxy resin waterproof layer to form a hot-melt particle bonding layer;

[0068] (4) After 48 hours of curing of the solvent-free epoxy resin waterproof lay...

Embodiment 3

[0073] A pavement method for a deck pavement structure of an orthotropic steel bridge, comprising the steps of:

[0074] (1) Sandblasting and derusting the steel bridge deck to make the cleanliness reach Sa2.5 level and the roughness is 80μm; according to 0.4kg / m 2 The amount of mica-containing epoxy resin used is artificially brushed and rolled to coat a mica-containing epoxy anti-corrosion layer;

[0075] (2) After 24 hours of mica-containing epoxy anti-corrosion layer curing, according to 3.0kg / m 2 The amount of solvent-free epoxy resin is used to scrape a solvent-free epoxy resin waterproof layer;

[0076] (3) Within 30 minutes of completing the solvent-free epoxy resin waterproof layer, according to 1.0kg / m 2 Sprinkle the hot-melt particles with a certain amount, so that half of them are trapped in the solvent-free epoxy resin waterproof layer to form a hot-melt particle bonding layer;

[0077] (4) After 48 hours of curing of the solvent-free epoxy resin waterproof lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com