Modified polypropylene mother particle for melt spray, its preparation method and use

A polypropylene modification technology, applied in textiles, papermaking, fiber treatment, etc., can solve problems such as attenuation, disappearance, impact on product range and life, and achieve high filtration efficiency and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

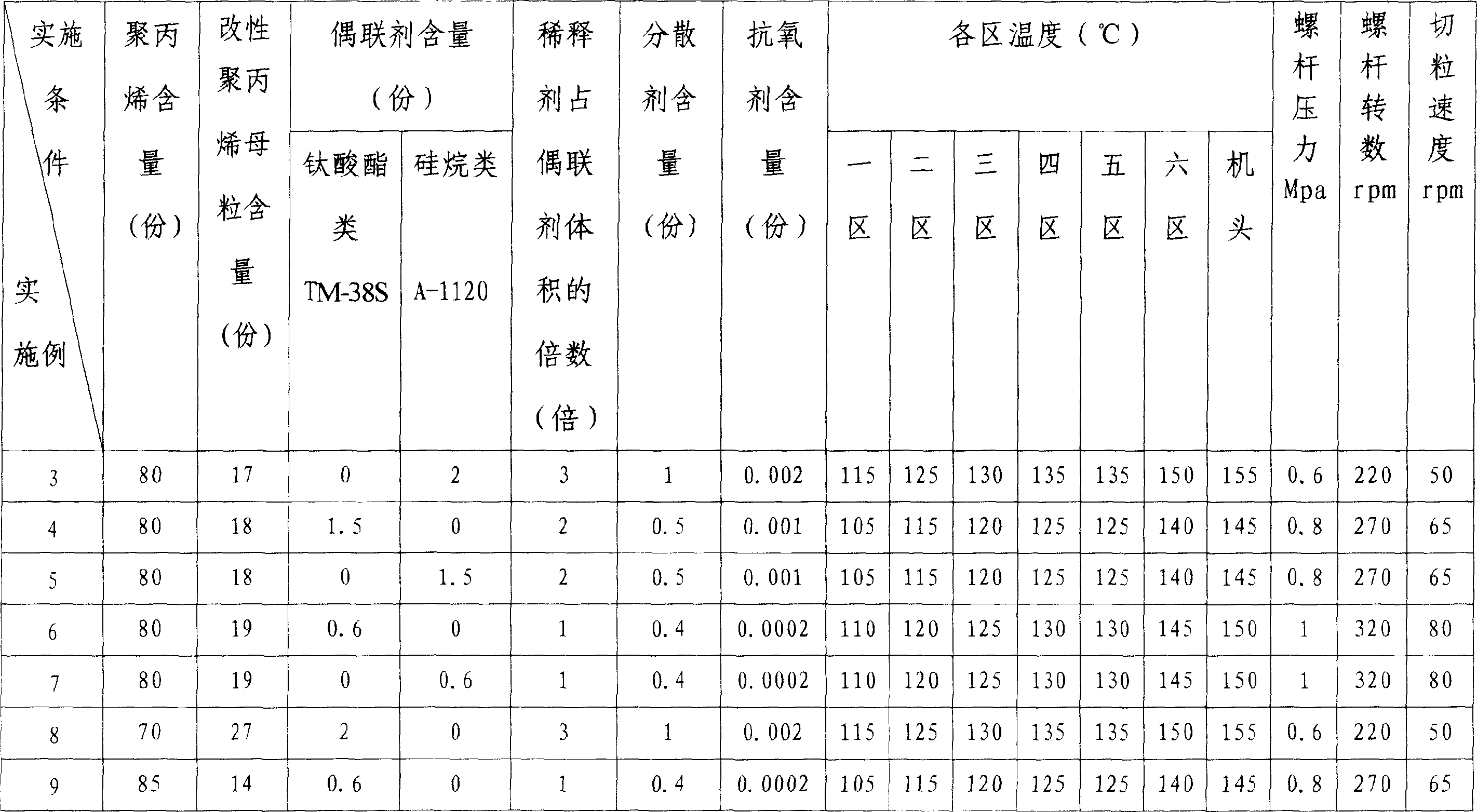

preparation example Construction

[0027] The invention simultaneously designs a preparation method of the modified polypropylene masterbatch for melt blowing. The preparation method is manufactured according to the modified polypropylene masterbatch formula of the present invention, comprising the steps of:

[0028] (1) Tourmaline surface modification: first dilute the coupling agent with a diluent petroleum ether that is 1 to 3 times the required volume, and then add the auxiliary coupling agent, dispersant and antioxidant according to the stated ratio Mix evenly with the tourmaline in a high-speed mixer to modify the surface of the tourmaline; the average particle size of the tourmaline particles is 0.2 to 0.5 microns;

[0029] (2) Vacuum drying: at a temperature of 100-110°C, vacuum-dry the modified tourmaline particles for 1.5-2.5 hours;

[0030] (3) Mixing and melting granulation: mix the dried and modified tourmaline particles with the polypropylene chips at a ratio of 15:85 to 30:70, preferably 20:80, ...

Embodiment 1

[0044] (1) Tourmaline surface modification: first pour 17 parts by weight of tourmaline particles and 1 part by weight of low molecular weight polyethylene wax and 0.002 part of antioxidant 1010 powder into a high-speed mixer, and stir at 2500r / min for 5 Minutes; then add 2 parts by weight of titanate diluted in twice the volume of titanate as a coupling agent in petroleum ether to the high-speed mixer three times, each time adding the coupling agent at an interval of 10 minutes, and fully stir evenly. stone surface modification;

[0045] (2) Vacuum drying: vacuum drying at 105° C. for 2 hours.

[0046] (3) Blending and granulation: Pour the dry modified tourmaline particles and 80 parts by weight of melt-blown polypropylene slices into a high-speed mixer and mix again for 10 minutes, and finally add the mixed raw materials into the twin-screw compounding extrusion Under-machine melt extrusion, the process parameters are: the temperature (℃) of each zone is: zone 1: 115℃; zon...

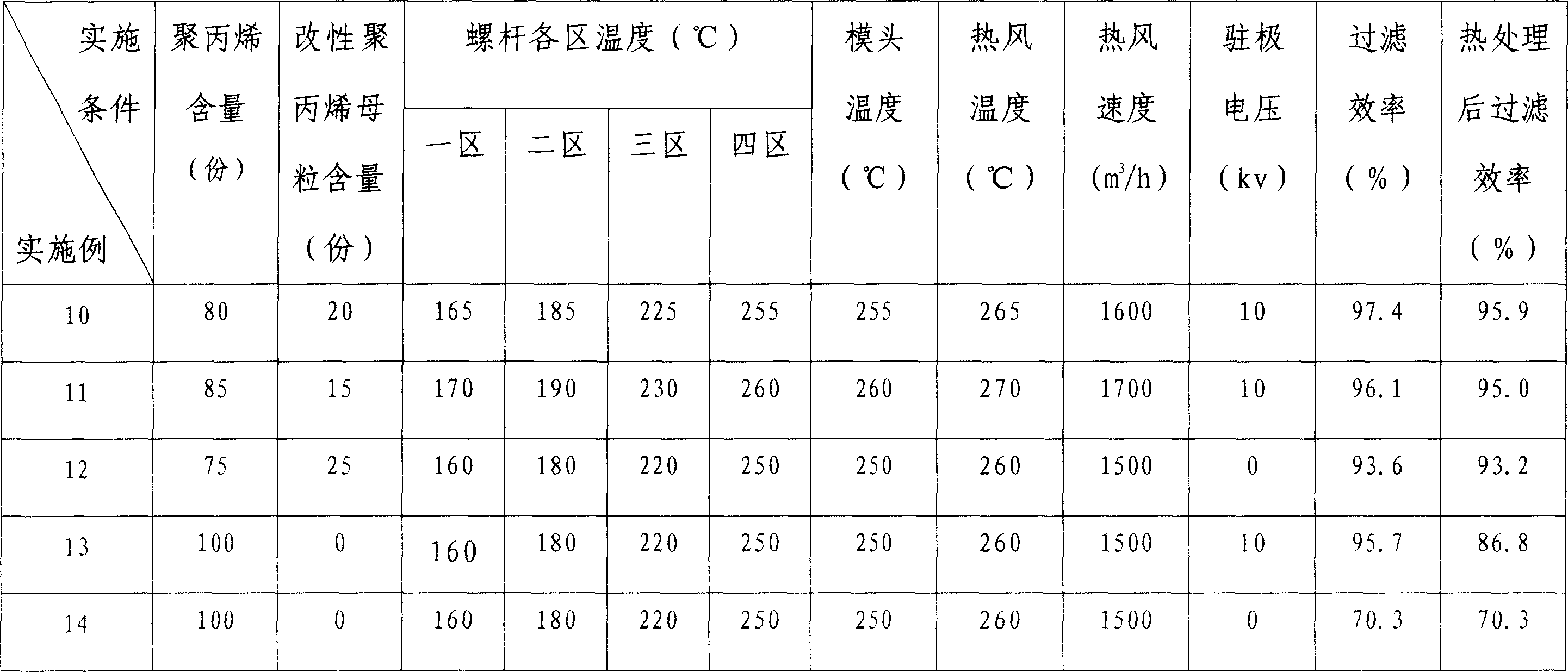

Embodiment 2

[0048] (1) According to the method of embodiment 1, the modified polypropylene masterbatch for melt-blowing is produced.

[0049] (2) Vacuum drying: vacuum drying at 110° C. for 1.5 hours.

[0050] (3) Mixing and melting granulation: After mixing 25 parts by weight of modified polypropylene masterbatch for melt blown with 75 parts by weight of polypropylene slices, they are added to a twin-screw extruder for melt extrusion. The process parameters are : The temperature in each zone (℃) is zone 1: 160℃; zone 2: 180℃; zone 3: 220℃; zone 4: 250℃; die head temperature: 250℃; Fibers with a diameter of 2 to 5 μm pass through two strands at a temperature of 260°C and a wind speed of 1500m 3 / h high-speed hot air flow stretching, the ejected fibers fall on the receiving device to form a fiber web, and the melt flow is controlled by adjusting the metering pump to make the fiber web weight up to 100g / cm 2 ; Subsequently, the fiber web is transported to the 10kv high-voltage electric fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com