Roll surface cleaning method and device

A technology for cleaning device and roller surface, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of uncleaned rollers and manual cleaning, etc., to reduce labor intensity, improve production efficiency, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

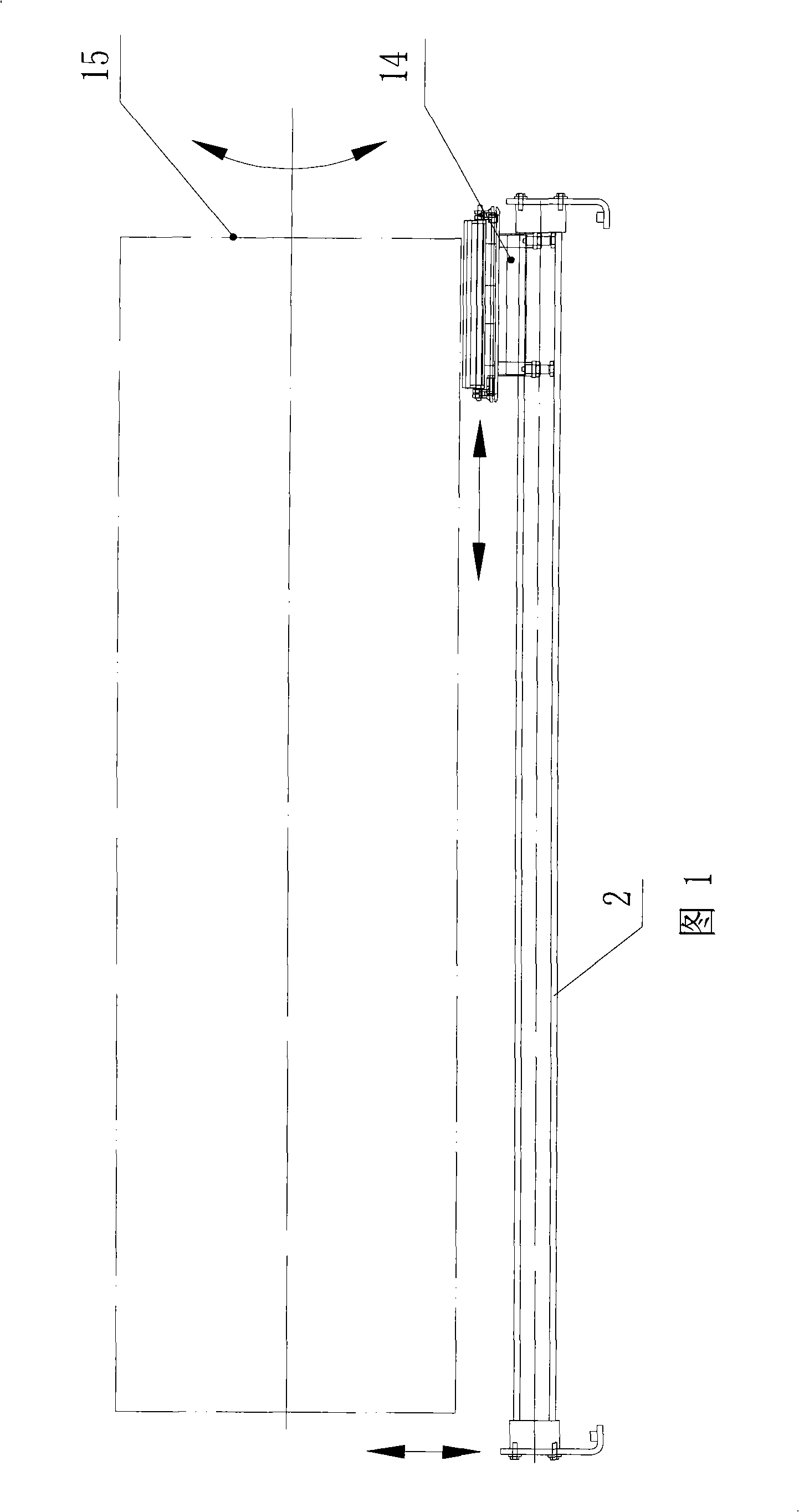

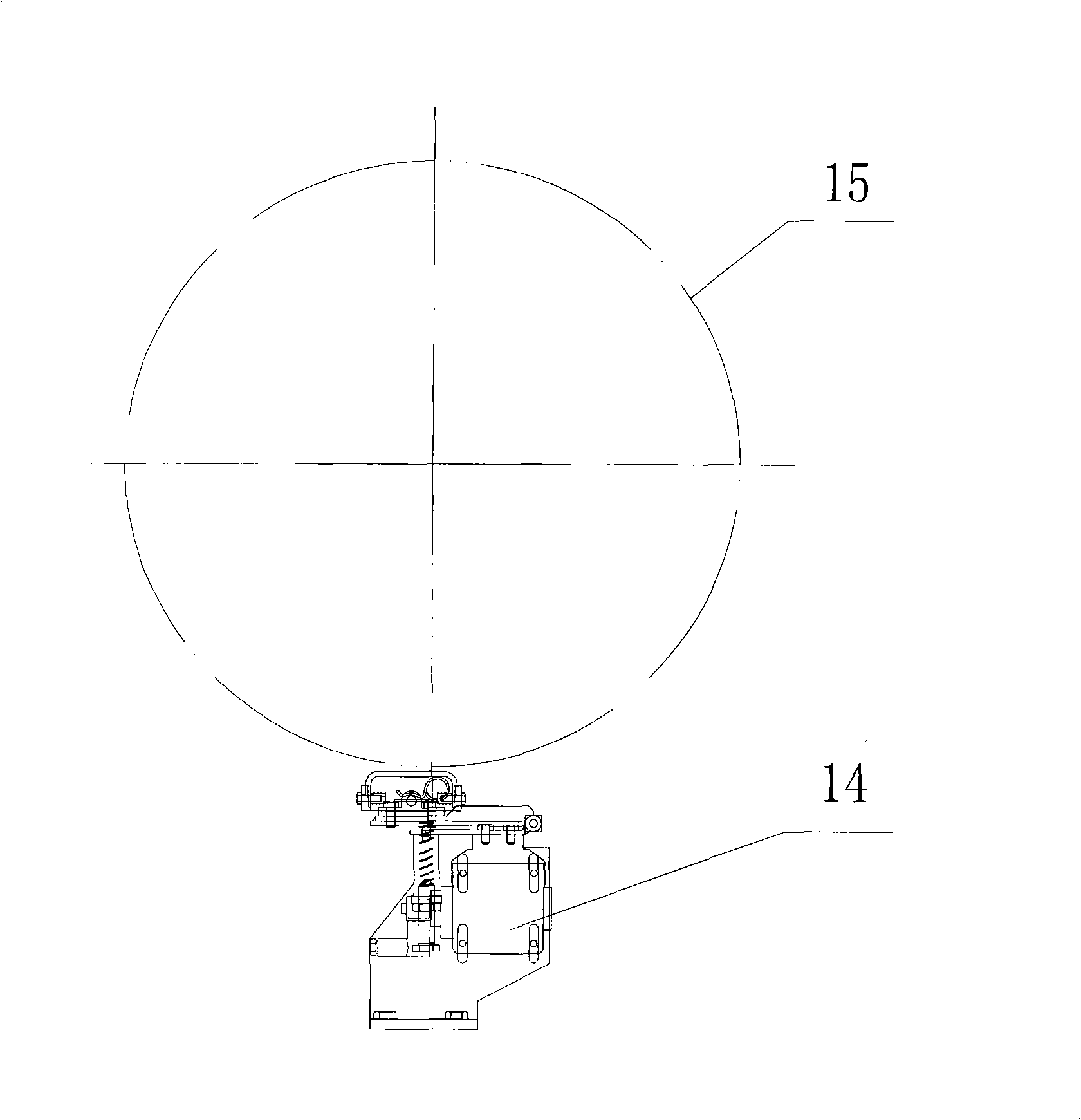

[0012] Such as Figure 4 As shown, a method for cleaning the roller surface, the roller 15 to be cleaned is compressed with a wiper block wrapped with felt or non-woven fabric (through the lifting of the roller or the swing of the wiper block to achieve compaction); then, the roller 15 starts to rotate ;The felt or non-woven fabric is driven by the traversing drive mechanism to make a linear reciprocating motion; through the rotation of the roller and the linear reciprocating motion of the felt or non-woven fabric, the felt or non-woven fabric can contact each position of the roller surface, thereby completing Cleaning of the roller surface.

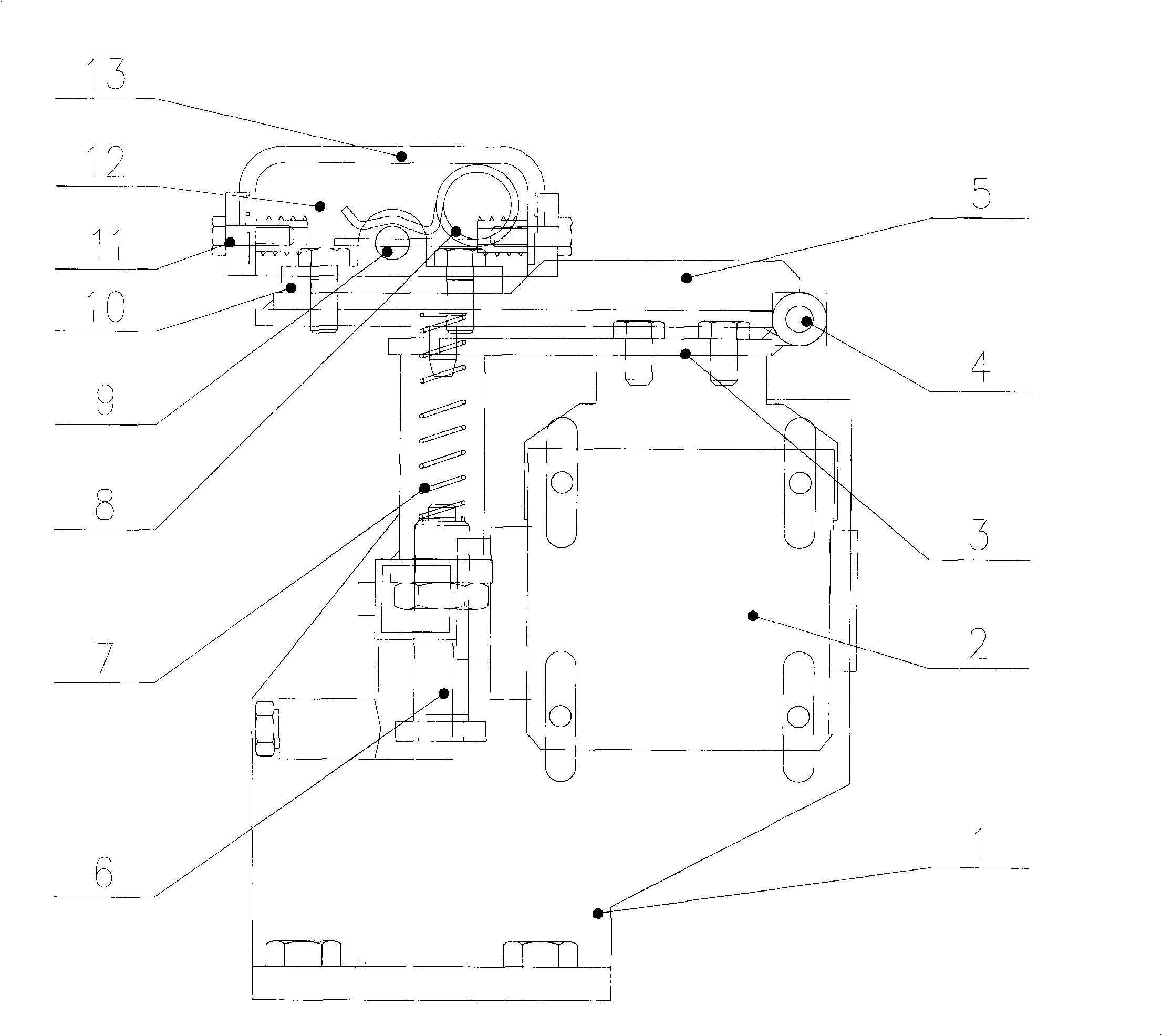

[0013] Such as image 3 As shown, the roller surface cleaning device for realizing the above method includes a cleaning block, an elastic mechanism, and a traversing driving mechanism. The cleaning block is arranged on the elastic mechanism, and the elastic mechanism is arranged on the traversing driving mechanism. The direction is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com