Lightweight felt material

A felt and lightweight technology, applied in the field of lightweight felt materials, can solve the problems of decreased sound-absorbing performance, less ability to improve sound-absorbing performance, etc., and achieve the effects of high-efficiency manufacturing, high sound-absorbing performance, excellent sound-absorbing and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

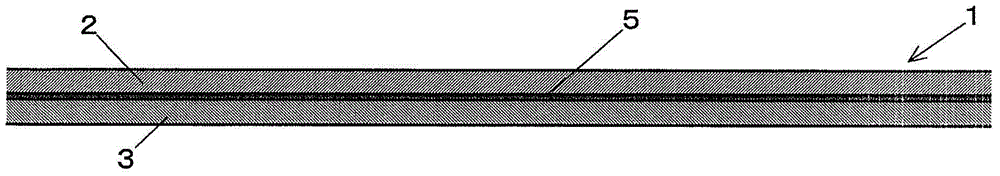

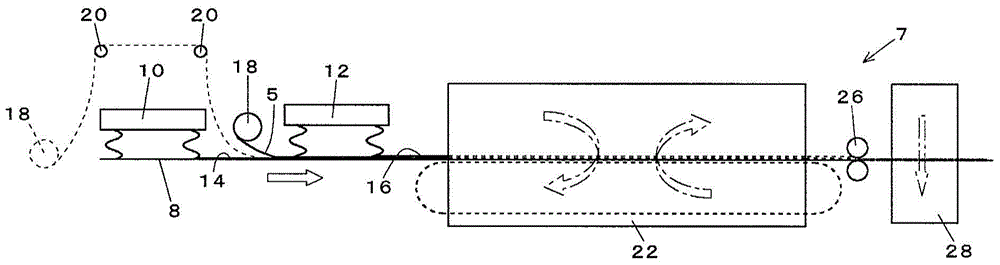

[0047] Next, although this invention is demonstrated based on an Example, this invention is not limited to an Example. for manufacturing figure 1 Lightweight felt material 1 shown, using image 3 The felt manufacturing device 7 shown is for 40% ultra-fine polyester fibers with a fineness of 0.75 denier, 15% hollow polyester fibers with a fineness of 15 deniers, and 25% low-melting point polyester fibers with a fineness of 4 deniers. Ester fibers and 20% polyester staple fibers with a fineness of 3 denier are mixed to form a weight per unit area of 150g / m 2 The two nets 14, 16. As the nonwoven sheet 5, use a weight per unit area of 40 g / m 2 Polyester melt-blown sheet (trade name: Kuraflex BTS0040EM, manufactured by Kuraray).

[0048] The nonwoven sheet 5 is held between the above-mentioned nets 14 and 16, and the whole is bonded by heating. The resulting lightweight felt material 1 has the non-woven sheet 5 positioned at the center of the felt material, and the thickne...

Embodiment 2

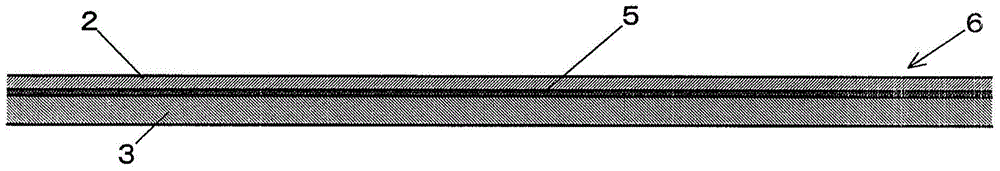

[0050] A lightweight felt material 1 having the same fiber composition as in Example 1 was manufactured by using a testing machine and using polyester regenerated fibers instead of polyester staple fibers having a fineness of 3 deniers in Example 1. In this lightweight felt material 1, the thickness of the upper hard cotton layer 2 is 19mm and the weight per unit area is 155g / m 2 , on the other hand, the thickness of the lower hard cotton layer 3 is 19mm and the weight per unit area is 155g / m 2 .

[0051] The resulting lightweight felt material 1 had a thickness of 38 mm and a weight per unit area of 350 g / m 2 . When the cost is considered, if it is about 20%, polyester regenerated fibers can be added instead of polyester staple fibers.

Embodiment 3

[0053] use image 3 In the felt manufacturing device 7 shown, the webs 14, 16 are composed of the same fibers as in Example 1, and the same nonwoven sheet 5 as in Example 1 is clamped by the two webs 14, 16, and the whole is heated and bonded to make a lightweight Quality felt material1. The resulting lightweight felt material 1 had a thickness of 38 mm and a weight per unit area of 407 g / m 2 .

[0054] The lightweight felt material 1 which is Example 2 and Example 3 was compared with the following products.

[0055] Comparison A: Melt-blown non-woven fabric (trade name: THINSULATE TC3303 300) with a thickness of 38mm (the weight per unit area is 356g / m 2 )

[0056] Comparison B: Melt-blown nonwoven fabric with a thickness of 38 mm (trade name: THINSULATE REGULAR 300)

[0057] Comparison C: Felt material with the same fiber composition as in Example 3 without interposing the nonwoven sheet 5 (thickness is 38 mm and weight per unit area is 386 g / m 2 )

[0058] The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com