Method for preparing modified starch tanning agent

A starch tanning agent and modification technology are applied in the field of leather synthetic tanning agent and its preparation, and in the field of preparation of degradable and environment-friendly modified starch tanning agent, which can solve the problems of hindering the application of starch, easy to mold, and low tanning properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

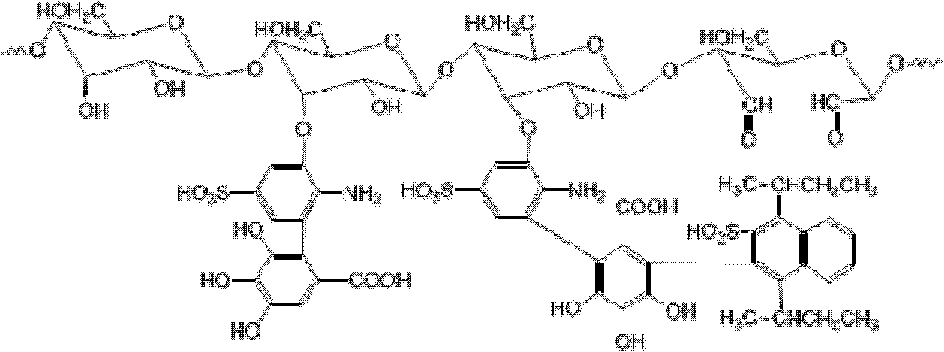

Image

Examples

Embodiment 1

[0012] Example 1: Add 15 grams of cornstarch and 0.5 grams of ammonium persulfate into 85 grams of deionized water, stir and heat to 90°C, add 3 milliliters of 6mol.L after 15 minutes -1 Hydrochloric acid solution, continue heat preservation reaction for 3 hours to obtain acid-decomposed oxidized starch; Sodium bicarbonate neutralizes the pH of the system to 7, adding 5 milliliters of HRP solution with a concentration of 0.5 g / L, and adding 15.6 grams of hydrogen peroxide solution with a mass fraction of 30%, and controlling the dropping time for 1 hour. Continue the heat preservation reaction for 3.5 hours to obtain the grafted modified starch; add 2.6 grams of periodic acid to the above grafted starch, neutralize the pH of the system to 3 with hydrochloric acid, heat to 35°C, and react for 3 hours to obtain the modified starch tanning agent .

Embodiment 2

[0013] Example 2: Add 16.5 grams of cornstarch and 0.6 grams of ammonium persulfate into 93.5 grams of deionized water, stir and heat to 91°C, add 3.2 milliliters of 6mol.L after 15 minutes -1 Hydrochloric acid solution, continue the heat preservation reaction for 3.1 hours to obtain the acid-decomposed oxidized starch; Sodium bicarbonate neutralizes the pH of the system to 7, adds 6 milliliters of HRP solution with a concentration of 0.5 g / L, and adds 17.2 grams of hydrogen peroxide solution with a mass fraction of 30%, and controls the dropping time for 1.1 hours. Continue the heat preservation reaction for 3.8 hours to obtain the grafted modified starch; add 2.8 grams of periodic acid to the above grafted starch, neutralize the pH of the system to 3 with hydrochloric acid, heat to 36°C, and react for 3.2 hours to obtain the modified starch tanning agent .

Embodiment 3

[0014] Example 3: Add 18 grams of cornstarch and 0.7 grams of ammonium persulfate into 102 grams of deionized water, stir and heat to 92°C, add 3.4 milliliters of 6mol.L-1 hydrochloric acid solution after 15 minutes, and continue the heat preservation reaction for 3.2 hours. Obtain acid-decomposed oxidized starch; add 10.8 grams of p-aminobenzenesulfonic acid, 7.0 grams of gallic acid and 18.7 grams of pull-off powder to the above-mentioned degraded starch solution, stir and heat to 32 ° C, and neutralize the pH of the system to 7 with sodium bicarbonate , adding 7 milliliters of HRP solution with a concentration of 0.5 g / liter, adding 18.7 grams of hydrogen peroxide solution with a mass fraction of 30%, controlling the dropping time for 1.2 hours, and continuing the insulation reaction for 4 hours after the dropping to obtain grafting Modified starch: add 3.1 g of periodic acid to the above grafted starch, neutralize the pH of the system to 3 with hydrochloric acid, heat to 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com