Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "With fullness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

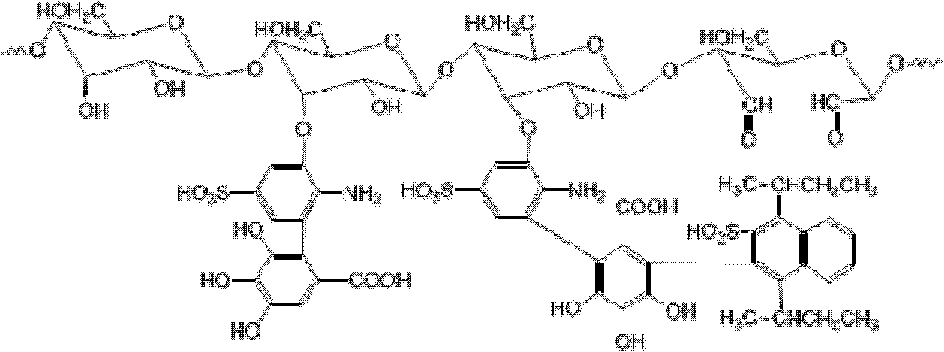

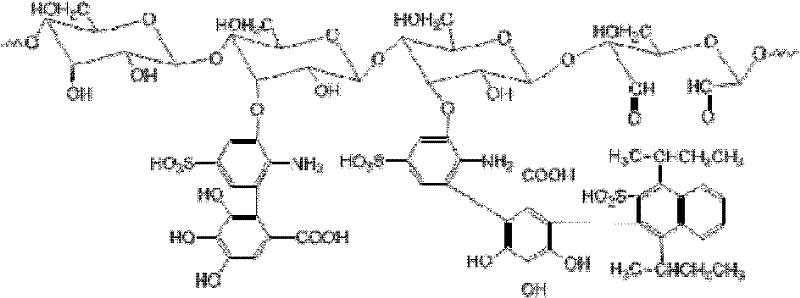

Method for preparing modified starch tanning agent

InactiveCN102020719AImprove absorption rateIncrease shrinkage temperatureTanning treatmentHigh absorptionGallic acid ester

The invention discloses a method for preparing a modified starch tanning agent, comprising the following steps of: firstly, degrading corn starch; in the presence of HRP (Horse Radish Peroxidase) / hydrogen peroxide (H2O2), grafting and modifying the degraded starch with sulfanilic acid, gallic acid and nekal; and then oxidizing the grafted starch with periodic acid. The invention has the innovation points that a nekal structure unit is introduced in the starch structure so as to improve the permeation wetting function of the modified starch tanning agent; the gallic acid structure unit is introduced to improve the tanning properties of the modified starch tanning agent, the sulfanilic acid is introduced to increase the dispersivity of the modified starch tanning agent, and dialdehyde action is used for improving the tanning properties of the modified starch tanning agent. The preparation method of the invention is peculiar and practical, and the obtained tanning agent is an environmentally-friendly leather tanning agent and is suitable for primary tanning and retanning. The shrinkage temperature (Ts) of pickled leather after primary tanning can be improved to 75-80 DEG C; and the retanned product has the advantages of wash resistance, high absorption rate on dyes and fatting agents and the like, is soft and plump.

Owner:SHAANXI UNIV OF SCI & TECH

Differential-shrinkage superfine composite draw textured yarn and processing technology thereof

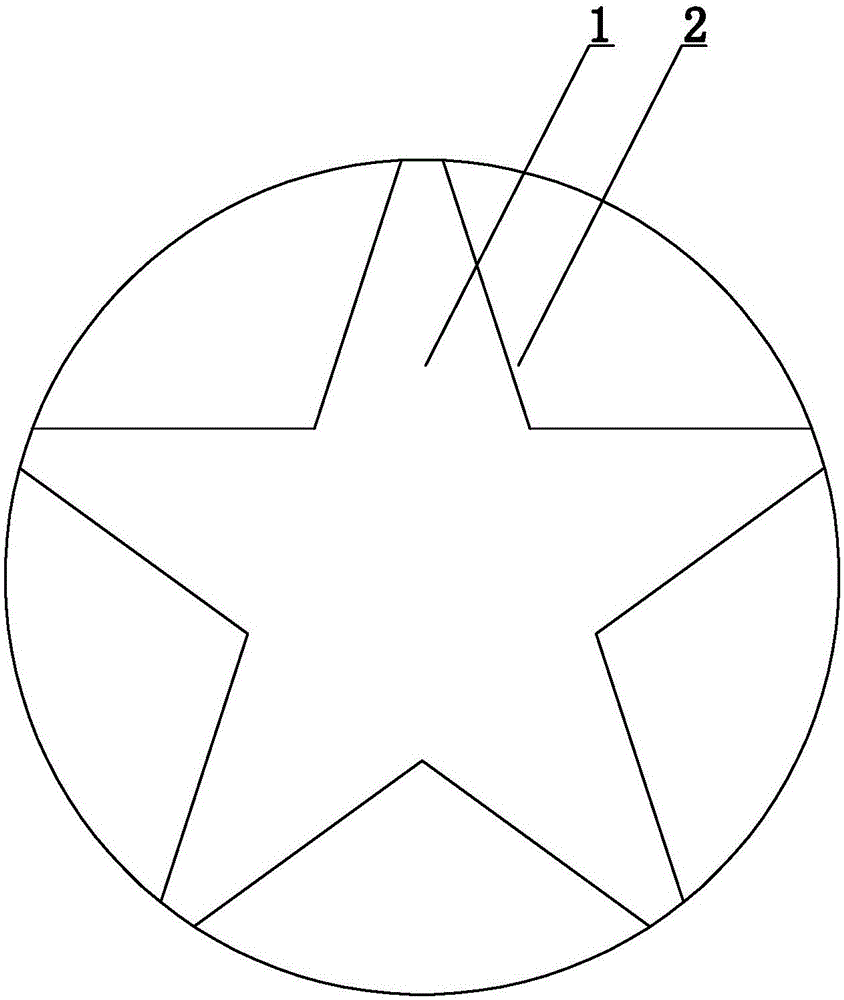

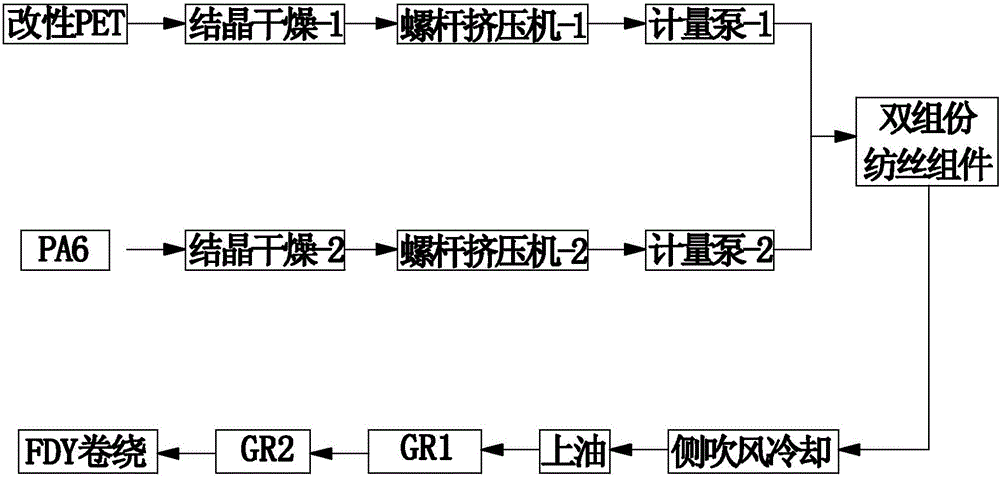

InactiveCN105839248AStructural balanceGood compatibilityFilament/thread formingConjugated synthetic polymer artificial filamentsYarnFiber

The invention relates to a differential-shrinkage superfine composite draw textured yarn and a processing technology thereof, and belongs to the technical field of fiber generation. The processing technology comprises the following steps of using modified copolyester and nylon 6 as raw materials, respectively melting and extruding by a screw extrusion machine, sending into double-component composite spinning equipment and special spinneret holes, cooling the sprayed melt, applying oil, winding, and spinning; preparing a differential-shrinkage splittable pre-oriented yarn, and enhancing elasticity, so as to obtain the differential-shrinkage superfine composite draw textured yarn. The differential-shrinkage superfine composite draw textured yarn prepared by the processing technology is applied to the processing of suede, waterproof fabrics and the like, so that the final fabric has the advantages of stiffness, density, fullness and the like.

Owner:ZHEJIANG GUXIANDAO INC CO

Differential-shrinkage superfine composite fiber and processing process thereof

InactiveCN105970355AWith fullnessStructural balanceFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer scienceNylon 6

The invention relates to a differential-shrinkage superfine composite fiber and a processing process thereof, and belongs to the technical field of fiber generation. According to a one-step spinning method, modified copolyester and nylon 6 are adopted as raw materials and subjected to copolyester through a screw extruder, and enter double-component composite spinning equipment and specially designed spinneret orifices, and ejected melt is cooled, oiled, drafted, subjected to heat setting and wound. The differential-shrinkage superfine composite fiber is applied to processing suede, waterproof fabric and the like, and the fabric has the advantages of being stiff and smooth, dense, full and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Antibacterial odor-resistant crease-resistant finishing process of blended fabric

InactiveCN108716116AAntibacterial, anti-odor and anti-wrinkle propertiesGood shaping effectBiochemical fibre treatmentWrinkle resistant fibresState of artEngineering

The invention discloses an antibacterial odor-resistant crease-resistant finishing process of a blended fabric. The antibacterial odor-resistant crease-resistant finishing process includes the steps:(1) singeing; (2) scouring, desizing and bleaching treatment; (3) antibacterial odor-resistant crease-resistant treatment; (4) preliminary drying; (5) baking; (6) washing; (7) drying. Compared with the prior art, the antibacterial odor-resistant crease-resistant finishing process has the advantages that the cotton and silk blended fabric has antibacterial odor-resistant crease-resistant performances, three finishing effects are simultaneously achieved, finishing time is shortened, and the cotton and silk blended fabric has good sizing effects and is free from ironing, waterproof, oil-proof, stiff, smooth, full, non-fouling and the like by the aid of the finishing process.

Owner:ANHUI ZHAOBAO TEXTILE TECH CO LTD

Cotton fabric non-ironing finishing agent

The invention discloses a cotton fabric non-ironing finishing agent, which comprises, by weight, 16-32 parts of ethylene glycol, 6-12 parts of 2-hydroxyethyl methacrylate, 6-8 parts of methyl methacrylate, 4-6 parts of lauryl methlacrylate, 2-6 parts of magnesium chloride, 2-4 parts of a glycerin rosin resin, 10-20 parts of ethyl acetate, 10-30 parts of butyl acetate, 20-60 parts of sodium carbonate, 20-30 parts of poly isobutyl ester, 10-20 parts of phosphotriester, 20-30 parts of lauryl methlacrylate, 20-30 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 20-30 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, and 400-600 parts of deionized water. According to the present invention, the production of the cotton fabric non-ironing finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the cotton fabric non-ironing finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shapingeffect, no ironing, starching, fullness, no stain, and the like.

Owner:王锶源

Water-soluble anti-wrinkle non-ironing finishing agent

The invention discloses a water-soluble anti-wrinkle non-ironing finishing agent, which comprises, by weight, 80-120 parts of alkyd resin, 100-180 parts of 2-(dimethylamino)ethyl methacrylate, 20-40 parts of a melamine resin, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropyl alcohol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of aglycerin rosin resin, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 5-15 parts of vinyl chloride vinyl ester, and 100-140 parts of deionized water. According to the present invention, the production of the water-soluble anti-wrinkle non-ironing finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the water-soluble anti-wrinkle non-ironing finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:姜维

Silk anti-wrinkle non-ironing finishing agent

The invention discloses a silk anti-wrinkle non-ironing finishing agent, which comprises, by weight, 10-30 parts of a melamine resin, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropyl alcohol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride, 4-8 parts of a glycerin rosin resin, 4-8 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 8-16 partsof polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 4-8 parts of methyl methacrylate, 5-15 parts of vinyl chloride vinyl ester, and 100-140 parts of deionized water. According to the present invention, the production of the silk anti-wrinkle non-ironing finishing agent is simple, the used productionraw materials are non-toxic, and the fabric treated by the silk anti-wrinkle non-ironing finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:顾香

Method for preparing modified starch tanning agent

InactiveCN102020719BImprove absorption rateIncrease shrinkage temperatureTanning treatmentHigh absorptionGallic acid ester

The invention discloses a method for preparing a modified starch tanning agent, comprising the following steps of: firstly, degrading corn starch; in the presence of HRP (Horse Radish Peroxidase) / hydrogen peroxide (H2O2), grafting and modifying the degraded starch with sulfanilic acid, gallic acid and nekal; and then oxidizing the grafted starch with periodic acid. The invention has the innovation points that a nekal structure unit is introduced in the starch structure so as to improve the permeation wetting function of the modified starch tanning agent; the gallic acid structure unit is introduced to improve the tanning properties of the modified starch tanning agent, the sulfanilic acid is introduced to increase the dispersivity of the modified starch tanning agent, and dialdehyde action is used for improving the tanning properties of the modified starch tanning agent. The preparation method of the invention is peculiar and practical, and the obtained tanning agent is an environmentally-friendly leather tanning agent and is suitable for primary tanning and retanning. The shrinkage temperature (Ts) of pickled leather after primary tanning can be improved to 75-80 DEG C; and the retanned product has the advantages of wash resistance, high absorption rate on dyes and fatting agents and the like, is soft and plump.

Owner:SHAANXI UNIV OF SCI & TECH

Crease-resistant ironing-free finishing agent for dacron

InactiveCN106906656AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresZinc nitrateSizing

The invention discloses a crease-resistant ironing-free finishing agent for dacron, which comprises the following components in parts by weight: 10-20 parts of polyurethane, 10-20 parts of crylic acid, 10-20 parts of zinc nitrate, 6-12 parts of ammonium citrate, 20-30 parts of triethanolamine, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of glycerinum rosin resin, 8-16 parts of polydivinyl acetylene, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid, 8-16 parts of acrylamide, 5-15 parts of vinyl chloride-vinyl ester and 80-120 parts of deionized water. The crease-resistant ironing-free finishing agent for dacron, provided by the invention, is simply prepared; the nontoxic production raw materials are selected; the fabric treated with the finishing agent is shrink-proof and crease-resistant, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陆海蓉

Organic silicon leather fatting agent

The invention discloses an organic silicon leather fatting agent. The organic silicon leather fatting agent comprises, by weight, 2-4 parts of methyl alcohol, 20-60 parts of olive oil, 4-6 parts of isopropyl alcohol, 5-10 parts of benzylene chloride, 6-8 parts of dihydroxytoluene urea resin, 10-20 parts of polyurethane, 10-30 parts of stearic acid, 8-16 parts of capryl alcohol, 4-8 parts of oleinic acid, 2-4 parts of sulfuric acid, 6-12 parts of sodium hydroxide, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid and 8-16 parts of acrylamide. The organic silicon leather fatting agent is easy to prepare, nonpoisonous production raw materials are selectively adopted, fabric treated with the finishing agent can be resistant to shrinkage and wrinkles, the shaping effect is good, ironing is avoided, and the fabric treated with the finishing agent has the characteristics of being stiff and smooth, plump, free of pollution and the like.

Owner:袁允兰

Wool fat class fatting agent

InactiveCN106906315AEasy to makeGood shaping effectLeather impregnationWrinkle skinP-Toluenesulfonic acid

The invention discloses a wool fat class fatting agent. The wool fat class fatting agent comprises, by weight, 60-80 parts of fine wool fat, 10-20 parts of ethanol amine, 6-12 parts of sodium methylate, 20-60 parts of olive oil, 2-4 parts of copper stearate, 6-8 parts of dihydroxytoluene urea resin, 10-20 parts of polyurethane, 10-30 parts of stearic acid, 8-16 parts of capryl alcohol, 4-8 parts of oleinic acid, 10-20 parts of p-toluenesulfonic acid, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid and 8-16 parts of acrylamide. The wool fat class fatting agent is easy to prepare, nonpoisonous production raw materials are selectively adopted, fabric treated with the finishing agent can be resistant to shrinkage and wrinkles, the shaping effect is good, ironing is avoided, and the fabric treated with the finishing agent has the characteristics of being stiff and smooth, plump, free of pollution and the like.

Owner:周昱帆

Water and oil-repellent anti-wrinkling finishing agent for baffeta

InactiveCN106906639AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresBenzoyl peroxideGlycerol

The invention discloses a water and oil-repellent anti-wrinkling finishing agent for baffeta. The water and oil-repellent anti-wrinkling finishing agent for baffeta comprises the following components in parts by weight: 100-160 parts of dimethylol urea resin, 40-60 parts of magnesium chloride hexahydrate, 100-160 parts of aluminum sulfate, 80-100 parts of trimethylol melamine, 20-30 parts of methacrylic glycerol trilaurate, 20-30 parts of zinc nitrate hexahydrate, 40-60 parts of poly-isobutyl ester, 20-40 parts of aluminum hydroxide, 12-24 parts of phosphotriester, 12-18 parts of antimonous oxide, 10-20 parts of benzoyl peroxide and 600-800 parts of deionized water. The water and oil-repellent anti-wrinkling finishing agent for baffeta is simply prepared; the nontoxic production raw materials are selected; the baffeta treated with the finishing agent is shrink-proof and anti-wrinkling, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陆亚洲

Wrinkle proofing agent for silk fabric

InactiveCN106906657AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresWrinkle skinSizing

The invention discloses a wrinkle proofing agent for a silk fabric. The wrinkle proofing agent contains the following components in parts by weight: 4-8 parts of citric acid, 6-12 parts of ammonium citrate, 20-30 parts of triethanolamine, 10-20 parts of sodium hypophosphite, 20-40 parts of formaldehyde resin, 10-16 parts of formic acid, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of glycerinum rosin resin, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 5-15 parts of vinyl chloride ester and 100-140 parts of deionized water. The wrinkle proofing agent for the silk fabric, provided by the invention, is simply prepared; the adopted production raw materials are nontoxic; the fabric treated with the wrinkle proofing agent is shrink-proof and anti-wrinkle, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陆海蓉

Anti-wrinkling finishing agent

InactiveCN106906654AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresBenzoyl peroxideAntimony trioxide

The invention discloses an anti-wrinkling finishing agent. The anti-wrinkling finishing agent comprises the following components in parts by weight: 80-100 parts of trimethylol melamine, 20-30 parts of lauryl methacrylate, 20-30 parts of zinc nitrate hexahydrate, 40-60 parts of poly isobutyl ester, 20-40 parts of aluminum hydroxide, 12-24 parts of phosphotriester, 12-18 parts of antimony trioxide, 10-20 parts of benzoyl peroxide, 16-24 parts of isopropyl alcohol, 2-8 parts of isopropyl acrylate and 10-12 parts of butyl acetate. The anti-wrinkling finishing agent disclosed by the invention has the advantages that the preparation is simple, the adopted production materials are non-toxic, and fabric treated by the finishing agent can be shrink-proof and anti-wrinkling, is good in forming effect and free in ironing, and has the characteristics of stiffness and smoothness, richness and no pollution and the like.

Owner:陆亚洲

Leather lubricating oil fatting agent

InactiveCN106906317AEasy to makeGood shaping effectLeather impregnationP-Toluenesulfonic acidStearic acid

The invention discloses a leather-lubricating oil fatting agent. The leather-lubricating oil fatting agent comprises, by weight, 20-30 parts of poly-ethoxyl castor oil, 2-4 parts of methyl alcohol, 20-60 parts of olive oil, 2-4 parts of copper stearate, 6-8 parts of dihydroxytoluene urea resin, 10-20 parts of polyurethane, 10-30 parts of stearic acid, 8-16 parts of capryl alcohol, 4-8 parts of oleinic acid, 10-20 parts of p-toluenesulfonic acid, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid and 8-16 parts of acrylamide. The leather-lubricating oil fatting agent is easy to prepare, nonpoisonous production raw materials are selectively adopted, fabric treated with the finishing agent can be resistant to shrinkage and wrinkles, the shaping effect is good, ironing is avoided, and the fabric treated with the finishing agent has the characteristics of being stiff and smooth, plump, free of pollution and the like.

Owner:周昱帆

Water-soluble finishing agent

InactiveCN107558222AEasy to makeGood shaping effectFibre treatmentBenzoyl peroxideDibenzoyl Peroxide

The invention discloses a water-soluble finishing agent, which comprises, by weight, 20-40 parts of a melamine resin, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropanol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride, 4-8 parts of a glycerin rosin resin, 4-8 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 5-15 parts of vinyl chloride vinyl ester, and 100-140 parts of deionized water. According to the present invention, the production of the water-soluble finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the water-solublefinishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:顾香

Silk fabric non-ironing finishing agent

InactiveCN107558198AEasy to makeGood shaping effectAnimal fibresMagnesium chloride hexahydrateChemistry

The invention discloses a silk fabric non-ironing finishing agent, which comprises, by weight, 20-30 parts of citric acid, 20-30 parts of triethanolamine, 10-20 parts of sodium hypophosphite, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropanol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of a glycerin rosin resin, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 5-15 parts of vinyl chloride vinyl ester, and 100-140 parts of deionized water. According to the present invention, the production of the silk fabric non-ironing finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the silk fabric non-ironing finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:姜维

Pure cotton non-ironing finishing liquid

The invention discloses a pure cotton non-ironing finishing liquid, which comprises, by weight, 16-32 parts of ethylene glycol, 10-20 parts of melamine, 6-12 parts of 2-hydroxyethyl methacrylate, 6-8parts of methyl methacrylate, 4-6 parts of lauryl methacrylate, 2-6 parts of magnesium chloride, 2-4 parts of a glycerin rosin resin, 10-20 parts of ethyl acetate, 20-30 parts of poly isobutyl ester,10-20 parts of phosphotriester, 20-30 parts of lauryl methacrylate, 20-30 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 20-30 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, and 200-300 parts of deionized water. According to the present invention, the production of the pure cotton non-ironing finishing liquid is simple, the used production raw materials are non-toxic, and the fabric treated by the pure cotton non-ironing finishing liquid has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:王锶源

Low-formaldehyde anti-wrinkling finishing solution for baffeta

InactiveCN106906638AEasy to makeGood shaping effectStain/soil resistant fibresWrinkle resistant fibresAnti wrinkleButyl methacrylate

The invention discloses a low-formaldehyde anti-wrinkling finishing solution for baffeta. The low-formaldehyde anti-wrinkling finishing solution for baffeta comprises the following components in parts by weight: 80-120 parts of butyl methacrylate, 100-160 parts of aluminum sulfate, 80-100 parts of trimethylol melamine, 20-30 parts of lauryl methacrylate, 20-30 parts of zinc nitrate hexahydrate, 40-60 parts of poly-isobutyl ester, 20-40 parts of aluminum hydroxide, 12-24 parts of phosphotriester, 12-18 parts of antimonous oxide, 10-20 parts of benzoyl peroxide and 500-800 parts of deionized water. The low-formaldehyde anti-wrinkling finishing solution for baffeta is simply prepared; the nontoxic production raw materials are selected; and the baffeta treated with the finishing agent is shrink-proof and anti-wrinkling, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陆亚洲

Cotton fabric non-ironing finishing liquid

InactiveCN107558195AEasy to makeGood shaping effectFibre treatmentBenzoyl peroxideDibenzoyl Peroxide

The present invention discloses a cotton fabric non-ironing finishing liquid, which comprises, by weight, 16-32 parts of ethylene glycol, 10-20 parts of melamine, 10-14 parts of a formaldehyde resin,6-12 parts of 2-hydroxyethyl methacrylate, 6-8 parts of methyl methacrylate, 4-6 parts of lauryl methacrylate, 2-6 parts of magnesium chloride, 2-4 parts of a glycerin rosin resin, 10-20 parts of phosphotriester, 20-30 parts of lauryl methacrylate, 20-30 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 20-30 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, and 200-300 parts of deionized water. According to the present invention, the production of the cotton fabric non-ironing finishing liquid is simple, the used production raw materials are non-toxic, and thefabric treated by the cotton fabric non-ironing finishing liquid has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:王锶源

Blended fabric non-iron finishing agent

The invention discloses a blended fabric non-iron finishing agent which comprises the following components in parts by weight: 30-50 parts of dihydroxymethyldihydroxyzolinone, 10-20 parts of acrylic acid, 6-12 parts of ammonium citrate, 20-30 parts of triethanolamine, 10-20 parts of sodium hypophosphite, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of glycerol rosin resin, 8-16 parts of polydivinyl acetylene, 10-18 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 8-16 parts of acrylamide, 5-15 parts of vinyl chloride-vinyl ester and 80-120 parts of deionized water. The blended fabric non-iron finishing agent is simple to manufacture. The adopted production raw materials are nontoxic. The fabric treated by the finishing agent is shrinkproof and crease-resistant, has favorable setting effect, is free of ironing, and is stiff, plump, non-polluting and the like.

Owner:陆海蓉

Water-soluble non-ironing finishing agent

The invention discloses a water-soluble non-ironing finishing agent, which comprises, by weight, 20-60 parts of isobutanol, 20-40 parts of a melamine resin, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropanol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of a glycerin rosin resin, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 5-15 parts of vinyl chloride vinyl ester, and 100-140 parts of deionized water. According tothe present invention, the production of the water-soluble non-ironing finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the water-soluble non-ironing finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:姜维

Blended fabric finishing agent

InactiveCN106906655AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresGlycerolVinyl chloride

The invention discloses a blended fabric finishing agent which comprises the following components in parts by weight: 6-12 parts of ammonium citrate, 20-30 parts of triethanolamine, 10-20 parts of sodium hypophosphite, 20-40 parts of formaldehyde resins, 10-16 parts of formic acid, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of glycerol rosin resin, 8-16 parts of polydivinyl acetylene, 10-18 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 8-16 parts of acrylamide, 5-15 parts of vinyl chloride-vinyl ester and 80-120 parts of deionized water. The blended fabric finishing agent is simple to manufacture. The adopted production raw materials are nontoxic. The fabric treated by the finishing agent is shrinkproof and crease-resistant, has favorable setting effect, is free of ironing, and is stiff, plump, non-polluting and the like.

Owner:陆海蓉

Silk anti-wrinkle finishing agent

The invention discloses a silk anti-wrinkle finishing agent, which comprises, by weight, 10-30 parts of a melamine resin, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropanol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride, 4-8 parts of a glycerin rosin resin, 4-8 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, and 100-140 parts of deionized water. According to the present invention, the production of the silk anti-wrinkle finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the silk anti-wrinkle finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:顾香

Blended fabric anti-crease finishing agent

The invention discloses a blended fabric anti-crease finishing agent which comprises the following components in parts by weight: 30-50 parts of dihydroxymethyldihydroxyzolinone, 6-12 parts of ammonium citrate, 20-30 parts of triethanolamine, 10-20 parts of sodium hypophosphite, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of glycerol rosin resin, 8-16 parts of polydivinyl acetylene, 10-18 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 8-16 parts of acrylamide, 5-15 parts of vinyl chloride-vinyl ester and 80-120 parts of deionized water. The blended fabric anti-crease finishing agent is simple to manufacture. The adopted production raw materials are nontoxic. The fabric treated by the finishing agent is shrinkproof and crease-resistant, has favorable setting effect, is free of ironing, and is stiff, plump, non-polluting and the like.

Owner:陆海蓉

Negative ion leather fatting agent

The invention discloses a negative ion leather fatting agent. The negative ion leather fatting agent comprises, by weight 4-6 parts of isopropyl alcohol, 5-10 parts of benzylene chloride, 6-8 parts of dihydroxytoluene urea resin, 10-20 parts of polyurethane, 10-30 parts of stearic acid, 8-16 parts of capryl alcohol, 4-8 parts of oleinic acid, 2-4 parts of sulfuric acid, 6-12 parts of sodium hydroxide, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid and 8-16 parts of acrylamide. The negative ion leather fatting agent is easy to prepare, nonpoisonous production raw materials are selectively adopted, fabric treated with the finishing agent can be resistant to shrinkage and wrinkles, the shaping effect is good, ironing is avoided, and the fabric treated with the finishing agent has the characteristics of being stiff and smooth, plump, free of pollution and the like.

Owner:王敏敏

Silk non-ironing finishing agent

The invention discloses a silk non-ironing finishing agent, which comprises, by weight, 10-30 parts of a melamine resin, 20-40 parts of a formaldehyde resin, 10-18 parts of 2-(dimethylamino)ethyl methacrylate, 4-6 parts of isopropanol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride, 2-4 parts of a glycerin rosin resin, 4-12 parts of lauryl methacrylate, 4-8 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-6 parts of ammonium citrate, 6-8 parts of glacial acetic acid, and 100-160 parts of deionized water. According to the present invention, the production of the silk non-ironing finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the silk non-ironing finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:顾香

Crease-resistant finishing agent for corduroy

InactiveCN106906660AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresBenzoyl peroxideEthyl acetate

The invention discloses a crease-resistant finishing agent for corduroy, which comprises the following components in parts by weight: 16-48 parts of coconut oil fatty acyl diethanol amine, 20-40 parts of glycerinum rosin resin, 10-20 parts of ethyl acetate, 10-30 parts of butyl acetate, 100-160 parts of dimethylol urea, 20-60 parts of sodium carbonate, 40-60 parts of poly-butyl ester, 12-24 parts of phosphotriester, 20-40 parts of aluminum sulfate, 20-40 parts of trimethylol melamine, 20-30 parts of lauryl methacrylate, 20-30 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide and 600-800 parts of deionized water. The crease-resistant finishing agent for corduroy, provided by the invention, is simply prepared; the nontoxic production raw materials are selected; the fabric treated with the finishing agent is shrink-proof and crease-resistant, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陆亚洲

Pure cotton non-ironing anti-wrinkle finishing liquid

The invention discloses a pure cotton non-ironing anti-wrinkle finishing liquid, which comprises, by weight, 20-40 parts of ethylene glycol, 10-20 parts of melamine, 10-14 parts of a formaldehyde resin, 6-12 parts of 2-hydroxyethyl methacrylate, 2-6 parts of magnesium chloride, 2-4 parts of a glycerin rosin resin, 10-20 parts of phosphotriester, 20-30 parts of lauryl methacrylate, 20-30 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 20-30 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, and 100-160 parts of deionized water. According to the present invention, the production of the pure cotton non-ironing anti-wrinkle finishing liquid is simple, the used production raw materials are non-toxic, and the fabric treated by the pure cotton non-ironing anti-wrinkle finishing liquid has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:王锶源

Water-soluble anti-wrinkle finishing agent

The invention discloses a water-soluble anti-wrinkle finishing agent, which comprises, by weight, 20-40 parts of a melamine resin, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropyl alcohol,6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of a glycerin rosin resin, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 5-15 parts of vinyl chloride vinyl ester, and 100-140 parts of deionized water. According to the present invention, the production of the water-soluble anti-wrinkle finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the water-soluble anti-wrinkle finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:顾香

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com