Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "With crisp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Snowflake melange yarn and processing method

The invention relates to the technical field of spinning, in particular to a snowflake melange yarn. The yarn comprises 50 percent of polyester fibers, 38 percent of cotton fibers and 12 percent of viscose by weight, wherein partial of or all fibers in at least one of the fibers are dyed fibers, the dyed fibers are mixed with the undyed fibers uniformly, and the uniformly-mixed fibers are spun to form the dreamy snowflake melange yarn through a spinning process. The yarn comprises the following processing steps: sprinkling oiling agent water on the dyed fibers for braising for at least 10 hours, weighing the fibers with different colors and in different proportions for uniform mixing, and putting the uniformly-mixed fibers in a spinner for spinning. In the melange yarn, the proportioning of the fibers and the color proportioning in each fiber are reasonable, and a small number of fibers in the fibers are only needed to be dyed. The melange yarn can improve the grade of products made of common raw materials obviously, has the characteristics of softness, stiffness and smoothness and comfortable wearing, and can be made into different T-shirts, high-grade underwear, coats, fashionable dresses and household textile products.

Owner:江阴市茂达棉纺厂有限公司

Method for prepearing delicious bamboo shoot

A bagged bamboo shoot with delicious taste is prepared from the canned bamboo shoot through cutting, fermenting, cleaning with diluted saline, rinsing, dewatering, flavoring, and loading it in bags, adding flavoring oil, vacuum sealing, sterilizing by high-temp water and cooling.

Owner:雷霖生

Anti-neutron radiation polyester fiber preparation method

InactiveCN104264268AHas the function of radiation protectionWith crispArtificial thread manufacturing machinesMonocomponent copolyesters artificial filamentBorideFiber

The invention discloses an anti-neutron radiation polyester fiber preparation method. According to a specific embodiment, the preparation method comprises the following steps: mixing 52%-76% of terephthalic acid, 23%-48% of ethylene glycol, boride or a heavy metal compound, which is mixed into ethylene glycol and the weight of which accounts for the total weight of ethylene glycol by 16%-25%, 0.5%-5% of a catalyst and 0.3%-2% of a stabilizer in percentage by mass in a reaction kettle, reacting under a condition of 245-260 DEG C for 30-50min, and obtaining a copolymer melt on a polycondensation section under conditions of 260-290 DEG C and a vacuum degree of 0.1-10KPa; extruding the copolymer melt once on a screw extruder and drying to obtain an anti-neutron radiation terylene chip; and processing the chip by the screw extruder, a pre-filter, a static mixer, a metering pump and a spinning component, spinning, quenching air and applying oil, processing by a chimney, coiling, etc. to obtain an anti-neutron radiation polyester fiber. The preparation method disclosed by the invention has the beneficial effects that terylene, which serves as a carrier, is copolymerized with the heavy metal compound, and the terylene fiber not only has an anti-radiation function, but also integrates various features of the terylene.

Owner:HAIAN HUARONG CHEM FIBER

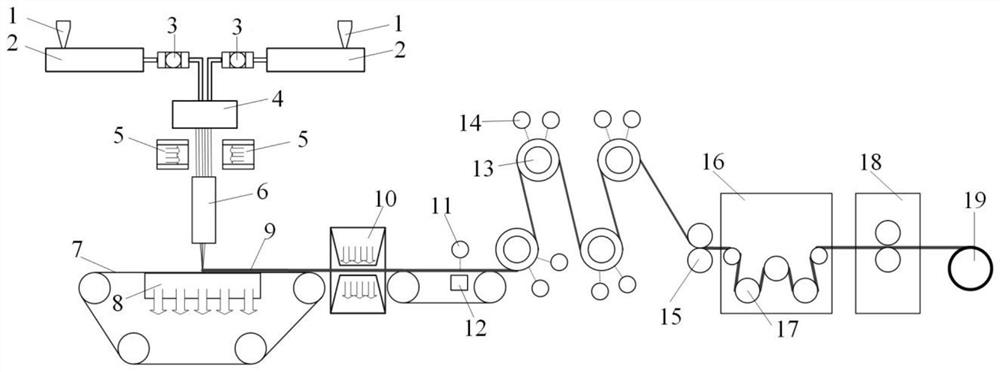

Preparation method of high-shrinkage orange slice type double-component spunbonded spunlace microfiber leather base cloth

ActiveCN113417078AHigh fullnessReduce spunlace energy consumptionFilament/thread formingHeating/cooling textile fabricsMicrofiberThermal shrinkage

The invention discloses a preparation method of high-shrinkage orange slice type double-component spunbonded spunlace microfiber leather base cloth. The method comprises the following steps of firstly, adding a hot air device and a fiber crimping device in a double-component spunbond / spunlace production line, and then spinning double-component composite fibers into a web; conveying the fiber web into the hot air device for thermal shrinkage treatment, and enabling the double-component composite fibers to generate a split trend by utilizing thermal shrinkage of high-shrinkage components in the double-component composite fibers; enabling the double-component composite fibers to be split and mutually entangled through a spunlace technology; conveying the double-component composite fibers into a fiber crimping device, and performing shrinkage and crimping treatment on non-woven cloth by utilizing the fiber crimping device, so that the high-shrinkage components are completely shrunk and crimped, and the double-component spunbonded spunlace microfiber leather base cloth is obtained. The method is simple in technological process and low in production cost and energy consumption, green and clean preparation of the microfiber leather base cloth can be achieved through a one-step method, and the prepared hollow orange slice type double-component spunbonded spunlace leather base cloth has the characteristics of being compact, soft, stiff and smooth and full in hand feeling.

Owner:TIANJIN POLYTECHNIC UNIV +2

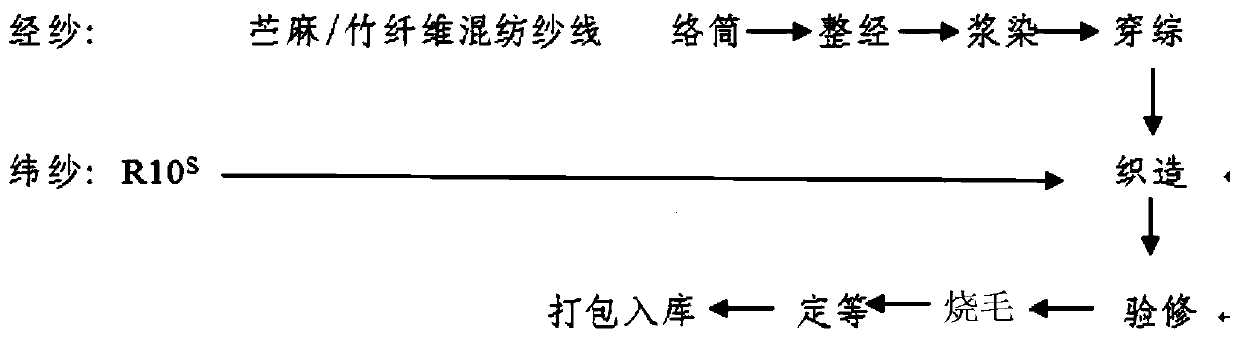

Comfortable and refreshing mat fabric containing tencel and Chinese bast fibers and production method

InactiveCN110004562AModerate thicknessGood moisture absorption and air permeabilityMercerising of indefinite length fabricsSucessive textile treatmentsFiberYarn

The invention discloses a comfortable and refreshing mat fabric containing tencel and Chinese bast fibers and a production method and relates to the technical field of textile weaving. The mat fabricis interwoven by tencel cotton yarn and Chinese bast fiber cotton yarn through the combined weave of reed mat weave and a honeycomb weave, the tencel cotton yarn is woven into the comfortable and refreshing mat fabric surface, tencel cotton fibers cover the comfortable and refreshing mat fabric surface, the Chinese bast fiber cotton yarn is woven inside the comfortable and refreshing mat fabric, the interior of the fabric is of a honeycomb three-dimensional structure, and the Chinese bast fibers are distributed on the cells of the fabric; the comfortable and refreshing mat fabric is interwovenby warps and wefts, the warps are produced by the tencel cotton yarn and the Chinese bast fiber cotton yarn according to the number ratio of 3:2, and the wefts are produced by the Chinese bast fibercotton yarn and the tencel cotton yarn according to the number ratio of 3:2. When the comfortable and refreshing mat fabric is used, the skin of a human body contacts with the tencel surface layer, coolness and smoothness are achieved, the heat of the fabric can penetrate the tencel surface layer to enter the cellular Chinese bast fiber layer and dispersed inside the Chinese bast fiber layer to bedissipated, and radiating and breathability of the fabric can be greatly increased.

Owner:JIHUA 3542 TEXTILE CO LTD

Antibacterial odor-resistant crease-resistant finishing process of blended fabric

InactiveCN108716116AAntibacterial, anti-odor and anti-wrinkle propertiesGood shaping effectBiochemical fibre treatmentWrinkle resistant fibresState of artEngineering

The invention discloses an antibacterial odor-resistant crease-resistant finishing process of a blended fabric. The antibacterial odor-resistant crease-resistant finishing process includes the steps:(1) singeing; (2) scouring, desizing and bleaching treatment; (3) antibacterial odor-resistant crease-resistant treatment; (4) preliminary drying; (5) baking; (6) washing; (7) drying. Compared with the prior art, the antibacterial odor-resistant crease-resistant finishing process has the advantages that the cotton and silk blended fabric has antibacterial odor-resistant crease-resistant performances, three finishing effects are simultaneously achieved, finishing time is shortened, and the cotton and silk blended fabric has good sizing effects and is free from ironing, waterproof, oil-proof, stiff, smooth, full, non-fouling and the like by the aid of the finishing process.

Owner:ANHUI ZHAOBAO TEXTILE TECH CO LTD

Cotton fabric non-ironing finishing agent

The invention discloses a cotton fabric non-ironing finishing agent, which comprises, by weight, 16-32 parts of ethylene glycol, 6-12 parts of 2-hydroxyethyl methacrylate, 6-8 parts of methyl methacrylate, 4-6 parts of lauryl methlacrylate, 2-6 parts of magnesium chloride, 2-4 parts of a glycerin rosin resin, 10-20 parts of ethyl acetate, 10-30 parts of butyl acetate, 20-60 parts of sodium carbonate, 20-30 parts of poly isobutyl ester, 10-20 parts of phosphotriester, 20-30 parts of lauryl methlacrylate, 20-30 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 20-30 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, and 400-600 parts of deionized water. According to the present invention, the production of the cotton fabric non-ironing finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the cotton fabric non-ironing finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shapingeffect, no ironing, starching, fullness, no stain, and the like.

Owner:王锶源

Water-soluble anti-wrinkle non-ironing finishing agent

The invention discloses a water-soluble anti-wrinkle non-ironing finishing agent, which comprises, by weight, 80-120 parts of alkyd resin, 100-180 parts of 2-(dimethylamino)ethyl methacrylate, 20-40 parts of a melamine resin, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropyl alcohol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of aglycerin rosin resin, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 5-15 parts of vinyl chloride vinyl ester, and 100-140 parts of deionized water. According to the present invention, the production of the water-soluble anti-wrinkle non-ironing finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the water-soluble anti-wrinkle non-ironing finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:姜维

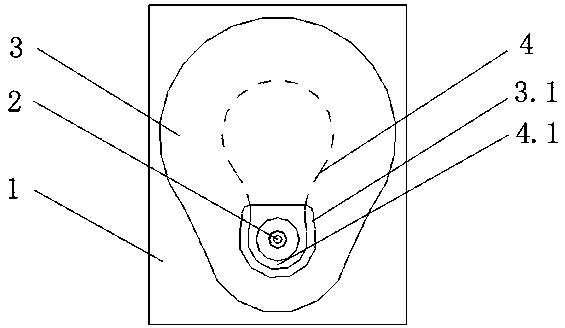

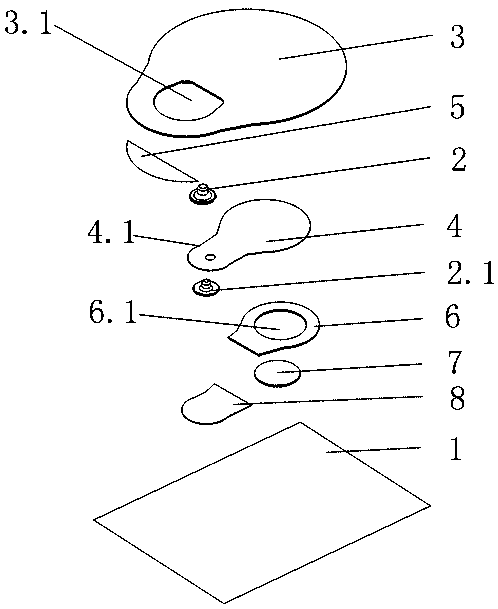

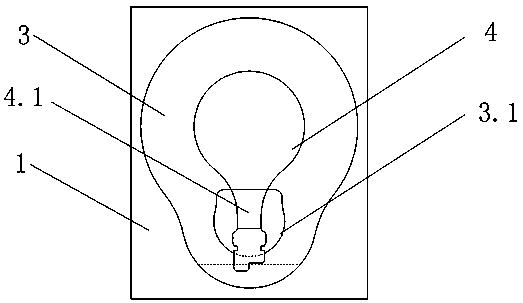

Eccentric electrocardio-electrode

PendingCN110881974AReduce usageFew levels of structureDiagnostic recording/measuringSensorsMechanical engineeringPhysics

The invention provides an eccentric electrocardio-electrode comprising a release sheet, a back lining and an electrode plate body. An acquisition part is formed at one end of the electrode plate bodyand a leading-out tail part is formed at other end and is used for arranging an electrode leading-out element or an electrode leading-out structure; and conductive biogel covers the bottom surface ofthe acquisition part of the electrode plate body. A through hole is formed in the end, corresponding to the leading-out tail part of the electrode plate body, of the back lining; the electrode plate body is arranged on the bottom face of the back lining; the back lining and the acquisition part of the electrode plate body are combined into one; and the electrode leading-out element or the electrode leading-out structure is exposed out of the through hole. The eccentric electrocardio-electrode based on a simple structural design has a simple process; the electrode plate body is prevented from being separated from the back lining; the usage of materials is reduced; and the cost is lowered. Besides, the comprehensive performances such as waterproofness, air permeability and comfort can be improved. And the through holes is used for exposing.

Owner:QINGDAO BRIGHT MEDICAL MFG

Processing process of special radish cream pumpkin cake

InactiveCN104757051AFull of nutritionImprove protectionDough treatmentBakery productsBiotechnologyNutrition

The invention discloses a processing process of a special radish cream pumpkin cake, and belongs to the field of food processing. The processing process is characterized by comprising the following components by weight: 5 kg of pumpkin, 1.5 kg of radish, 1L of milk, 650 g of cooked sesame flour, 820 g of brown sugar, 200 g of corn starch, 500 g of honey, 125 g of almond broken grains, 500 g of soybean oil and 25 g of baking soda; the processing flow comprises the following steps: selecting the raw material; processing; adding pumpkin; forming; frying. The process has the beneficial effects that the product has golden color, is sweet and palatable, has crisp mouthfeel, and has the unique fragrant sticky flavor of the pumpkin and the crispness of the radish; the product is delicious, rich in nutrition, contributes to protection of gastric mucosa and help of digestion, has the special curative effects of preventing diabetes and reducing blood sugar and is easy to operate; the product is an environment-friendly food which is not only delicious but also rich in nutrition.

Owner:陶峰

Silk anti-wrinkle non-ironing finishing agent

The invention discloses a silk anti-wrinkle non-ironing finishing agent, which comprises, by weight, 10-30 parts of a melamine resin, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropyl alcohol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride, 4-8 parts of a glycerin rosin resin, 4-8 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 8-16 partsof polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 4-8 parts of methyl methacrylate, 5-15 parts of vinyl chloride vinyl ester, and 100-140 parts of deionized water. According to the present invention, the production of the silk anti-wrinkle non-ironing finishing agent is simple, the used productionraw materials are non-toxic, and the fabric treated by the silk anti-wrinkle non-ironing finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:顾香

Crease-resistant ironing-free finishing agent for dacron

InactiveCN106906656AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresZinc nitrateSizing

The invention discloses a crease-resistant ironing-free finishing agent for dacron, which comprises the following components in parts by weight: 10-20 parts of polyurethane, 10-20 parts of crylic acid, 10-20 parts of zinc nitrate, 6-12 parts of ammonium citrate, 20-30 parts of triethanolamine, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of glycerinum rosin resin, 8-16 parts of polydivinyl acetylene, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid, 8-16 parts of acrylamide, 5-15 parts of vinyl chloride-vinyl ester and 80-120 parts of deionized water. The crease-resistant ironing-free finishing agent for dacron, provided by the invention, is simply prepared; the nontoxic production raw materials are selected; the fabric treated with the finishing agent is shrink-proof and crease-resistant, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陆海蓉

Formula of black pepper beef-flavor black rice crusts

The invention relates to the technical field of rice crust foods, and particularly discloses a formula of black pepper beef-flavor black rice crusts. The rice crusts are prepared from the following raw materials in parts by weight: 300 to 500 parts of black rice, 50 to 60 parts of palm oil, 5 to 10 parts of edible salt, 5 to 8 parts of a beef-flavor seasoning and 0.5 to 1 part of a food additive.The invention overcomes the defects of the prior art, and the black rice and the beef-flavor seasoning are combined, so that the black rice crusts have the crispness of rice crusts and the fragrance of beef, and meanwhile, the black rice crusts have the characteristics of rich nutrients, and high edible and medicinal value.

Owner:ANHUI LEJINJI FOOD

Organic silicon leather fatting agent

The invention discloses an organic silicon leather fatting agent. The organic silicon leather fatting agent comprises, by weight, 2-4 parts of methyl alcohol, 20-60 parts of olive oil, 4-6 parts of isopropyl alcohol, 5-10 parts of benzylene chloride, 6-8 parts of dihydroxytoluene urea resin, 10-20 parts of polyurethane, 10-30 parts of stearic acid, 8-16 parts of capryl alcohol, 4-8 parts of oleinic acid, 2-4 parts of sulfuric acid, 6-12 parts of sodium hydroxide, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid and 8-16 parts of acrylamide. The organic silicon leather fatting agent is easy to prepare, nonpoisonous production raw materials are selectively adopted, fabric treated with the finishing agent can be resistant to shrinkage and wrinkles, the shaping effect is good, ironing is avoided, and the fabric treated with the finishing agent has the characteristics of being stiff and smooth, plump, free of pollution and the like.

Owner:袁允兰

Wool fat class fatting agent

InactiveCN106906315AEasy to makeGood shaping effectLeather impregnationWrinkle skinP-Toluenesulfonic acid

The invention discloses a wool fat class fatting agent. The wool fat class fatting agent comprises, by weight, 60-80 parts of fine wool fat, 10-20 parts of ethanol amine, 6-12 parts of sodium methylate, 20-60 parts of olive oil, 2-4 parts of copper stearate, 6-8 parts of dihydroxytoluene urea resin, 10-20 parts of polyurethane, 10-30 parts of stearic acid, 8-16 parts of capryl alcohol, 4-8 parts of oleinic acid, 10-20 parts of p-toluenesulfonic acid, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid and 8-16 parts of acrylamide. The wool fat class fatting agent is easy to prepare, nonpoisonous production raw materials are selectively adopted, fabric treated with the finishing agent can be resistant to shrinkage and wrinkles, the shaping effect is good, ironing is avoided, and the fabric treated with the finishing agent has the characteristics of being stiff and smooth, plump, free of pollution and the like.

Owner:周昱帆

Water and oil-repellent anti-wrinkling finishing agent for baffeta

InactiveCN106906639AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresBenzoyl peroxideGlycerol

The invention discloses a water and oil-repellent anti-wrinkling finishing agent for baffeta. The water and oil-repellent anti-wrinkling finishing agent for baffeta comprises the following components in parts by weight: 100-160 parts of dimethylol urea resin, 40-60 parts of magnesium chloride hexahydrate, 100-160 parts of aluminum sulfate, 80-100 parts of trimethylol melamine, 20-30 parts of methacrylic glycerol trilaurate, 20-30 parts of zinc nitrate hexahydrate, 40-60 parts of poly-isobutyl ester, 20-40 parts of aluminum hydroxide, 12-24 parts of phosphotriester, 12-18 parts of antimonous oxide, 10-20 parts of benzoyl peroxide and 600-800 parts of deionized water. The water and oil-repellent anti-wrinkling finishing agent for baffeta is simply prepared; the nontoxic production raw materials are selected; the baffeta treated with the finishing agent is shrink-proof and anti-wrinkling, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陆亚洲

Wrinkle proofing agent for silk fabric

InactiveCN106906657AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresWrinkle skinSizing

The invention discloses a wrinkle proofing agent for a silk fabric. The wrinkle proofing agent contains the following components in parts by weight: 4-8 parts of citric acid, 6-12 parts of ammonium citrate, 20-30 parts of triethanolamine, 10-20 parts of sodium hypophosphite, 20-40 parts of formaldehyde resin, 10-16 parts of formic acid, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of glycerinum rosin resin, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 5-15 parts of vinyl chloride ester and 100-140 parts of deionized water. The wrinkle proofing agent for the silk fabric, provided by the invention, is simply prepared; the adopted production raw materials are nontoxic; the fabric treated with the wrinkle proofing agent is shrink-proof and anti-wrinkle, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陆海蓉

Anti-wrinkling finishing agent

InactiveCN106906654AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresBenzoyl peroxideAntimony trioxide

The invention discloses an anti-wrinkling finishing agent. The anti-wrinkling finishing agent comprises the following components in parts by weight: 80-100 parts of trimethylol melamine, 20-30 parts of lauryl methacrylate, 20-30 parts of zinc nitrate hexahydrate, 40-60 parts of poly isobutyl ester, 20-40 parts of aluminum hydroxide, 12-24 parts of phosphotriester, 12-18 parts of antimony trioxide, 10-20 parts of benzoyl peroxide, 16-24 parts of isopropyl alcohol, 2-8 parts of isopropyl acrylate and 10-12 parts of butyl acetate. The anti-wrinkling finishing agent disclosed by the invention has the advantages that the preparation is simple, the adopted production materials are non-toxic, and fabric treated by the finishing agent can be shrink-proof and anti-wrinkling, is good in forming effect and free in ironing, and has the characteristics of stiffness and smoothness, richness and no pollution and the like.

Owner:陆亚洲

Leather lubricating oil fatting agent

InactiveCN106906317AEasy to makeGood shaping effectLeather impregnationP-Toluenesulfonic acidStearic acid

The invention discloses a leather-lubricating oil fatting agent. The leather-lubricating oil fatting agent comprises, by weight, 20-30 parts of poly-ethoxyl castor oil, 2-4 parts of methyl alcohol, 20-60 parts of olive oil, 2-4 parts of copper stearate, 6-8 parts of dihydroxytoluene urea resin, 10-20 parts of polyurethane, 10-30 parts of stearic acid, 8-16 parts of capryl alcohol, 4-8 parts of oleinic acid, 10-20 parts of p-toluenesulfonic acid, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid and 8-16 parts of acrylamide. The leather-lubricating oil fatting agent is easy to prepare, nonpoisonous production raw materials are selectively adopted, fabric treated with the finishing agent can be resistant to shrinkage and wrinkles, the shaping effect is good, ironing is avoided, and the fabric treated with the finishing agent has the characteristics of being stiff and smooth, plump, free of pollution and the like.

Owner:周昱帆

Water-soluble finishing agent

InactiveCN107558222AEasy to makeGood shaping effectFibre treatmentBenzoyl peroxideDibenzoyl Peroxide

The invention discloses a water-soluble finishing agent, which comprises, by weight, 20-40 parts of a melamine resin, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropanol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride, 4-8 parts of a glycerin rosin resin, 4-8 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 5-15 parts of vinyl chloride vinyl ester, and 100-140 parts of deionized water. According to the present invention, the production of the water-soluble finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the water-solublefinishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:顾香

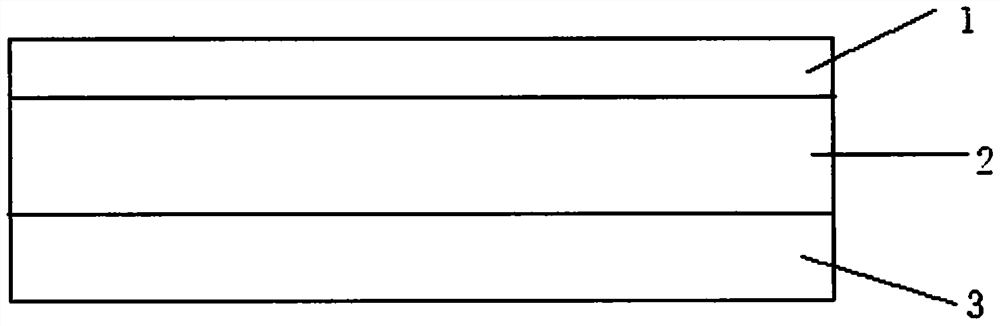

Windproof breathable ultralight composite material

InactiveCN111844930AAntibacterial and antibacterialWith ultra lightSynthetic resin layered productsClothingsPolyesterPolymer science

The invention discloses a windproof breathable ultralight composite material which comprises a base layer, a breathable layer is arranged on the base layer, a windproof layer is arranged on the breathable layer, the base layer is made of bamboo charcoal fiber fabric, the breathable layer is formed by blending silk fibers and silver fibers, and the windproof layer is made of lycra, nylon fibers, polyester fibers and acrylic fibers. Compared with the prior art, the windproof breathable ultralight composite material is good in breathability and windproof effect.

Owner:JURONG RIPOSTE SPORTS GOODS CO LTD

Silk fabric non-ironing finishing agent

InactiveCN107558198AEasy to makeGood shaping effectAnimal fibresMagnesium chloride hexahydrateChemistry

The invention discloses a silk fabric non-ironing finishing agent, which comprises, by weight, 20-30 parts of citric acid, 20-30 parts of triethanolamine, 10-20 parts of sodium hypophosphite, 20-40 parts of a formaldehyde resin, 4-6 parts of isopropanol, 6-12 parts of 2-hydroxyethyl methacrylate, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of a glycerin rosin resin, 8-16 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, 4-12 parts of ammonium citrate, 2-8 parts of glacial acetic acid, 6-16 parts of acrylamide, 5-15 parts of vinyl chloride vinyl ester, and 100-140 parts of deionized water. According to the present invention, the production of the silk fabric non-ironing finishing agent is simple, the used production raw materials are non-toxic, and the fabric treated by the silk fabric non-ironing finishing agent has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:姜维

Pure cotton non-ironing finishing liquid

The invention discloses a pure cotton non-ironing finishing liquid, which comprises, by weight, 16-32 parts of ethylene glycol, 10-20 parts of melamine, 6-12 parts of 2-hydroxyethyl methacrylate, 6-8parts of methyl methacrylate, 4-6 parts of lauryl methacrylate, 2-6 parts of magnesium chloride, 2-4 parts of a glycerin rosin resin, 10-20 parts of ethyl acetate, 20-30 parts of poly isobutyl ester,10-20 parts of phosphotriester, 20-30 parts of lauryl methacrylate, 20-30 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide, 20-30 parts of polydivinyl acetylene, 10-16 parts of naphthenic acid, and 200-300 parts of deionized water. According to the present invention, the production of the pure cotton non-ironing finishing liquid is simple, the used production raw materials are non-toxic, and the fabric treated by the pure cotton non-ironing finishing liquid has characteristics of wrinkle resistance, shrinkage resistance, good shaping effect, no ironing, starching, fullness, no stain, and the like.

Owner:王锶源

Snowflake melange yarn and processing method

The invention relates to the technical field of spinning, in particular to a snowflake melange yarn. The yarn comprises 50 percent of polyester fibers, 38 percent of cotton fibers and 12 percent of viscose by weight, wherein partial of or all fibers in at least one of the fibers are dyed fibers, the dyed fibers are mixed with the undyed fibers uniformly, and the uniformly-mixed fibers are spun toform the dreamy snowflake melange yarn through a spinning process. The yarn comprises the following processing steps: sprinkling oiling agent water on the dyed fibers for braising for at least 10 hours, weighing the fibers with different colors and in different proportions for uniform mixing, and putting the uniformly-mixed fibers in a spinner for spinning. In the melange yarn, the proportioning of the fibers and the color proportioning in each fiber are reasonable, and a small number of fibers in the fibers are only needed to be dyed. The melange yarn can improve the grade of products made of common raw materials obviously, has the characteristics of softness, stiffness and smoothness and comfortable wearing, and can be made into different T-shirts, high-grade underwear, coats, fashionable dresses and household textile products.

Owner:江阴市茂达棉纺厂有限公司

Formula of lentinus edodes-flavor bread

InactiveCN107788067AWith crispFull of nutritionDough treatmentModified nutritive productsNutrientFlavor

The invention relates to the technical field of bread food, and in particular discloses a mushroom-flavored bread formula, which is made of the following raw materials in parts by weight: 1000 parts of wheat flour, 500-600 parts of water, 100-300 parts of white sugar, and 200-200 parts of fresh eggs. 300 parts, butter 100-150 parts, shiitake mushrooms 40-50 parts, salt yeast 10-15 parts, bread improver 5-8 parts, vitamin C 2-3 parts, sodium dehydroacetate 0.3-0.8 parts, leavening agent 0.8 ~1.5 parts, 1~2 parts of citric acid. The present invention overcomes the deficiencies of the prior art, utilizes the combination of bread and shiitake mushrooms, and shiitake mushrooms are rich in vitamin B group, iron, potassium, provitamin D, sweet in taste, flat in nature, high in protein and low in fat, and have a high taste Delicious, refreshing aroma, rich nutrition.

Owner:ANHUI LEJINJI FOOD

Garment finishing agent

InactiveCN106498725AOil-resistantWith crispStain/soil resistant fibresLiquid repellent fibresMagnesium chloride hexahydrateRosin

The invention discloses a garment finishing agent. The garment finishing agent is prepared from, by weight, 40 parts of hydroxy ethyl acrylate, 15 parts of polyurethane, 10 parts of acrylic acid, 12 parts of zinc nitrate, 10 parts of ammonium citrate, 20 parts of triethanolamine, 8 parts of magnesium chloride hexahydrate, 6 parts of rosin glycerin ester resin, 5 parts of vinyl chloride vinyl ester and 100 parts of deionized water. The garment finishing agent has the advantages that the garment finishing agent is easy to manufacture, raw materials selected for producing the garment finishing agent are non-toxic, textiles treated by the garment finishing agent are shrink-proof, crease-resistant, stiff, smooth, plump and non-fouling, good type approval effects can be realized, ironing and pressing can be omitted, and the like.

Owner:启东兴龙电子科技有限公司

Crease-resistant fabric knitted by warps and wefts

The invention discloses a crease-resistant fabric knitted by warps and wefts, wherein the crease-resistant fabric is formed by knitting of the warps and the wefts. The warps are formed by knitting and blending of 100% Merino superfine wool fibers and polyester fibers, and the wefts are formed by knitting and blending of Cheviot fibers and mohair fibers. The warps comprise, by weight, 63%-69% of the 100% Merino superfine wool fibers and 31%-37% of the polyester fibers, and the wefts comprise, by weight, 44%-51% of the Cheviot fibers and 49%-56% of the mohair fibers. According to the crease-resistant fabric knitted by the warps and the wefts, the crease-resistant fabric is formed by knitting of the warps and the wefts and is compact in structure, the warps and the wefts are composed of the 100% Merino superfine wool fibers, the polyester fibers, the Cheviot fibers and the mohair fibers, and the crease-resistant fabric has the advantages of being elastic and formfitting, stiff and smooth, crease-resistant, good in shape retention and high in strength.

Owner:WUJIANG XUYANG TEXTILE

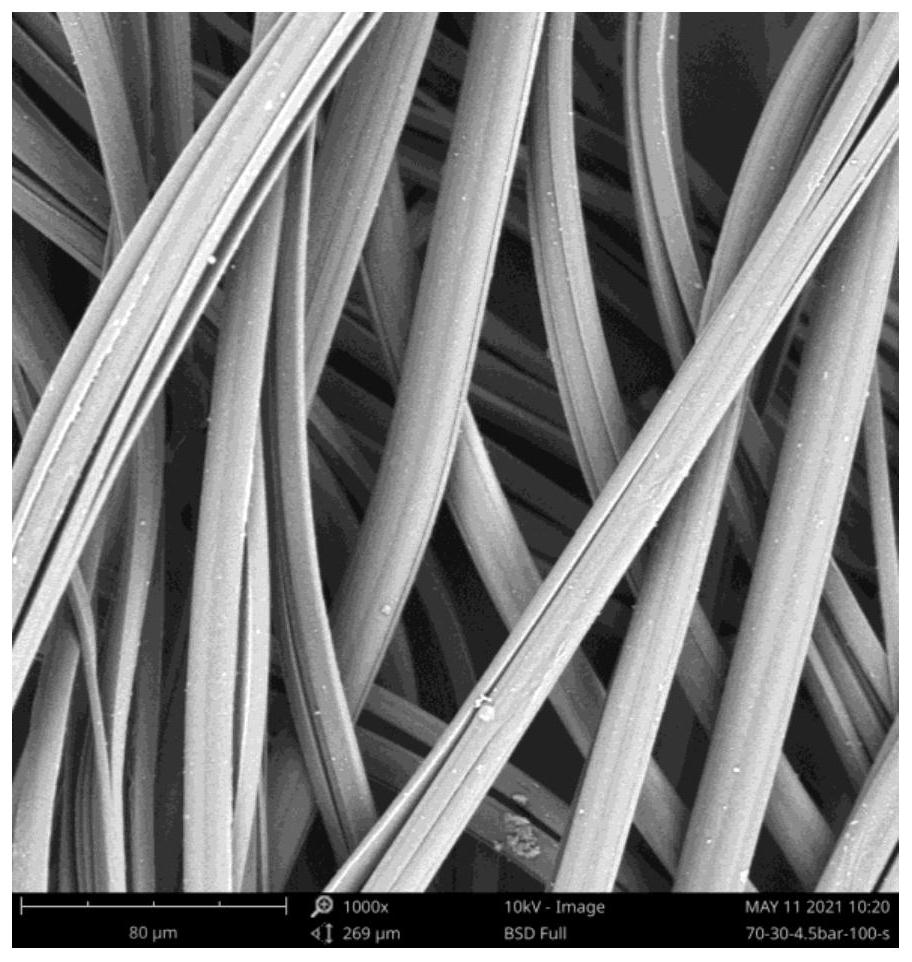

A kind of air-jet vortex spinning multi-component antibacterial yarn and preparation method thereof

ActiveCN112877825BImprove antibacterial propertiesHigh strengthContinuous wound-up machinesOpen-end spinning machinesFiberPolyester

The invention provides an air-jet vortex spinning multi-component antibacterial yarn. The antibacterial yarn is 32S yarn; Long staple cotton 18.5‑21.5%, fine denier polyester staple fiber 14‑16%, antibacterial polyester staple fiber 28.5‑31.5%, lyocell staple fiber 13.5‑16.5%. The invention also provides a preparation method of air-jet vortex spinning multi-component antibacterial yarn. The yarn produced by the invention has high strength, crispness yet softness and antibacterial properties. Using this yarn as weft yarn, the fabric made has the functions of crispness, antibacterial, anti-pilling, moisture absorption and quick drying, and has been made into medical hand washing clothes. Combined request.

Owner:潍坊迅纺新材料科技有限公司

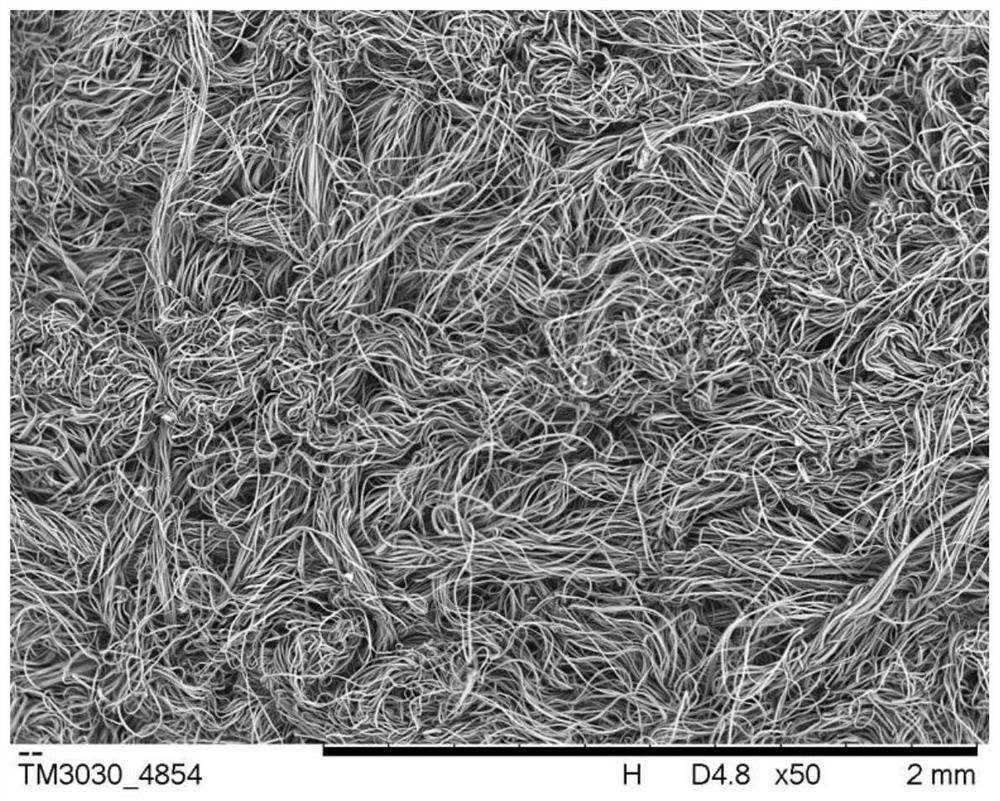

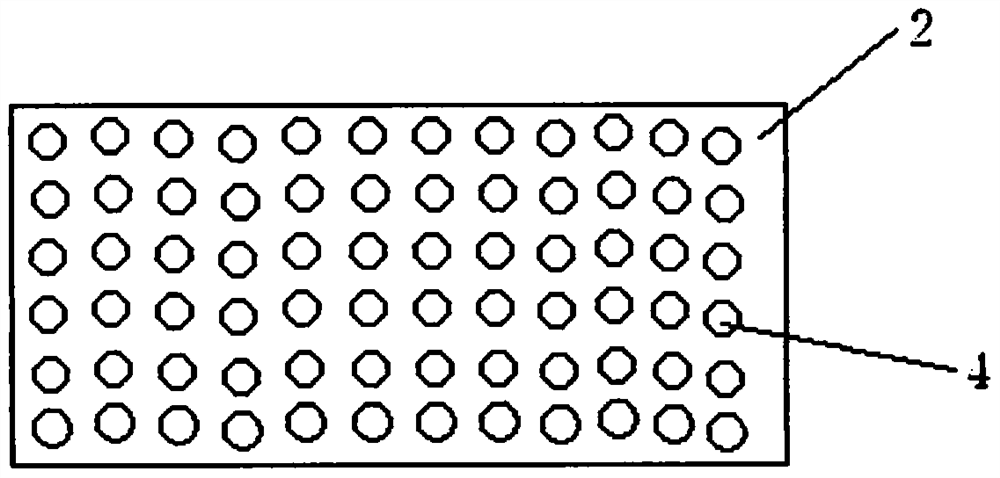

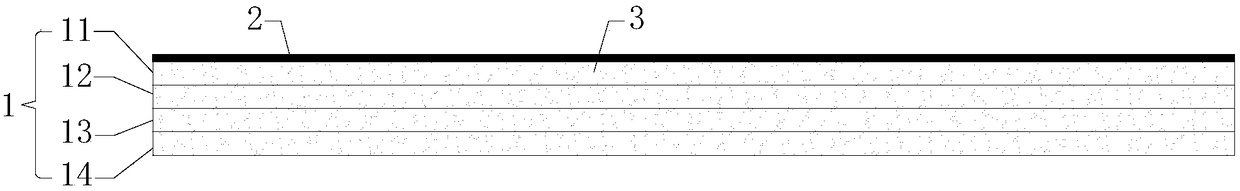

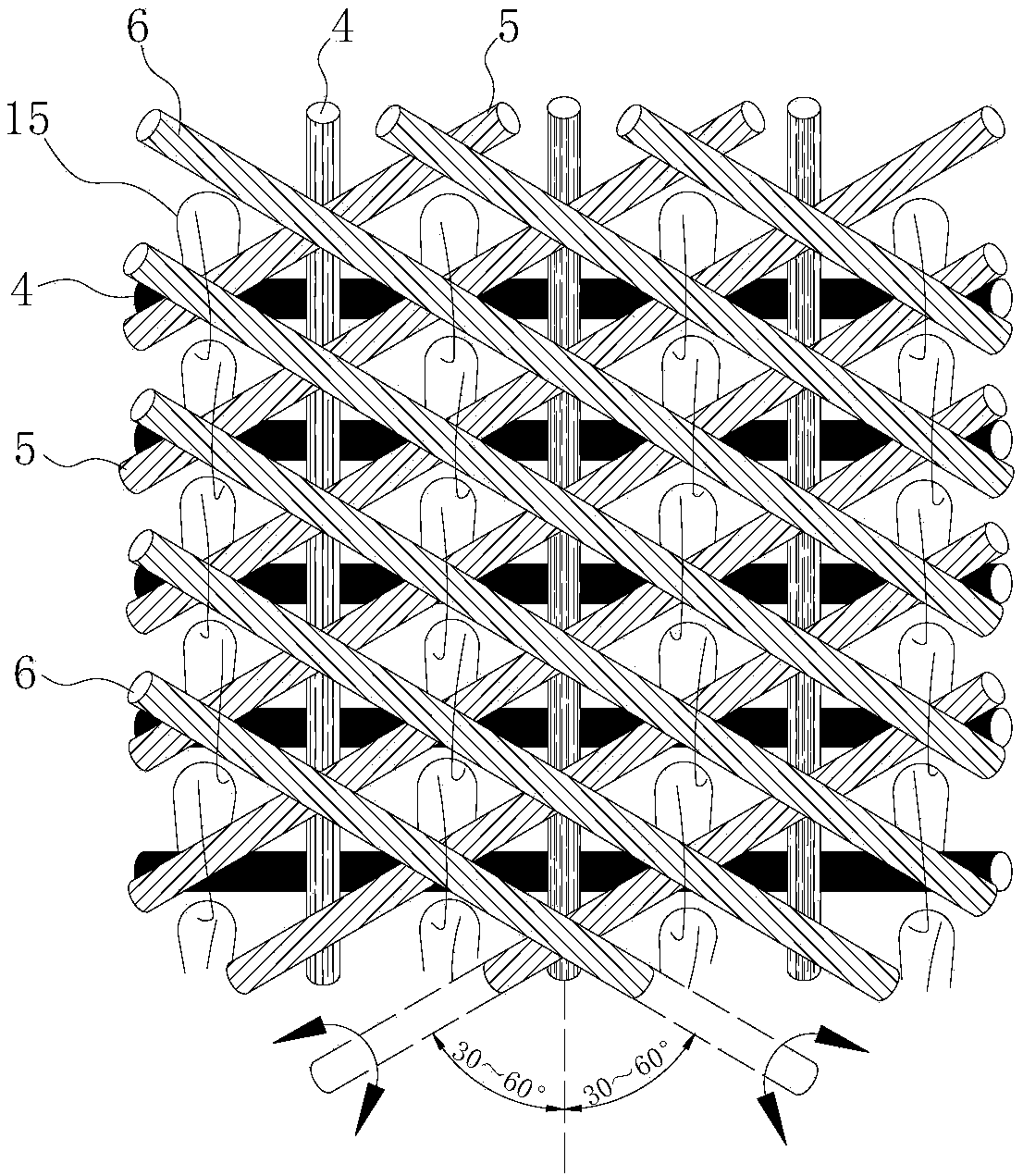

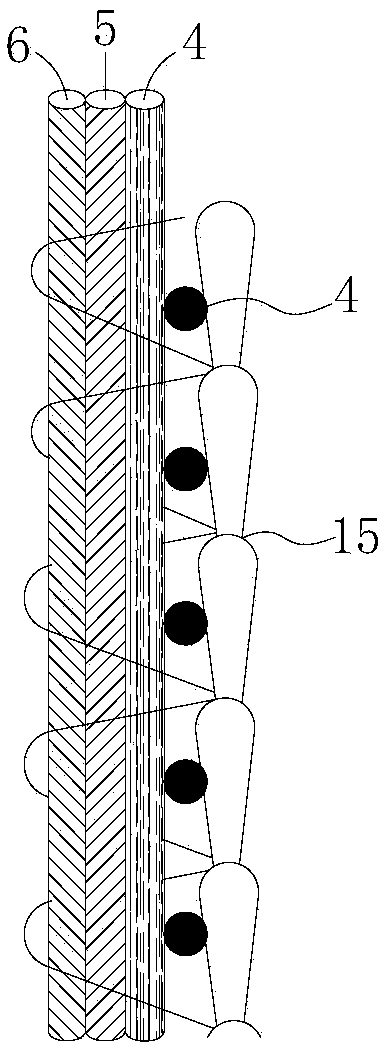

An environmentally friendly multi-axial warp-knitted fusible interlining containing bamboo activated carbon powder and its preparation process

ActiveCN106087442BFeel goodImprove stabilityFibre chemical featuresCoatingsEnvironmental resistanceActivated carbon

The invention discloses an environment-friendly warp-knitted adhesive lining containing bamboo activated carbon powder. The environment-friendly warp-knitted adhesive lining comprises base cloth and adhering layers, wherein bamboo activated carbon powder is fixed in the base cloth, the base cloth is of a multi-axial warp-knitted stricture and sequentially comprises a lining weft yarn layer, a lining warp yarn layer, a first oblique yarn lining layer and a second oblique yarn lining layer from top to bottom, the lining weft yarn layer and the lining warp yarn layer are respectively formed by warp-direction arrangement and weft-direction arrangement of skin core compound fiber yarns, the skin core compound fiber yarns are formed by the compounding of polylactic acid fiber skin layer and a polypropylene fiber core layer, the first oblique yarn lining layer is formed by the arrangement of chitosan fiber yarns, the second oblique yarn lining layer is formed by the arrangement of chitin fiber yarns, and one or two surfaces of the base cloth are coated with the adhering layers. The invention further provides a preparation process of the adhesive lining. The adhesive lining has the advantages of stiffness, smoothness, environmental friendliness, strong weather resistance and the like, has antimicrobial activity and hygroscopicity and further has the effects of purifying air, eliminating peculiar smell, absorbing moisture, preventing mold, inhibiting bacteria and killing pests.

Owner:鹤山市新康富服装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com