Preparation method of high-shrinkage orange slice type double-component spunbonded spunlace microfiber leather base cloth

A spunbond spunlace and two-component technology, applied in the field of nonwoven fabrics, can solve the problems of nonwoven fabrics such as flat and thin hand feeling, limited application range, and complicated process, so as to reduce spunlace energy consumption, facilitate complete shrinkage, and improve the hand feel. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

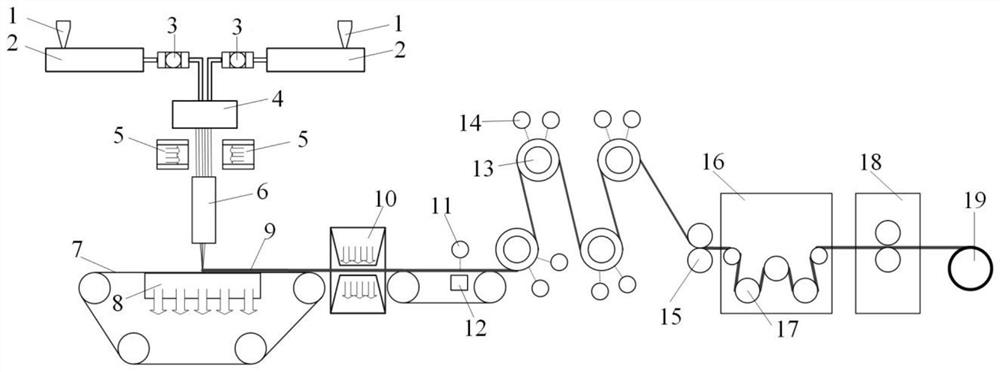

[0027] The present invention provides a kind of preparation method (abbreviation method) of high-shrinkage segmental orange type two-component spunbonded spunlace superfiber leather base cloth, it is characterized in that, this method comprises the following steps:

[0028] (1) Add a hot air device 10 and a fiber crimping device 16 in the two-component spunbond / spunlace production line; according to the spinning direction, the hot air device 10 is installed between the web forming curtain 7 and the spunlace process, that is, the web forming curtain 7 (that is, the position after the fibers form the fiber web 9), and the front of the spunlace process; the fiber crimping device 16 is arranged between the pressing roller 15 and the drying box 18, that is, behind the pressing roller 15 and in front of the drying box 18 ;

[0029] (2) Two-component composite fiber is spun into a net: first, two kinds of polymers are formed into a two-component raw silk melt by conjugate spinning; ...

Embodiment 1

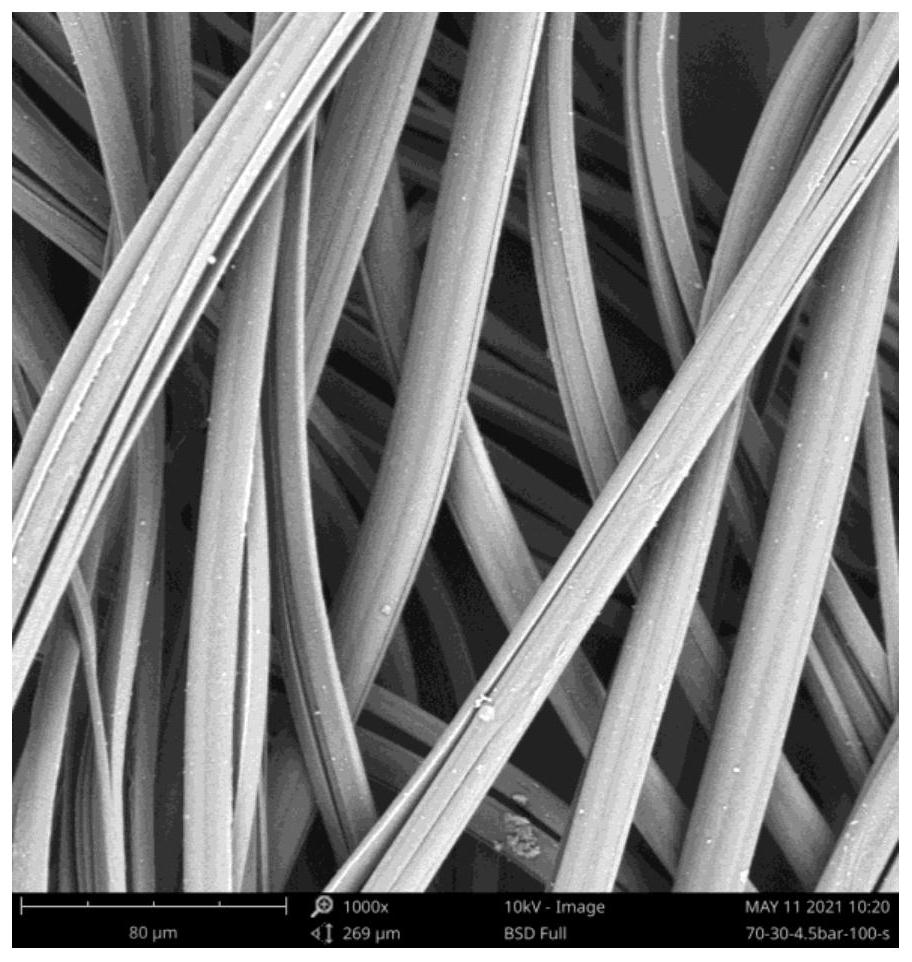

[0051] In this example, the HSPET-PA6 hollow orange segment two-component spunbonded spunlace superfiber leather base fabric is prepared, and the specific steps are as follows:

[0052] (1) Add the hot air device 10 and the fiber crimping device 16 into the two-component spunbond / spunlace production line, the hot air device 10 is installed behind the web curtain 7, and the fiber crimping device 16 is installed behind the pressure roller 15;

[0053] (2) Import HSPET and PA6 polymer slices into the drying tower for pre-crystallization and drying treatment respectively. After extruded and melted by a screw extruder and filtered by a melt filtration system, the compounding is completed in the two-component spinning assembly 4 Spinning, then cooled by side blowing, air drafting, and evenly laid on the netting curtain 7; the temperature of side blowing is 20°C, the relative humidity is 70%, the wind speed is 1m / s, and the drawing pressure is 0.55Mpa. The elongation speed is 5000m / m...

Embodiment 2

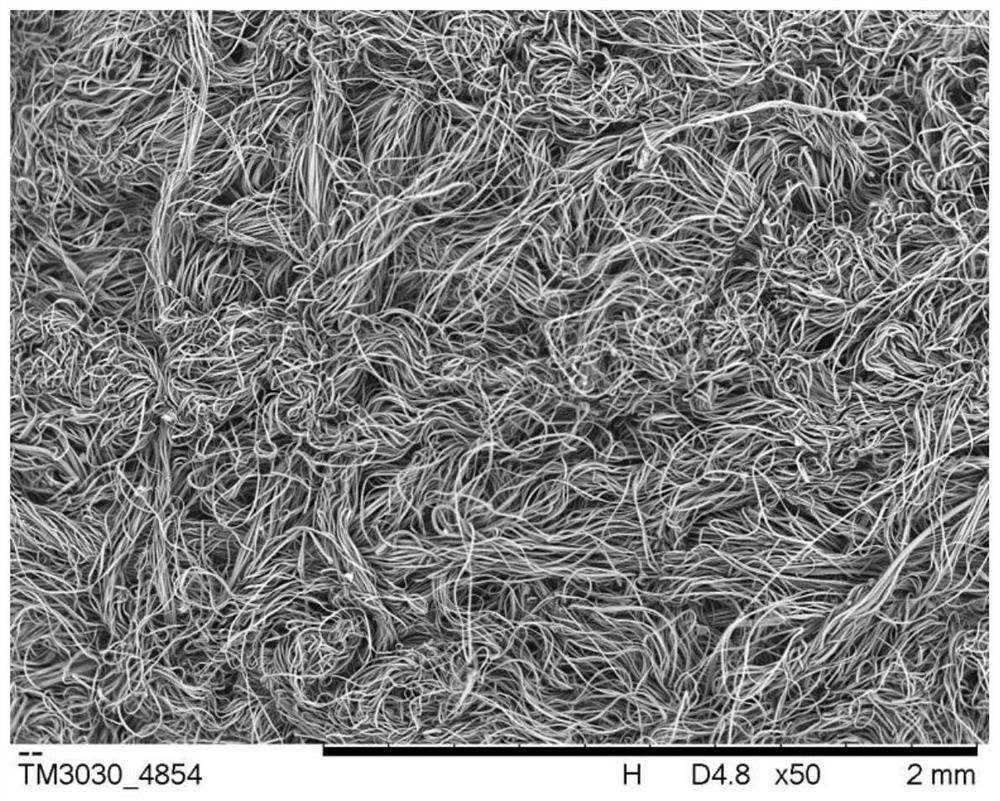

[0067] In this example, the HSPET-PA6 hollow orange segment two-component spunbonded spunlace superfiber leather base fabric is prepared, and the specific steps are as follows:

[0068] (1) Add the hot air device and fiber crimping device to the two-component spunbond / spunlace production line, the hot air device is installed behind the web curtain, and the fiber crimping device is installed behind the pressure roller;

[0069] (2) Import HSPET and PA6 polymer slices into the drying tower for pre-crystallization and drying treatment respectively. After extruded and melted by a screw extruder and filtered by a melt filtration system, the compounding is completed in the two-component spinning assembly 4 Spinning, then cooled by side air blowing, air drafting, and evenly laid on the web forming curtain 7; The elongation speed is 4000m / min, and the surface density of the fiber web is 120g / m 2 ;

[0070] The volume ratio of HSPET to PA6 melt is 5:5, the third monomer isophthalic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com