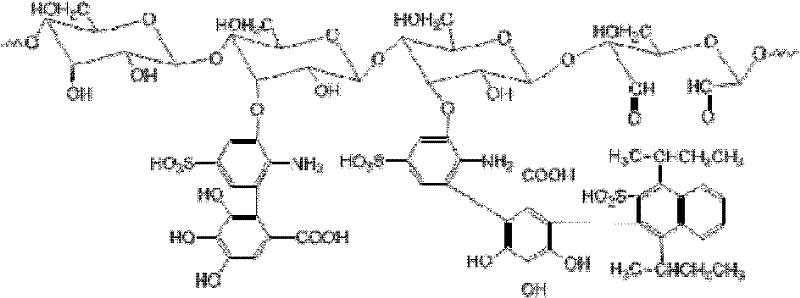

Method for preparing modified starch tanning agent

A starch tanning agent and modification technology are applied in the field of leather synthetic tanning agent and its preparation, and in the field of preparation of degradable and environmentally friendly modified starch tanning agent, which can solve the problems of easy mildew, poor permeability, hindering the application of starch and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: Add 15 grams of cornstarch and 0.5 grams of ammonium persulfate into 85 grams of deionized water, stir and heat to 90°C, add 3 milliliters of 6mol.L after 15 minutes -1 Hydrochloric acid solution, continue heat preservation reaction for 3 hours to obtain acid-decomposed oxidized starch; Sodium bicarbonate neutralizes the pH of the system to 7, adding 5 milliliters of HRP solution with a concentration of 0.5 g / L, and adding 15.6 grams of hydrogen peroxide solution with a mass fraction of 30%, and controlling the dropping time for 1 hour. Continue the heat preservation reaction for 3.5 hours to obtain the grafted modified starch; add 2.6 grams of periodic acid to the above grafted starch, neutralize the pH of the system to 3 with hydrochloric acid, heat to 35°C, and react for 3 hours to obtain the modified starch tanning agent .

Embodiment 2

[0013] Example 2: Add 16.5 grams of cornstarch and 0.6 grams of ammonium persulfate into 93.5 grams of deionized water, stir and heat to 91°C, add 3.2 milliliters of 6mol.L after 15 minutes -1 Hydrochloric acid solution, continue the heat preservation reaction for 3.1 hours to obtain the acid-decomposed oxidized starch; Sodium bicarbonate neutralizes the pH of the system to 7, adds 6 milliliters of HRP solution with a concentration of 0.5 g / L, and adds 17.2 grams of hydrogen peroxide solution with a mass fraction of 30%, and controls the dropping time for 1.1 hours. Continue the heat preservation reaction for 3.8 hours to obtain the grafted modified starch; add 2.8 grams of periodic acid to the above grafted starch, neutralize the pH of the system to 3 with hydrochloric acid, heat to 36°C, and react for 3.2 hours to obtain the modified starch tanning agent .

Embodiment 3

[0014] Example 3: Add 18 grams of cornstarch and 0.7 grams of ammonium persulfate into 102 grams of deionized water, stir and heat to 92°C, add 3.4 milliliters of 6mol.L-1 hydrochloric acid solution after 15 minutes, and continue the heat preservation reaction for 3.2 hours. Obtain acid-decomposed oxidized starch; add 10.8 grams of p-aminobenzenesulfonic acid, 7.0 grams of gallic acid and 18.7 grams of pull-off powder to the above-mentioned degraded starch solution, stir and heat to 32 ° C, and neutralize the pH of the system to 7 with sodium bicarbonate , adding 7 milliliters of HRP solution with a concentration of 0.5 g / liter, adding 18.7 grams of hydrogen peroxide solution with a mass fraction of 30%, controlling the dropping time for 1.2 hours, and continuing the insulation reaction for 4 hours after the dropping to obtain grafting Modified starch: add 3.1 g of periodic acid to the above grafted starch, neutralize the pH of the system to 3 with hydrochloric acid, heat to 37...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com