Differential-shrinkage superfine composite fiber and processing process thereof

A technology of ultra-fine composite fiber and processing technology, applied in fiber treatment, conjugated synthetic polymer artificial filament, filament/thread forming, etc., can solve the problem of fiber microstructure damage, limited product varieties, and mechanical properties that cannot meet the needs of use Requirements and other issues to achieve the effect of uniform structure and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

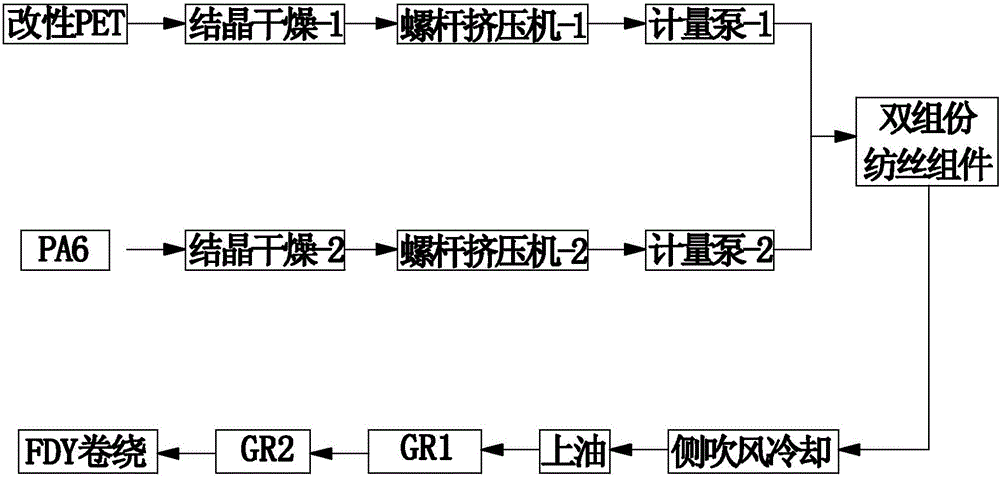

[0031] This embodiment is a processing technology of different shrinkage ultrafine composite fibers. The intrinsic viscosity of the copolyester is 0.700dl / g, the melting point is 230°C, the moisture content of the dry slice is less than 50ppm, and the temperature in each zone of the screw is 250-270°C; the relative viscosity of nylon 6 is 2.3 , the moisture content of dry slices is less than 100ppm, and the temperature of each zone of the screw is 260-280°C.

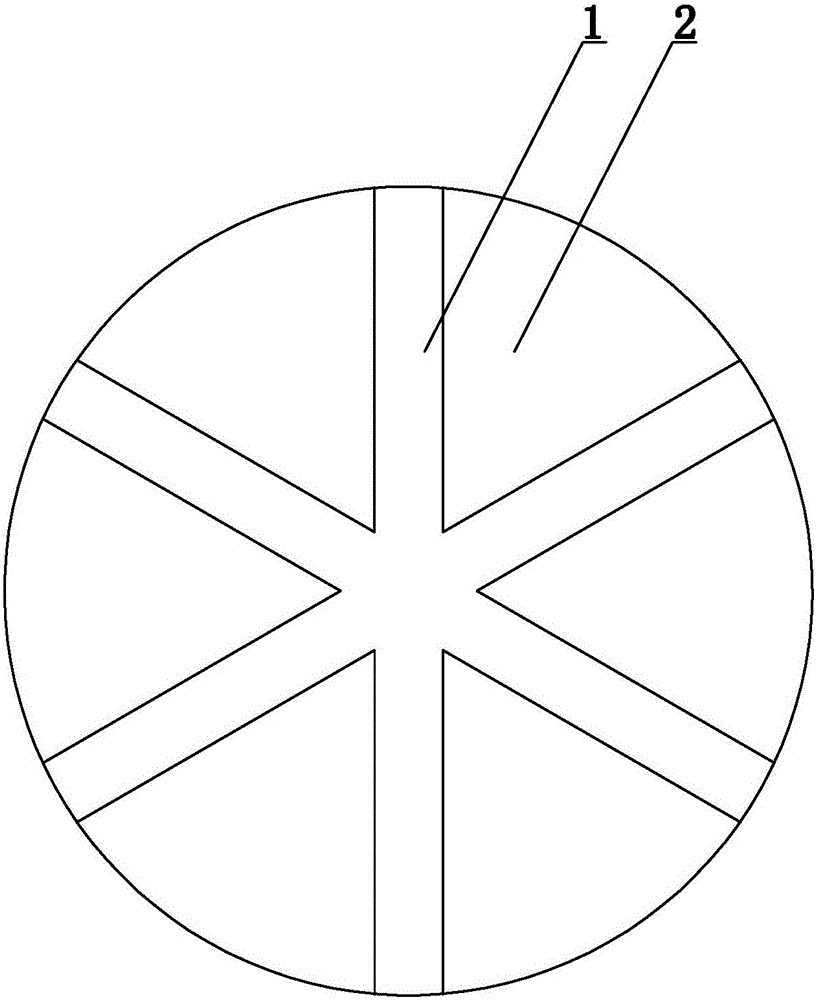

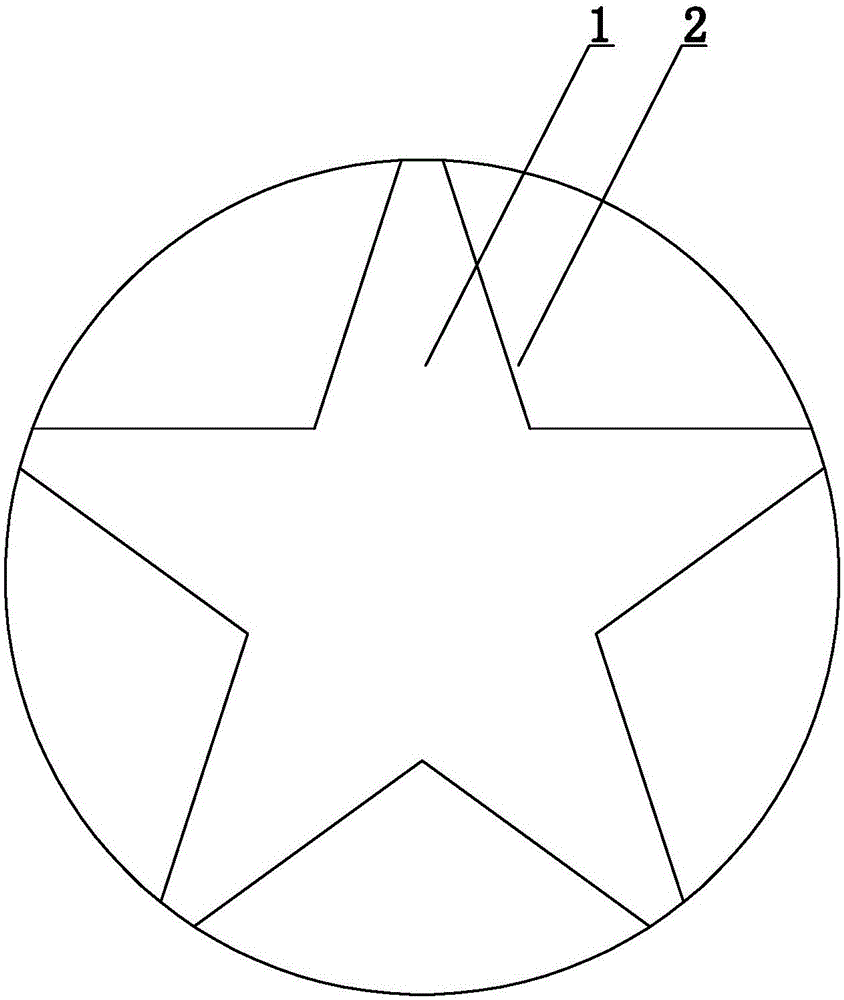

[0032] The mass ratio of modified copolyester to nylon 6 is 30:70, and the cross-section of the fiber is hexagonal star (such as figure 1 shown), the spinning box temperature is 270°C, the side blowing wind speed is 0.4m / s; the first hot roll speed is 2000m / min, the temperature is 70°C; the second hot roll speed is 4000m / min, the temperature is 100°C, and 50dtex / 36f different shrinkage polyester nylon composite FDY.

Embodiment 2

[0034] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that the intrinsic viscosity of the copolyester is 0.700dl / g, the melting point is 232°C, the moisture content of the dry chip is less than 50ppm, and the temperature of each zone of the screw is 250-270°C; nylon 6 is relatively The viscosity is 2.3, the moisture content of dry slices is less than 100ppm, and the temperature of each zone of the screw is 260-280°C.

[0035]The mass ratio of modified copolyester to nylon 6 is 40:60, the cross-section of the fiber is hexagonal star, the temperature of the spinning box is 275°C, the wind speed of side blowing is 0.5m / s; the speed of the first hot roller is 2200m / min, and the temperature is 80 ℃; the speed of the second hot roller is 4200m / min, and the temperature is 110℃, and the different shrinkage polyester nylon composite FDY of 100dtex / 36f is obtained.

Embodiment 3

[0037] The settings and working principle of this embodiment are the same as those of Embodiment 1, the difference is that the intrinsic viscosity of the copolyester is 0.700dl / g, the melting point is 234°C, the moisture content of the dry chip is less than 50ppm, and the temperature in each zone of the screw is 250-270°C; nylon 6 is relatively The viscosity is 2.3, the moisture content of dry slices is less than 100ppm, and the temperature of each zone of the screw is 260-280°C.

[0038] The mass ratio of modified copolyester to nylon 6 is 50:50, the cross section of the fiber is hexagonal star shape, the temperature of the spinning box is 280°C, the wind speed of side blowing is 0.6m / s; the speed of the first hot roller is 2400m / min, and the temperature is 90 °C; the speed of the second hot roller is 4400m / min, and the temperature is 120 °C, and a 150dtex / 36f different shrinkage polyester nylon composite FDY is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com