Method and device for processing fabric surface functionality

A treatment method and technology of surface treatment agent, which are applied in the treatment of textile materials, liquid/gas/steam textile material treatment, and textile material drum treatment, etc. The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

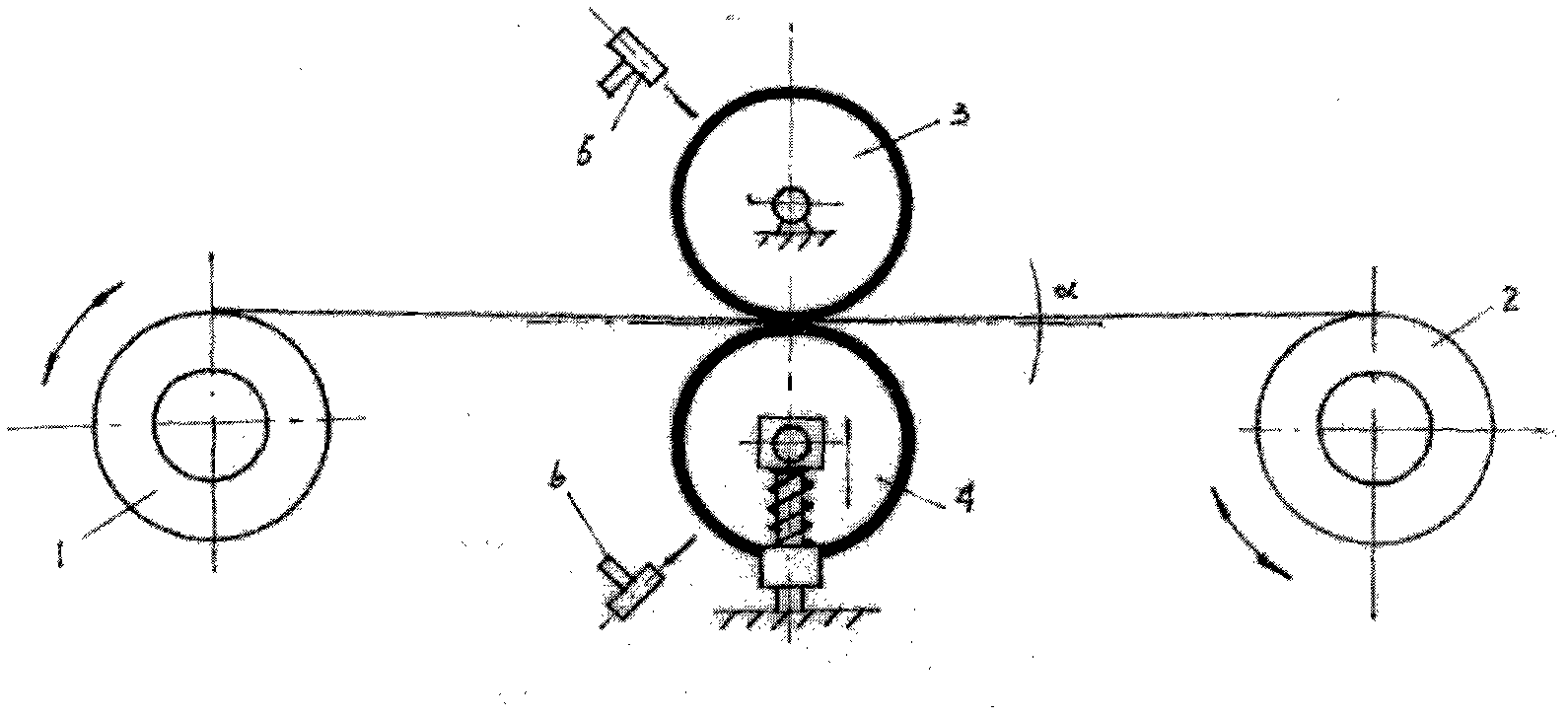

Method used

Image

Examples

specific Embodiment

[0011] With a solid content of 30% polyacrylic acid film-forming resin emulsion and antibacterial agent FM-2598 (Jiangsu Provincial Institute of Silk Sciences provides) with pure water to prepare the surface treatment liquid for spraying, this processing liquid contains 10% film-forming resin emulsion and 5% antibacterial agent, the surface treatment liquid is evenly sprayed onto the felt layer on the surface of the extrusion roller through the upper and lower sprayers, so that the liquid absorption of the felt layer reaches 100% (ratio of liquid absorption to dry weight of the felt), and 100% mulberry silk fabric is 20m / min running speed through the extrusion roller, the extrusion force is 2kg, the total penetration of the surface treatment liquid on the front and back of the fabric is about 1 / 2, the fabric is dried, and then the anti-mildew test is carried out. The test results showed that the antibacterial rate of the fabric against Penicillium was greater than 70%, while t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com