Automatic pasting production line for scrapers, sponges and felts

An automatic pasting and production line technology, applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve problems such as slow time-consuming, low work efficiency, and affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

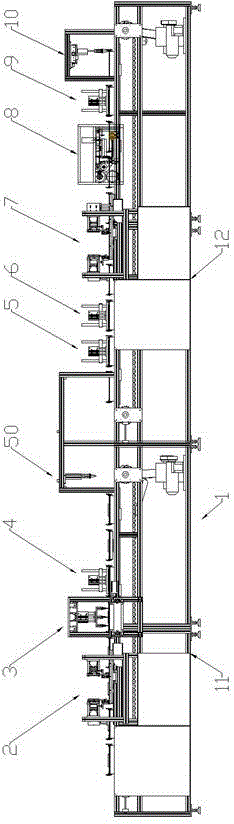

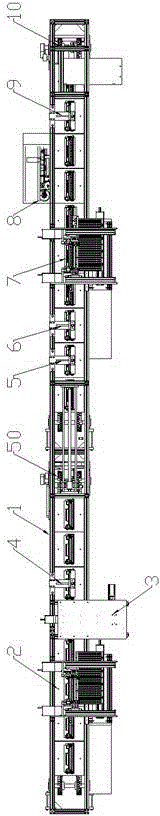

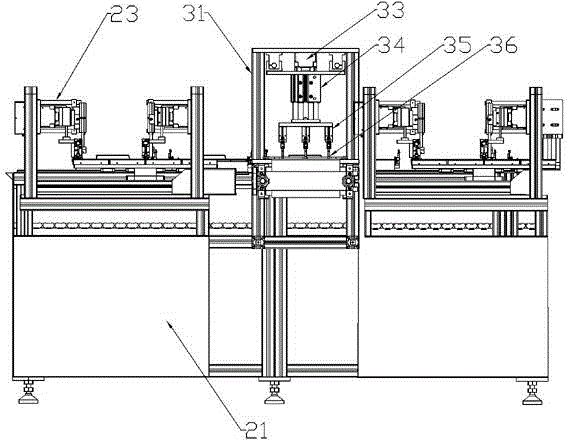

[0028] Such as figure 1 with figure 2 As shown, in this embodiment, the present invention includes a main base body 1, a controller, a transmission belt arranged on the main base body 1, and a motor connected to the transmission belt and electrically connected to the controller. The main base body 1 is sequentially provided with a short sponge mechanism 2, a long sponge mechanism 3, a long sponge compression mechanism 4, a short sponge compression mechanism 5, and a glue dispensing mechanism along the conveying direction of the transmission belt. Mechanism I6, felt sticking mechanism 7, scraper sticking mechanism 8, glue dispensing mechanism II9 and blanking mechanism 10, the short sponge sticking mechanism 2, the long sponge sticking mechanism 3, and the long sponge pressing mechanism 4. The short sponge pressing mechanism 5, the dispensing mechanism I6, the felt sticking mechanism 7, the scraper blade mechanism 8, the glue dispensing mechanism II9 and the blanking mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com