Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Efficient cleaning method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

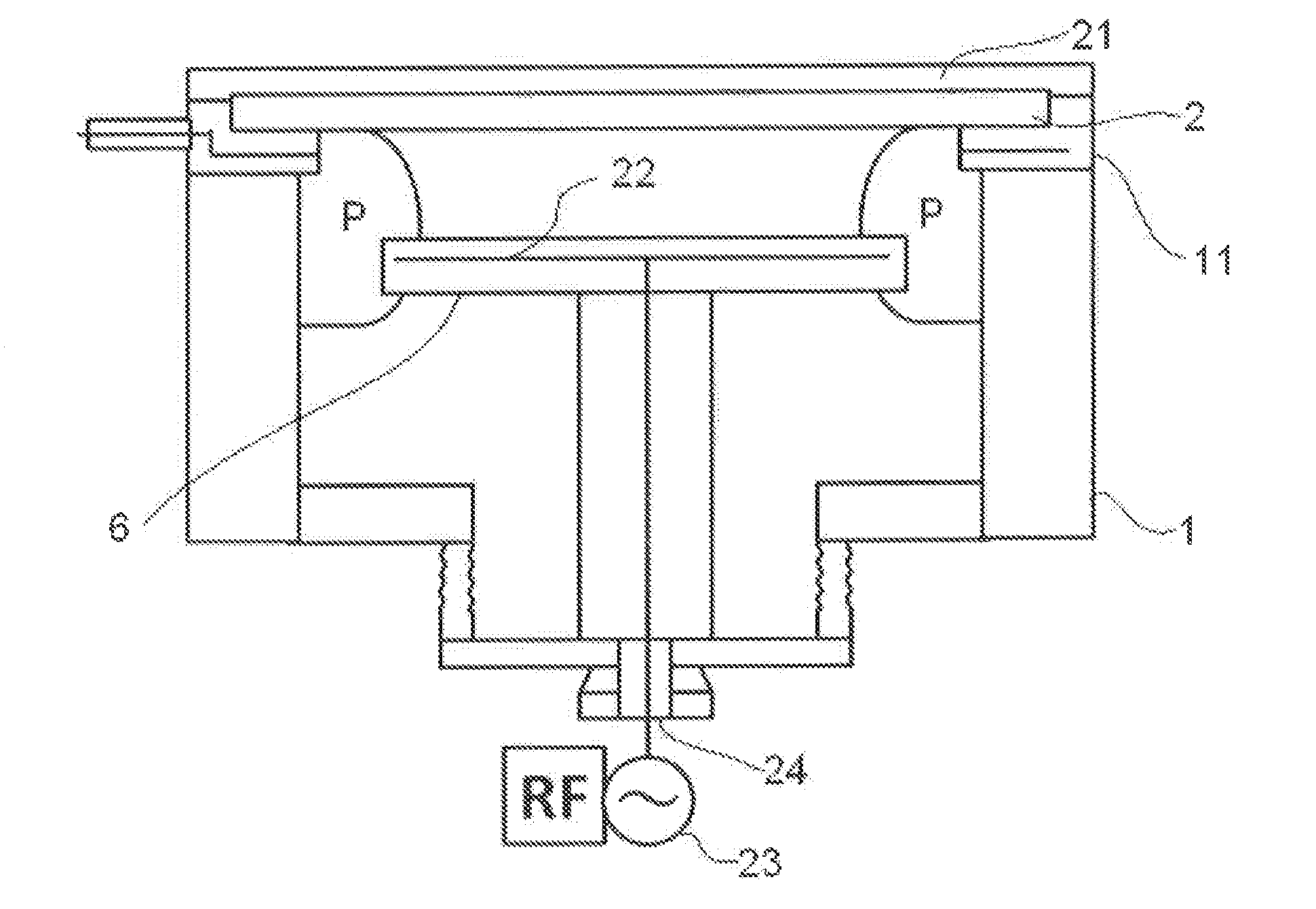

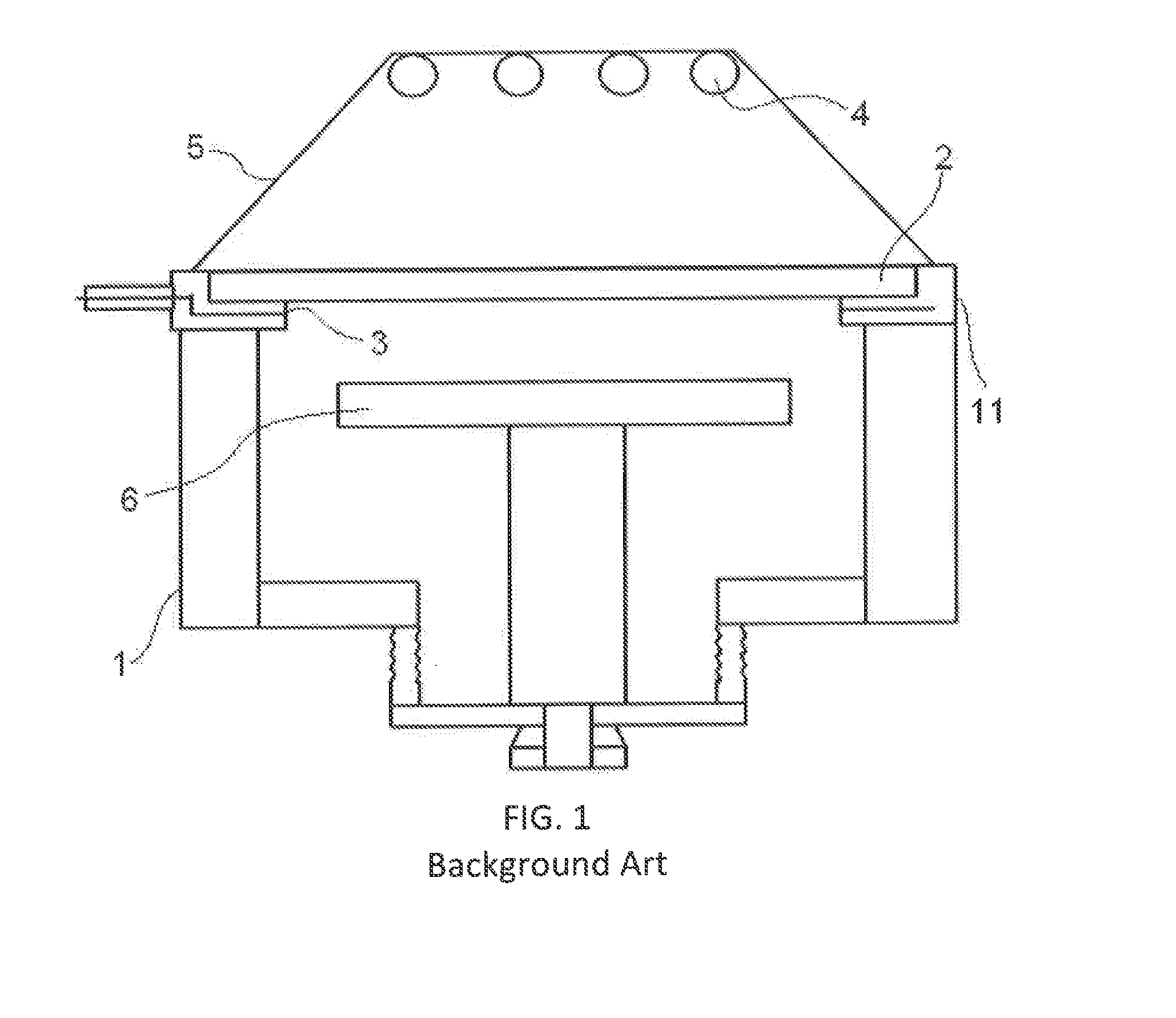

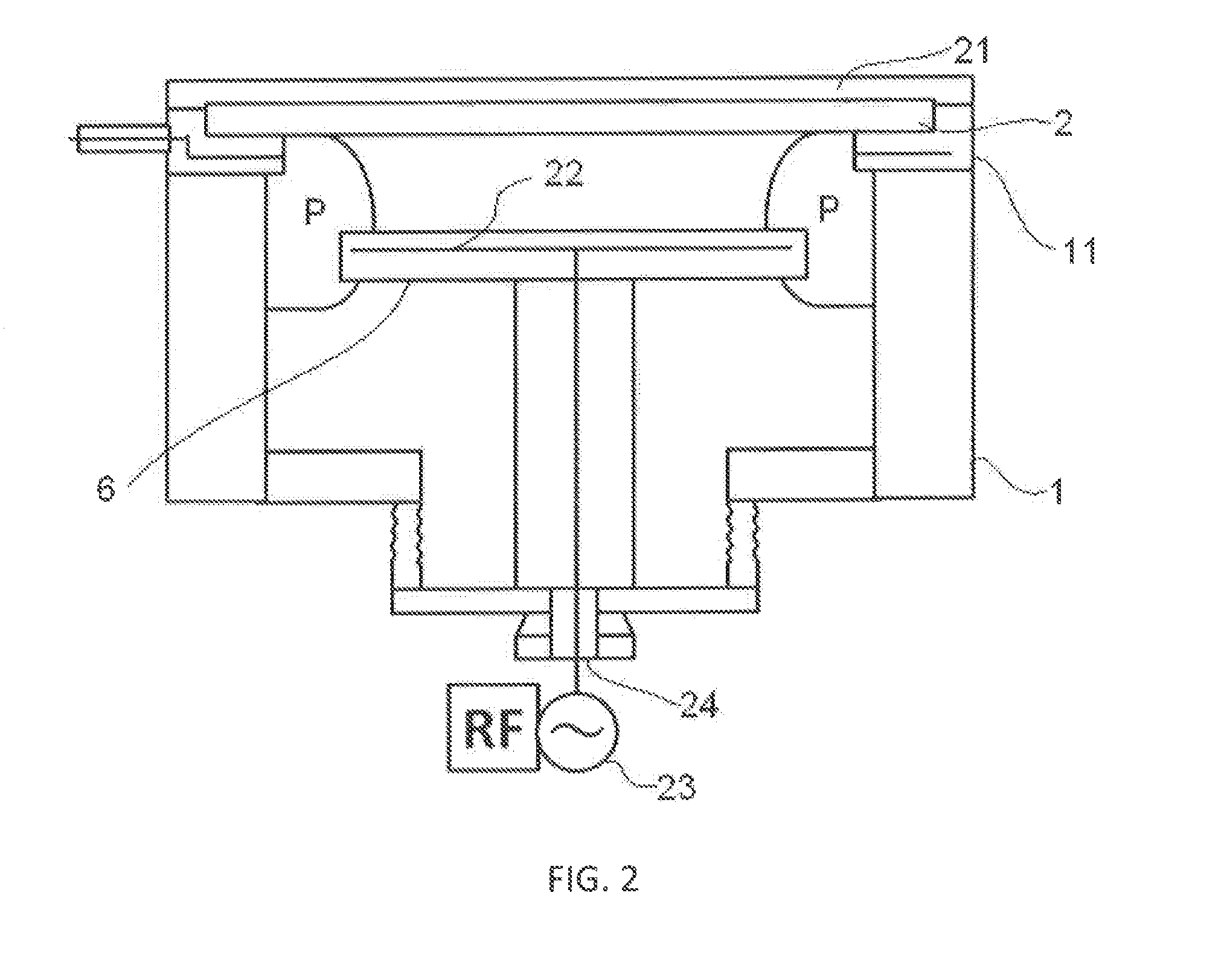

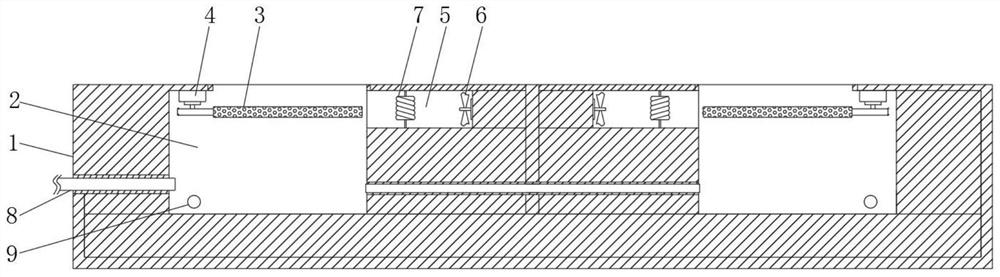

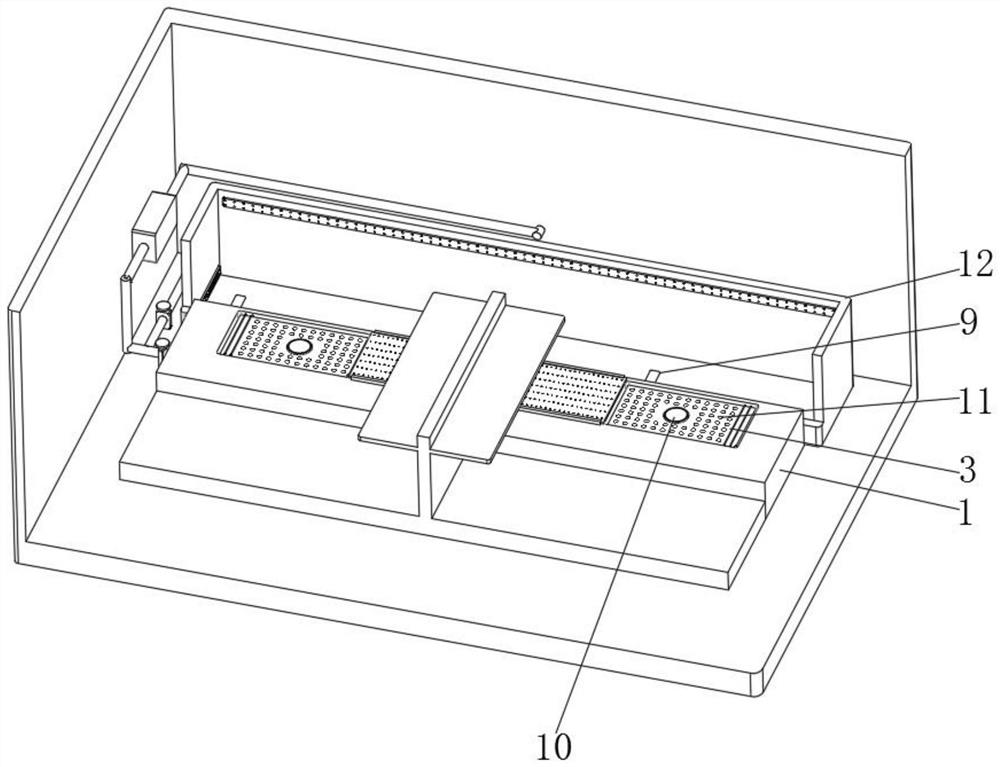

UV Irradiation Apparatus with Cleaning Mechanism and Method for Cleaning UV Irradiation Apparatus

InactiveUS20140116335A1Efficient implementationEfficient cleaning methodLiquid surface applicatorsElectric discharge tubesUltravioletEngineering

A UV irradiation apparatus for processing a semiconductor substrate includes: a UV lamp unit; a reaction chamber disposed under the UV lamp unit; a gas ring with nozzles serving as a first electrode between the UV lamp unit and the reaction chamber; a transmission window supported by the gas ring; an RF shield which covers a surface of the transmission window facing the UV lamp unit; a second electrode disposed in the reaction chamber for generating a plasma between the first and second electrodes; and an RF power source for supplying RF power to one of the first or second electrode.

Owner:ASM IP HLDG BV

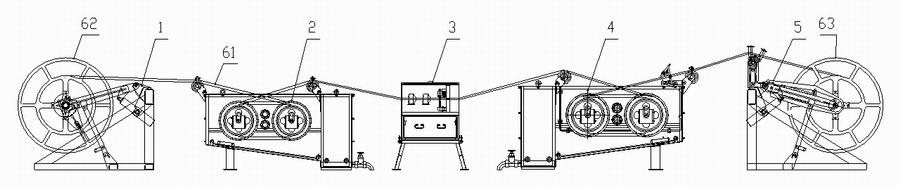

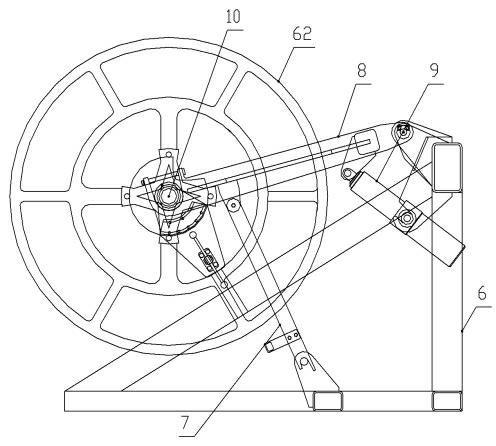

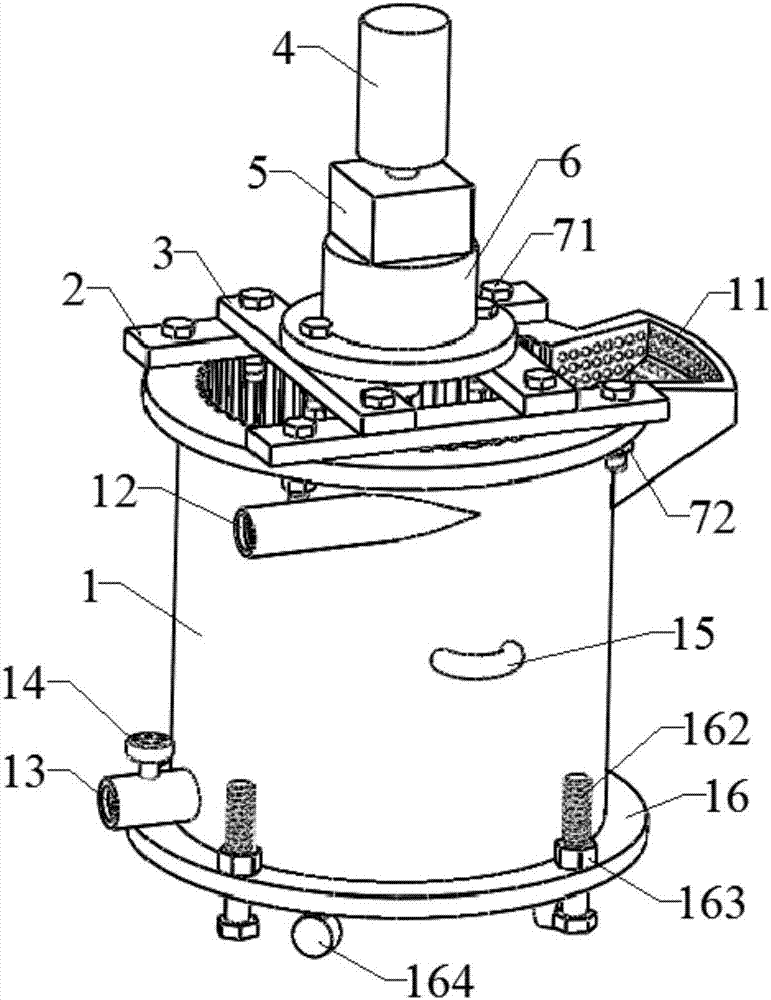

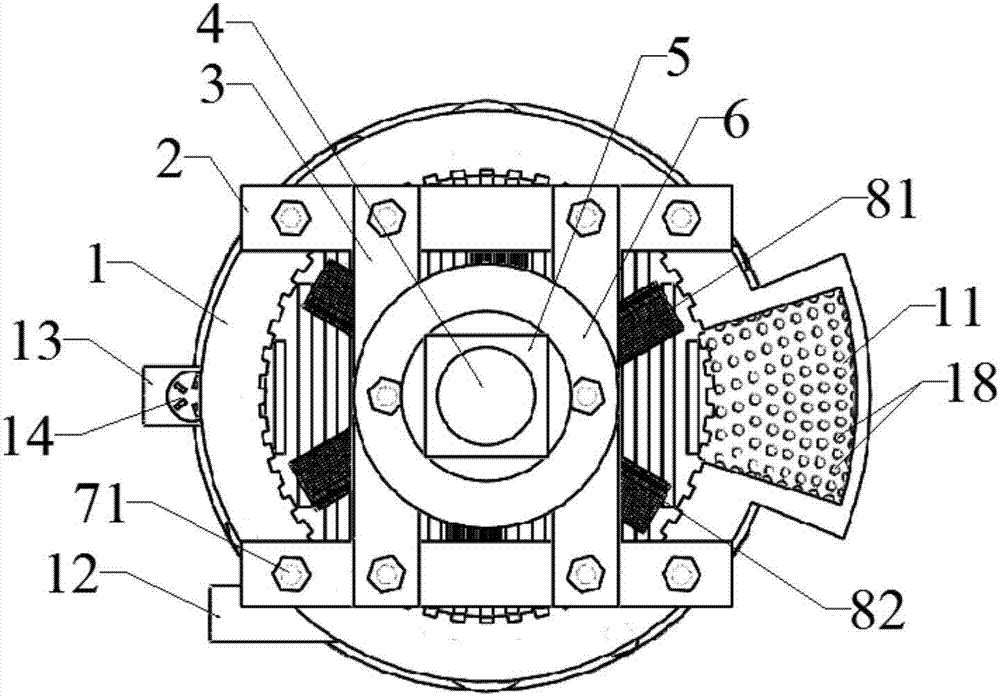

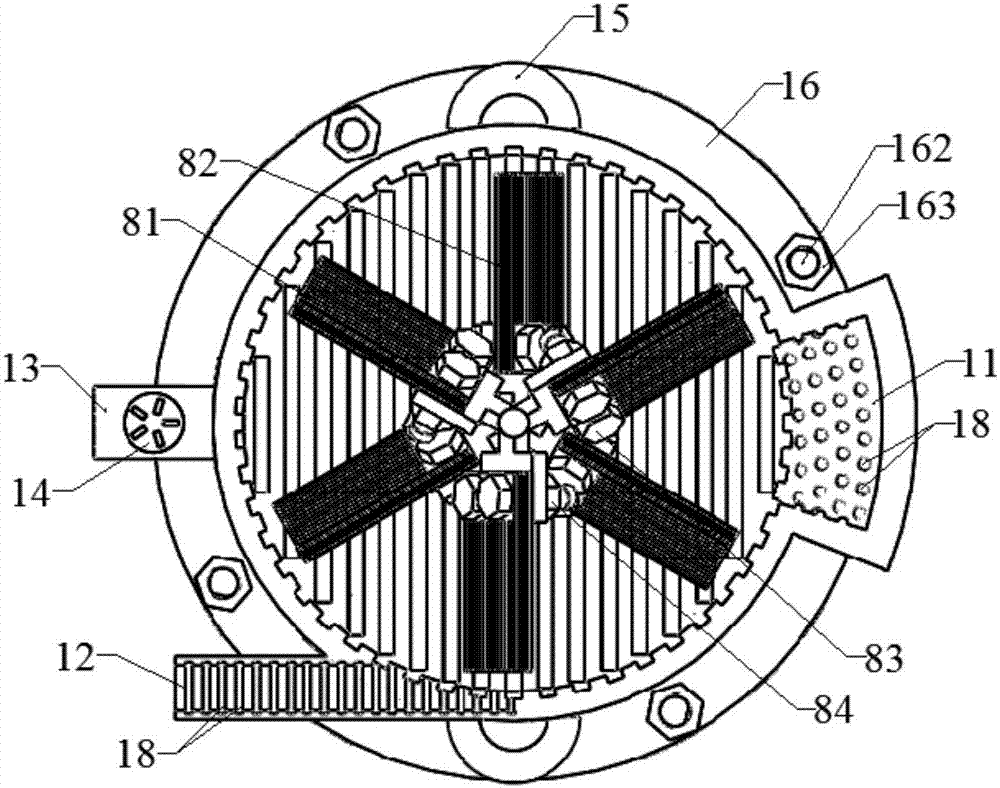

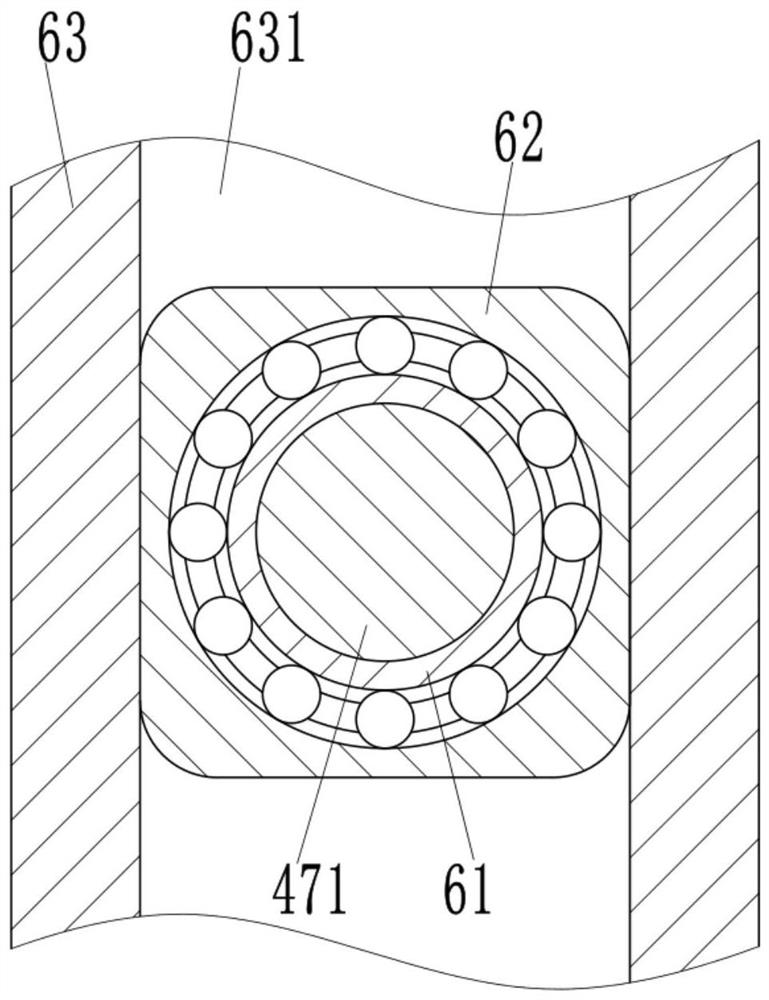

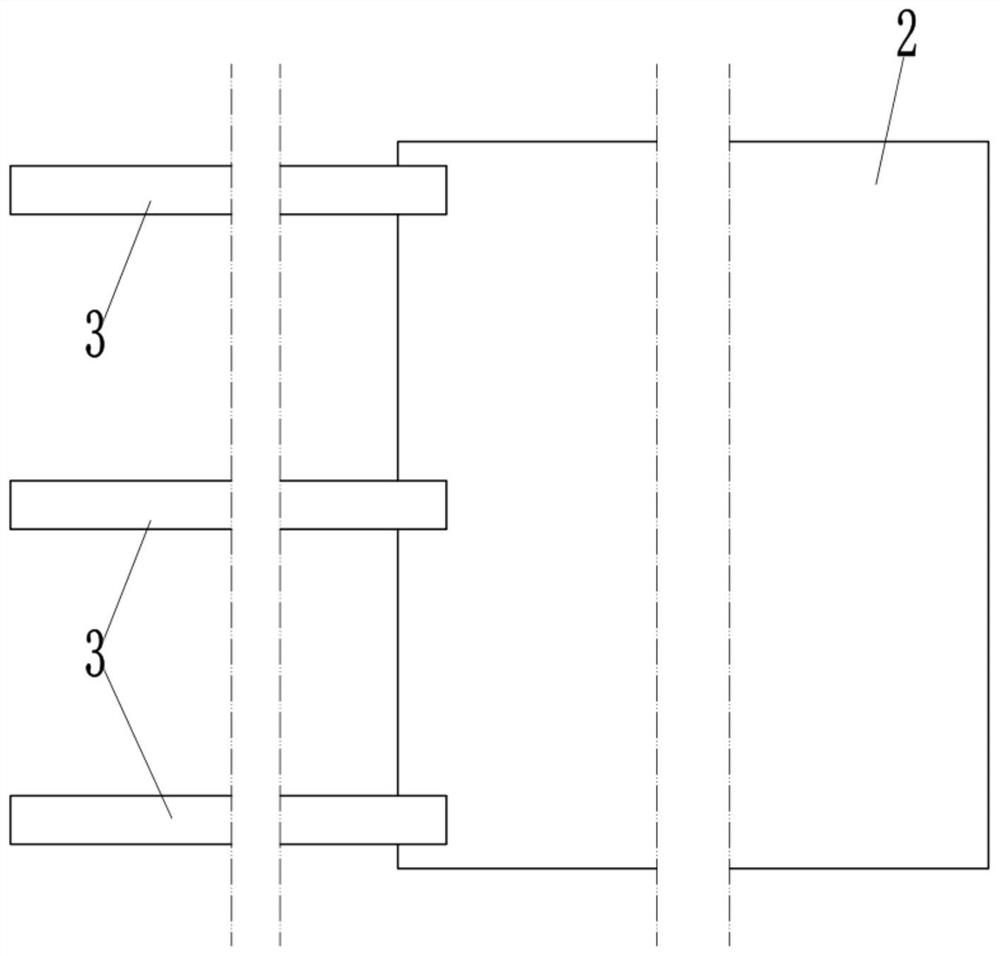

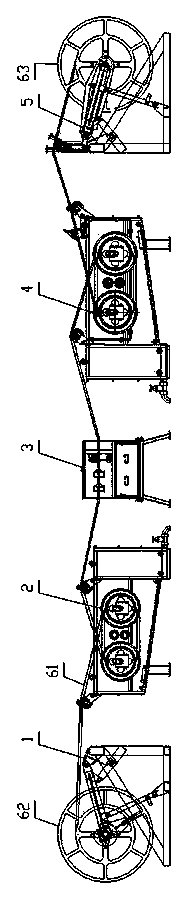

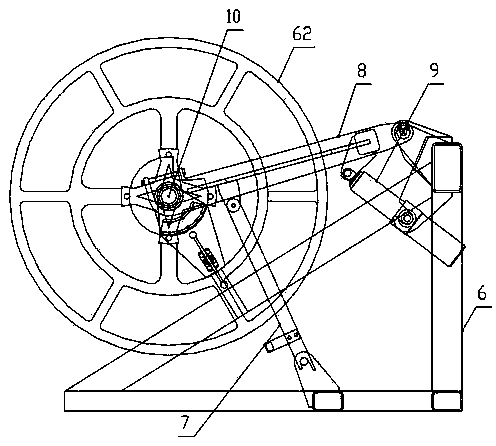

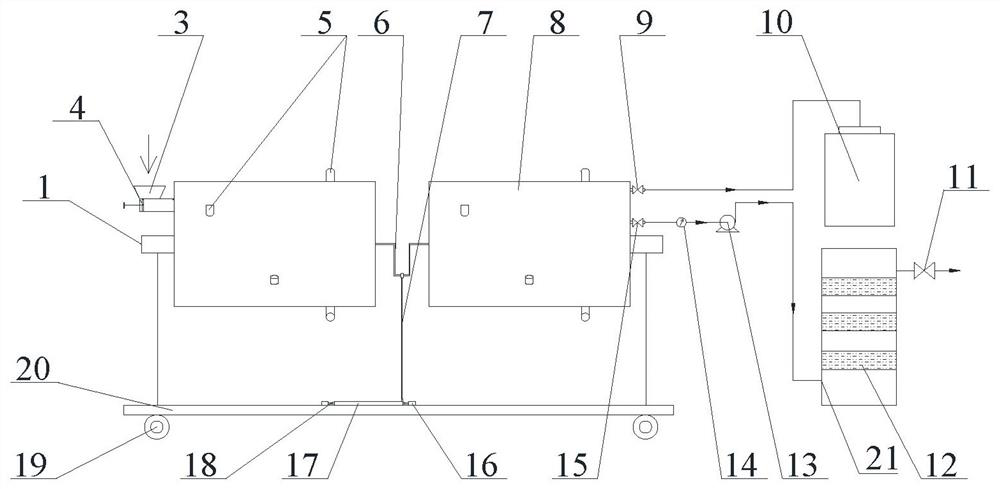

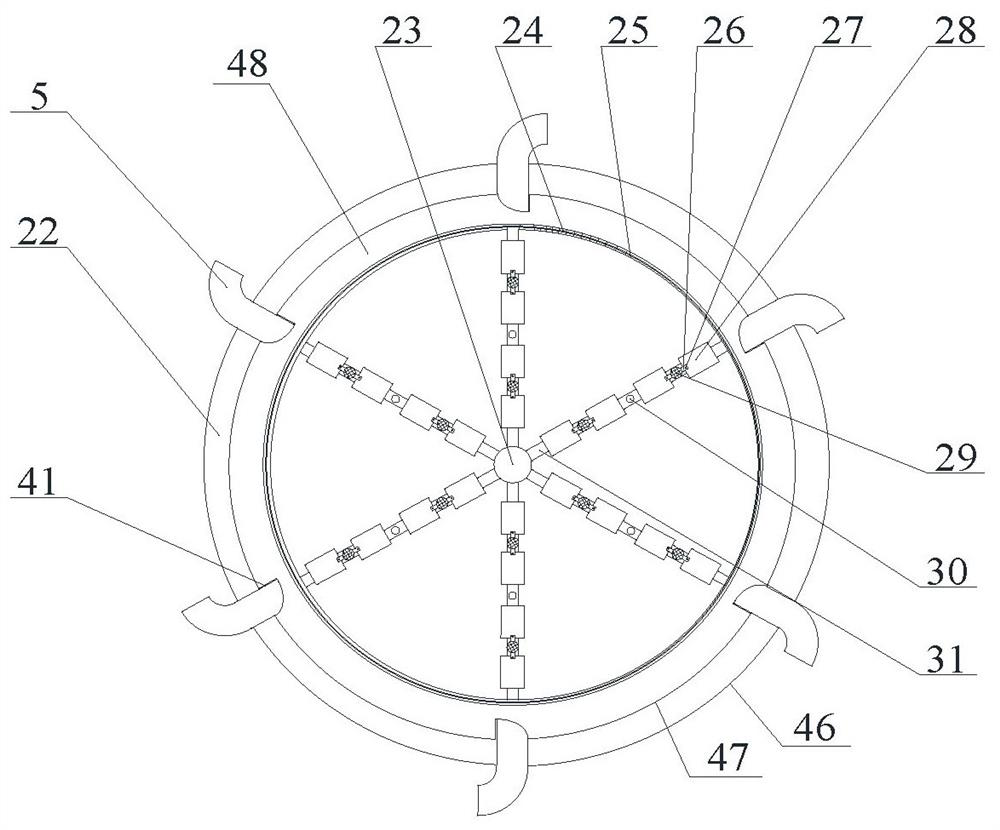

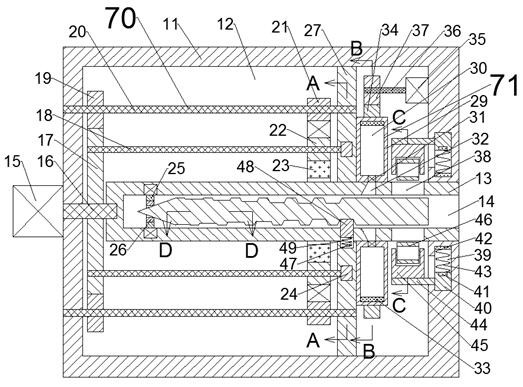

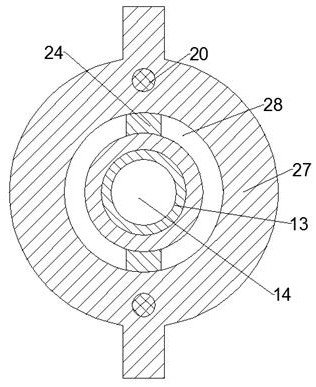

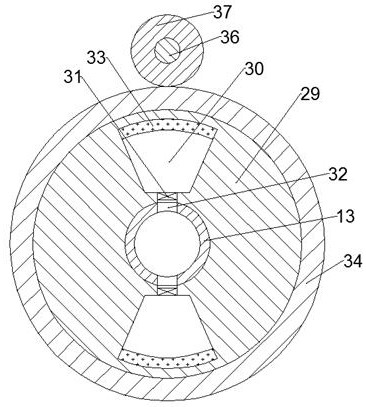

Environment-friendly cleaning and maintenance machine for steel wire rope

ActiveCN102247961AHeight adjustableSatisfy the requirements of pay-offCleaning processes and apparatusEngineeringUltimate tensile strength

The invention discloses an environment-friendly cleaning and maintenance machine for a steel wire rope. The machine comprises a wire pay-off mechanism, a cleaning mechanism, a dirt-removing mechanism, a maintenance mechanism and a wire take-up mechanism, which are arranged in sequence, wherein the steel wire rope is cleaned and maintained by the wire pay-off mechanism, the cleaning mechanism, the dirt-removing mechanism, the maintenance mechanism and the wire take-up mechanism in sequence. By the adoption of the cleaning and maintenance machine disclosed by the invention, the problems of massive dirt accumulation, rust formation and damage happening during the use process of different types of steel wire ropes for constructions can be effectively avoided; and accidents of personal injury, traffic interruption and power failure, which are caused by the breakage of steel wire ropes during the construction process, can be effectively prevented by periodically cleaning and greasing steel wire ropes with the cleaning and maintenance machine every year. The cleaning and maintenance machine disclosed by the invention can be used for cleaning different types of steel wire ropes in a simple and highly-efficient method, has stable performances and good cleaning and maintenance effects. The cleaning and maintenance machine is easy to operate during the use process and has the beneficial effects of reducing the labor intensity, increasing the work efficiency, ensuring the service safety against twisting of steel wire ropes, prolonging the service life and the operating reliability of steel wire ropes and providing powerful guarantee for safety production.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

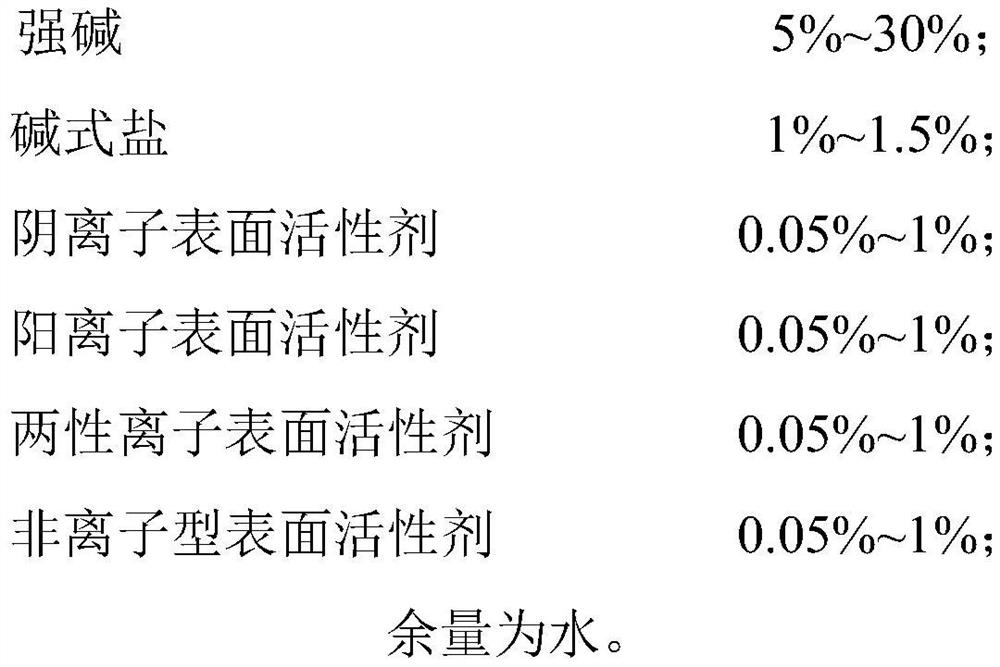

Tasteless double-functional material for cleaning and lubricating semiconductor packaging mold

ActiveCN102786725ARealize the moistening effectIncrease productivitySemiconductor packageCleansing Agents

The invention discloses a tasteless double-functional material for cleaning and lubricating a semiconductor packaging mold. The double-functional material is prepared from the following raw materials in parts by mass: 100 parts of unvulcanized rubber, 0.1 to 50 parts of cleaning agent, 0.1 to 10 parts of mold-cleaning auxiliary agent, 0.1 to 10 parts of mold-lubricating agent, 0.1 to 10 parts of curing agent and 5 to 100 parts of filling agent. The tasteless double-functional material for cleaning and lubricating the semiconductor packaging mold is harmless and environment-friendly, and can stick a pollutant on the surface of the mold and absorb the pollutant onto the surface of curing rubber. Meanwhile, a mold-lubricating effect is achieved, the production efficiency is improved, the time is saved, and the cost is reduced. The tasteless double-functional material is used without being pre-heated, and a cleaning method is simple and high in efficiency.

Owner:TECORE SYNCHEM

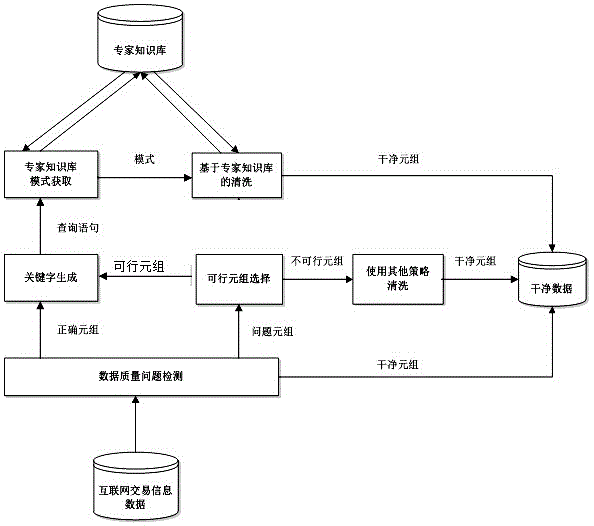

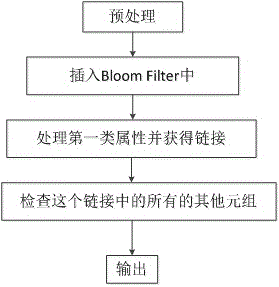

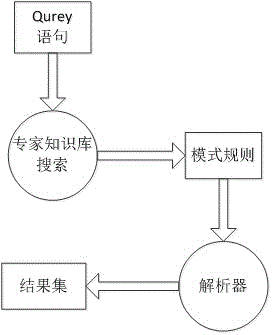

Data cleaning algorithm based on Internet trading information

InactiveCN105045807AEfficient cleaning methodSafe cleaning methodSpecial data processing applicationsNetwork methodData cleansing

The invention provides a method for cleaning data based on different data resources, i.e., different Internet trading platforms. According to the method, firstly, tuples in a database are classified; correctness-confirmed tuple data in the tuples are subjected to mode interaction with an expert knowledge base; fuzzy matching based on retrieval contents of the knowledge base is used as a tool to obtain corresponding mode knowledge; then, the found mode knowledge is used for cleaning applicable data with quality problems. Meanwhile, a proper efficient detection scheme is also provided for quality errors of different types of mass data. A BP (Back Propagation) neural network method is adopted for realizing the self-learning expert knowledge base, thereby providing an efficient and safe cleaning mode for the Internet trading information data cleaning.

Owner:ZHEJIANG LISHI TECH

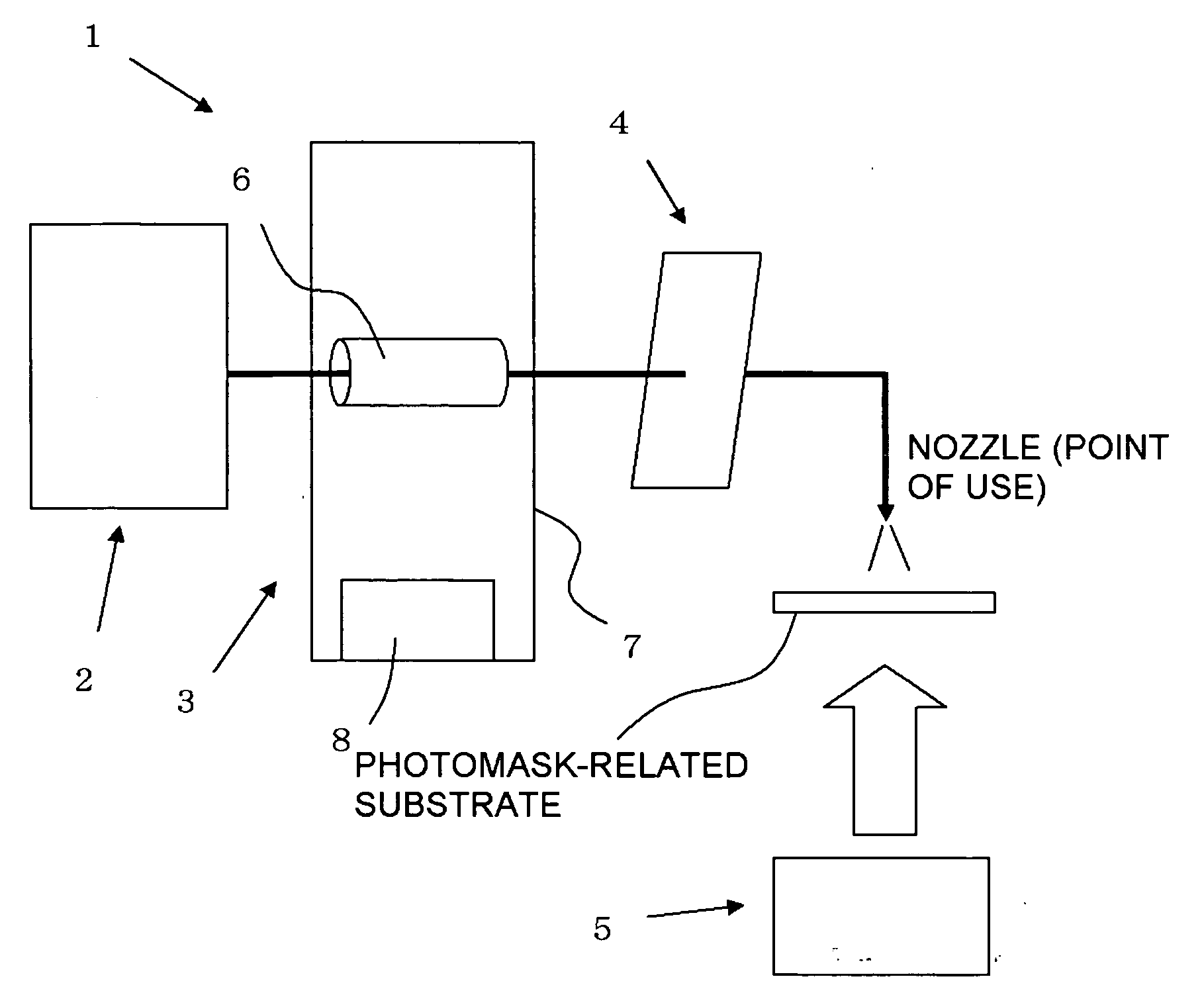

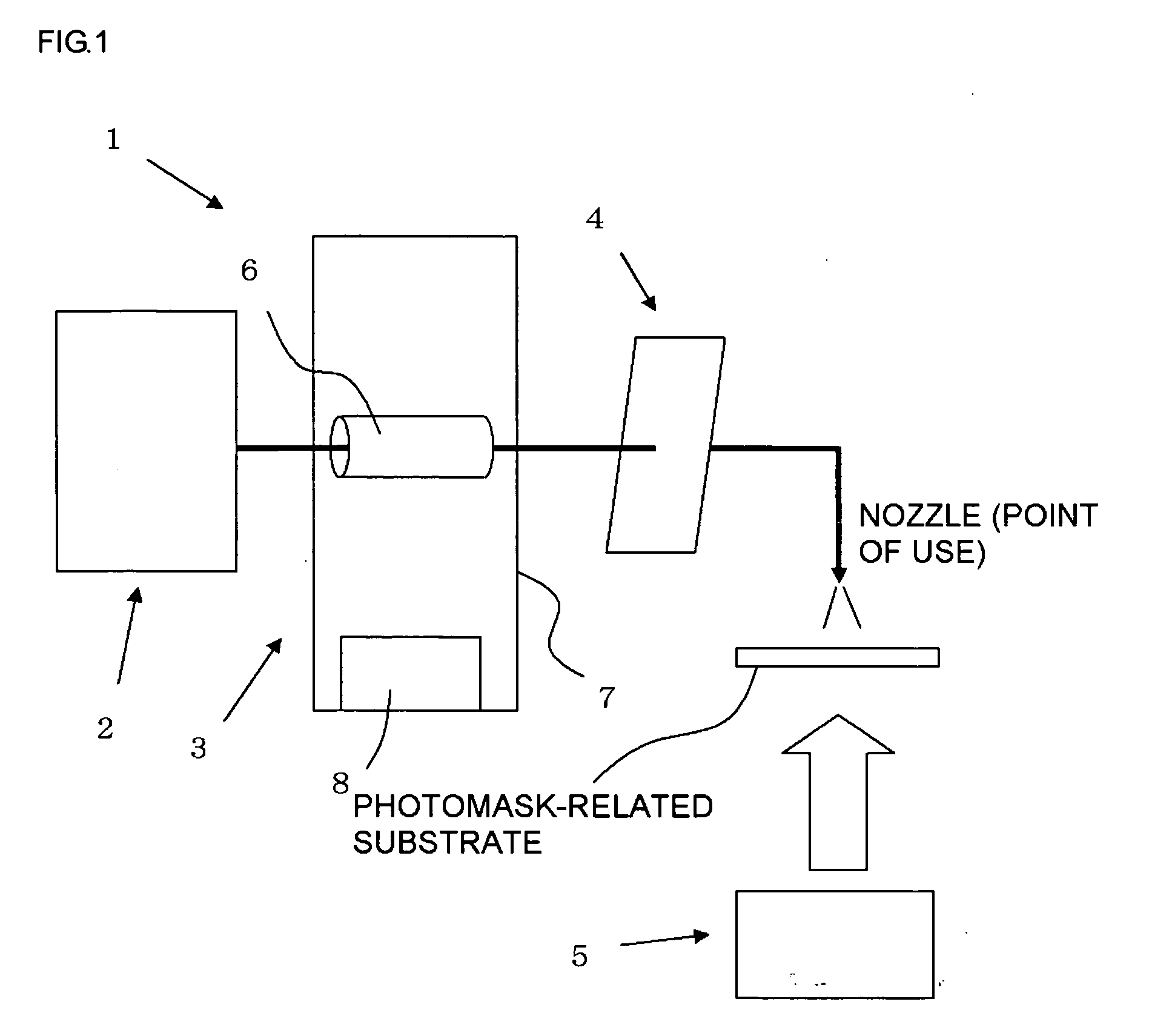

Method for cleaning photomask-related substrate, cleaning method, and cleaning fluid supplying apparatus

ActiveUS20100083985A1Cleaning inexpensively and effectivelyEfficient removalOriginals for photomechanical treatmentCleaning using liquidsForeign matterWater use

Provided is a method for cleaning a photomask-related substrate, the method in which, when a photomask-related substrate contaminated by a sulfate ion, the photomask-related substrate being selected from a substrate for a photomask, a photomask blank, a photomask, and a production intermediate thereof, is cleaned with pure water, a deaerating step of removing dissolved gas by deaeration is performed in advance on the pure water used for cleaning. Moreover, provided is a method for cleaning a substrate to be cleaned by supplying a cleaning fluid to a cleaning apparatus, the method in which, when the substrate to be cleaned is cleaned by filtering the cleaning fluid with a filter for removing foreign matter and supplying the filtered cleaning fluid to the cleaning apparatus through a supply pipe, at least, prior to a supply of the filtered cleaning fluid to the cleaning apparatus, the filtered cleaning fluid is discharged to the outside of a system through a discharge pipe, and then the filtered cleaning fluid is supplied to the cleaning apparatus through the supply pipe. As a result, provided is a cleaning method that can increase cleaning efficiency for a sulfate ion in a simple and easy way and can reduce the generation of minute foreign matter extremely when, in particular, a photomask-related substrate selected from a substrate for a photomask, a photomask blank, a photomask, and a production intermediate thereof is cleaned.

Owner:SHIN ETSU CHEM IND CO LTD

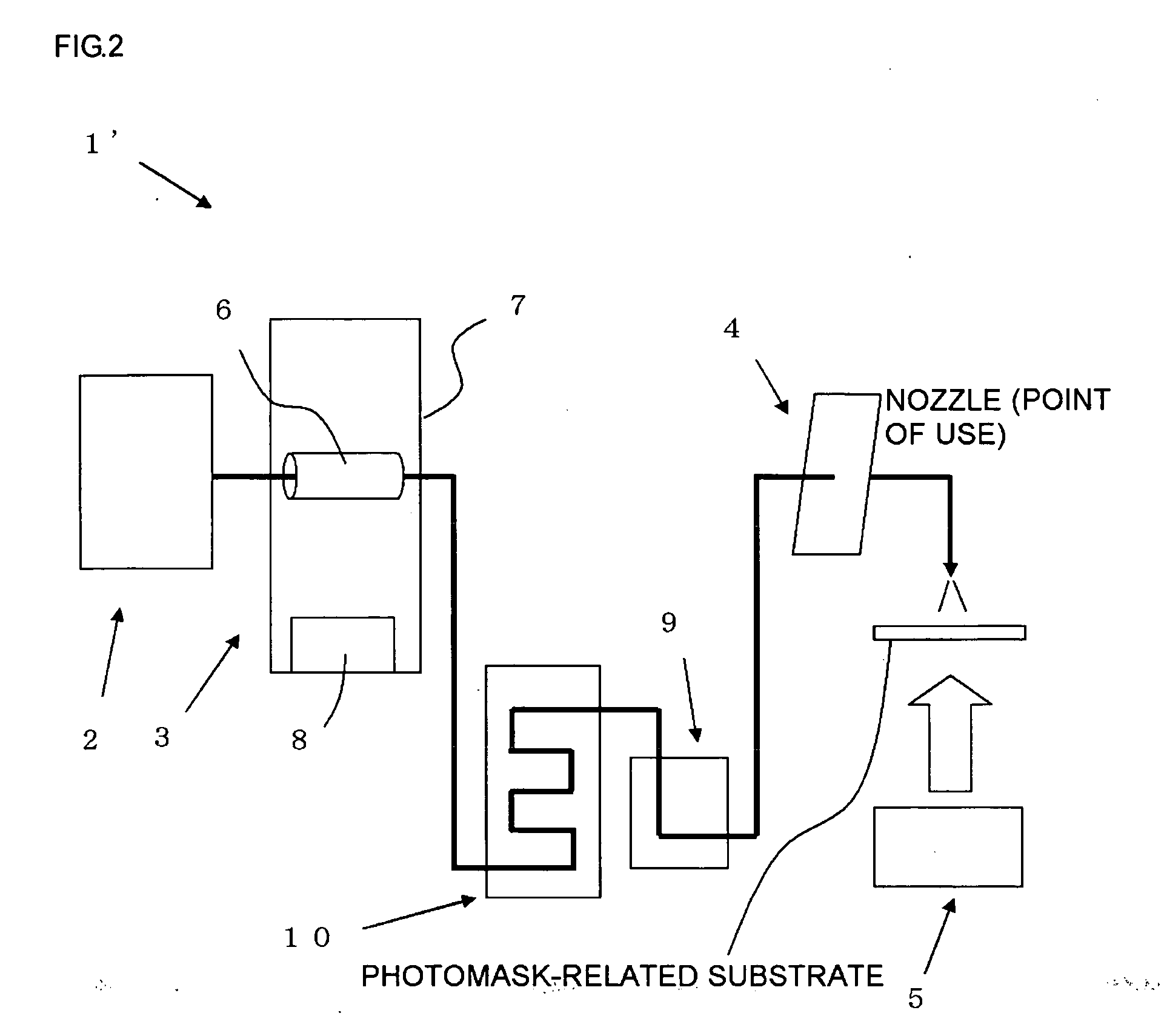

Nondestructive cleaning method for laser gyroscope cavity after optical machining

ActiveCN109622503AEliminate static electricityEfficient removalCleaning using liquidsWater basedGyroscope

The invention discloses a nondestructive cleaning method for a laser gyroscope cavity after optical machining. Through pretreatment and the cleaning mode of combination of sequential soaking in organic liquid I and organic liquid II and ultrasonic cleaning, rosin cerate and protective paint on the cavity surface and in holes are effectively removed; after rinsing, water-based liquid I is used fordecomposing residual organic pollutants into small molecules which are easy to remove, meanwhile, residual polishing powder is dissolved into soluble metal complexing ions; then, water-based liquid IIis utilized to oxidize other metal particles into ions, and the ions are dissolved into a liquid to be removed; and finally, through anhydrous ethanol dehydration and the mode of cooperation of high-purity nitrogen and ion air gun dry-blowing, static electricity on the surface of the cavity is eliminated, thus re-adsorption of the pollutants is avoided, and high-cleanliness cleaning of the cavityafter optical machining is achieved. According to the nondestructive cleaning method, no strong acid or strong alkali is adopted, the roughness and finish degree of the cleaned optical surface are not changed, the high-airtightness adjustment requirement for the laser gyroscope resonant cavity can be met, and the cavity is cleaned nondestructively.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

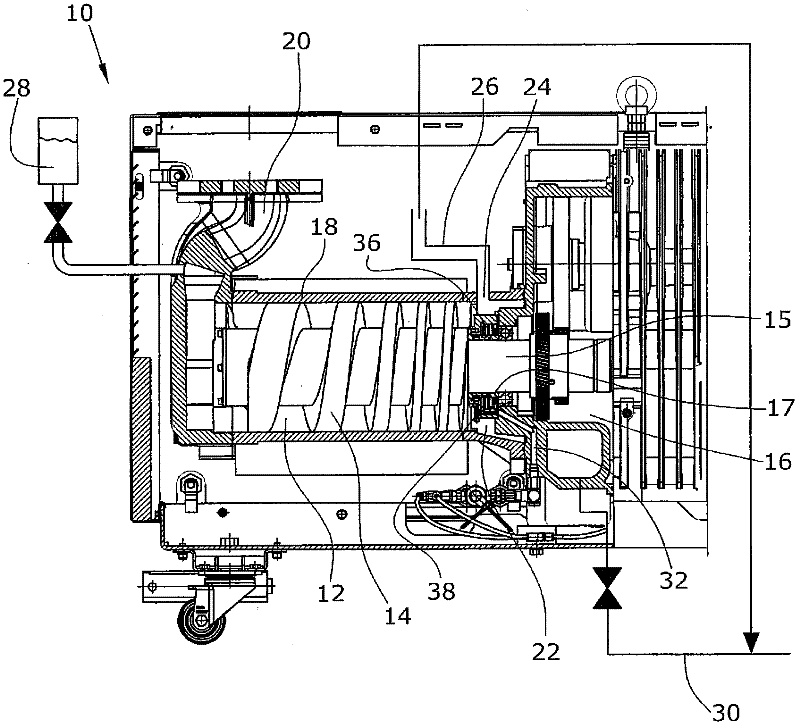

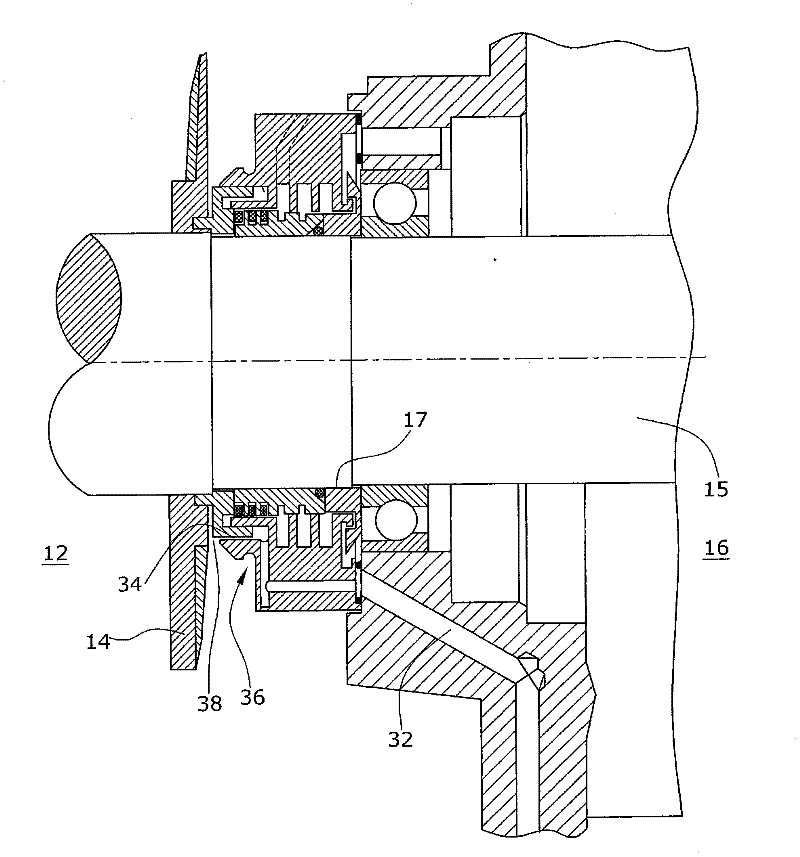

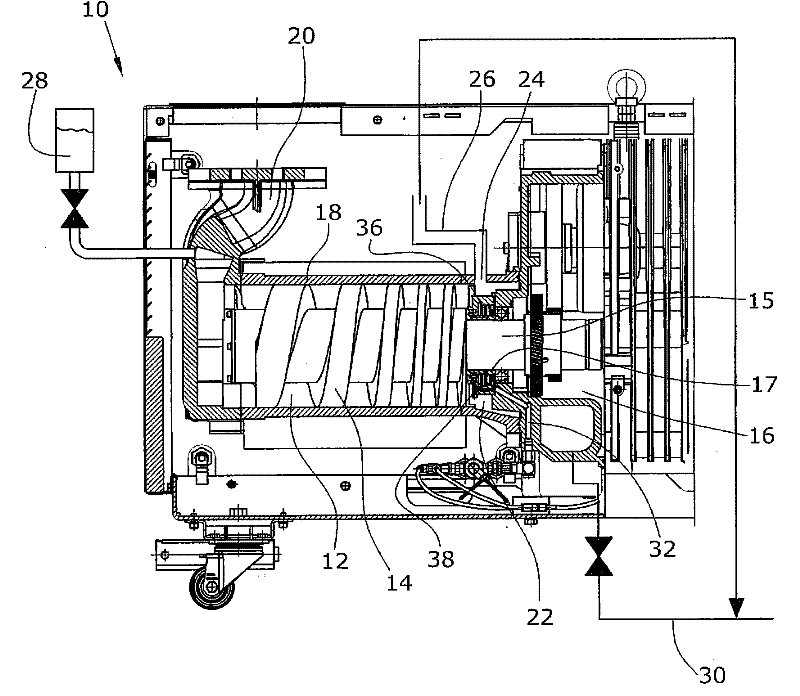

Method for cleaning a vacuum pump

InactiveCN102202805AAvoid damageIncreased available useful timeHollow article cleaningCorrosion preventionVacuum pumpImpurity

The invention relates to an effective method for cleaning a vacuum pump (10) comprising a pump chamber (12) with at least one pump rotor (14), characterized by the steps of: a) filling the pump chamber (12) with a cleaning fluid (28), b) distributing the cleaning fluid (28) in the pump chamber (12), c) dissolving impurities using the cleaning fluid (28) and d) draining the cleaning fluid (28) from the pump chamber (12).

Owner:OERLIKON LEYBOLD VACUUM +1

Method for cleaning glass element

ActiveCN111804664AEfficient removalNo damageInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsComposite materialCeramic materials

The invention relates to a method for cleaning a glass element. The preparation method includes the steps that a polished glass element is firstly placed in an acid cleaning fluid for the first ultrasonic processing and the second ultrasonic processing in turn; then the glass element is placed in an alkaline cleaning fluid for the third ultrasonic processing, and finally a cleaned glass element isobtained through water-washing and drying; and the frequency of the first ultrasonic processing is 10 KHz-30 KHz, and the frequency of the second ultrasonic processing is 40 KHz-70 KHz. The method for cleaning the glass element can effectively improve the efficiency of cleaning the glass element and has no damage to the glass element.

Owner:万津实业(赤壁)有限公司

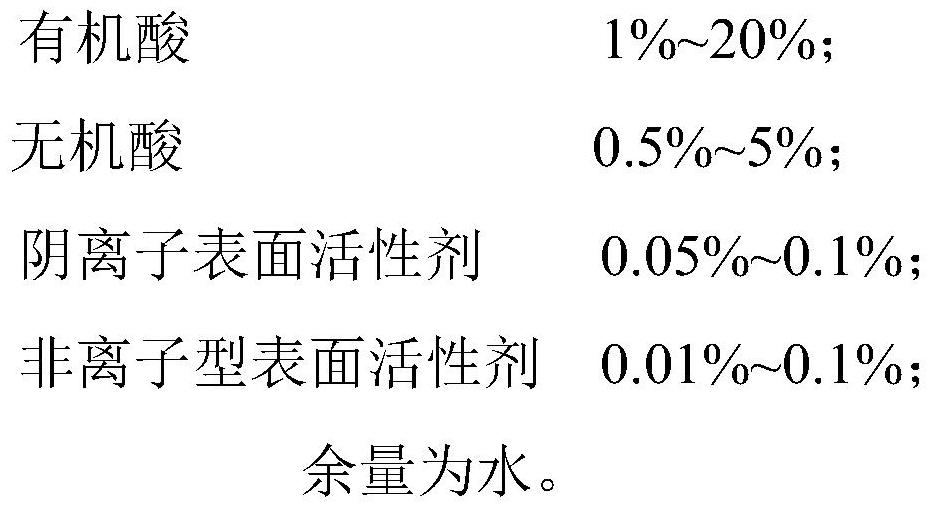

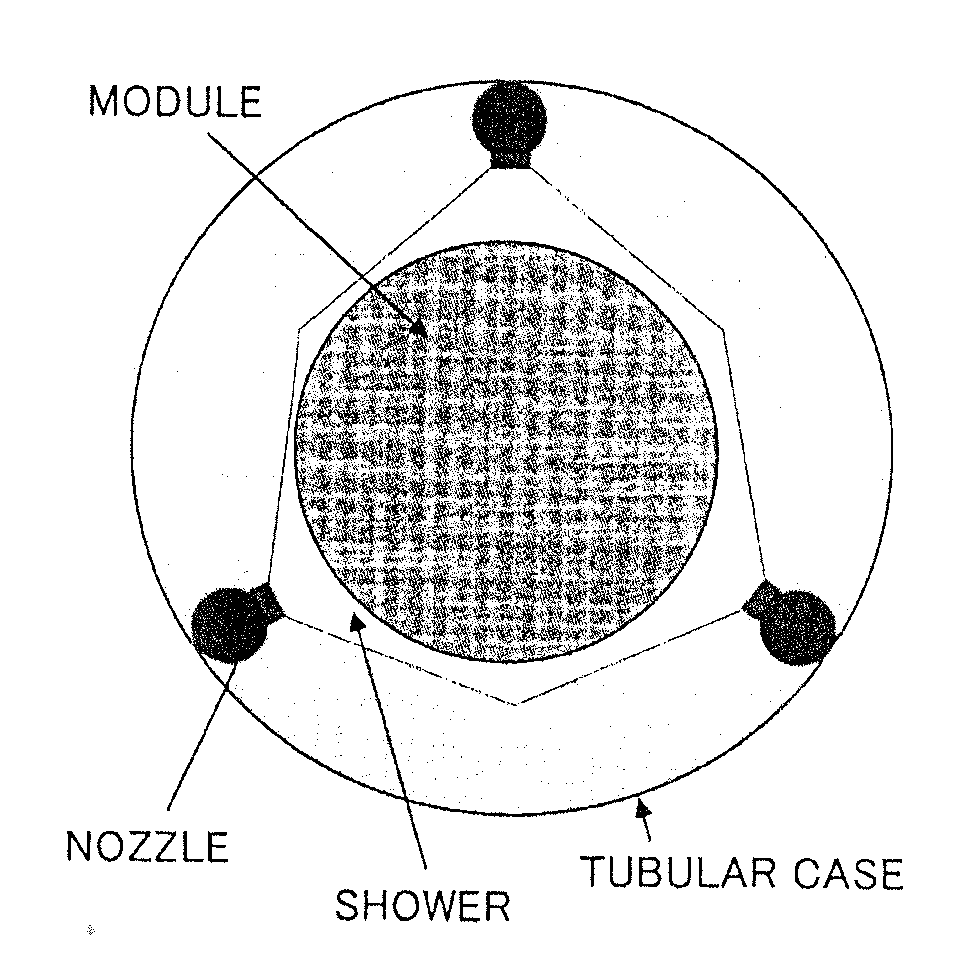

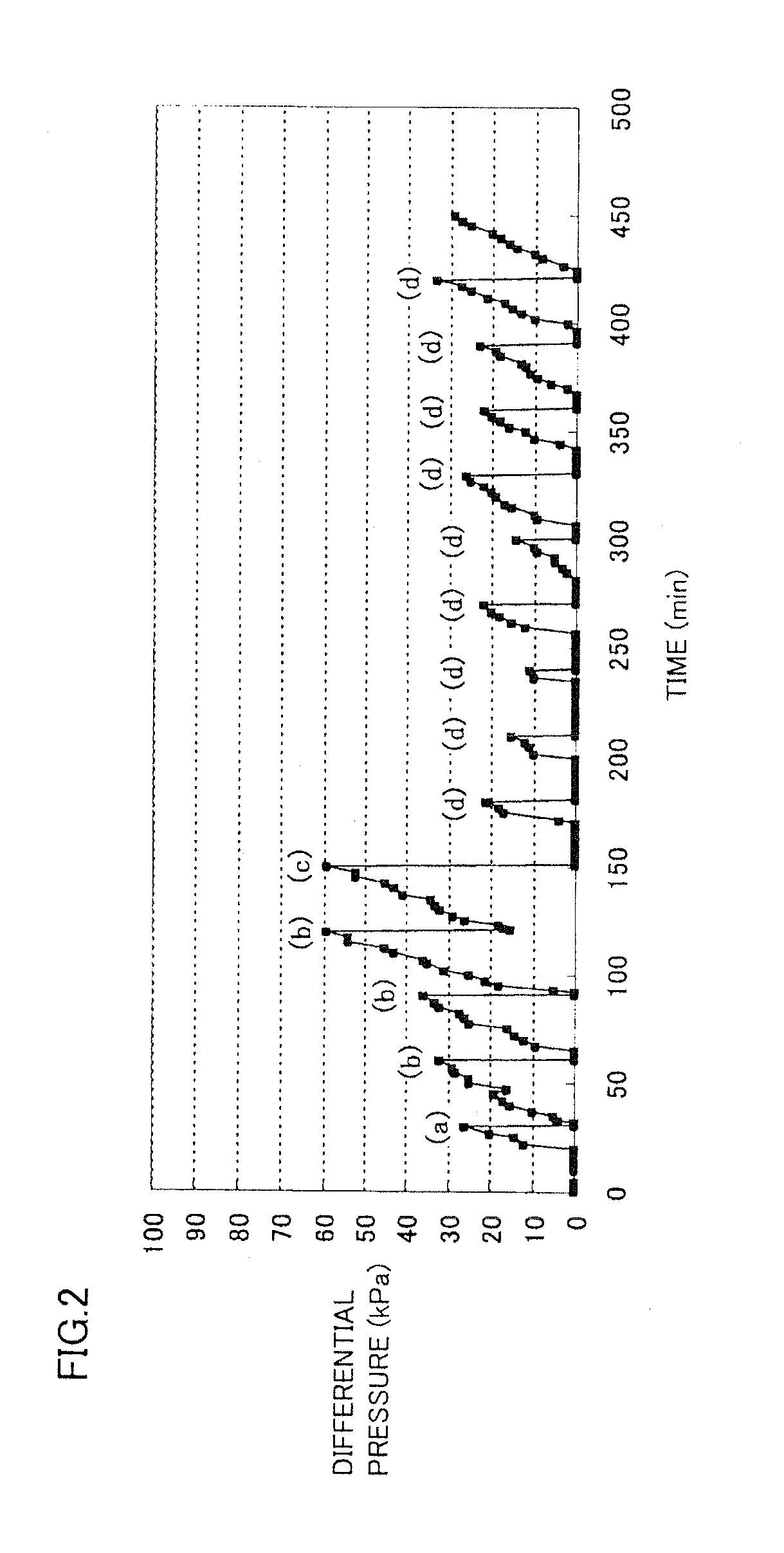

Cleaning method for filtration membrane and membrane filtration apparatus

InactiveUS20120074059A1Excellent in recovery of filtration capabilityAvoid quality lossMembranesSemi-permeable membranesFiltration membraneWater flow

There is provided a cleaning method for a hydrophobic filtration membrane used for membrane filtration of water to be treated such as seawater, discharged water and ballast water including a jelly-like suspended substance and clogged with the suspended substance in the water to be treated, the filtration membrane being brought into contact with limonene-containing water, or backwashing of the filtration membrane with a cleaning liquid being done, and then, a flow having air taken therein being applied onto a surface of the filtration membrane or a water stream from an eductor nozzle being sprayed onto the filtration membrane. There is also provided a membrane filtration apparatus capable of efficiently performing the above-mentioned cleaning method.

Owner:SUMITOMO ELECTRIC IND LTD

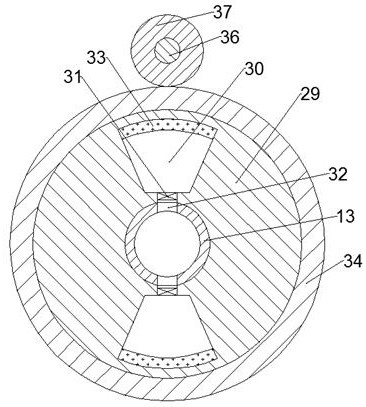

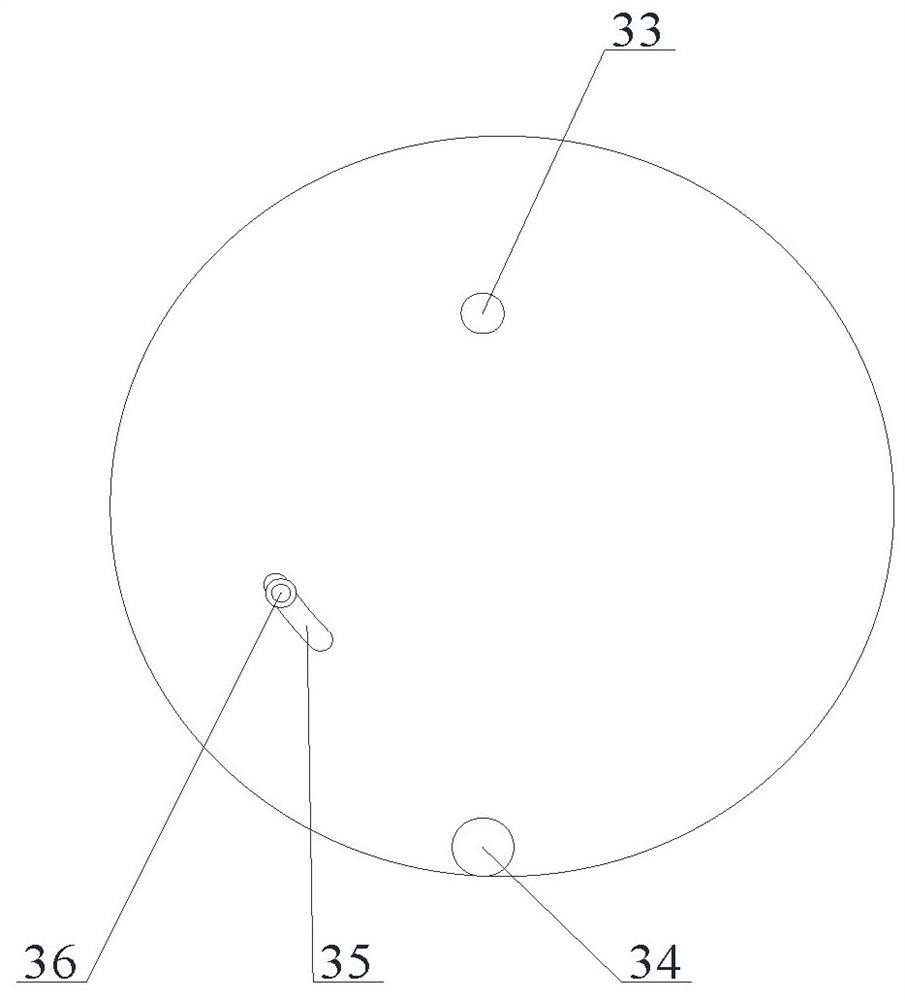

Bionic stirring machine for injection grout, hybrid power bionic stirring system and slurrying method of hybrid power bionic stirring system

ActiveCN107053468AIncrease smoothnessImprove efficiencyMixing operation control apparatusFoundation engineeringProcess engineeringSlurry

The invention discloses a bionic stirring machine for injection grout, a hybrid power bionic stirring system and a slurrying method of the hybrid power bionic stirring system. The bionic stirring machine for injection grout comprises a stirring tank with a feed inlet and a slurry discharge pipe. The bottom face of the stirring tank is an inclined face which is inclined towards the slurry discharge pipe. The upper end of the stirring tank is fixedly provided with a power portion through a supporting frame. The power output end of the power portion is connected with a stirring shaft in the stirring tank. A stirring paddle is vertically or obliquely arranged on the stirring shaft. When the stirring paddle is obliquely arranged on the stirring shaft, the inclination direction of the stirring paddle is opposite to the rotation direction of the stirring shaft. The inner surface of the stirring tank, the inner surface of the feed inlet, the inner surface of the slurry discharge pipe and the stirring paddle are each provided with a plurality of bionic non-smooth units. The superficial area of faces, making contact with the bionic non-smooth units, of the stirring tank, the feed inlet and the slurry discharge pipe is 20-50% of the superficial area of the inner surfaces of the components, and the superficial area of the faces, making contact with the stirring paddle, of all the bionic non-smooth units on the stirring paddle is 20-60% of the superficial area of all surfaces of the stirring paddle.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

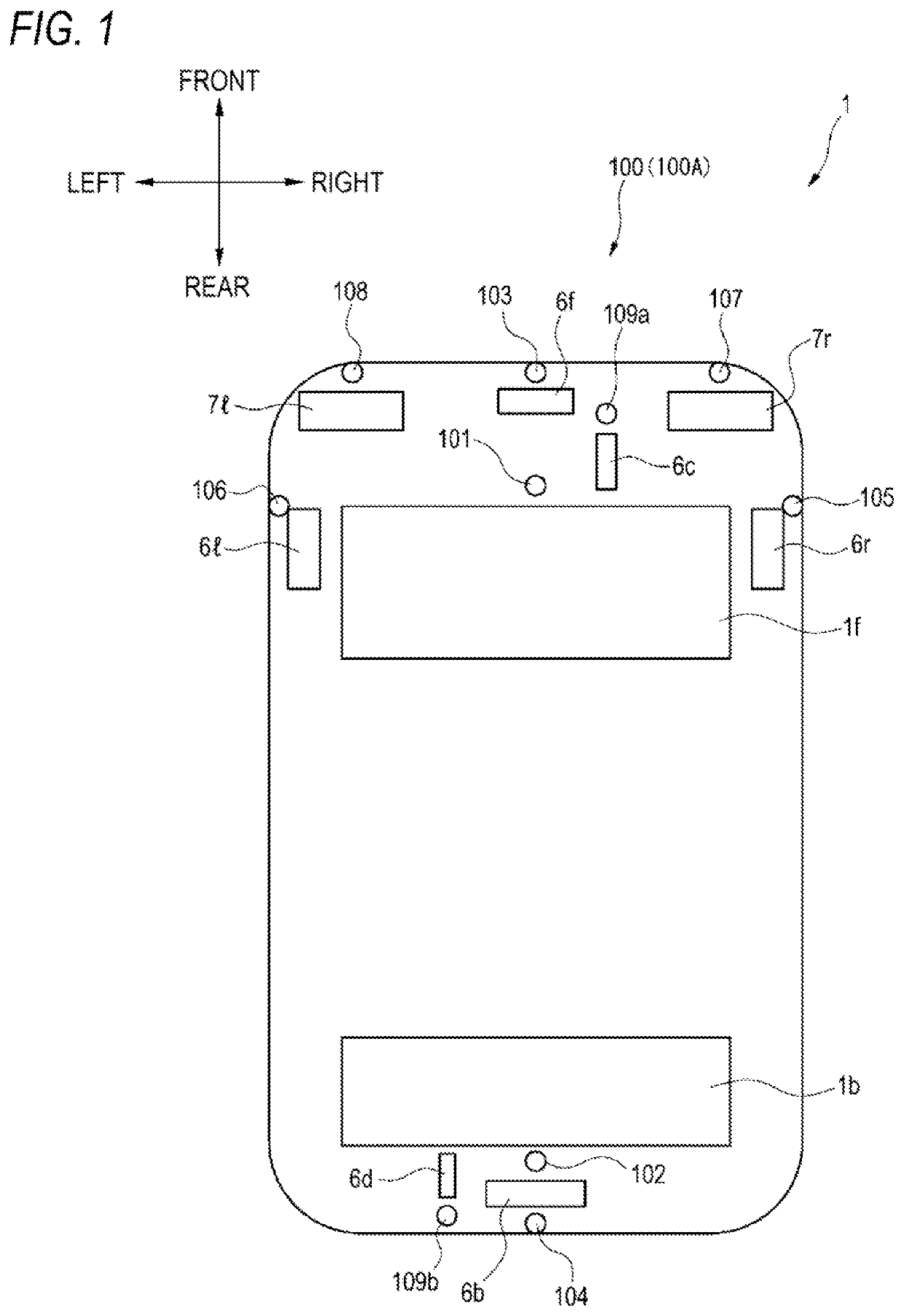

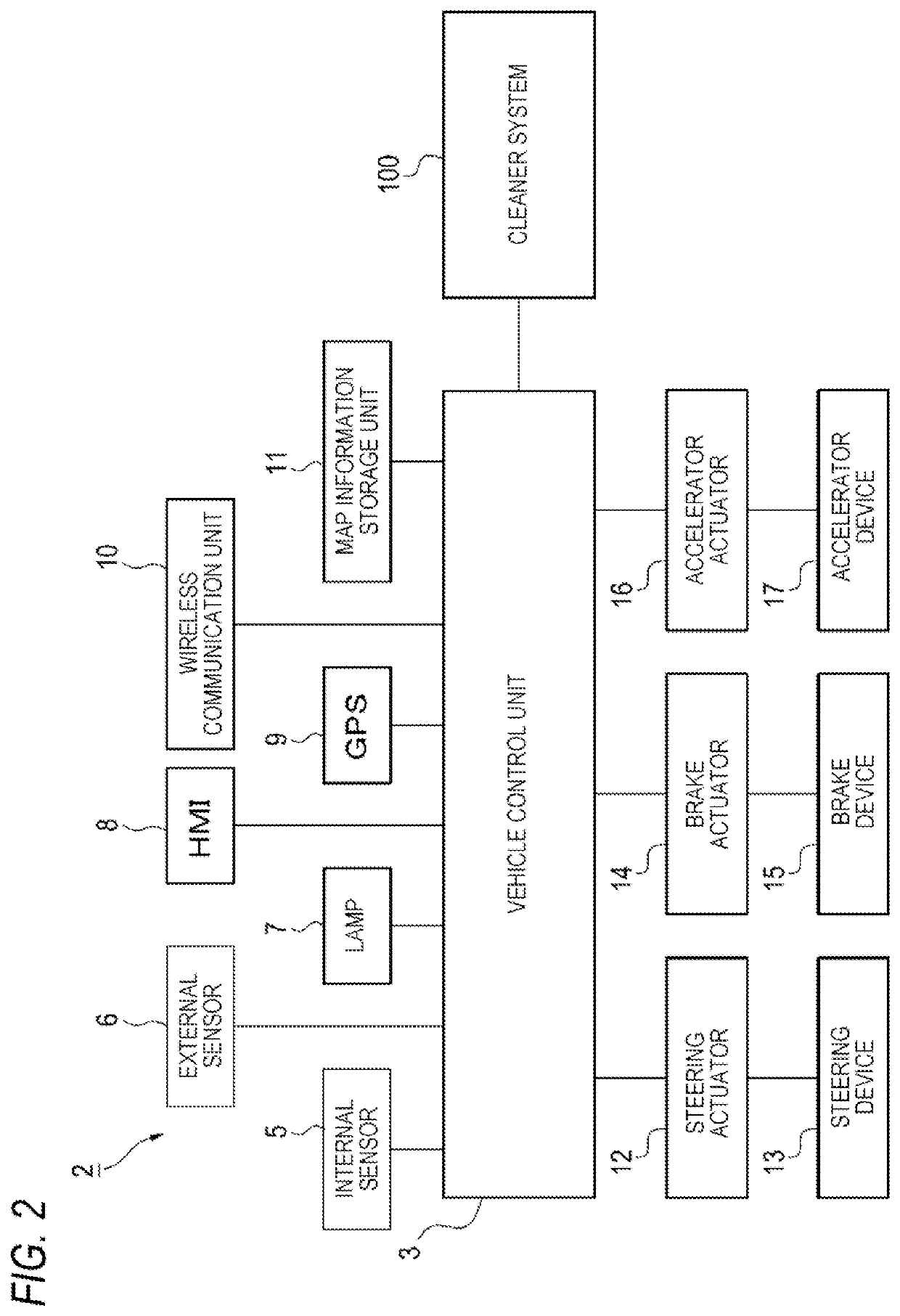

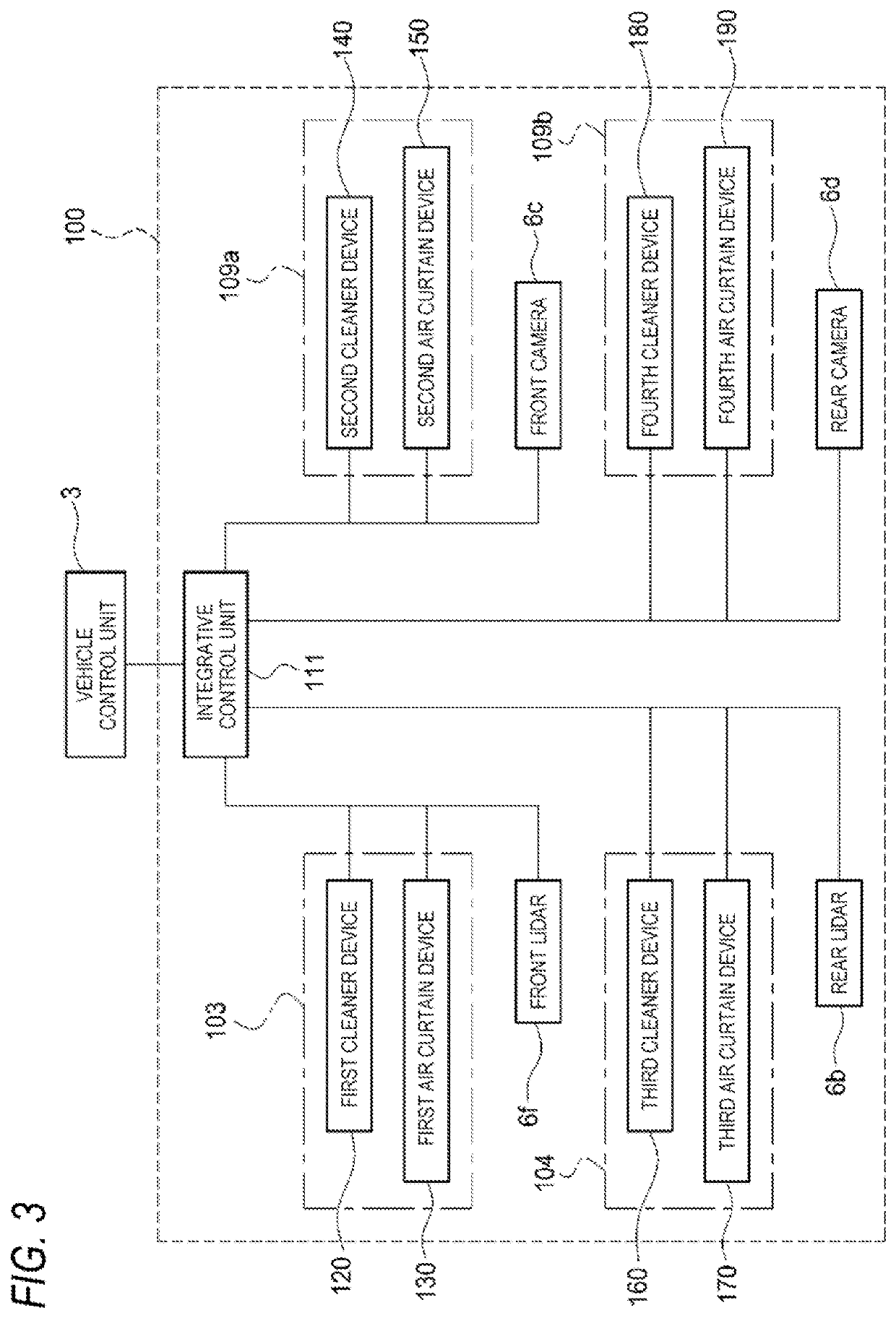

Vehicle cleaner system and sensor system with vehicle cleaner

PendingUS20220348168A1Efficient cleaning methodReduce power consumptionVehicle cleaningCleaning using gasesControl engineeringControl cell

A sensor system equipped with a vehicular cleaner comprising: a sensor configured to operate in a normal mode and a standby mode; a cleaner unit configured to clean the sensor in response to an operation signal output in accordance with a dirt determination result of the sensor; and a control unit configured to control the sensor and the cleaner unit. The sensor is configured to operate in the normal mode, in which the sensor is operated at a predetermined cycle, and in the standby mode, in which the sensor is operated at a cycle longer than in the normal mode. The cleaner unit is configured to operate in a regular mode in which the cleaner unit operates in response to the operation signal and to operate in a block mode in which the cleaner unit does not operate even when the operation signal is input.

Owner:KOITO MFG CO LTD

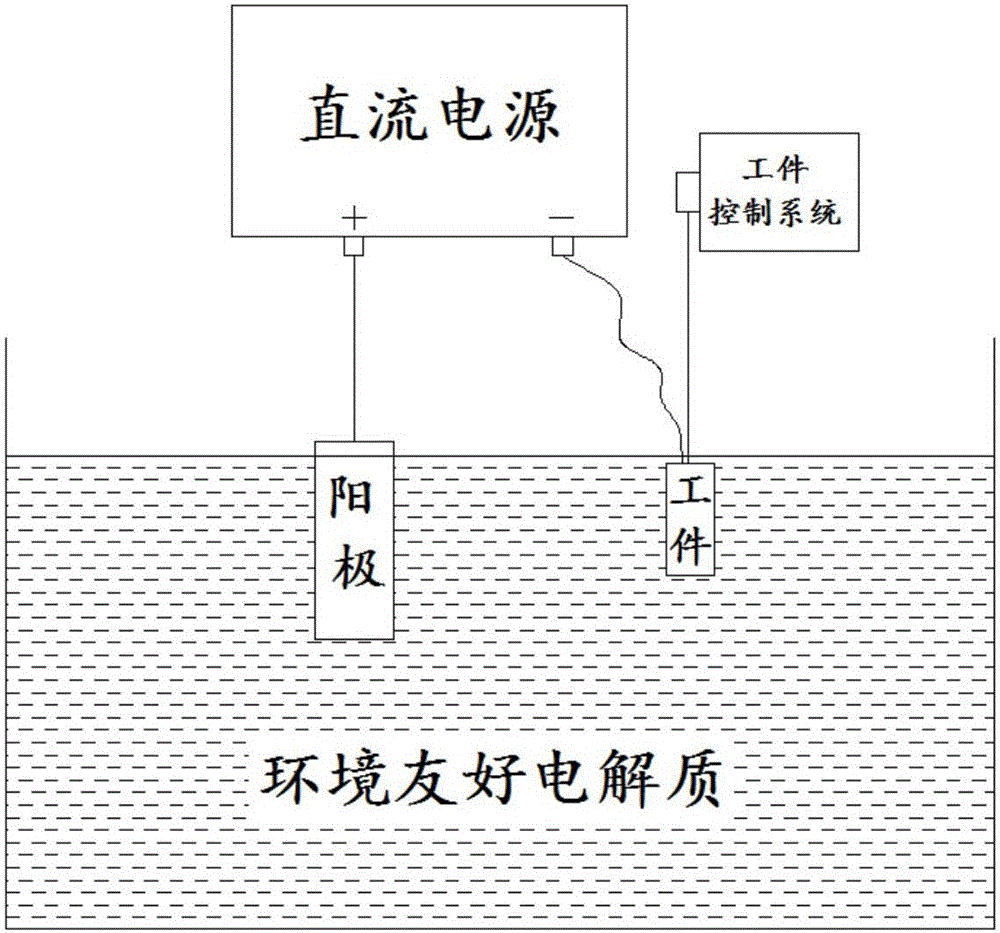

Rebar cleaning method

The invention relates to a rebar cleaning method and belongs to the field of surface cleaning and treatment for metal materials. The method comprises: using a rebar workpiece as a cathode, dipping the cathode and an anode in 5-15% by mass of carbonate or phosphate cleaning liquid, applying direct-current electric field between the two electrodes, and removing oxide scale from the surface of the workpiece. In the environment-friendly cleaning liquid, the oxide scale is removed from the surface of a rebar using electrolytic plasma technique, the process is simple, performing is easy, and the method is low in cost and low in pollution and is an efficient and environment-friendly cleaning method.

Owner:SOUTHEAST UNIV

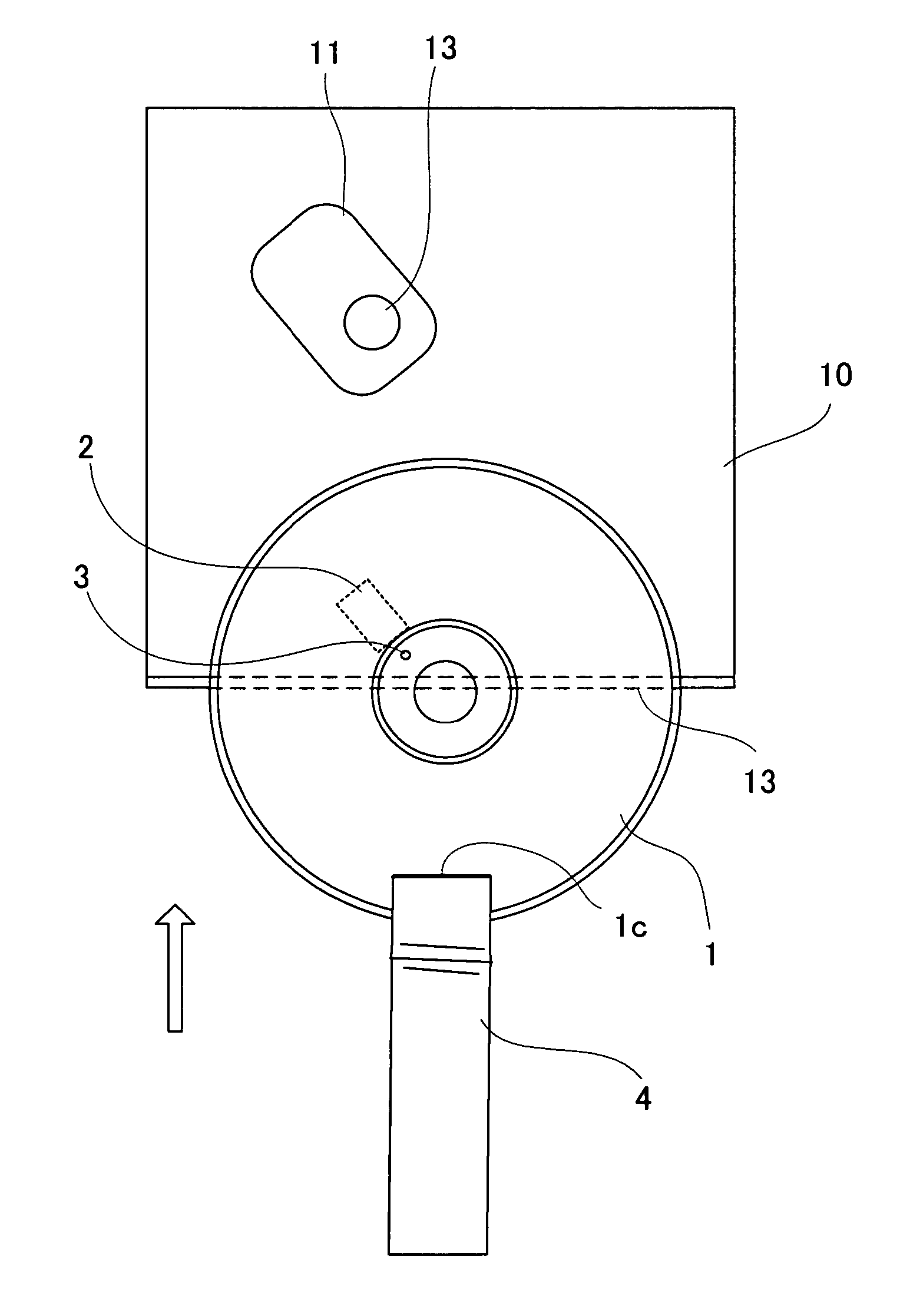

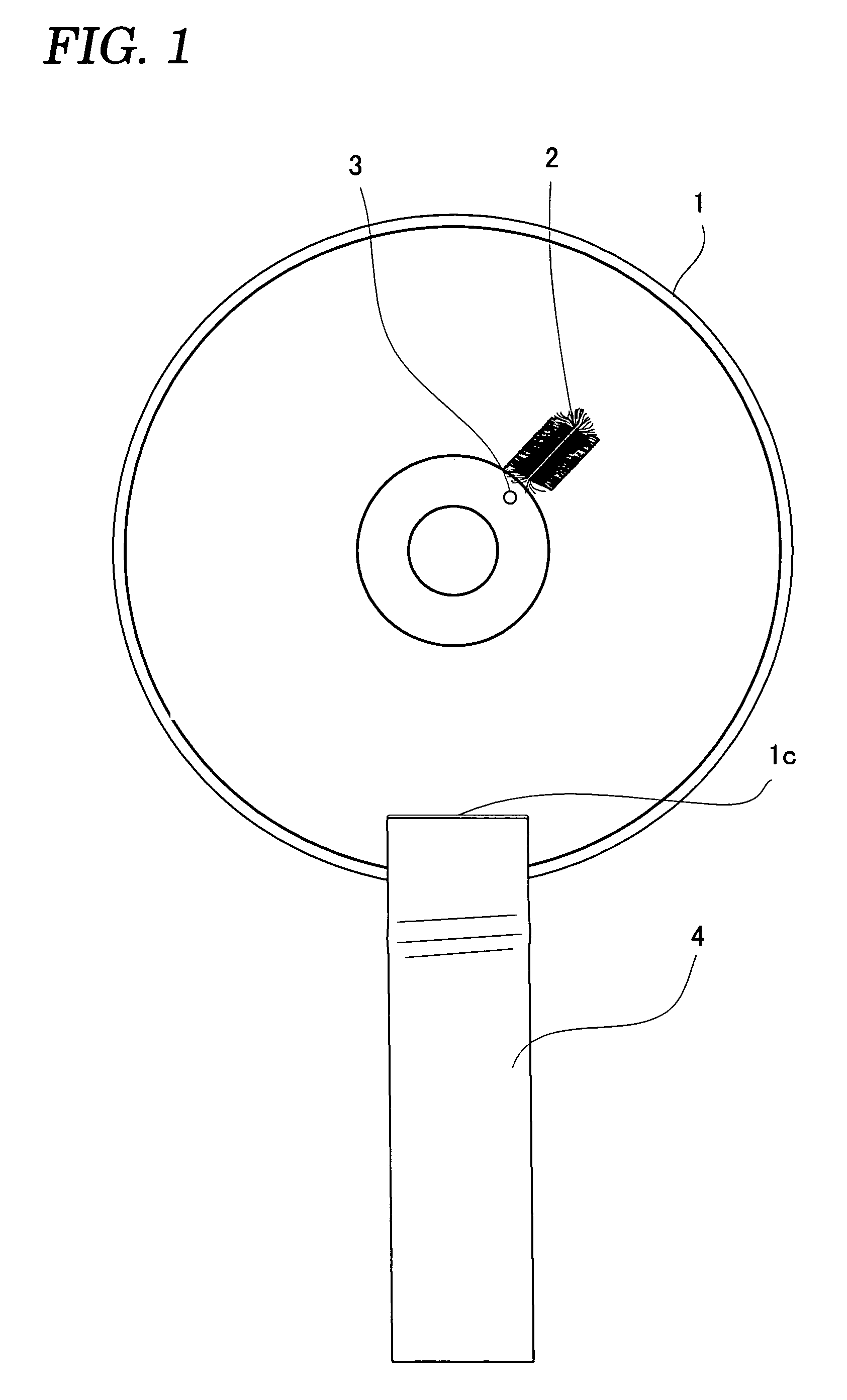

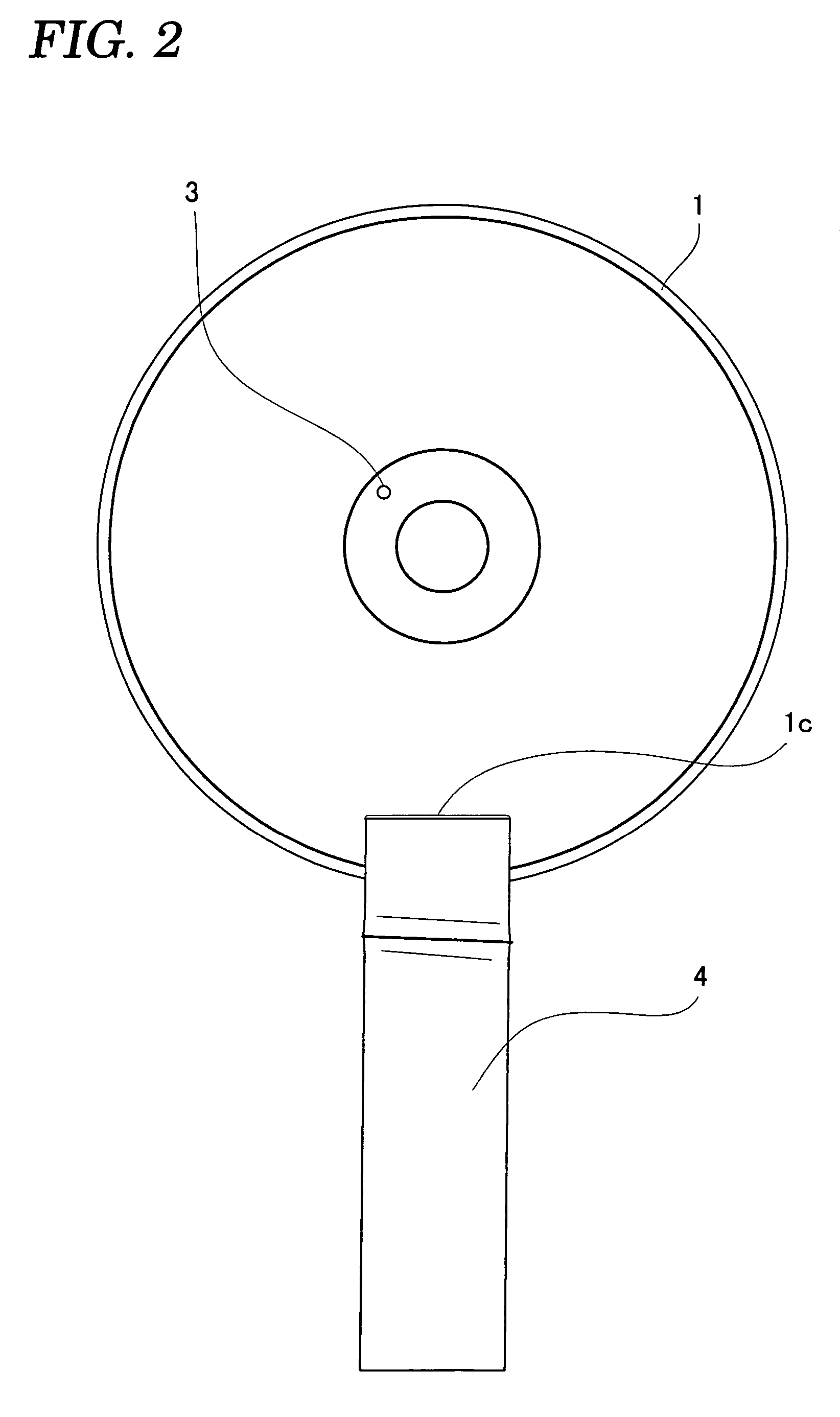

Lens cleaner and lens cleaning method for optical disc device

ActiveUS7197755B2Efficient cleaning methodSimple and inexpensiveOptical head protectionRecord information storageCamera lensBristle

By not recording a signal which can be the subject of focussing on a disc, a simple and inexpensive lens cleaner is provided which is able to perform cleaning of an object lens in a simple and reliable manner, without causing the disc to rotate, even in a standard disc device. In order to clean the object lens of the optical disc device, a bristle brush which makes contact with the object lens is provided on the disc, an operating ribbon for operating the disc from the outside of the device is attached to the disc, and no recording face that can be the subject of focussing by the object lens is provided, or alternatively, no signal that can be the subject of focussing by the object lens is recorded, on the face of the disc adjacent to the object lens.

Owner:CLARION CO LTD

Device for removing suspended matters after printing and dyeing sewage treatment

InactiveCN111717975AEasy to removeEfficient cleaning methodSpecific water treatment objectivesTreatment involving filtrationProcess engineeringSewage treatment

The invention discloses a device for removing suspended matters after printing and dyeing sewage treatment. The device comprises a reaction tank and a filter cloth, a plurality of cloth strips which are linearly and uniformly distributed are fixed at one end of the filter cloth, the cloth strips are wound on an unwinding wheel, and the other end of the filter cloth sequentially bypasses extendingends of a first driving roller, two gravity rollers, a second driving roller and a third driving roller to be wound on a winding wheel; a removing mechanism is arranged above the position between thesecond transmission roller and the third transmission roller; and each gravity roller is provided with a vertical guide mechanism. Flocculated bodies can be removed in the suspension period, and the removing mode is simple and efficient.

Owner:深圳市创智联环保设备有限公司

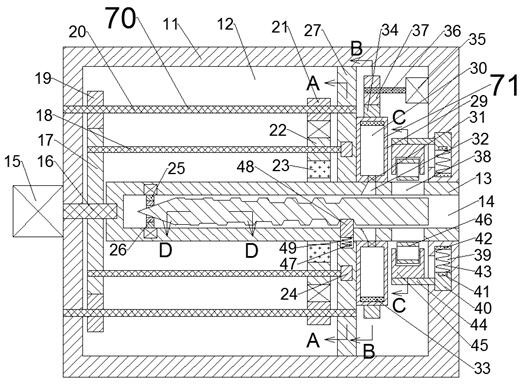

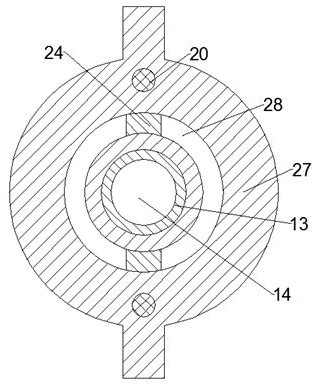

Fine cleaning equipment for feeding screw of injection molding machine

The invention discloses fine cleaning equipment for a feeding screw of an injection molding machine. The fine cleaning equipment comprises a box body, an arrangement space is formed in the box body, acleaning box is fixedly arranged on the inner wall of the right side of the arrangement space, a cleaning cavity with a rightward opening is formed in the cleaning box, a cleaning mechanism is arranged on the left side of the arrangement space, the cleaning mechanism comprises a first motor, and the first motor is fixedly connected with the left end surface of the box body. According to the finecleaning equipment, the cleaning work of the feeding screw of the injection molding machine can be automatically completed, the screw is clamped through two conveying belts with opposite transmissiondirections, the screw is made to rotate leftwards to move into the cleaning cavity, a cleaning scraper is elastically arranged on the inner wall of the lower side of the cleaning cavity, and the surface of the screw is preliminarily cleaned; and in addition, a metal polishing piece is further arranged on the equipment, and through high-speed rotation and movement of an electromagnet, the metal polishing piece rapidly polishes the surface of the screw.

Owner:佛山市掌拓精密科技有限公司

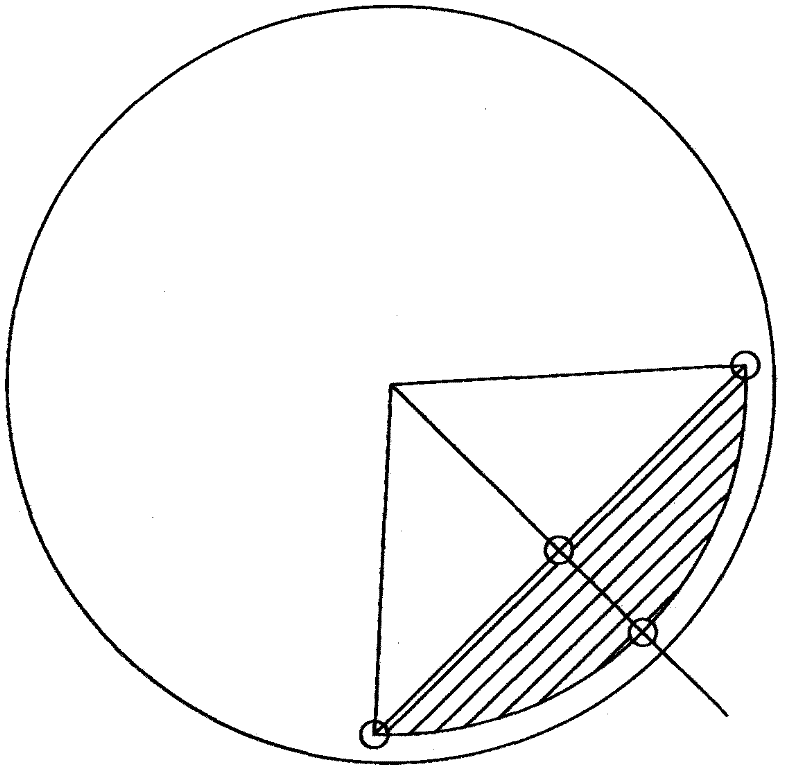

Local positioning cleaning method of wafer surface

InactiveCN102214558AAccurate cleaning methodEfficient cleaning methodSemiconductor/solid-state device manufacturingCleaning using liquidsManufacturing cost reductionEngineering

The invention discloses a local positioning cleaning method of a semiconductor wafer surface. Compared with the conventional whole dipping cleaning technology, the method disclosed by the invention is characterized in that the wafer does not need to be wholly dipped in a large amount of a chemical agent to remove impurities, but is locally subjected to positioning cleaning by using agentia droplets at the tip of a minimal contact. The method has the characteristic that only microlitre-level agentia dose is required in each cleaning process, so as to reach the purpose of removing pollutant on the wafer surface, thus largely reducing the use amount of the cleaning agentia and pure water and reaching the effects of saving energy, reducing emission and reducing manufacturing cost.

Owner:叶伟清

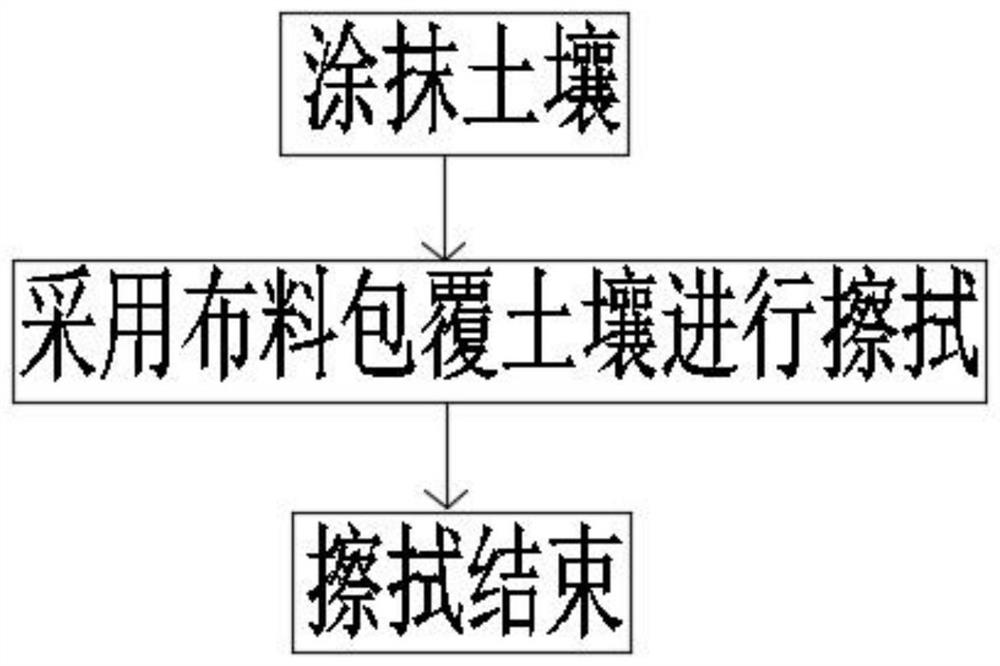

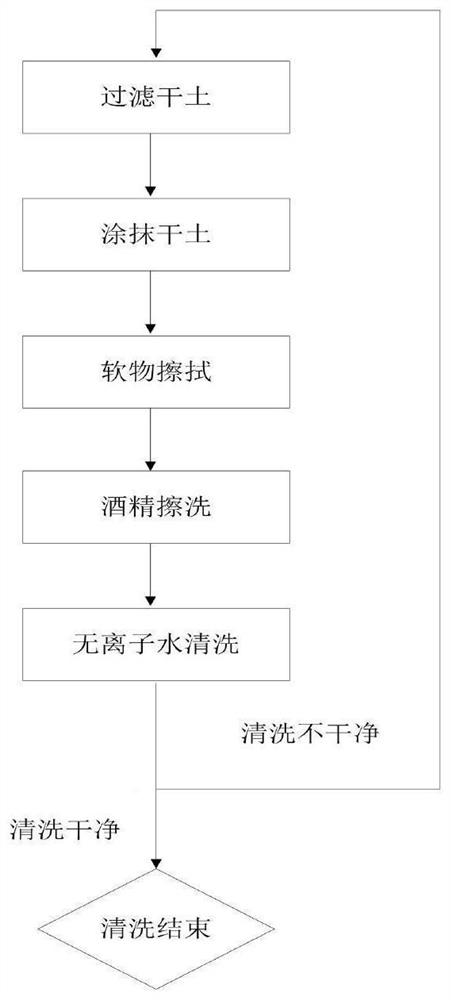

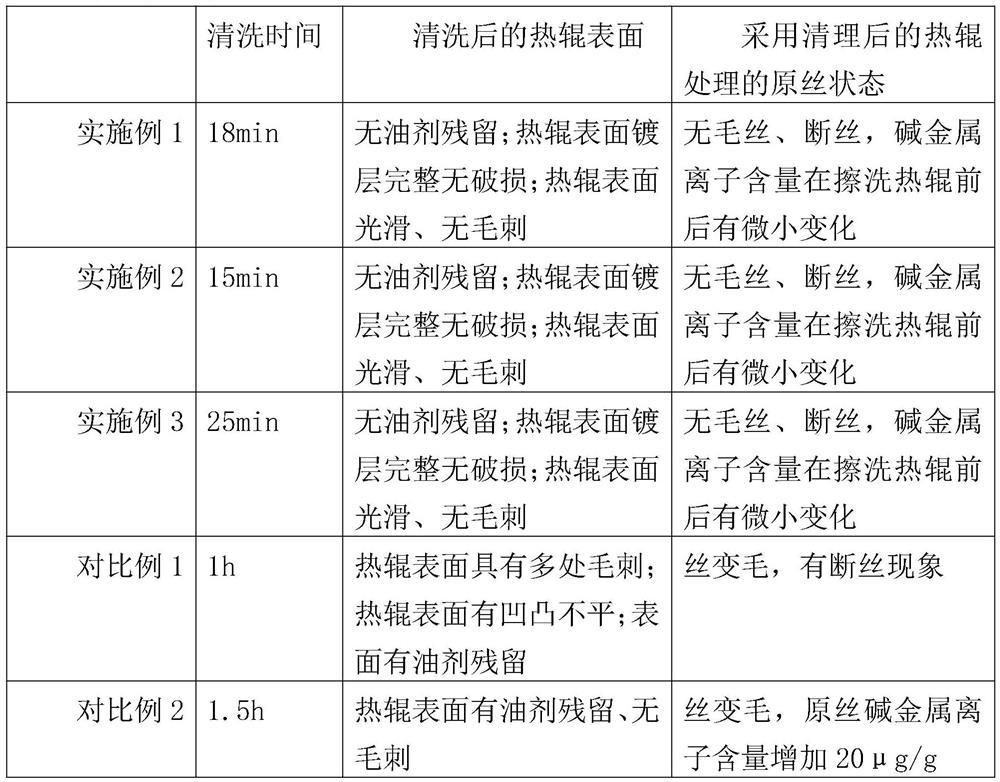

Cleaning method of polyacrylonitrile carbon fiber precursor drying and densifying equipment

ActiveCN113020133AWon't hurtQuality is not affectedCleaning using toolsCleaning using liquidsPolymer scienceCarbon fibers

The invention provides a cleaning method of polyacrylonitrile carbon fiber precursor drying and densifying equipment. The cleaning method comprises the following steps: 1, smearing soil on the drying and densifying equipment; and 2, coating the soil with cloth and wiping the drying and densifying equipment to remove attachments on the surface of the drying and densifying equipment. According to the cleaning method of the polyacrylonitrile carbon fiber precursor drying and densifying equipment, the cleaning effect is good, the surface of the densifying equipment equipment is not damaged, and the performance of a precursor and a carbon fiber is not affected.

Owner:山西钢科碳材料有限公司

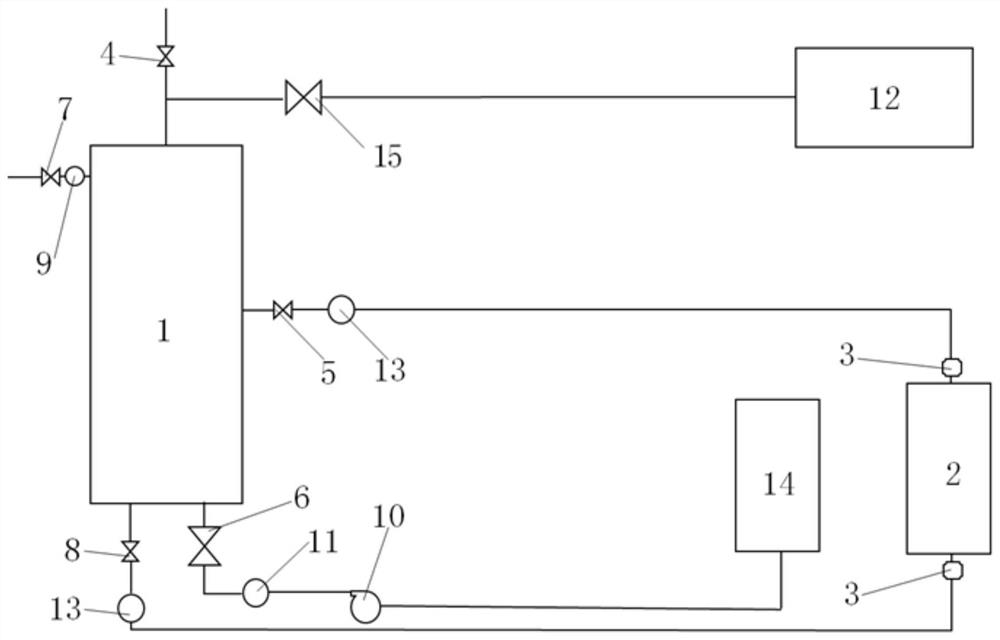

Flexible tubular large-aperture membrane filtration device and cleaning method thereof

The invention discloses a flexible tubular large-aperture membrane filtration device and a cleaning method thereof. According to the invention, the diameter of a tubular membrane in the membrane filtration device is not less than 5 mm; the aperture of the tubular membrane is 6-200 [mu]m; the tubular membrane is made of a homogeneous membrane, so forward and reverse cleaning and filtering effects are the same; the tubular membrane has sufficient flexibility for physical deformation; and gas in a gas source can enter the membrane filtration device through an opened water production side gas inlet valve and an opened water inlet side bottom gas inlet valve respectively and then is discharged through a water production side gas outlet valve, and no gas seal is formed under the condition of weak pressure regardless of hydrophilic, hydrophobic or humid conditions. Traditional water cleaning is replaced by gas cleaning in the invention, cleaning is completed by means of gas such as air, dirt and the like which are hidden on the inner wall of the membrane filtration device and are difficult to clean are effectively removed, cleaning is more thorough, and water consumption is reduced; the filtering effect is not affected by water flux, so yield is high; cleaning does not depend on chemical reagents, so reagent residues do not exist, and use safety is high; and the cleaning method is simple, efficient, energy-saving and consumption-reducing.

Owner:迈海(苏州)环保科技有限公司

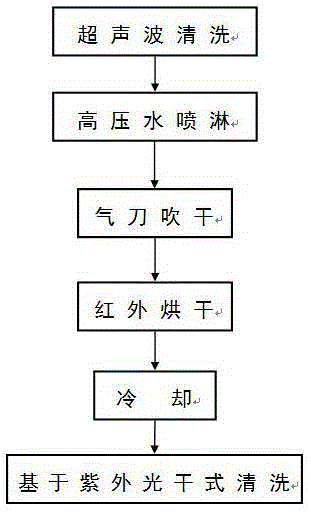

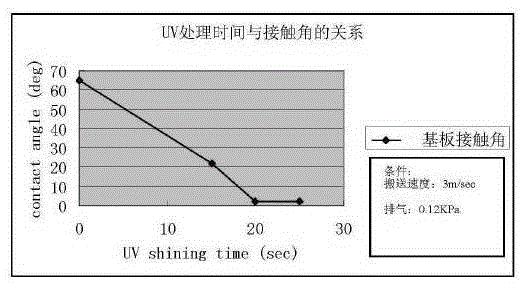

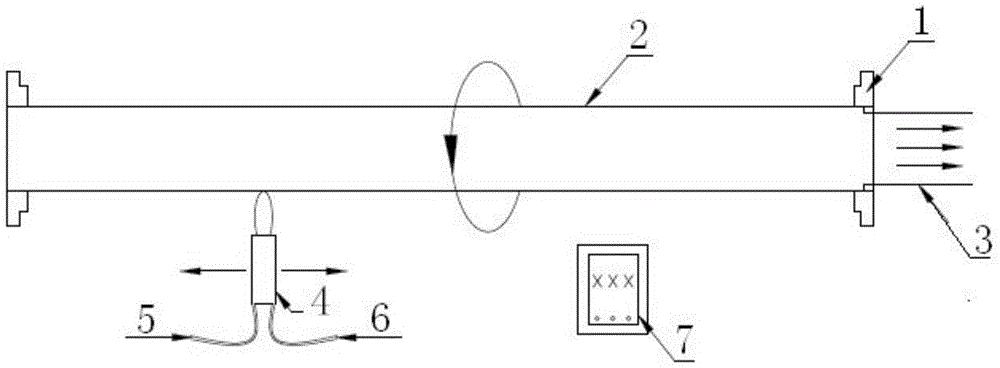

A dry cleaning method based on ultraviolet light

ActiveCN103008311BImprove reliabilityImprove the quality effectFlexible article cleaningEnvironmental resistanceUltraviolet lights

The invention relates to an ultraviolet-based dry type cleaning method, in particular to an ultraviolet cleaning method for cleaning organic pollutants on a surface of a TFT-LCD (thin film transistor-liquid crystal display) glass substrate. The dry type cleaning method is effectively combined with a wet type cleaning method, the surface of the TFT-LCD glass substrate is subjected to two different types of wet type cleaning methods including ultrasonic cleaning and high-pressure water sprinkling, and then is subjected to the ultraviolet-based dry type cleaning, the particles and the organic pollutants attached to the surface are removed, and then the cleanness reaches to an atomic level. The ultraviolet-based dry type cleaning method has the advantages that the cleaning effect is good, the speed is high, the green and environment-friendly effects are realized, the secondary pollution is avoided, the uniformity is high, and the like. The TFT-LCD glass substrate cleaned by the ultraviolet-based dry type cleaning method has the advantages that the finished rate is high and the quality is high, and a good foundation is laid for the subsequent process flow of the glass substrate.

Owner:JIANGSU YUDI OPTICAL CO LTD

Municipal lifting device and application thereof

InactiveCN113522858AAchieve the purpose of cleaningTo achieve hygieneCleaning using liquidsWater flowStructural engineering

The invention relates to a municipal lifting device which comprises a supporting part. The supporting part is of a hollow structure with the top open, a lifting plate is arranged on the inner side of the supporting part, a washing space for washing the lifting plate is formed in the hollow inner side of the supporting part, water flow holes are formed in the lifting plate in a penetrating mode, and a driving piece for driving the lifting plate to vertically lift and lower is arranged on the inner side of the supporting part. The invention further discloses application of the municipal lifting device. The lifting device is applied to the ground close to the periphery of a urinal and installed underground in an embedded mode, the top of the supporting part is horizontal to the ground, and the lifting plate is opposite to the position of the urinal and supports the feet of a user. According to the public content, the supporting part, the lifting plate and other structures are ingeniously combined with a urinal in a male toilet and a squatting urinal in a male-female toilet, so that the situation that urine remains on the ground, and consequently the environment and surrounding air are polluted is avoided.

Owner:魏周

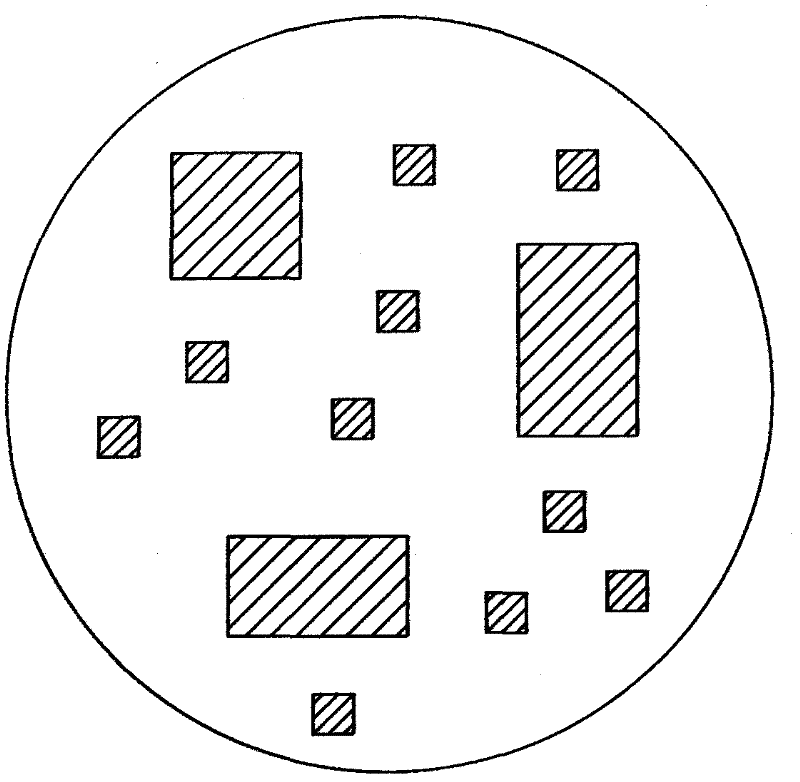

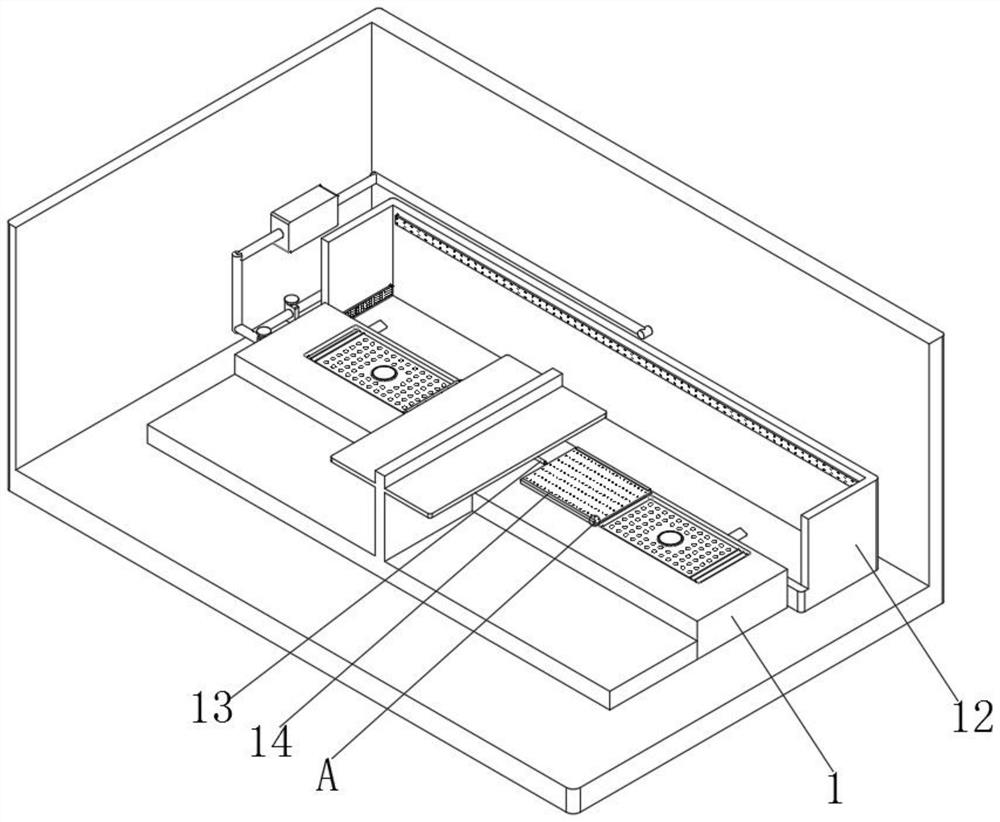

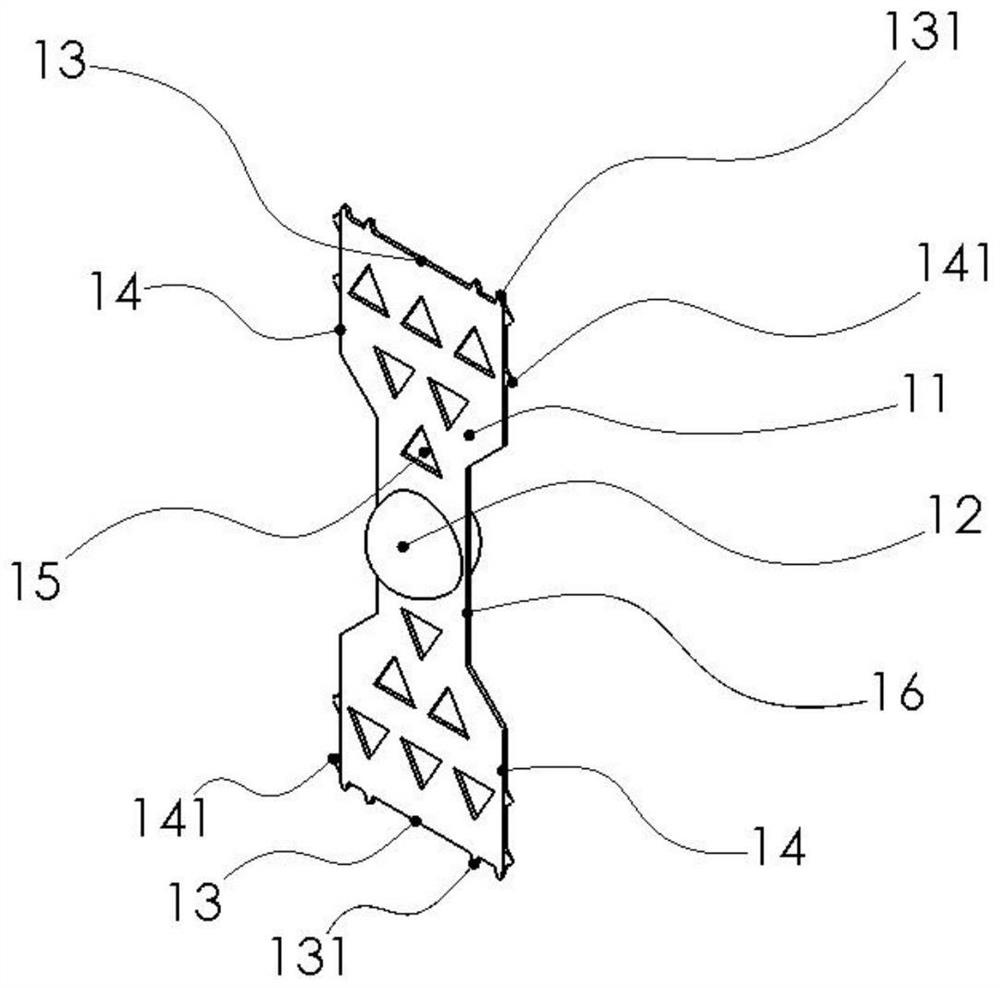

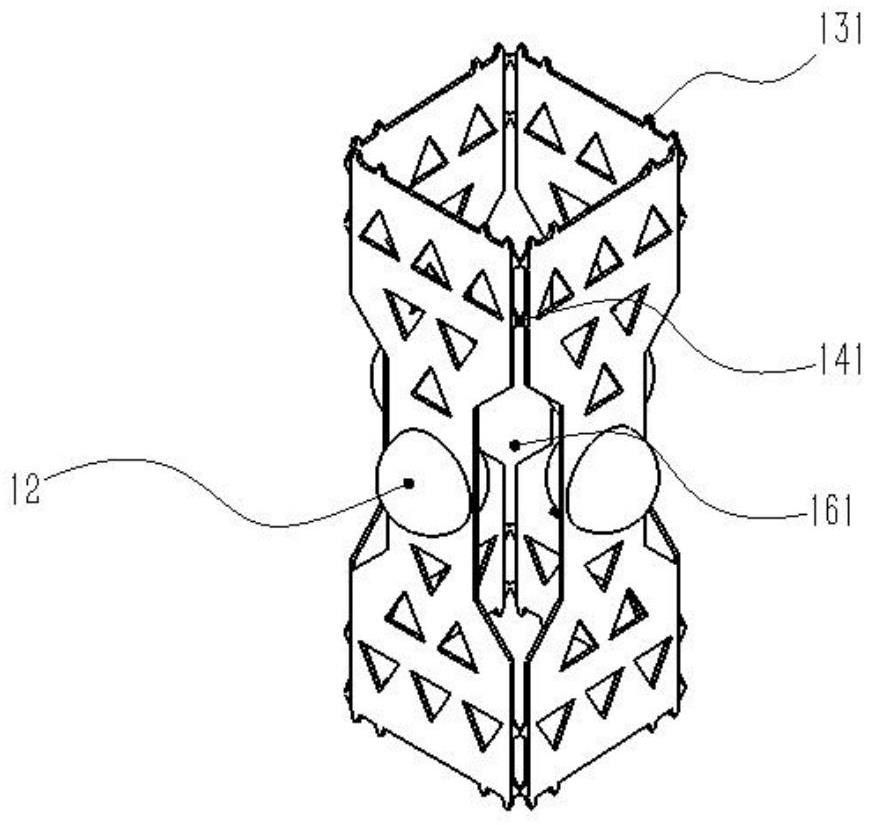

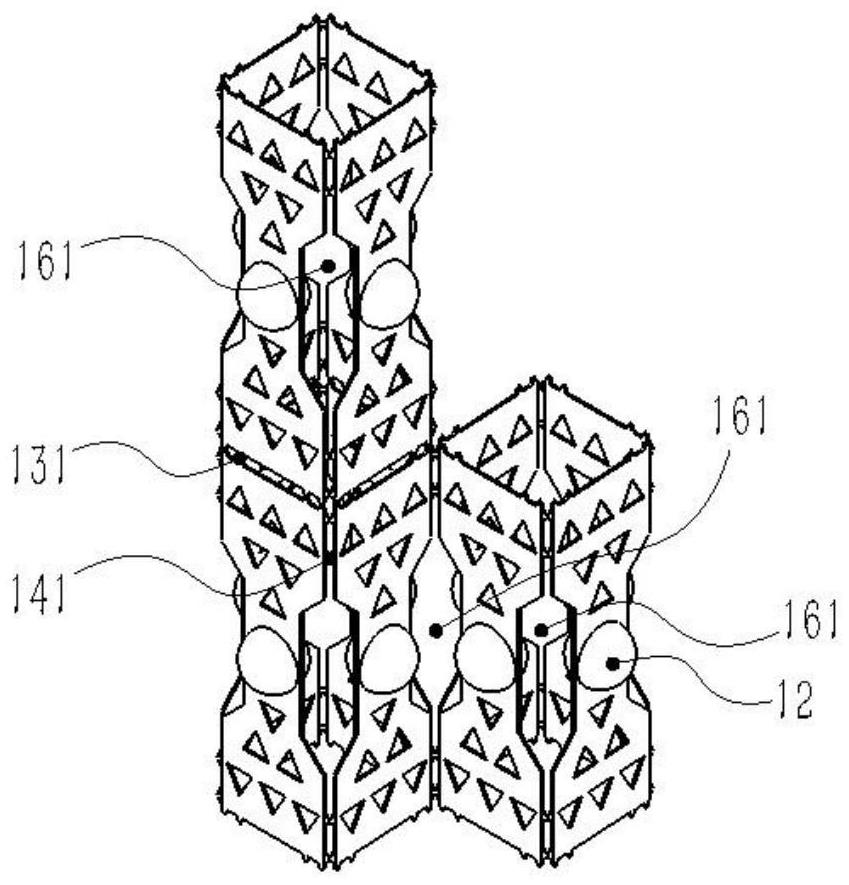

Supporting structure for 3D printing and method for removing supporting structure

InactiveCN113953535AEasy outflowSave materialAdditive manufacturing apparatusIncreasing energy efficiencyStructural engineeringInternal stress

The invention discloses a supporting structure for 3D printing and a method for removing the supporting structure. The supporting structure for 3D printing comprises multiple auxiliary supporting units, each auxiliary supporting unit comprises a supporting body, each supporting body is of a plate-shaped structure, connecting points are arranged on the top face, the bottom face and the side faces of each plate-shaped structure, and the two side faces of each plate-shaped structure are sunken towards the center position; a mass block is arranged at the center position of each plate-shaped structure, and hollowed-out parts are arranged at the non-center positions of the plate-shaped structures; and a powder outflow hole is formed between every two auxiliary supporting units connected through the connecting points on the side faces of the auxiliary supporting units. Multiple three-dimensional structures can be formed through the connecting points, so that different inherent frequencies of the auxiliary supporting structure are formed, the situation that the inherent frequencies of the auxiliary supporting structure and parts are the same can be avoided, the inherent frequencies of the auxiliary supporting structure are adjustable, and part resonance is avoided conveniently when the auxiliary supporting structure is removed. When the auxiliary supporting structure is removed, part internal stress can be effectively eliminated through vibration, and part stress release is convenient.

Owner:SHANDONG LABOR VOCATIONAL & TECHN COLLEGE

Tasteless double-functional material for cleaning and lubricating semiconductor packaging mold

ActiveCN102786725BRealize the moistening effectIncrease productivitySemiconductor packageMaterials science

The invention discloses a tasteless double-functional material for cleaning and lubricating a semiconductor packaging mold. The double-functional material is prepared from the following raw materials in parts by mass: 100 parts of unvulcanized rubber, 0.1 to 50 parts of cleaning agent, 0.1 to 10 parts of mold-cleaning auxiliary agent, 0.1 to 10 parts of mold-lubricating agent, 0.1 to 10 parts of curing agent and 5 to 100 parts of filling agent. The tasteless double-functional material for cleaning and lubricating the semiconductor packaging mold is harmless and environment-friendly, and can stick a pollutant on the surface of the mold and absorb the pollutant onto the surface of curing rubber. Meanwhile, a mold-lubricating effect is achieved, the production efficiency is improved, the time is saved, and the cost is reduced. The tasteless double-functional material is used without being pre-heated, and a cleaning method is simple and high in efficiency.

Owner:TECORE SYNCHEM

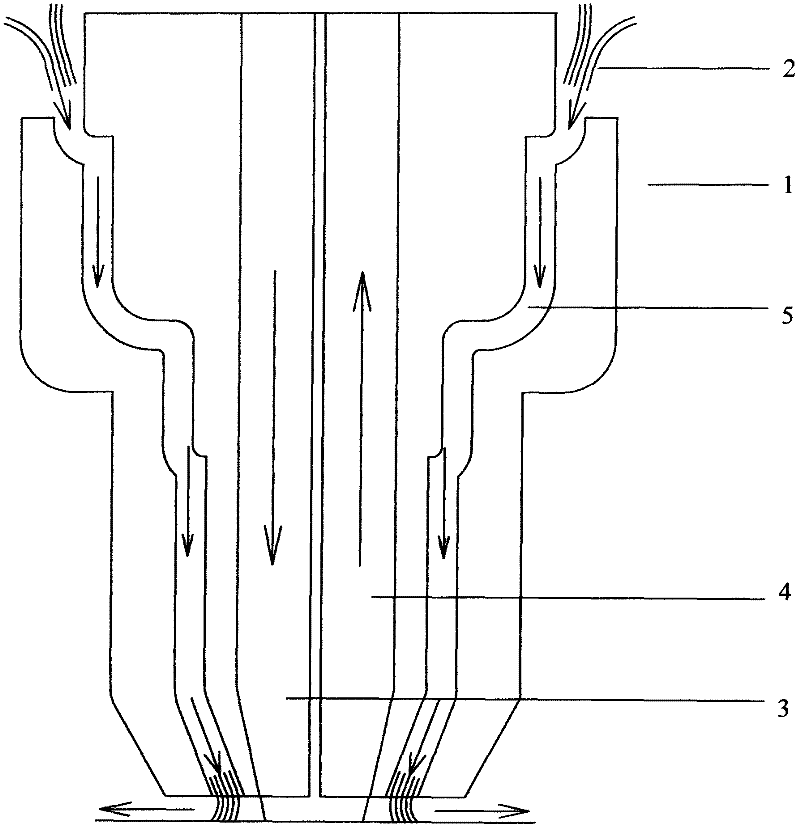

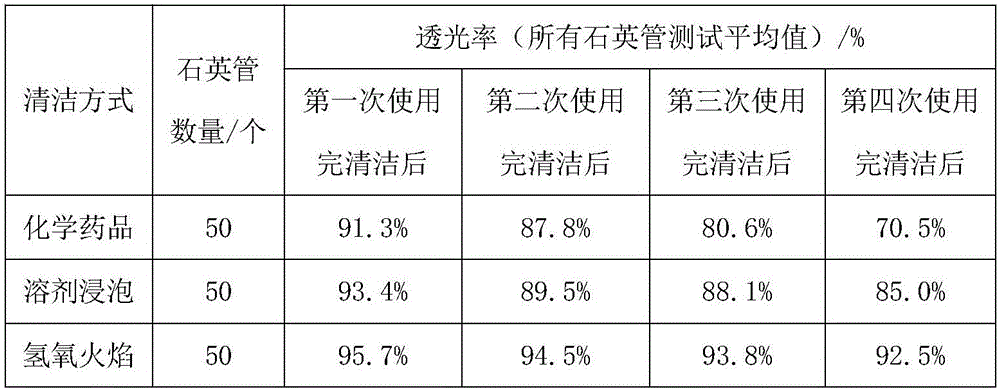

A cleaning method for quartz central tube in an optical fiber ultraviolet curing furnace

ActiveCN104226654BHigh light transmittanceIncrease the number of recyclingHollow article cleaningManufacturing technologyUltraviolet

The invention relates to the technical field of optical fiber manufacturing, in particular to a device and a method for cleaning a quartz central tube in an optical fiber ultraviolet curing furnace. The device comprises a clamping rotary device used for fixing a to-be-cleaned quartz central tube and a movable oxyhydrogen flame generating device for heating the to-be-heated quartz central tube, wherein the clamping rotary device is provided with an air sucking device; a temperature sensing device is arranged on the to-be-cleaned quartz tube and is connected with a control device by virtue of a signal wire; the clamping rotary device, the oxyhydrogen flame generating device and the air sucking device are connected with the control device by virtue of signal wires. An oxyhydrogen flame lamp is adopted for heating and baking the quartz central tube and a mode of sucking out exhaust gas such as carbon dioxide after UV rubber combustion by use of the air sucking device is used for overcoming the defects of the cleaning method, so that the cleaning effect is relatively thorough, the inner wall of the quartz central tube can not be damaged, the light transmittance and cyclic utilization times of the quartz central tube are effectively improved, and furthermore the optical fiber coating and curing quality is ensured.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH

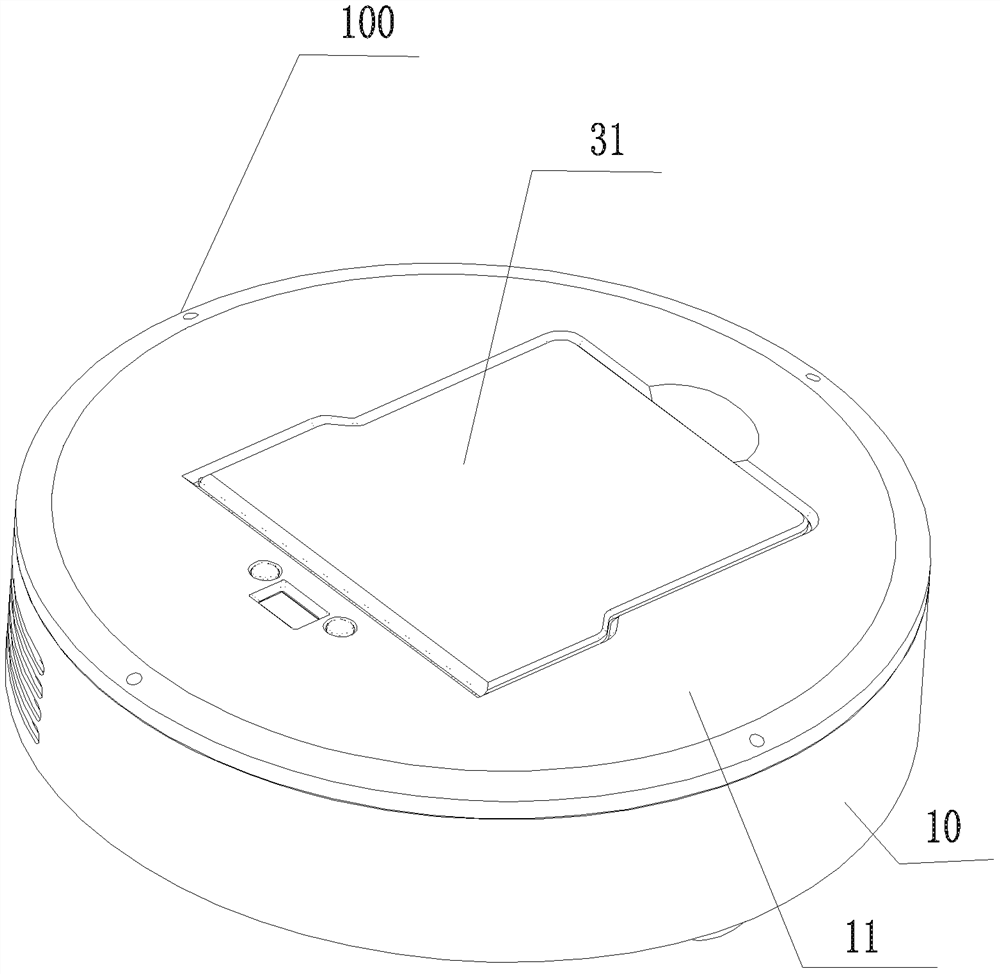

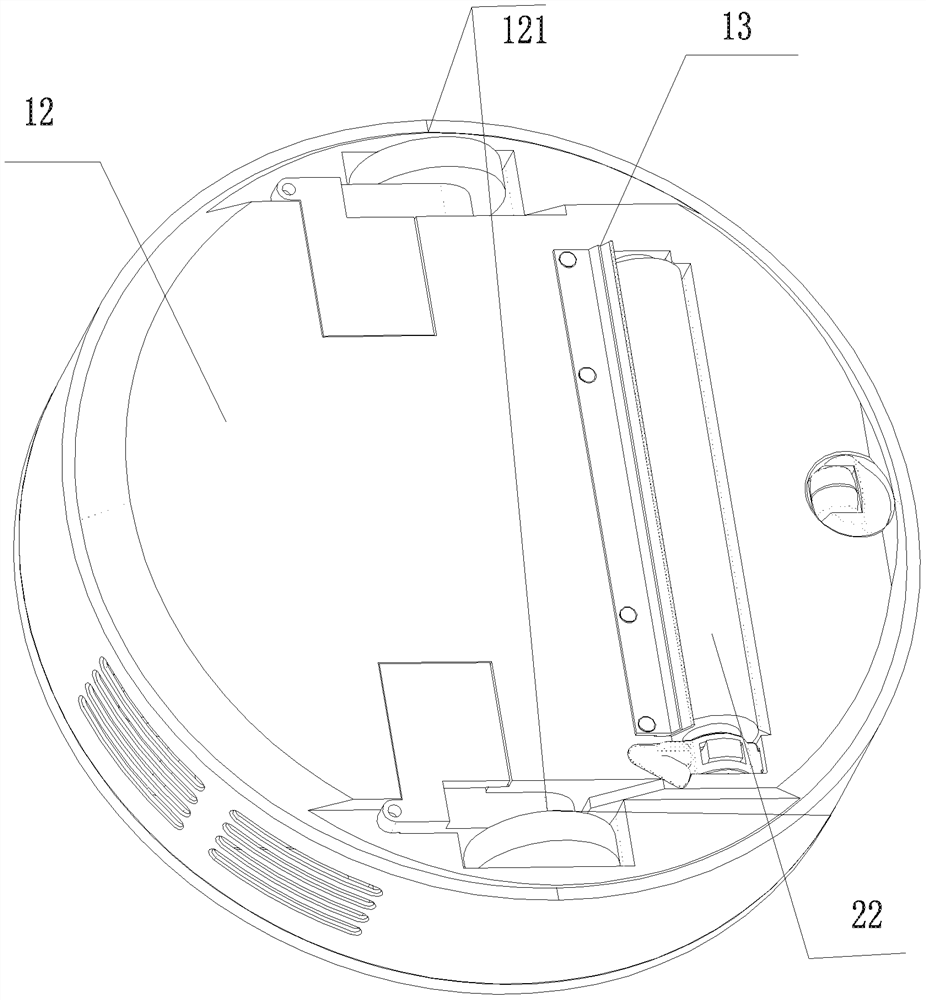

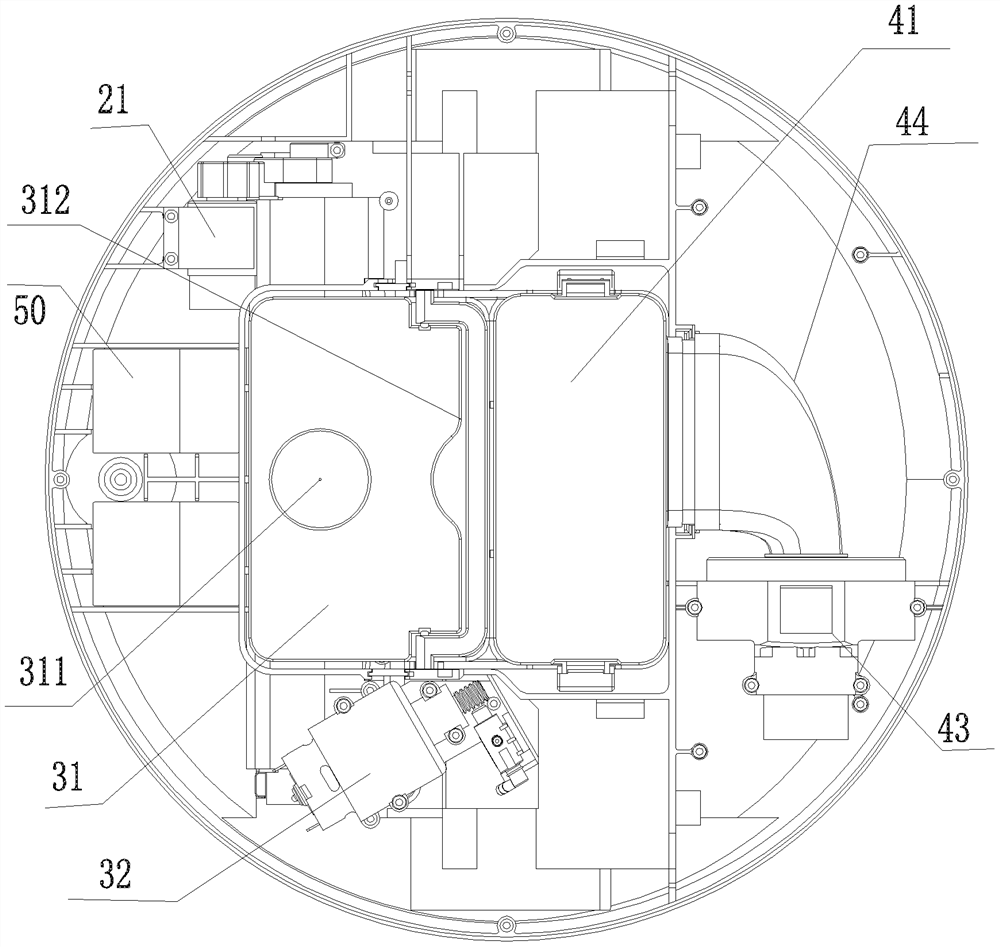

A floor wiping robot and cleaning method thereof

ActiveCN111405863BEfficient cleaning methodWill not cause secondary pollutionMachine detailsWorkspaceMechanical engineering

A floor wiping robot (100), comprising: a housing (10); a liquid supply device (30) arranged in the housing (10), used to provide cleaning liquid to the floor wiping device (20); the floor wiping device ( 20), arranged on the housing (10), driven by the first drive mechanism (21) to wipe the working surface; the recovery device (40), arranged in the housing (10), used to recover the mopping device ( 20) the dirty liquid left on the working surface after wiping the working surface; the control device (60) is respectively connected with the wiping device (20), the liquid supply device (30) and the recovery device (40) to control the wiping robot (100) ) walk and work in the working area. Also provided is a cleaning method for the mopping robot (100).

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

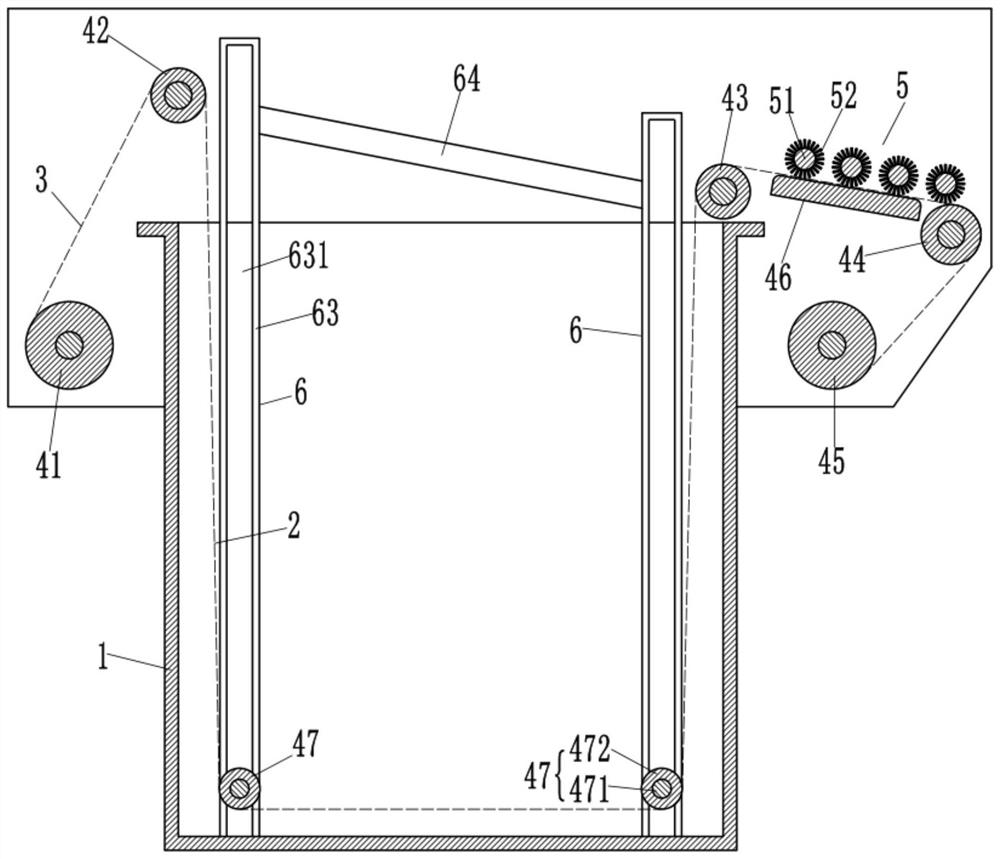

Environment-friendly cleaning and maintenance machine for steel wire rope

ActiveCN102247961BHeight adjustableSatisfy the requirements of pay-offCleaning processes and apparatusEngineeringUltimate tensile strength

The invention discloses an environment-friendly cleaning and maintenance machine for a steel wire rope. The machine comprises a wire pay-off mechanism, a cleaning mechanism, a dirt-removing mechanism, a maintenance mechanism and a wire take-up mechanism, which are arranged in sequence, wherein the steel wire rope is cleaned and maintained by the wire pay-off mechanism, the cleaning mechanism, the dirt-removing mechanism, the maintenance mechanism and the wire take-up mechanism in sequence. By the adoption of the cleaning and maintenance machine disclosed by the invention, the problems of massive dirt accumulation, rust formation and damage happening during the use process of different types of steel wire ropes for constructions can be effectively avoided; and accidents of personal injury, traffic interruption and power failure, which are caused by the breakage of steel wire ropes during the construction process, can be effectively prevented by periodically cleaning and greasing steel wire ropes with the cleaning and maintenance machine every year. The cleaning and maintenance machine disclosed by the invention can be used for cleaning different types of steel wire ropes in a simple and highly-efficient method, has stable performances and good cleaning and maintenance effects. The cleaning and maintenance machine is easy to operate during the use process and has the beneficial effects of reducing the labor intensity, increasing the work efficiency, ensuring the service safety against twisting of steel wire ropes, prolonging the service life and the operating reliability of steel wire ropes and providing powerful guarantee for safety production.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

Cleaning method of water purifier

InactiveCN104909433ALarge filter areaImprove filtering effectUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiberHollow fibre

The invention discloses a cleaning method of a water purifier. The water purifier comprises a filter unit with a hollow fiber ultra-filtration membrane, a water tank unit for storing the water already purified by use of the filter unit, and a drainage unit for draining the purified water stored in the water tank unit and sewage after cleaning. The cleaning method comprises a conventional mechanical cleaning method and specifically comprises the steps of water injection, cleaning, sewage disposal and re-cleaning. The cleaning method of the water purifier is high in efficiency, simple and convenient, and an electromagnetic valve is used for controlling water inflow and outflow, so that the system is simpler and can be widely applied to cleaning of hollow fiber ultra-filtration membrane water purifiers.

Owner:WUHU SUNRISE NEW BUILDING MATERIALS TECH

Multi-element waste light simplified energy-saving emission-reducing aerobic and anaerobic composting system

ActiveCN111606746AEfficient heat and mass transferMeet the sealing performanceBio-organic fraction processingMicroorganism based treatmentEnvironmental engineeringFermentation

The invention relates to a multi-element waste light simplified energy-saving emission-reducing aerobic and anaerobic composting system. The system comprises a rack, a cylindrical fermentation bin anda ventilation-crushing composite device. The fermentation bin is hermetically arranged and mounted on the rack. The fermentation bin is divided into three layers from outside to inside, namely a leachate anaerobic fermentation cavity, a ventilation cavity and a material aerobic fermentation composting cavity in sequence, a spring-back water baffle is arranged at the bottom of the ventilation cavity, the ventilation-crushing composite device is arranged in the material aerobic fermentation composting cavity, and gas produced in the fermentation bin is discharged after being treated to reach the standard. According to the invention, harmless cleaning treatment of perishable organic garbage can be carried out by taking village and town families as units.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

How to clean glass components

ActiveCN111804664BEfficient removalNo damageInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsMetallurgyWater washing

The invention relates to a cleaning method for a glass element. The preparation method comprises the following steps: placing the polished glass element in an acidic cleaning solution for the first ultrasonic treatment and the second ultrasonic treatment in sequence, and then placing the polished glass element in an alkaline cleaning solution. In the cleaning solution, the third ultrasonic treatment is carried out, and finally, water washing and drying are carried out to obtain the cleaned glass element; wherein, the frequency of the first ultrasonic treatment is 10KHz~30KHz, and the frequency of the second ultrasonic treatment is 40KHz~70KHz. The cleaning method can effectively improve the cleaning efficiency of the glass element without damage to the glass element.

Owner:万津实业(赤壁)有限公司

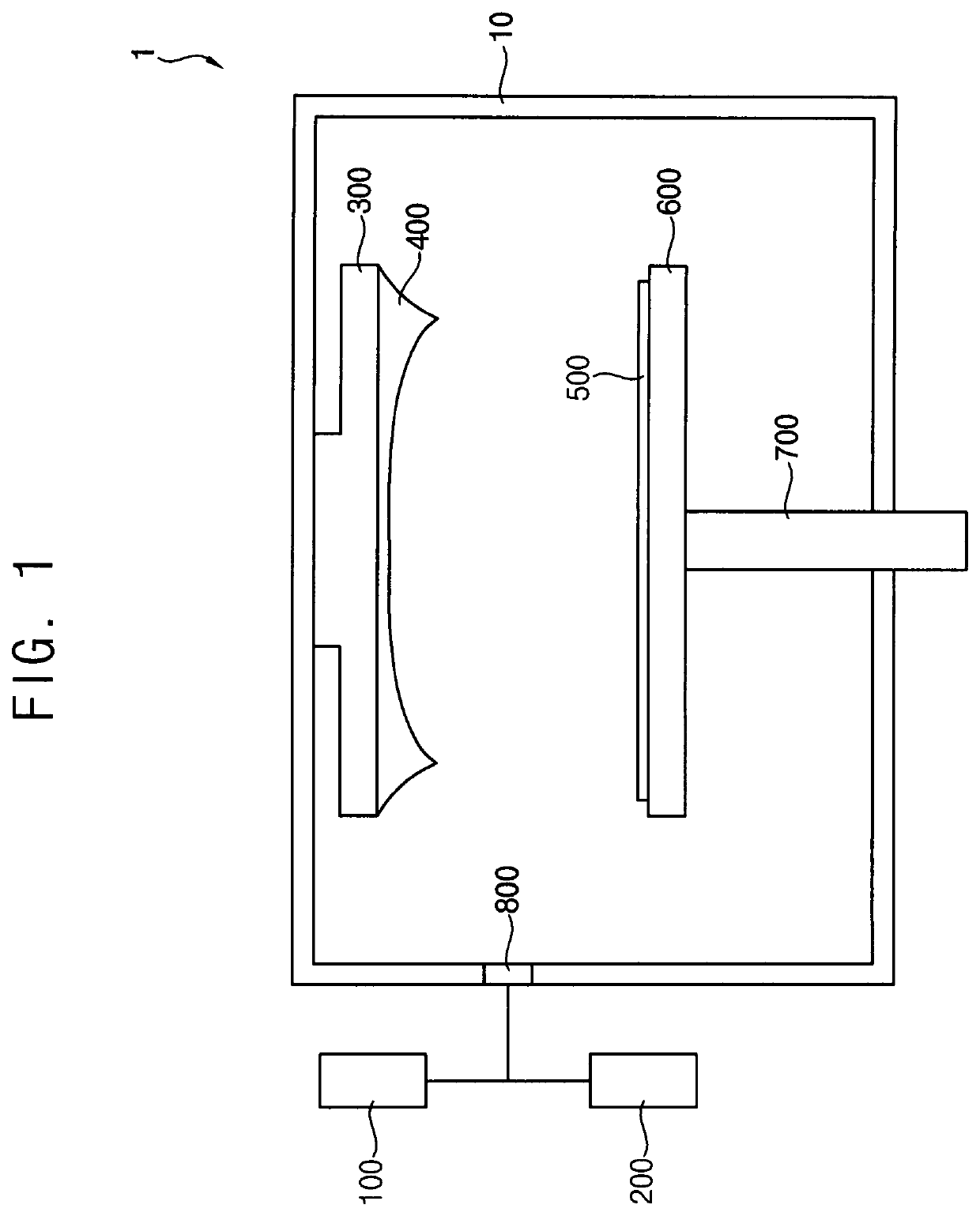

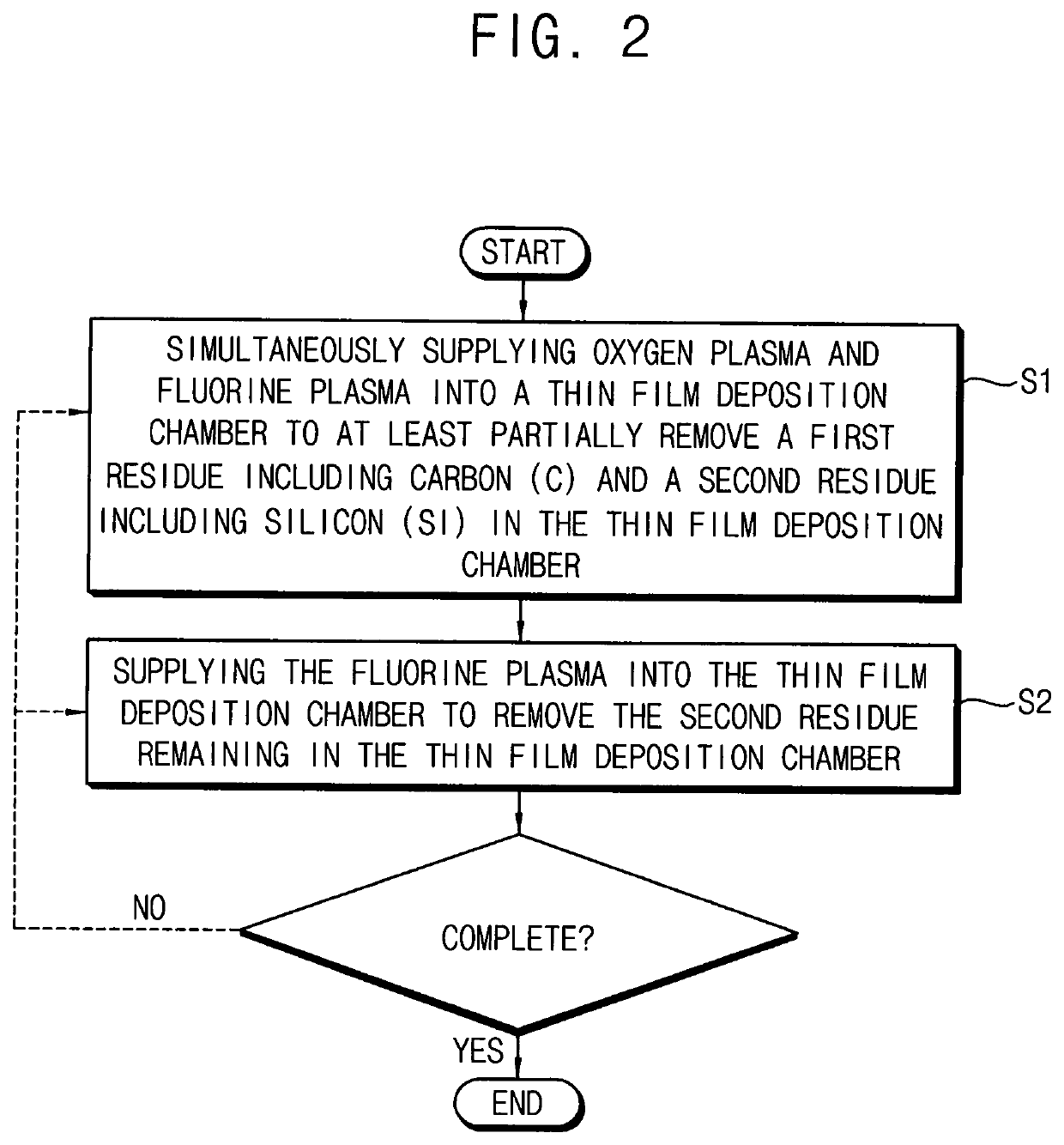

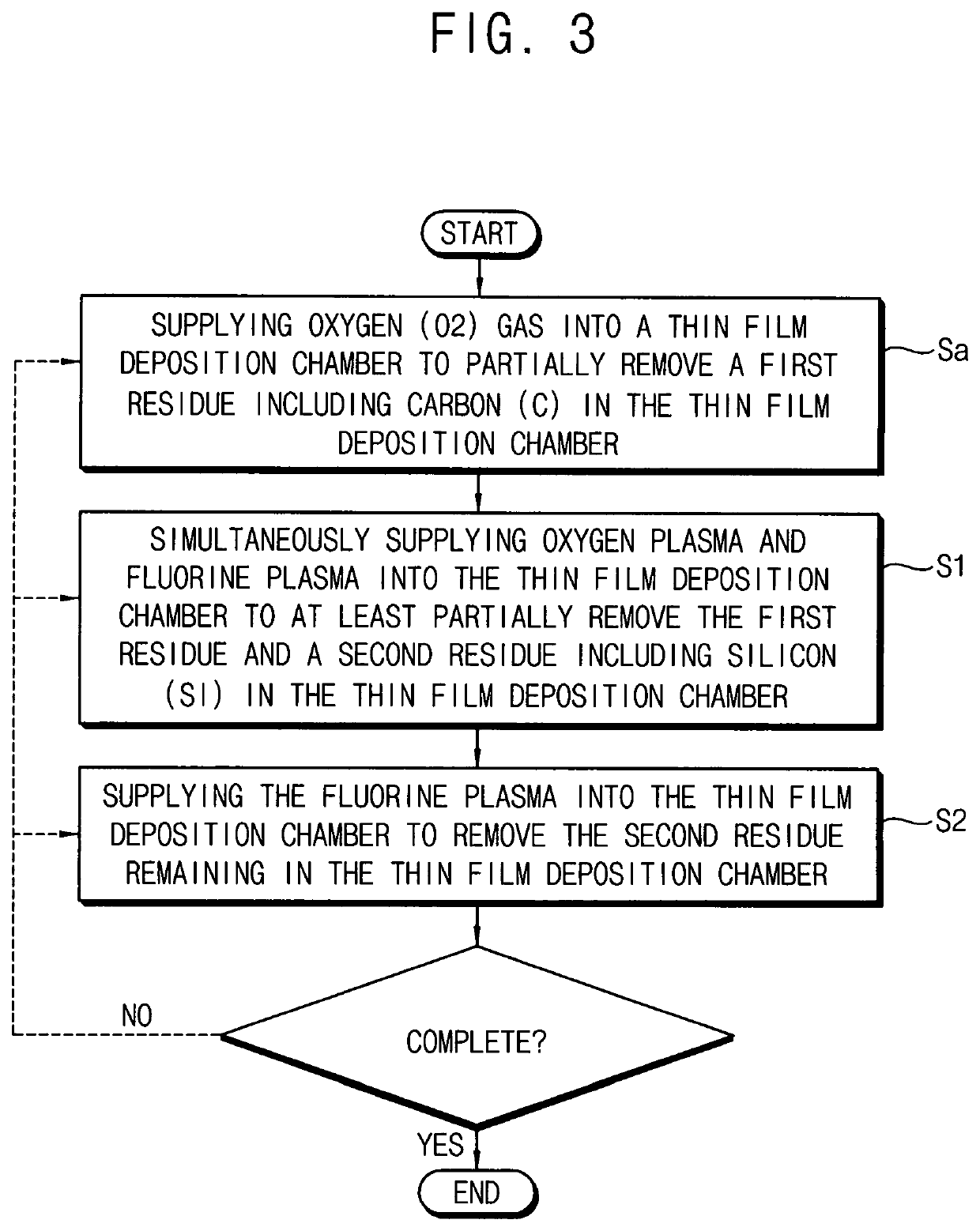

Cleaning method of a thin film deposition chamber and method of manufacturing semiconductor device using the cleaning method

InactiveUS20200131629A1Efficient removalQuality improvementElectric discharge tubesSemiconductor/solid-state device manufacturingDevice materialOxygen plasma

A cleaning method of a thin film deposition chamber may include i) simultaneously providing oxygen plasma and fluorine plasma in a thin film deposition chamber to at least partially remove a first residue including carbon (C) and a second residue including silicon (Si) in the thin film deposition chamber, and ii) providing fluorine plasma without oxygen plasma in the thin film deposition chamber to remove the second residue remaining in the thin film deposition chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

A kind of injection molding machine feeding screw fine cleaning equipment

The invention discloses a fine cleaning device for the feeding screw of an injection molding machine, which includes a box body, and the box body is provided with an arrangement space, and the inner wall on the right side of the arrangement space is fixed with a cleaning box, and the cleaning box is provided with an opening For the cleaning chamber to the right, a cleaning mechanism is provided on the left side of the arrangement space, and the cleaning mechanism includes a first motor, which is fixedly connected to the left end surface of the box body, and the invention can automatically complete the feeding of the injection molding machine. For the cleaning of the screw, the present invention clamps the screw through two conveyor belts with opposite transmission directions, and makes the screw rotate to the left and move into the cleaning chamber. A cleaning scraper is elastically arranged on the inner wall of the lower side of the cleaning chamber to perform preliminary cleaning on the surface of the screw. , In addition, the present invention is also equipped with a metal polishing sheet, through the high-speed rotation and movement of the electromagnet, the metal polishing sheet can quickly polish the surface of the screw.

Owner:佛山市掌拓精密科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com