Method for cleaning a vacuum pump

A vacuum pump and cleaning technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the troublesome and time-consuming problems of cleaning vacuum pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

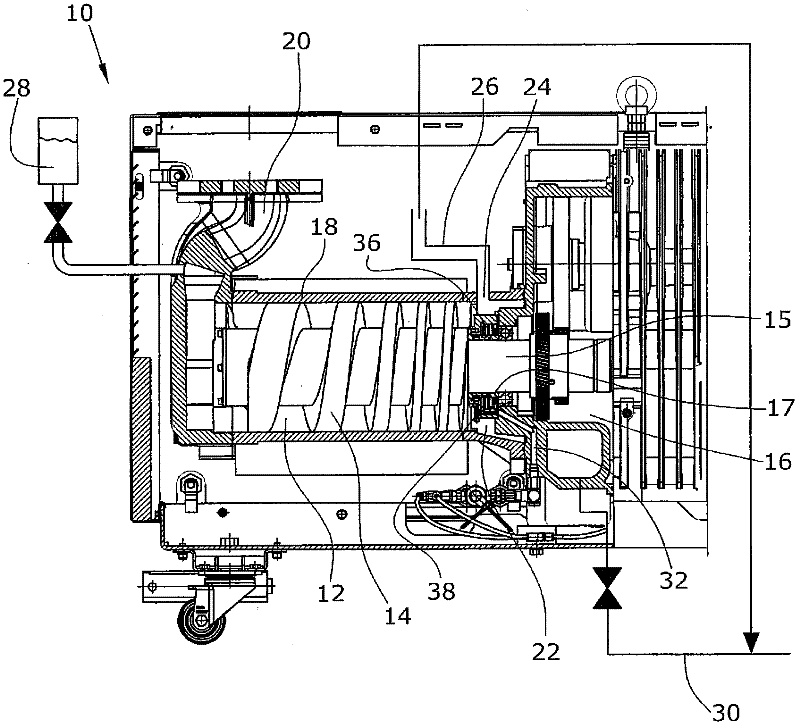

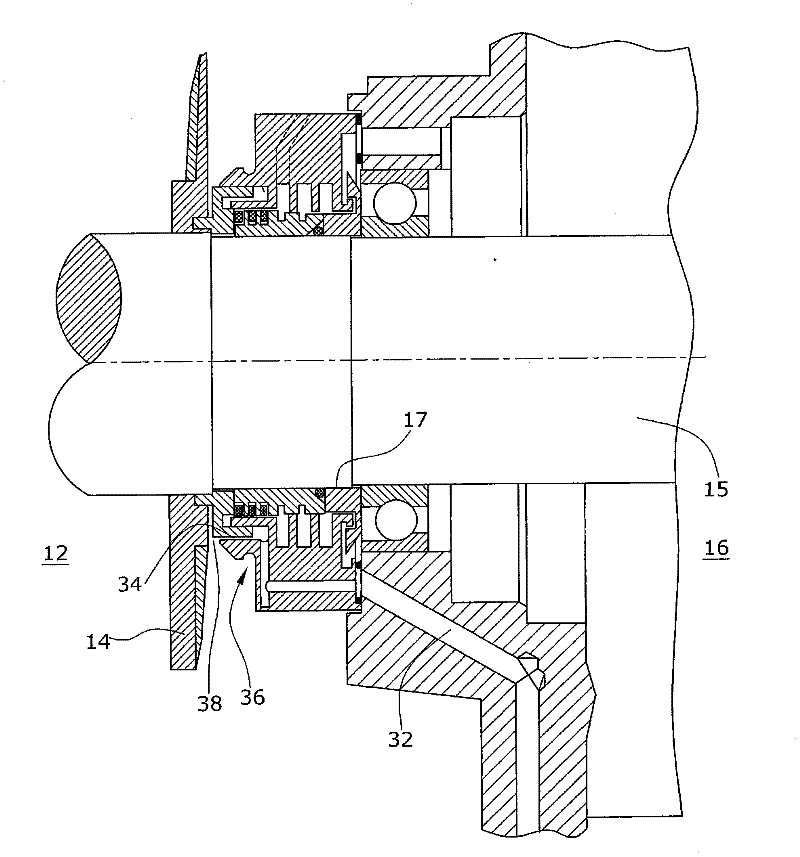

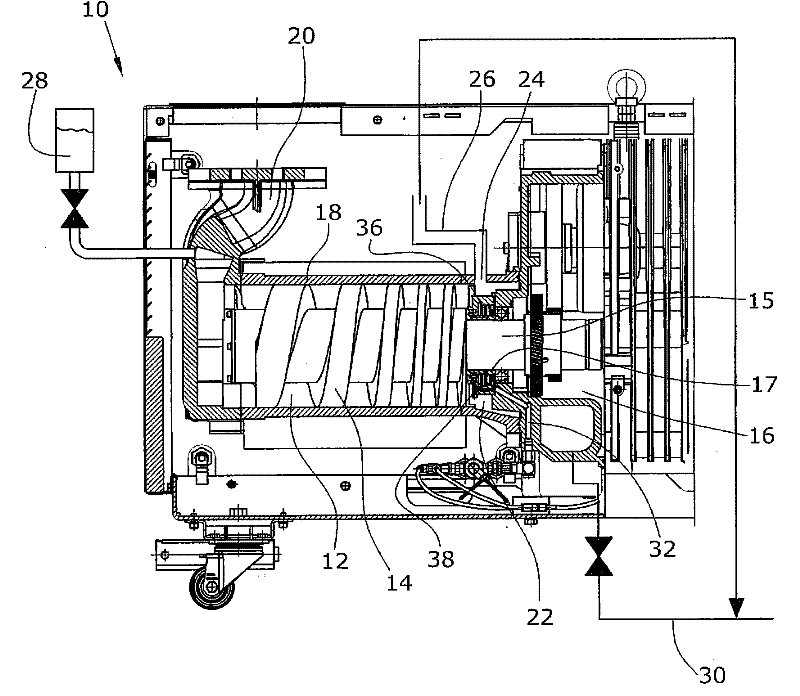

[0017] The illustrated vacuum pump 10 comprises a pump chamber 12 (suction chamber) in which a rotor 14 is supported for axial compression. The rotor 14 is driven via a transmission arranged outside the pump chamber 12 and contained in a transmission compartment 16 . The pump chamber 12 is enclosed by a housing 18 . Housing 18 has a pump chamber inlet 20 and a pump chamber outlet 22 . The shaft 15 of the rotor 14 enters the transmission compartment 16 from the pump chamber 12 through a passage 17 between the housing 18 and the transmission compartment 16 . exist figure 2 Channel 17 is shown in detail in .

[0018] A degassing opening 24 is formed in the top of the housing, and a degassing duct 26 is provided on the degassing opening 24 . The degassing pipe 26 is connected with the exhaust line 30 , and the exhaust line 30 is connected with the pump chamber outlet 22 .

[0019] When the vacuum pump is operated with water vapor and diethylzinc, these substances react as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com