Method for cleaning glass element

A component and glass technology, applied in the field of glass component cleaning, can solve the problems of glass component surface scratches, large sewage discharge, poor polishing powder removal effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Specific steps are as follows:

[0088] 1) Provide polished glass components, the polishing powder used is: cerium oxide.

[0089] 2) Soak the glass element obtained in step 1) in an aqueous solution of citric acid with a mass concentration of 8% for 30 minutes, and then take it out, wherein the soaking temperature is 25°C.

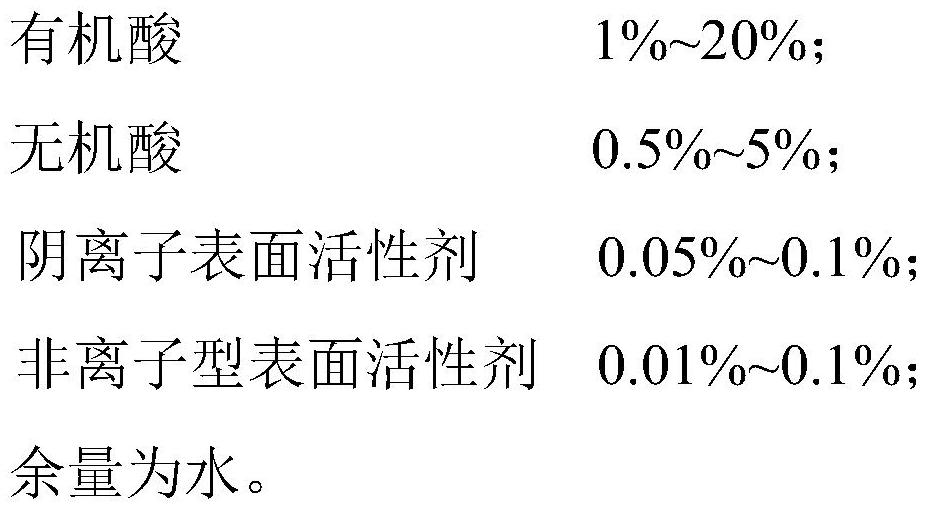

[0090] 3) The glass element obtained in step 2) is placed in an acid cleaning solution, and the first ultrasonic treatment and the second ultrasonic treatment are successively carried out; wherein, the frequency of the first ultrasonic treatment is 28KHz; the ultrasonic time is 30min, and the ultrasonic temperature 45°C; the frequency of the second ultrasonic treatment is 40KHz; the ultrasonic time is 30min, and the ultrasonic temperature is 45°C; the composition of the acid cleaning solution is as follows:

[0091]

[0092]

[0093] Among them, the nonionic surfactant is nonylphenol polyoxyethylene ether; the anionic surfactant is a mixture...

Embodiment 2

[0099] Specific steps are as follows:

[0100] 1) Provide polished glass components, the polishing powder used is: cerium oxide.

[0101] 2) Soak the glass element obtained in step 1) in an aqueous solution of citric acid with a mass concentration of 8% for 30 minutes, and then take it out, wherein the soaking temperature is 25°C.

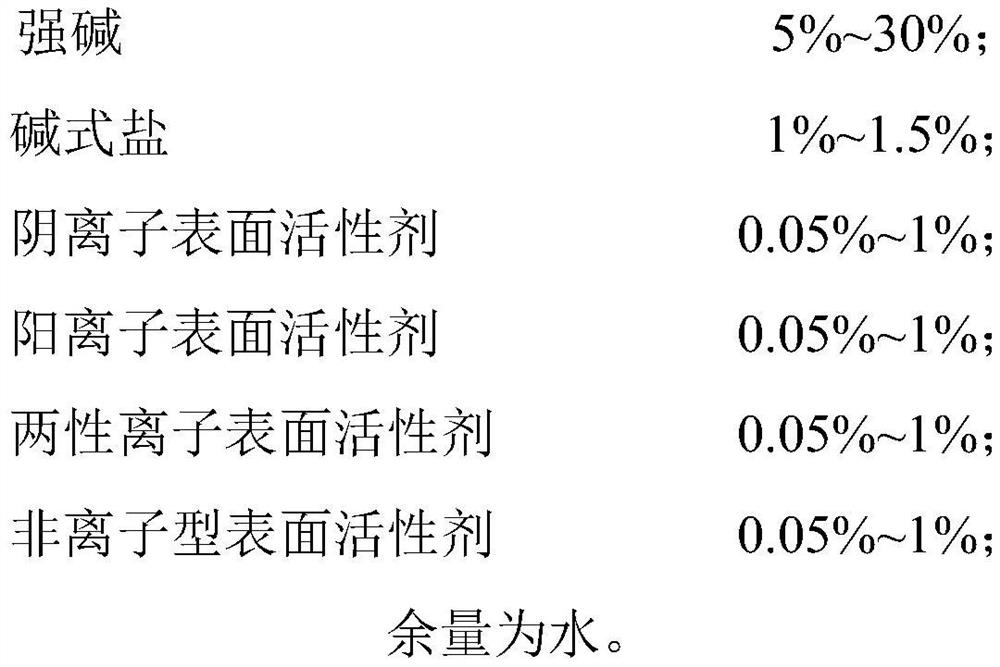

[0102] 3) The glass element obtained in step 2) is placed in an acid cleaning solution, and the first ultrasonic treatment and the second ultrasonic treatment are successively carried out; wherein, the frequency of the first ultrasonic treatment is 20KHz; the ultrasonic time is 30min, and the ultrasonic temperature 45°C; the frequency of the second ultrasonic treatment is 70KHz; the ultrasonic time is 30min, and the ultrasonic temperature is 45°C; the composition of the acid cleaning solution is as follows:

[0103]

[0104] Among them, the nonionic surfactant is nonylphenol polyoxyethylene ether; the anionic surfactant is a mixture of sodium dod...

Embodiment 3

[0110] Specific steps are as follows:

[0111] 1) Provide polished glass components, the polishing powder used is: cerium oxide.

[0112] 2) Soak the glass element obtained in step 1) in an aqueous solution of citric acid with a mass concentration of 8% for 30 minutes, and then take it out, wherein the soaking temperature is 25°C.

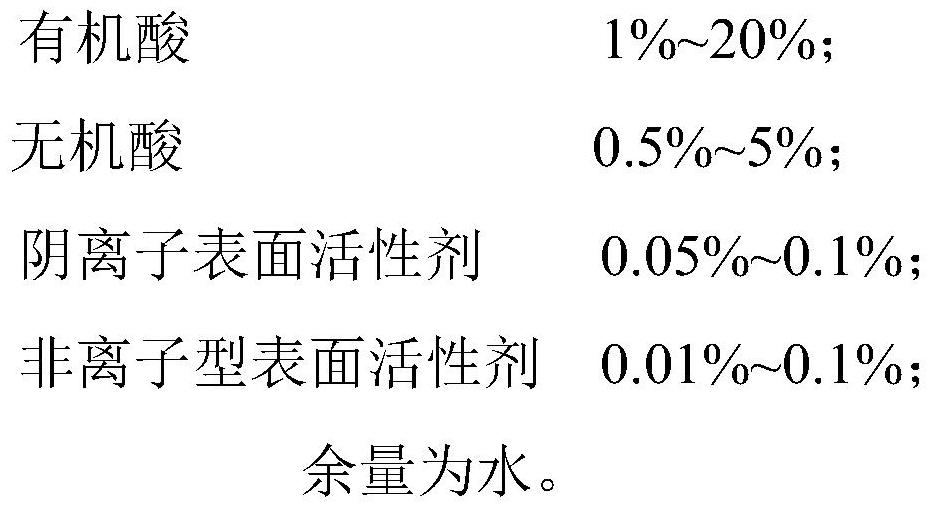

[0113] 3) The glass element obtained in step 2) is placed in an acid cleaning solution, and the first ultrasonic treatment and the second ultrasonic treatment are successively carried out; wherein, the frequency of the first ultrasonic treatment is 10KHz; the ultrasonic time is 30min, and the ultrasonic temperature 45°C; the frequency of the second ultrasonic treatment is 50KHz; the ultrasonic time is 30min, and the ultrasonic temperature is 45°C; the composition of the acid cleaning solution is as follows:

[0114]

[0115] Among them, the nonionic surfactant is nonylphenol polyoxyethylene ether; the anionic surfactant is a mixture of sodium d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com