Device for removing suspended matters after printing and dyeing sewage treatment

A printing and dyeing sewage and cleaning device technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve problems such as cleaning troubles, and achieve the effect of simple cleaning methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

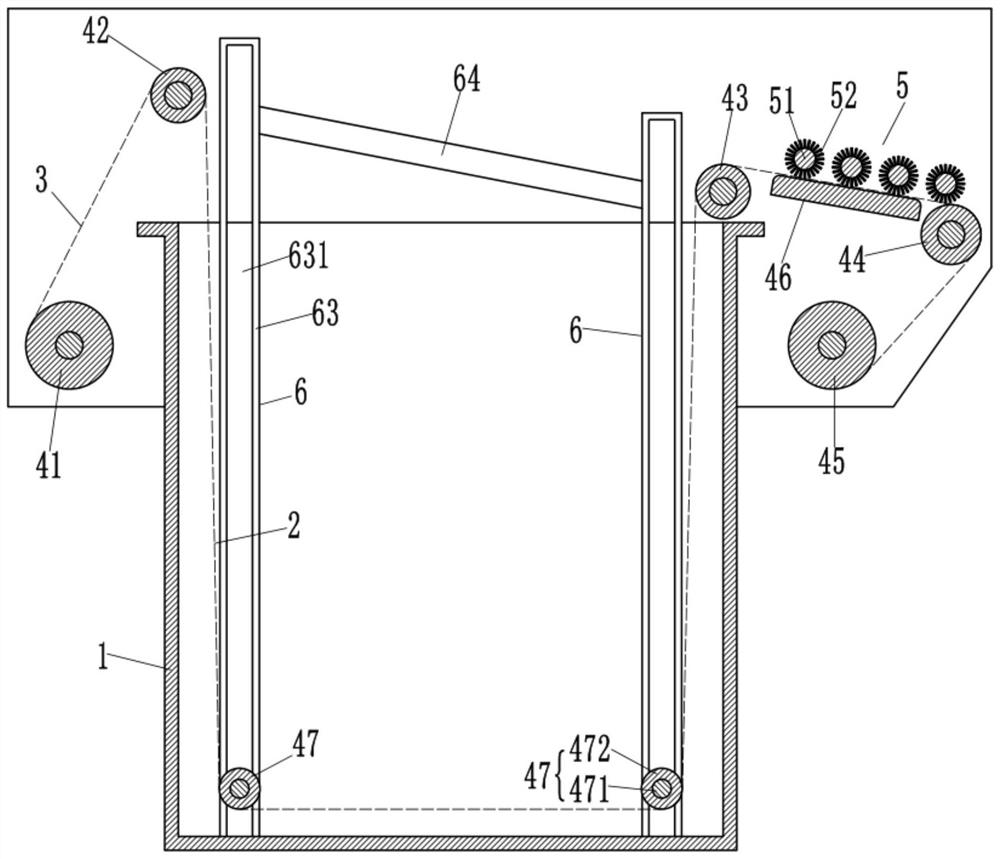

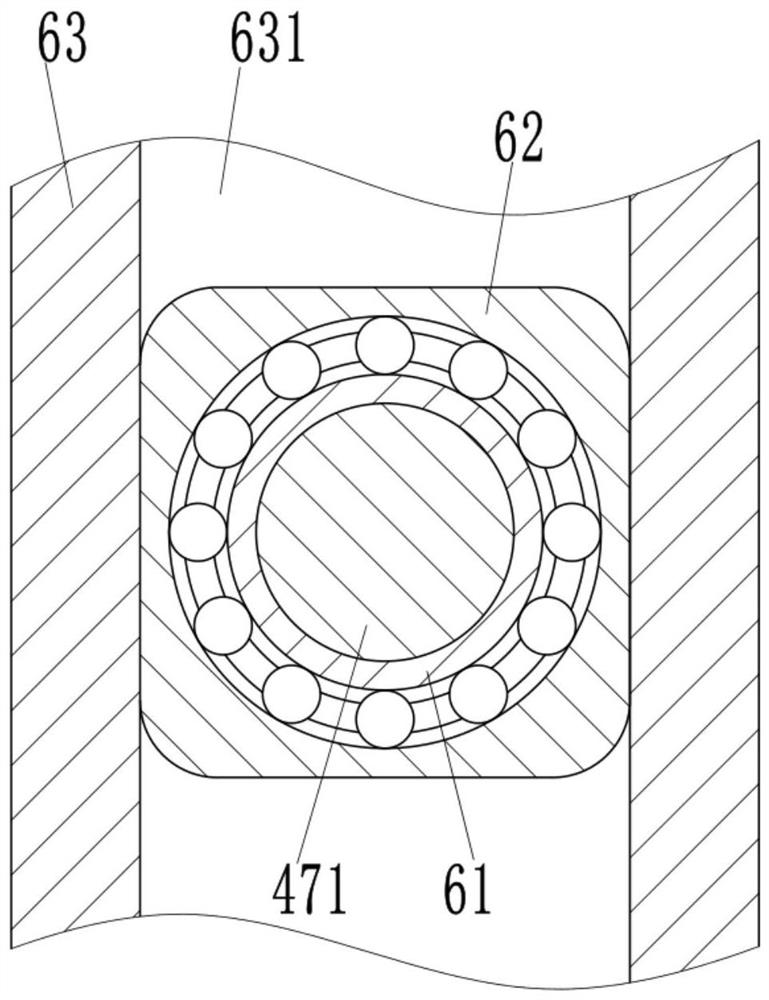

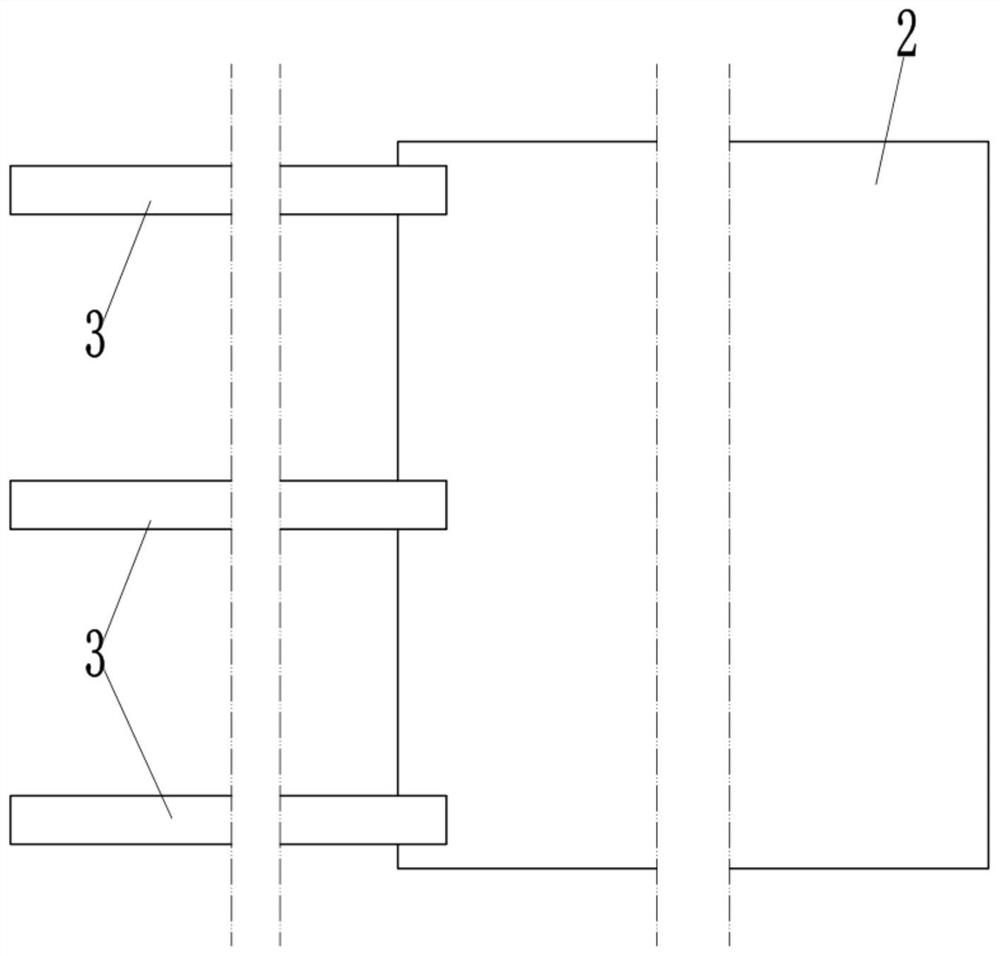

[0017] Examples, see e.g. Figure 1 to Figure 3 As shown, a device for removing suspended solids after printing and dyeing sewage treatment includes a reaction tank 1 and a filter cloth 2, one end of the filter cloth 2 is fixed with a plurality of linear and uniform cloth strips 3, and the cloth strips 3 are wound on the unwinding On the wheel 41, the other end of the filter cloth 2 is wound on the rewinding wheel 45 successively around the protruding end of the first transmission roller 42, two gravity rollers 47, the second transmission roller 43 and the third transmission roller 44; Above the middle of the second transmission roller 43 and the third transmission roller 44, a clearing mechanism 5 is provided; each gravity roller 42 is provided with a vertical guide mechanism 6;

[0018] The unwinding wheel 41, the first driving roller 42, two gravity rollers 47, the second driving roller 43, the third driving roller 44 and the winding wheel 45 are all hinged on the frame, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com