Heat conduction coefficient and contact thermal resistance testing device

A technology of contact thermal resistance and thermal conductivity, which is applied in the field of devices for accurately measuring material thermal conductivity and contact thermal resistance, can solve the problems of temperature measurement uncertainty error, difficult interface contact thermal resistance measurement accuracy, etc., to improve test accuracy, Effects of reducing heat loss and eliminating uncertainty errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

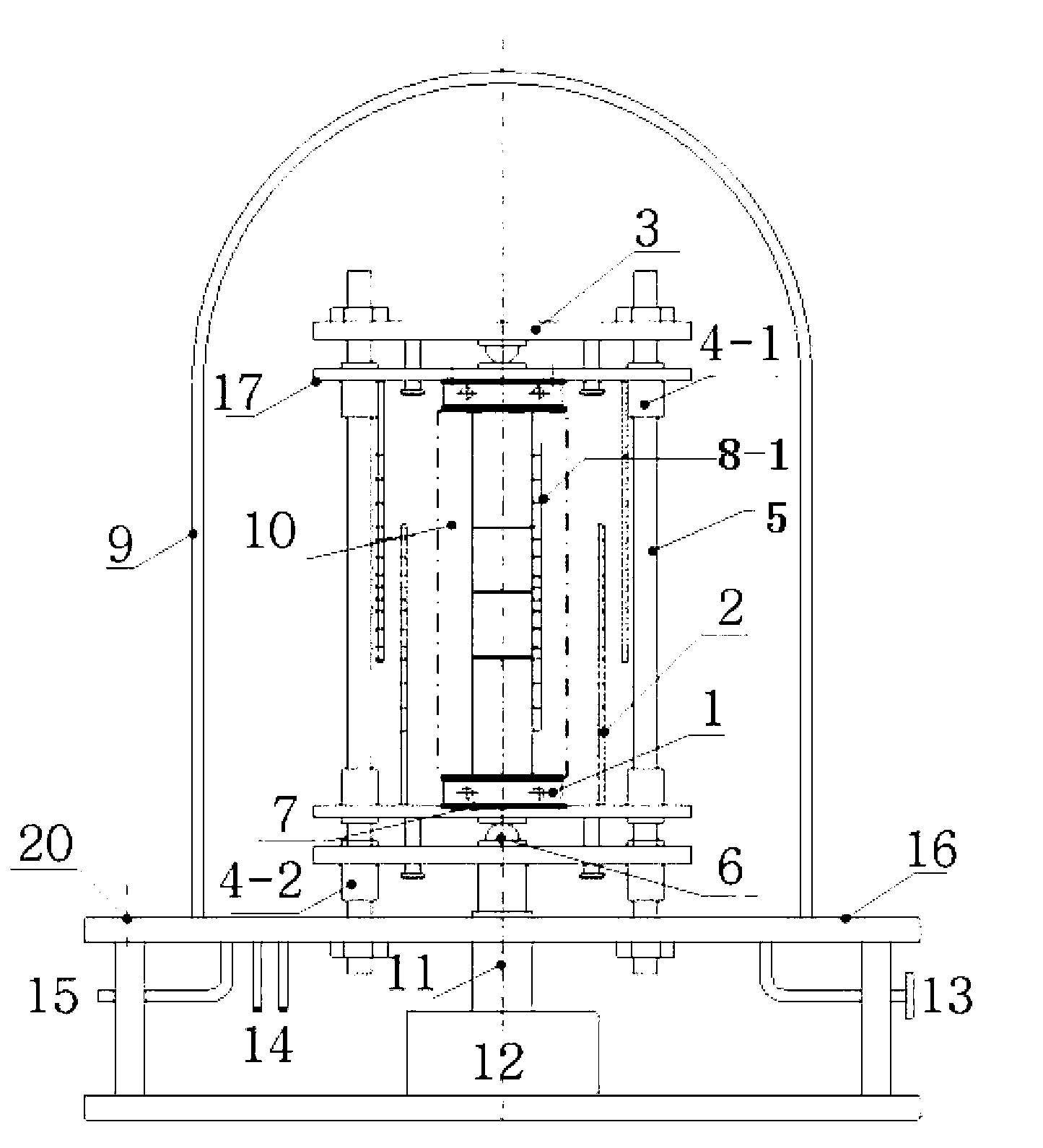

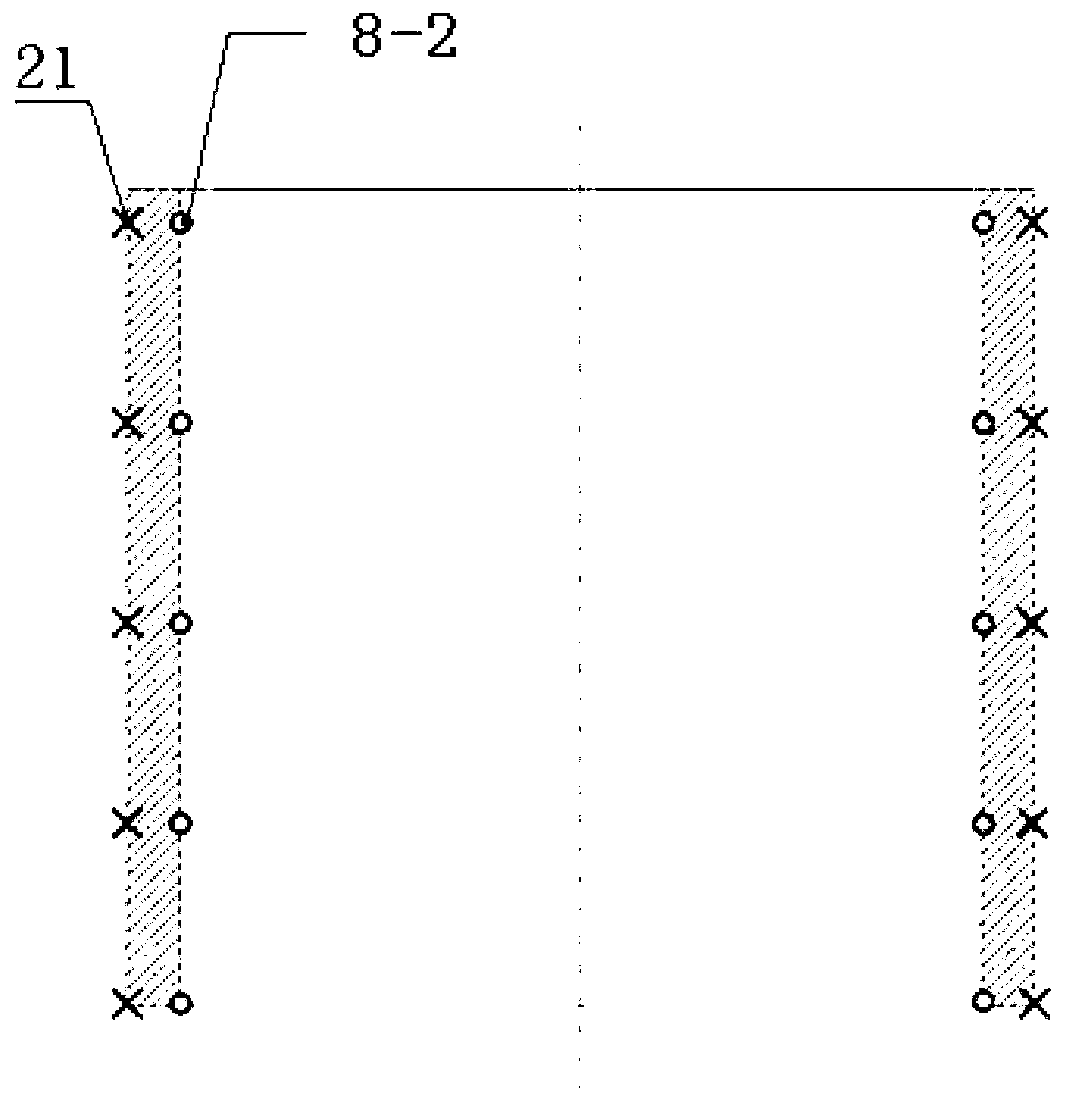

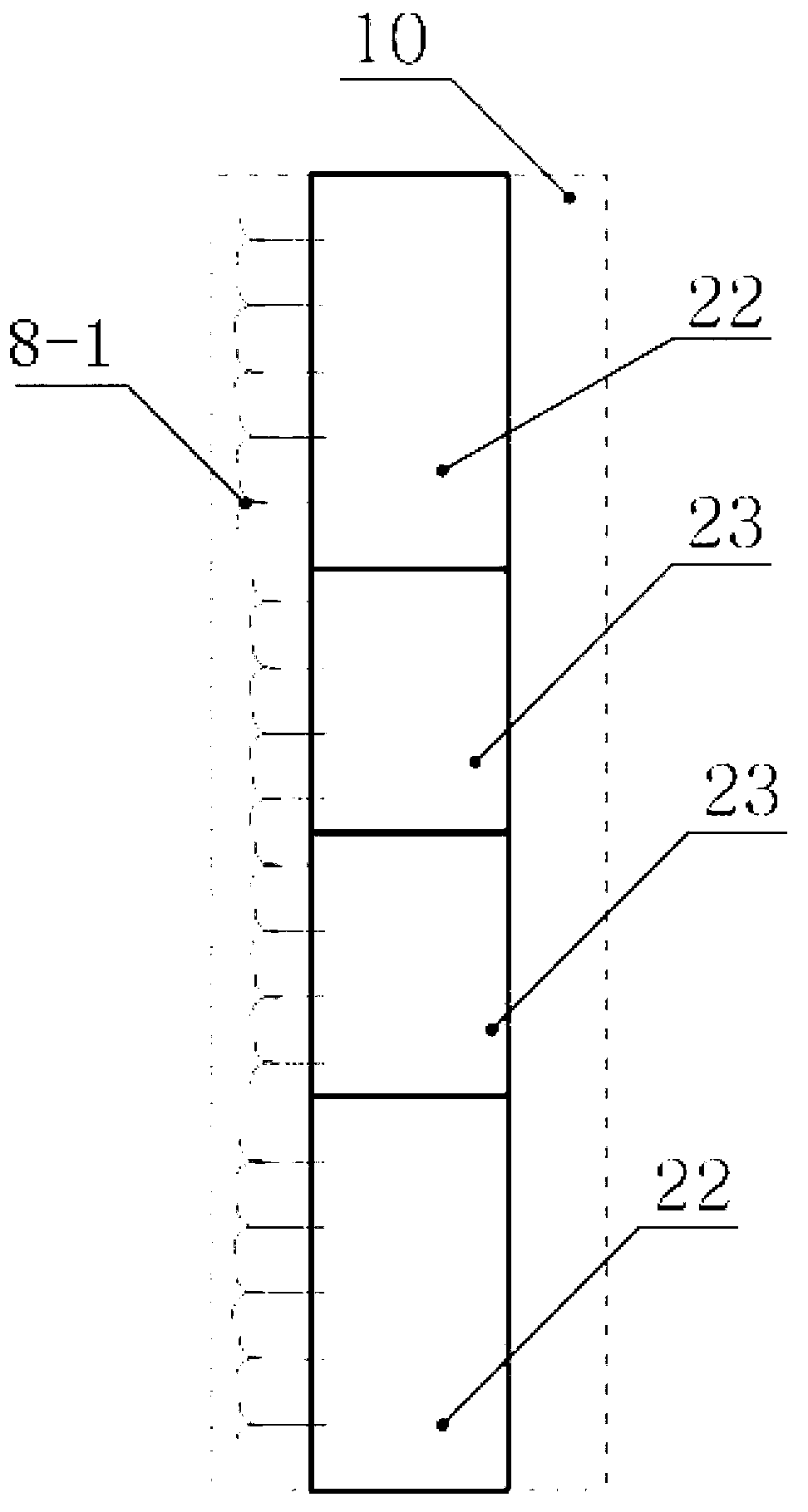

[0012] combine figure 1 , figure 2 and image 3 , a thermal conductivity and thermal contact resistance testing device, including a control system, a bracket 3, a first ball bushing 4-1, a second ball bushing 4-2, a sliding screw 5, an orientation steel ball and a pressure sensor 6, an auxiliary Heater 7, first temperature sensor 8-1, first temperature sensor 8-2, vacuum cover 9, test piece test area 10, stress loading device, vacuum exhaust port 13, water inlet and outlet 14, data acquisition system, sealed chassis 16, support plate 17, level adjustment rod 20, heating wire 21.

[0013] The stress loading device is composed of a hydraulic cylinder 11 and a pressure power source 12. The hydraulic cylinder 11 is located above the pressure power source 12; the data acquisition system is composed of a first temperature sensor 8-1 and a sealed data joint 15. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com