Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

145 results about "Drilled shaft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A drilled shaft is constructed by drilling a cylindrical borehole to design diameter and depth, lowering reinforcing steel (rebar) into the drilled shaft, and then filling the shaft with concrete. The finished foundation element resists compression, tension, and lateral loads.

Construction method of hydroelectric power station surge chamber vertical shaft under soft rock geological condition

ActiveCN101349064ASimple designEnsure safetyArtificial islandsUnderwater structuresSteam-electric power stationGeomorphology

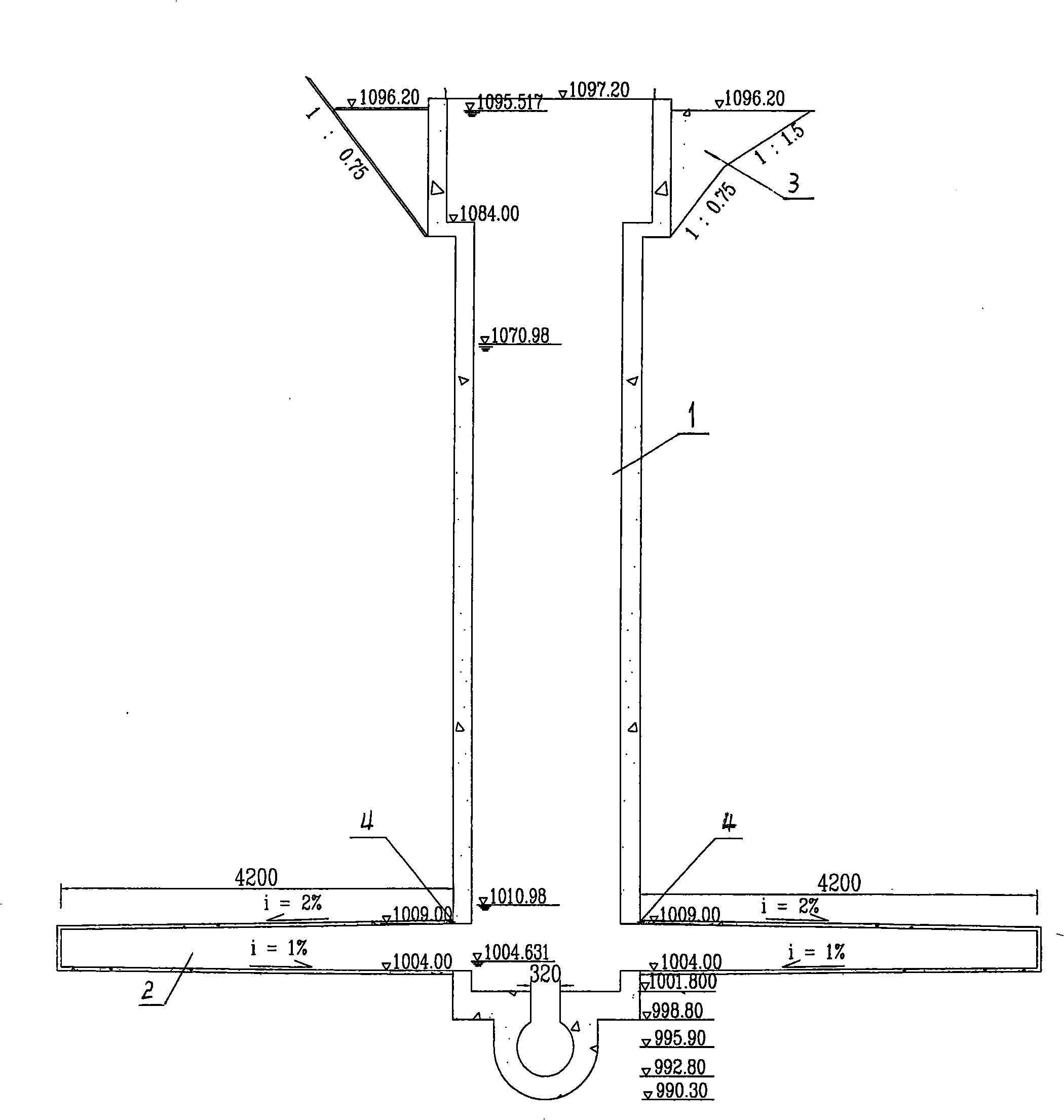

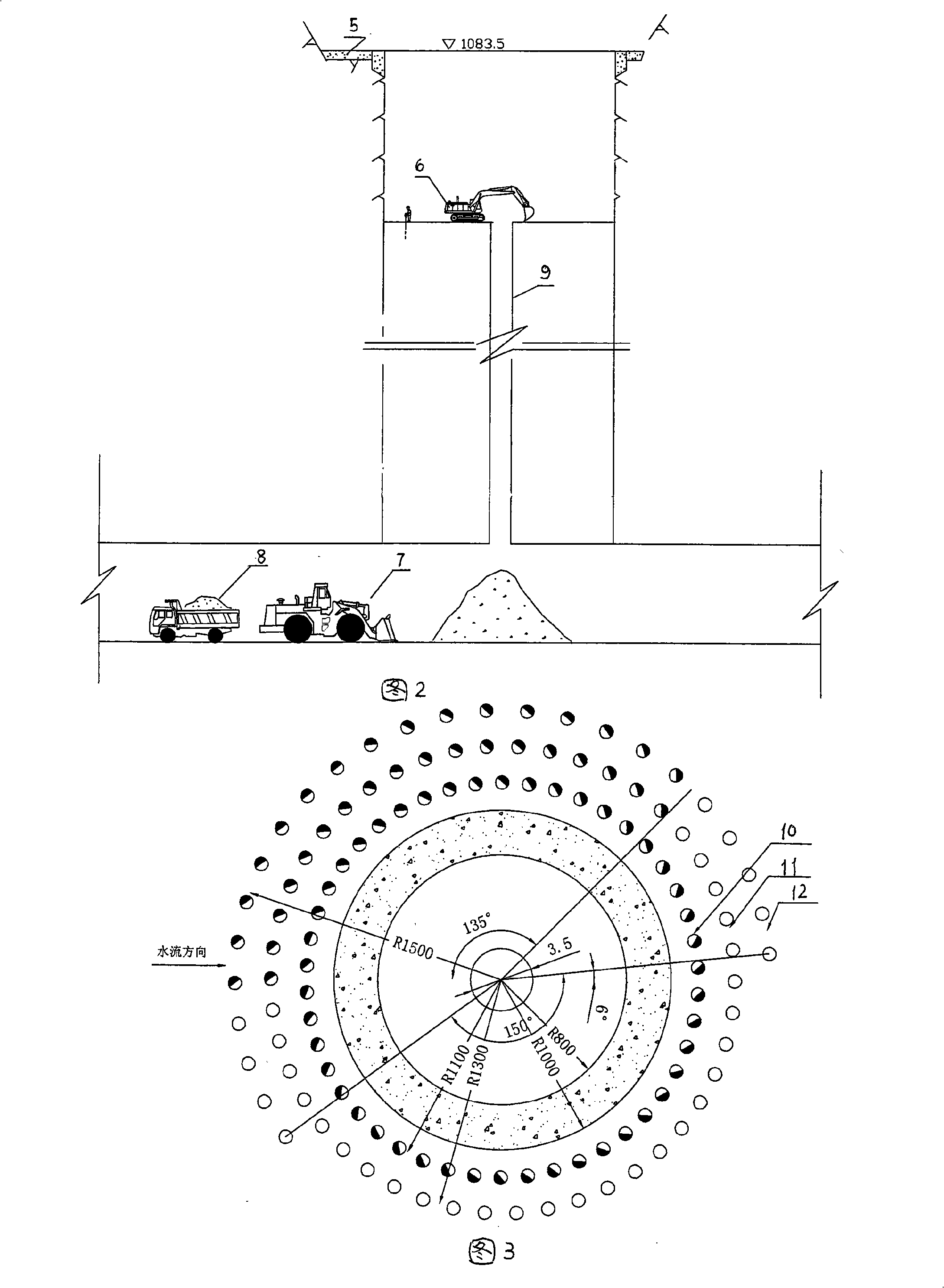

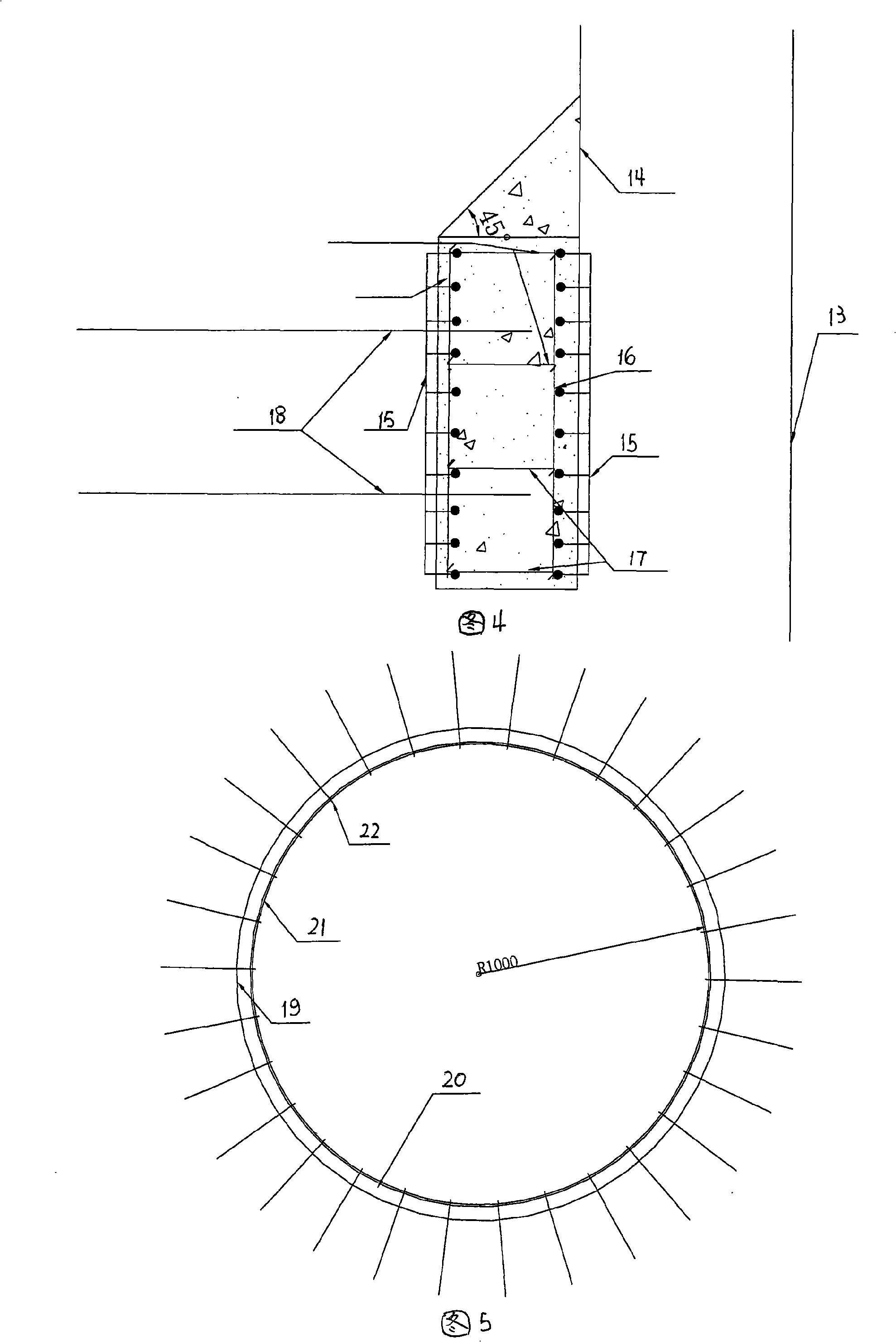

The invention relates to a method for constructing a drilled shaft of a surge chamber in a hydropower station under the condition of weak rock geology; the excavation diameter of the drilled shaft is more than or equal to 20 meters; and the depth of the drilled shaft is more than or equal to 50 meters. The method comprises the following steps: firstly, a safe prestress reinforcing measure is adopted; a prestress anchor rope is arranged in a side slope of the drilled shaft; the deep rock holes in the periphery of the drilled shaft are subjected to consolidation and grouting; the periphery of the drilled shaft is cast with reinforced concrete for locking a mouth, etc; the construction sequence of excavating the drilled shaft comprises that: a raise-boring machine drills a guide hole of phi 216 millimeters from top to bottom; the raise-boring machine enlarges and excavates a small guide well of phi 1, 400 millimeters; a slag slipping guide well of phi 2, 500 millimeters is enlarged and excavated manually from bottom to top; and the slag slipping guide well is enlarged and excavated from top to bottom. The slag slipping guide well is excavated by manual drilling and blasting; slag is naturally slipped and mechanically loaded in the bottom of the well; a large well is enlarged and excavated through drilling and blasting by a manual air drill; and the skimmed slag in a hydraulic backhoe well slips to the bottom of a passage through the slag slipping guide well and is mechanically loaded in the bottom of the well. The construction method has the characteristics of having reasonable construction arrangement, alternately and simultaneously carrying out a plurality of construction types and saving the construction period.

Owner:SINOHYDRO BUREAU 5 +1

Hole enlargement apparatus

InactiveUS6305885B1Simple and inexpensive to manufactureEasy to disassembleThread cutting toolsWood turning toolsCombined useEngineering

A hole enlargement apparatus which uses a simple spring biased disc to center a larger hole cutter in the existing hole and a disc retention means to ensure that the disc does not fall unretrievably into the enlarged hole. The apparatus is used in conjunction with a conventional large hole cutter of the type having a toothed cylindrical cup, a hub axially secured in a bottom portion of the cup, and a pilot bit axially and removably secured through the hub and cup. The hole enlargement apparatus comprises: a guide member having a disc portion dimensioned to matingly fit within the existing hole, a rim portion connected to a rear portion of the disc portion adapted to seat on the workpiece, and a disc center guide opening dimensioned to slidingly accept a shaft the diameter of the pilot bit; a drill bit replacement shaft having a hub end portion and an opposite disc end portion; a cotter pin carried by the disc end portion of the drill replacement shaft to prevent the guide member from sliding off the disc end portion of the shaft; and, a spring to bias and maintain the disc portion in the existing hole.

Owner:LINTHICUM LEO

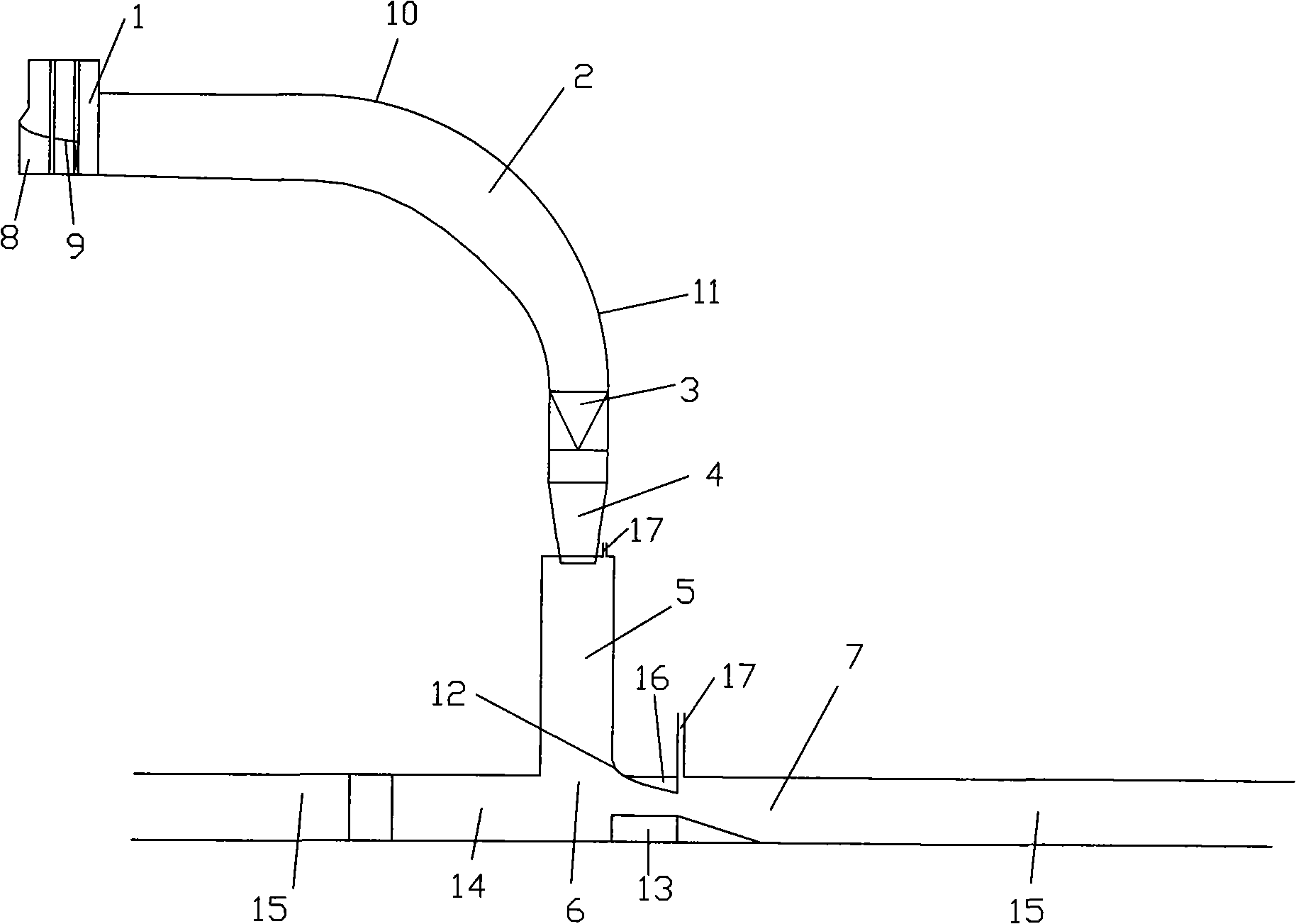

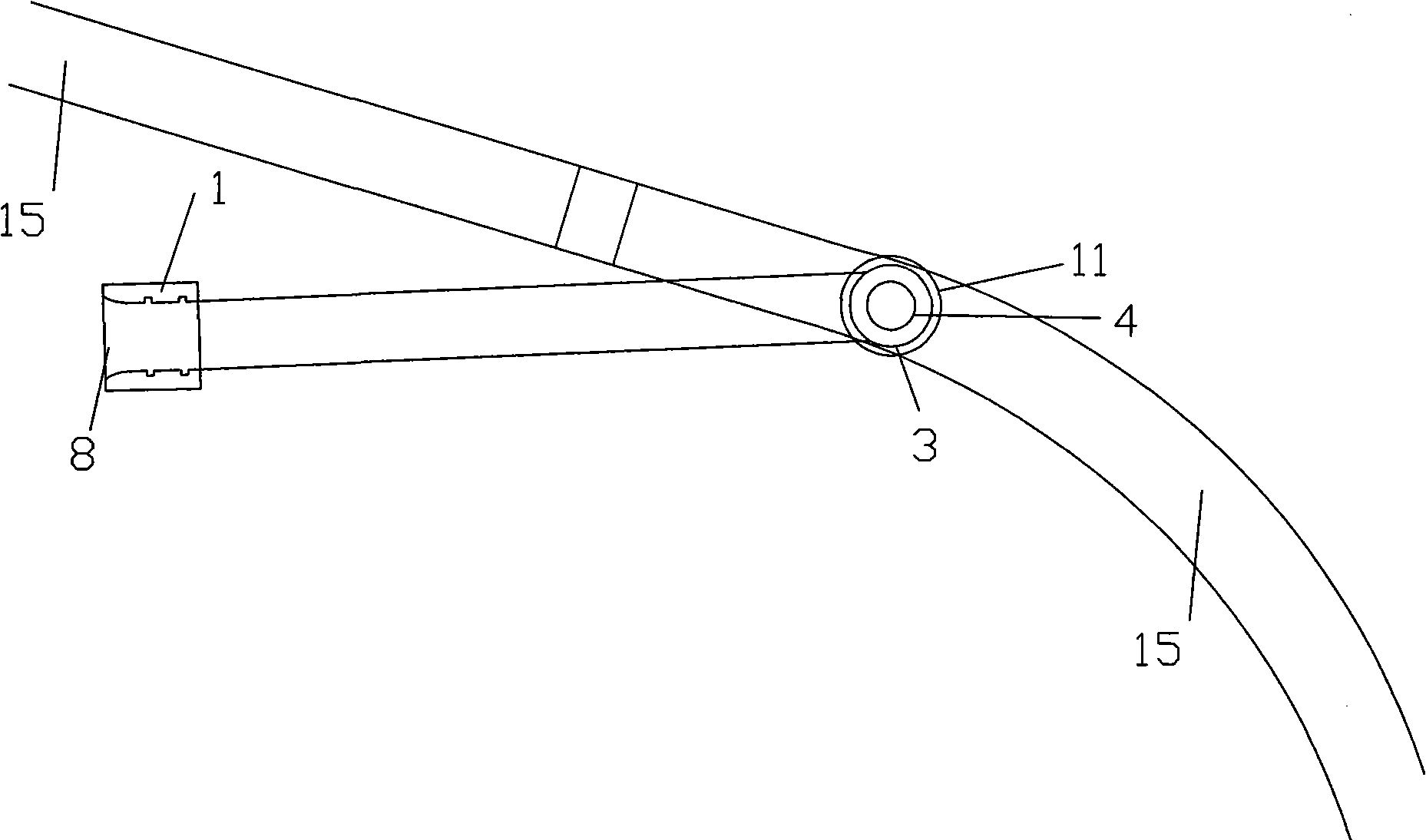

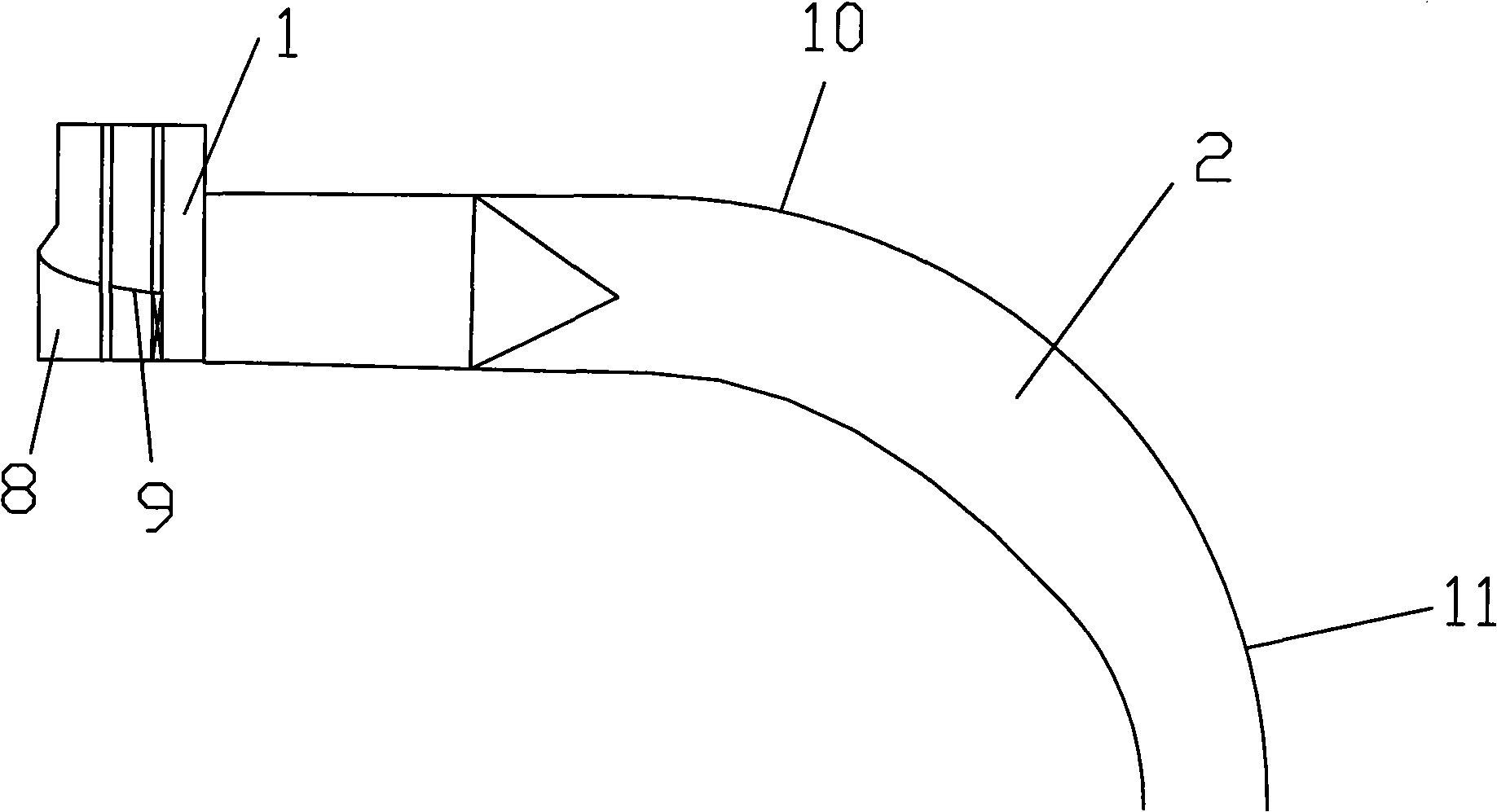

Rotational flow silo equipped with air entrainment ridge

The invention discloses a gyrating drilled shaft provided with an aeration ridge. The invention is characterized in that the gyrating drilled shaft is provided with an aeration ridge on the wall surface at the middle lower part of the drilled shaft section, the aeration ridge is formed by gradually shrinking the drilled shaft connected with the upper flat section of a flood discharging tunnel from the middle part to the middle lower part and then suddenly expanding the wall surface, and at least two aeration holes are distributed on the annular aeration ridge formed by the sudden expansion, each of the aeration holes is spliced with a vent pipe communicating with the atmosphere. The vent pipes can be selectively buried on the outer side of the gyrating drilled shaft. The gyrating drilled shaft disclosed by the invention enables near-wall water layers at the lower reaches of the aeration ridge to become into aerated water flows, thereby increasing the flow cavitation number, playing the effects of air entrainment and cavitation prevention, preventing the overflowing section at the middle lower part of the drilled shaft from being damaged by cavitation erosion, and ensuring the safe flood discharging operation of the gyrating drilled shaft.

Owner:SICHUAN UNIV

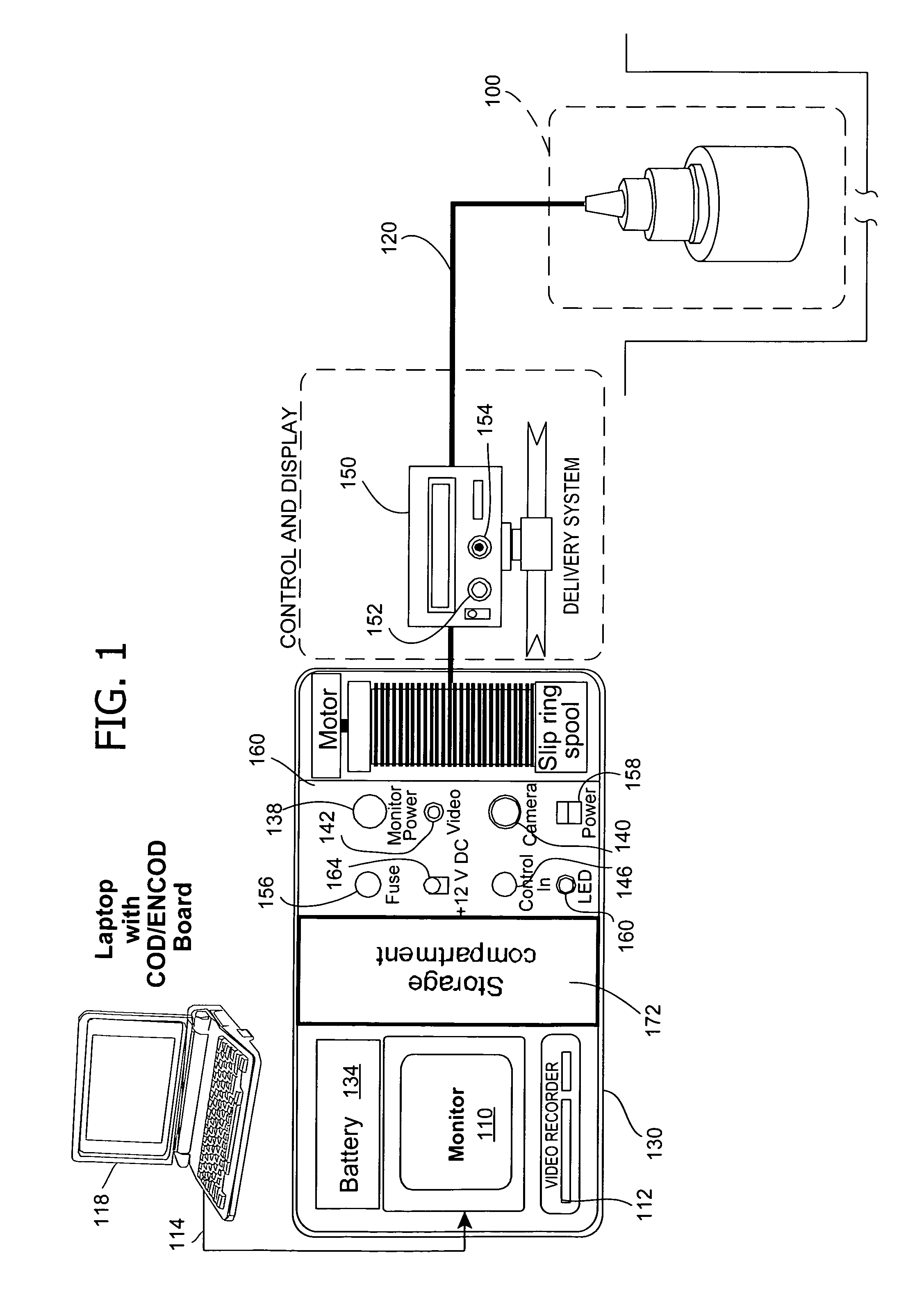

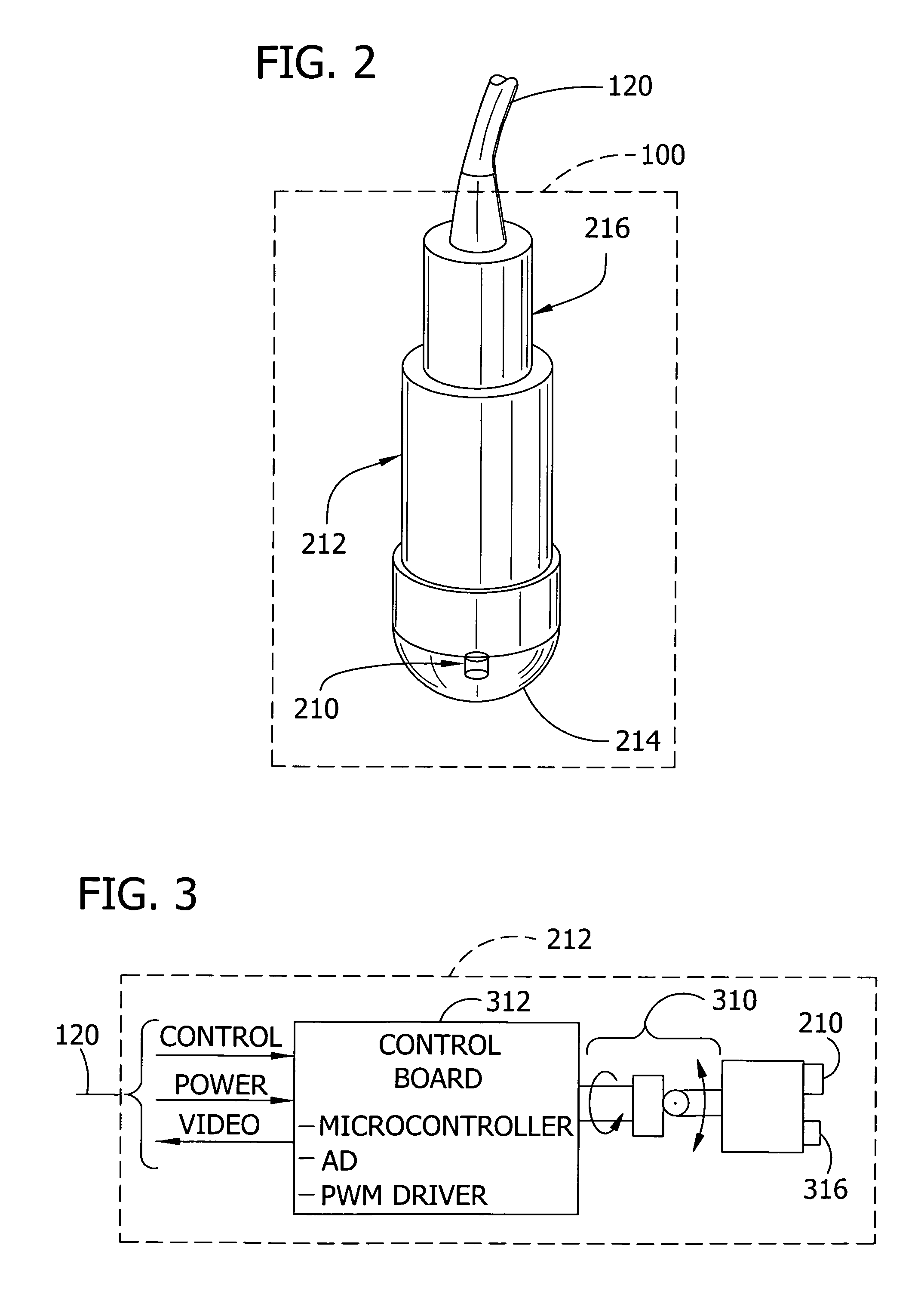

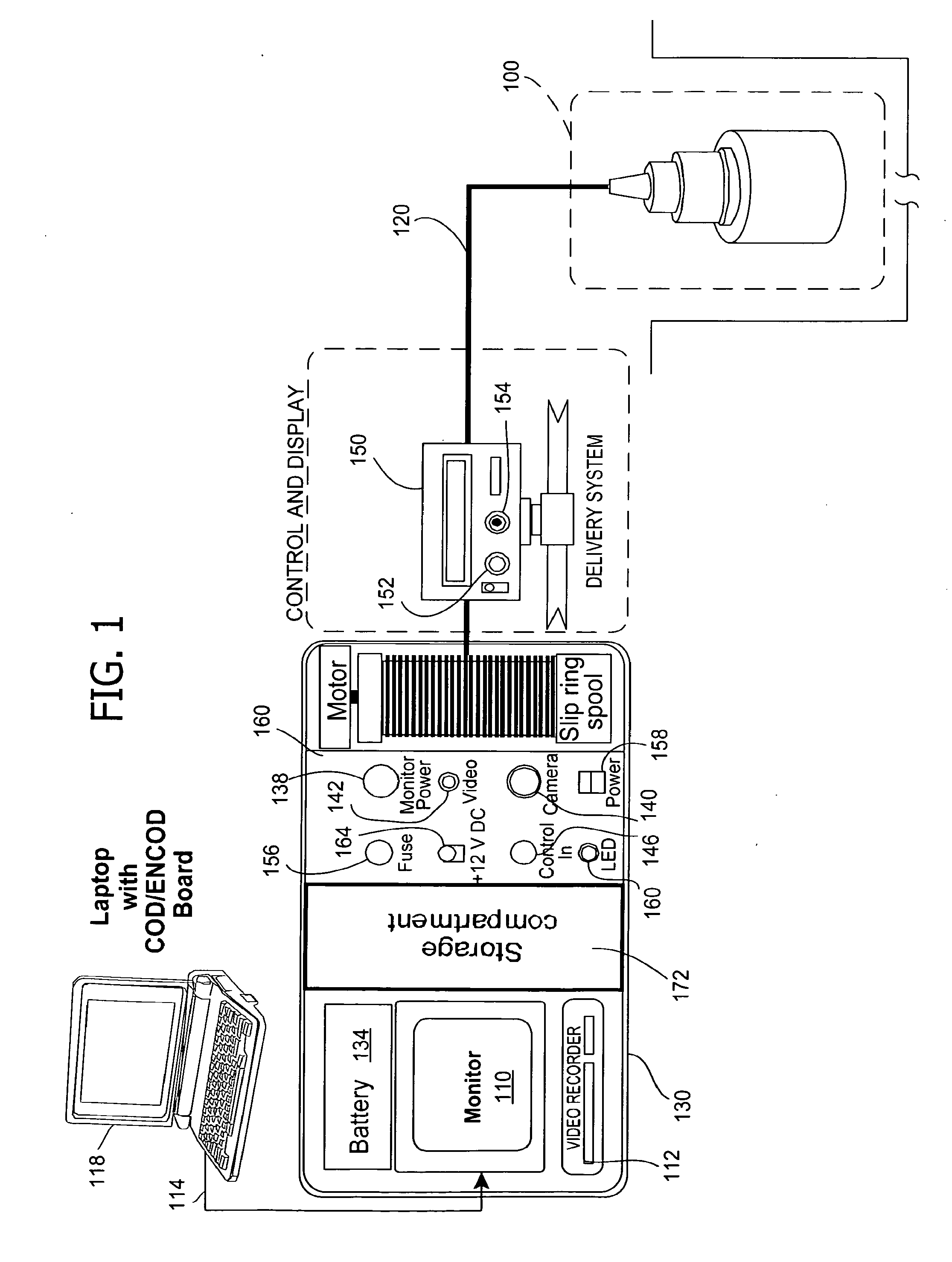

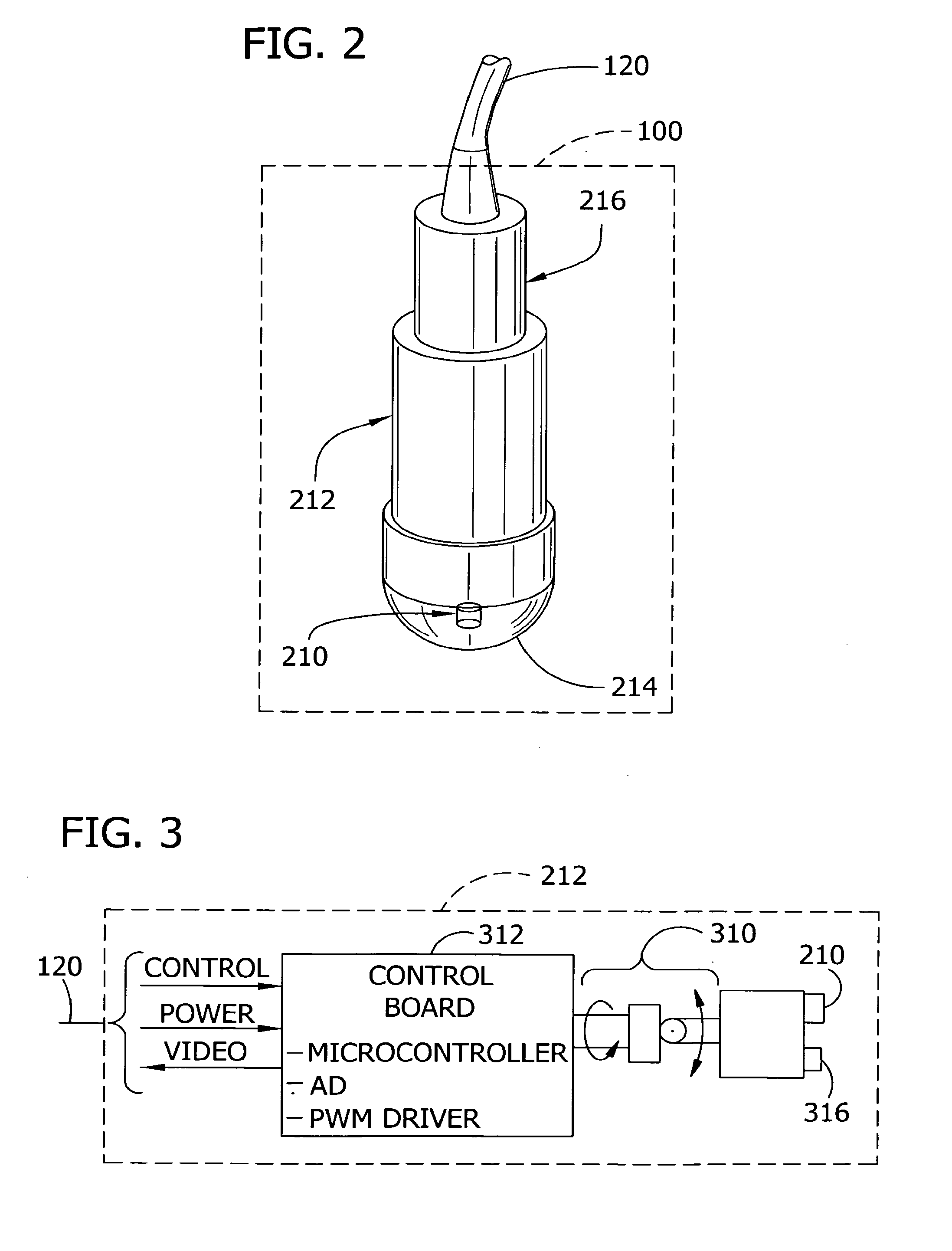

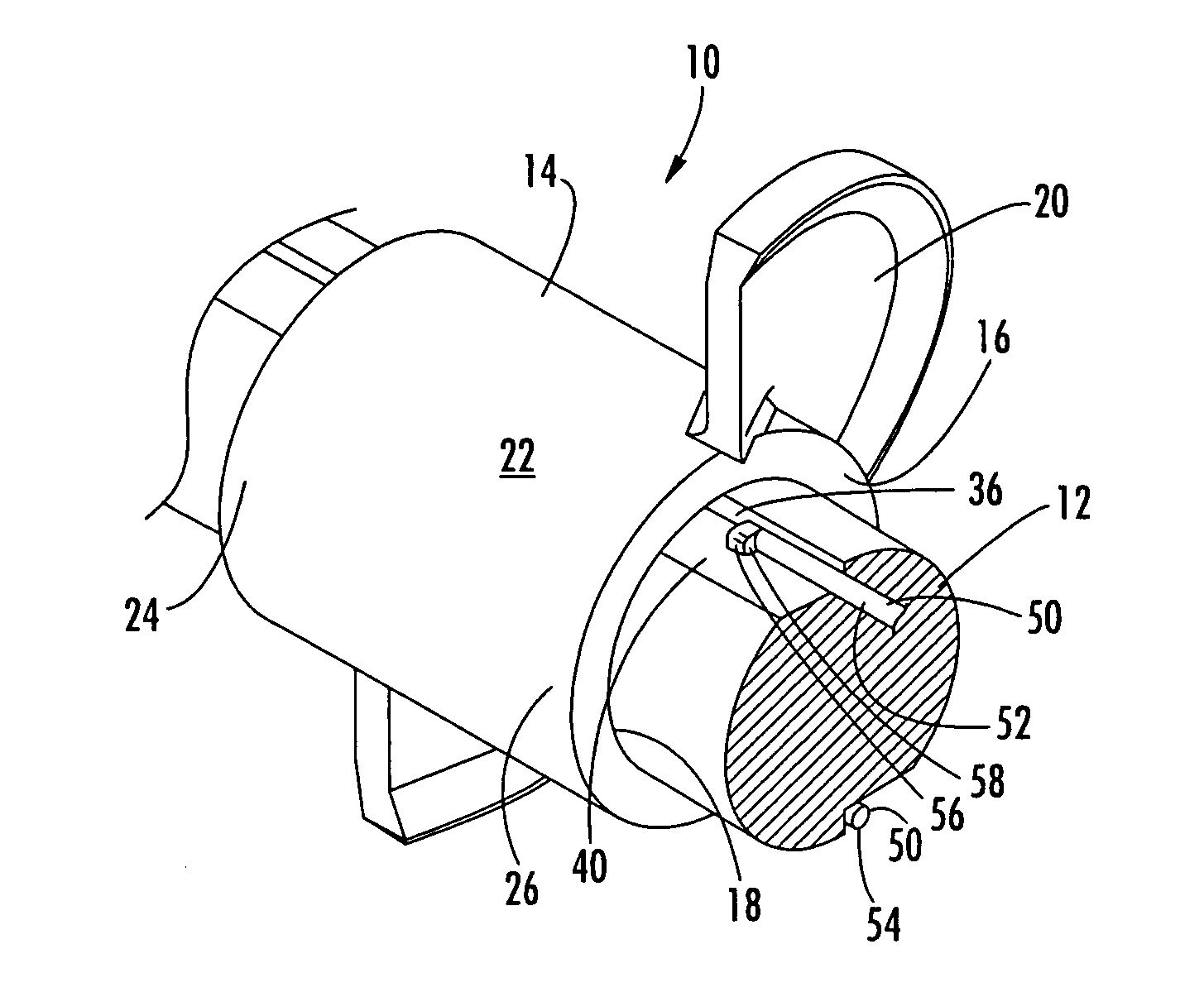

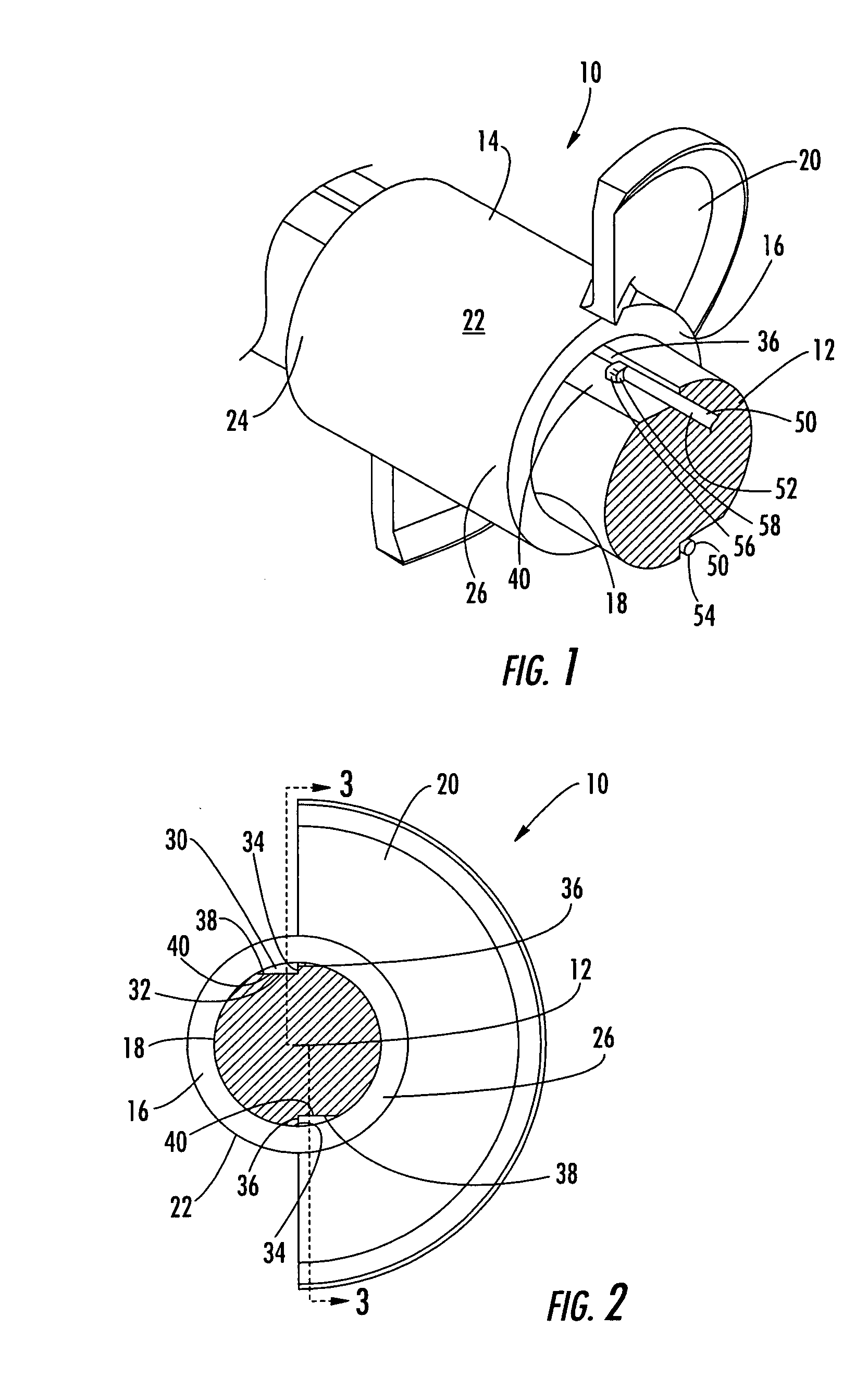

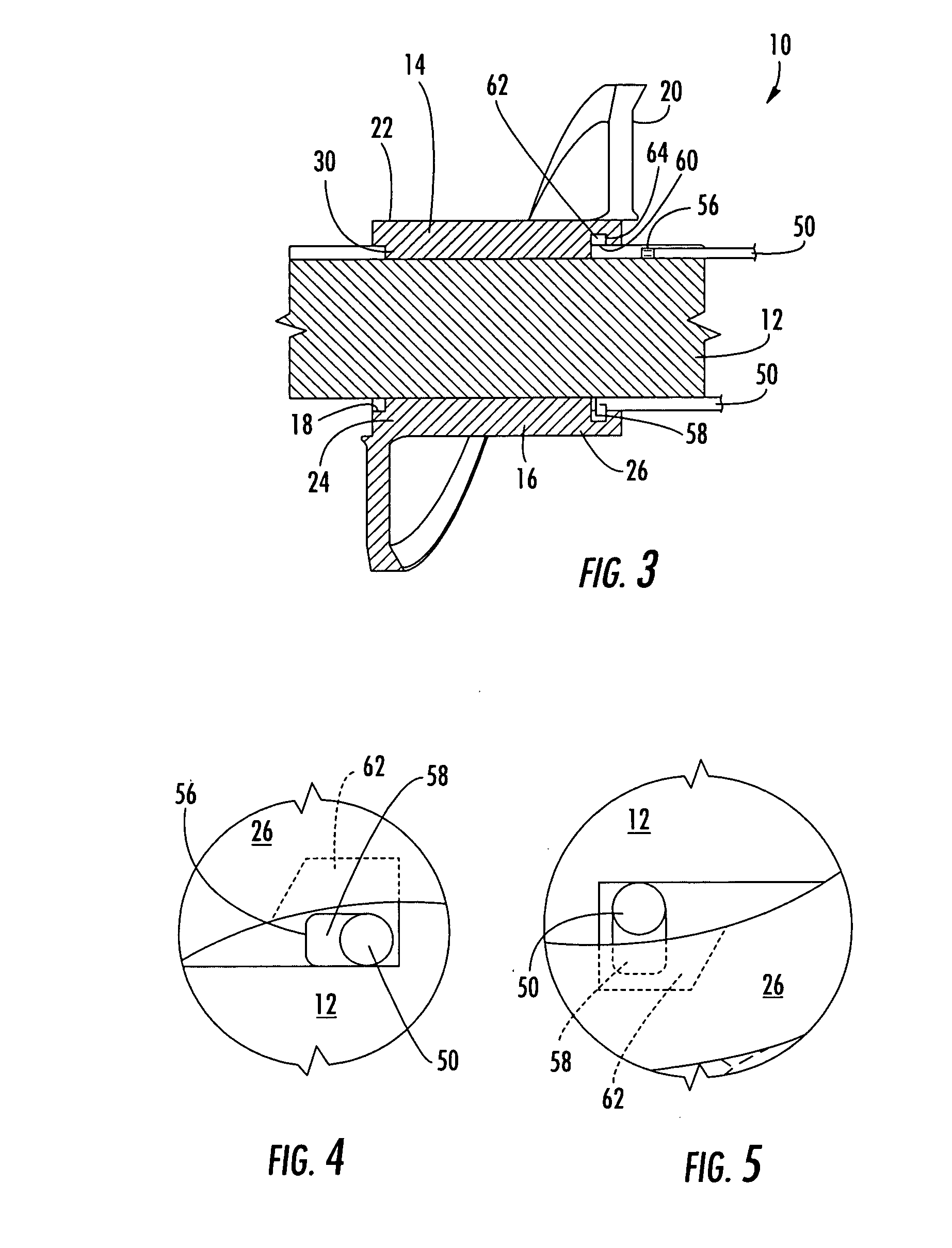

Borescope for drilled shaft inspection

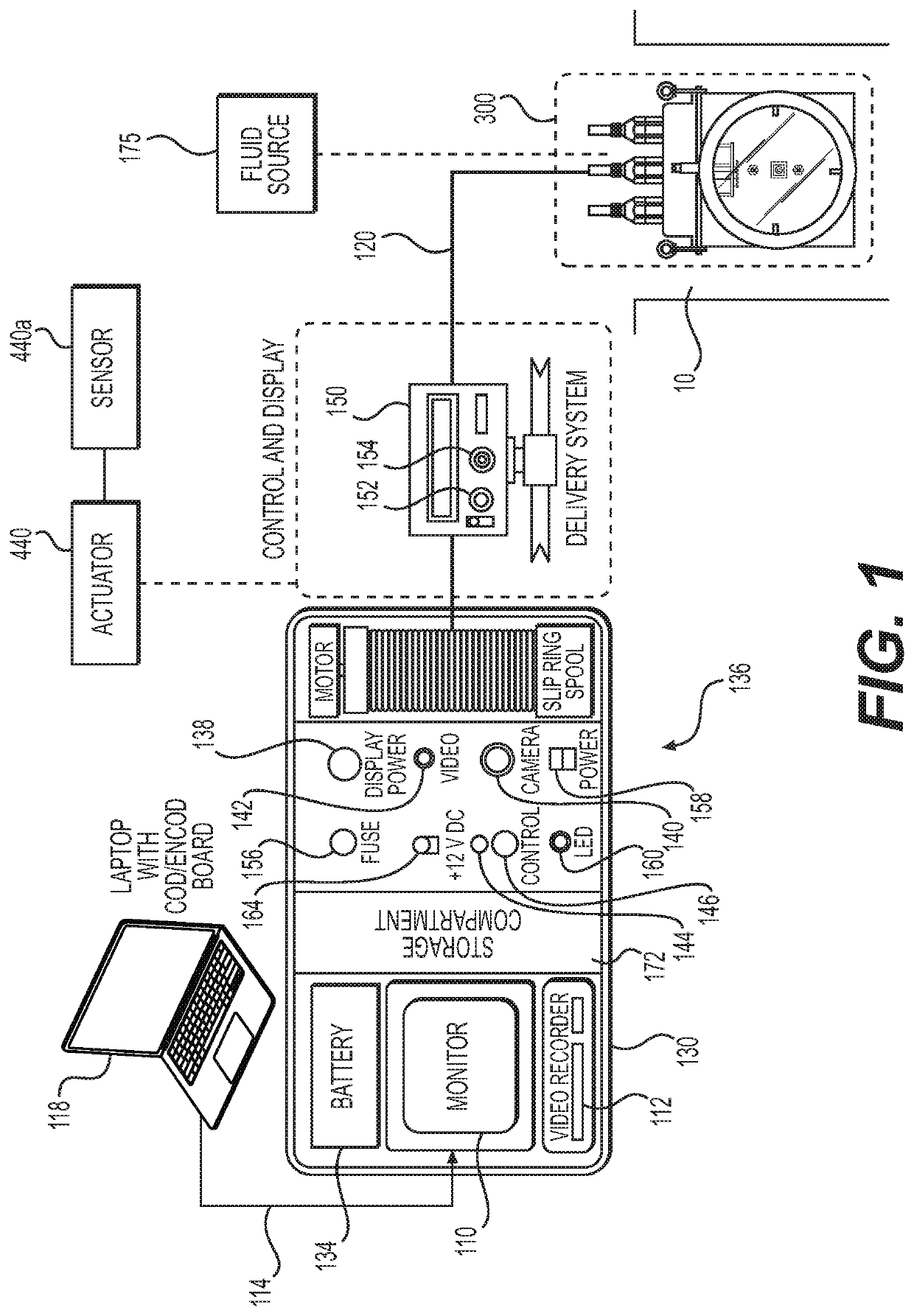

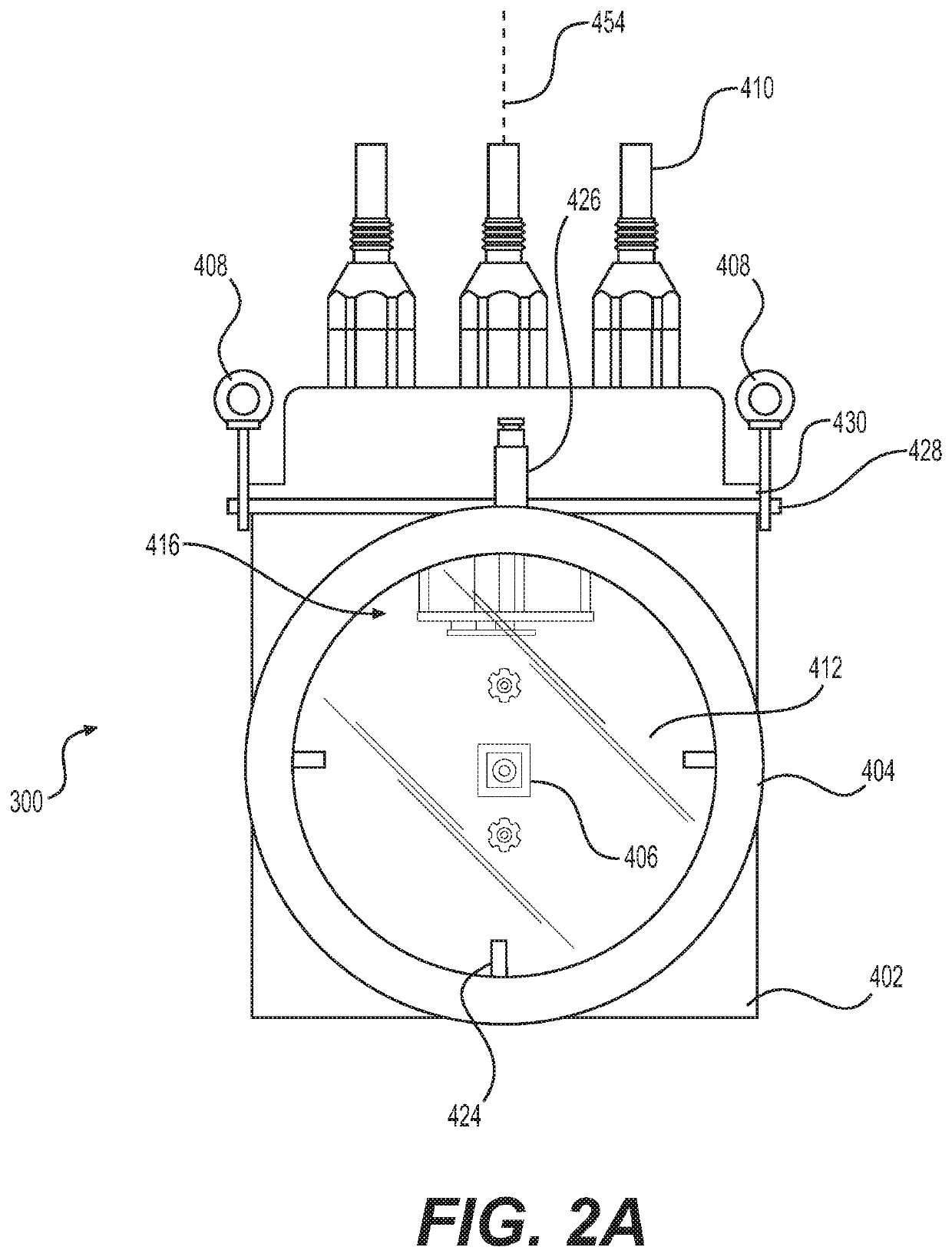

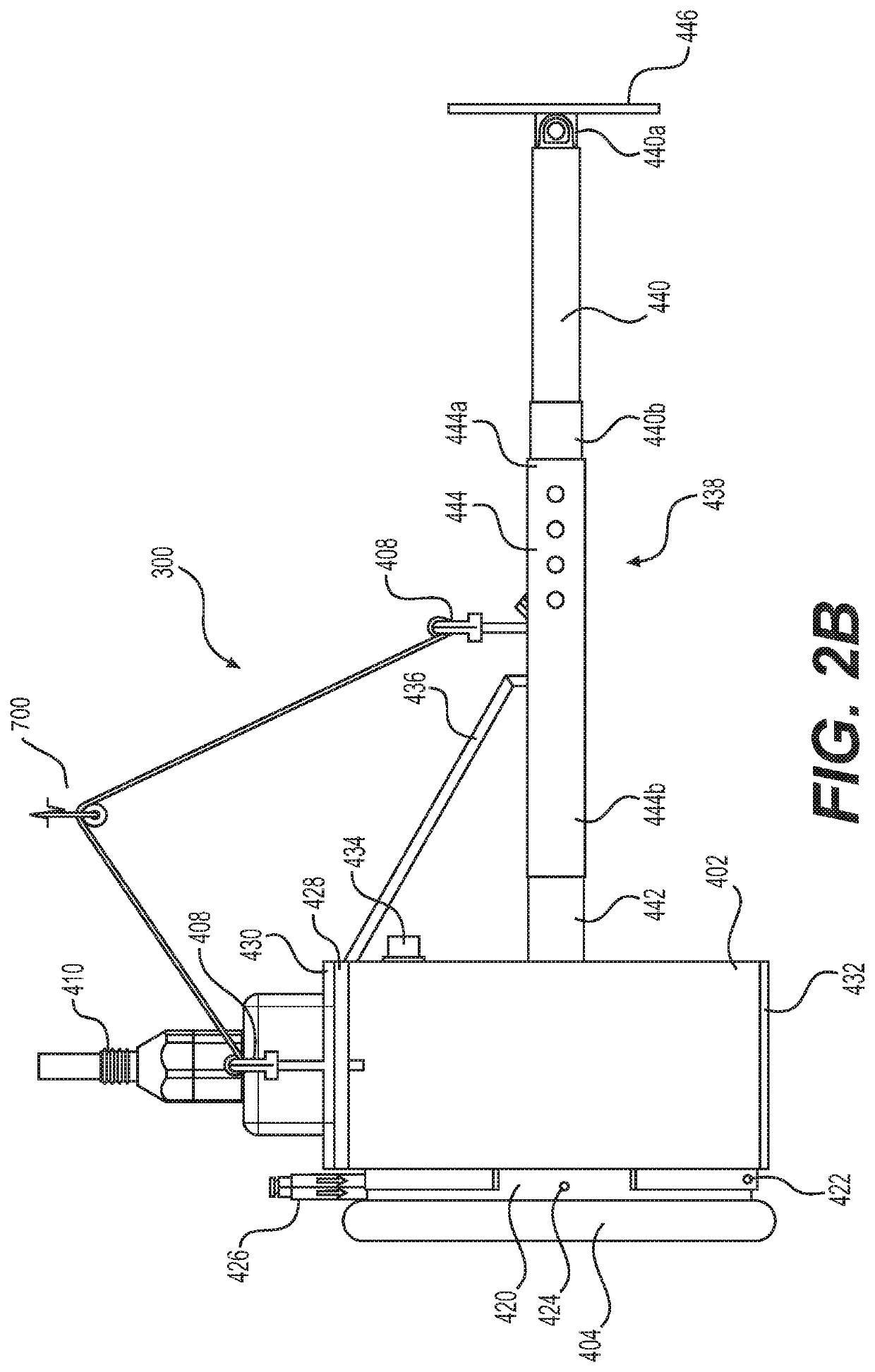

InactiveUS7187784B2Economical and inexpensiveEfficient storageElectric/magnetic detection for well-loggingSurveyComputer graphics (images)Visual inspection

Visual inspection of an interior surface of a borehole. A housing adapted to be lowered in the borehole supports a portable camera for generating images of a portion of the interior surface of the borehole and a light source for illuminating an area adjacent the camera. A monitor receives signals from the camera and, in response thereto, displays the images generated by the camera. A viewing envelope positioned adjacent the camera defines a viewing area adjacent the camera, particularly for use in visually inspecting slurry-filled boreholes.

Owner:AVER TECH INC

Method for rebuilding guide current hole to jet flow internal energy dissipating drilled shaft flood discharge hole

InactiveCN101280557AReduced risk of cavitation damageImprove securityBarrages/weirsWater-power plantsJet flowWater flow

The invention relates to a method that a diversion tunnel is rebuilt into a jet current internal energy dissipation tunnel, which belongs to the technical field of water conservancy and hydropower. The method is characterized in that: a drilled shaft is built at the downstream of the water inlet of the diversion tunnel; the lower part of the drilled shaft is connected with the top of the diversion tunnel, and the top is connected with a throat-type pressure tunnel; the outlet of the pressure tunnel in the drilled shaft is shrunk into a jet exit; a blanking adapter is arranged at the diversion tunnel of fore half section at the joint between the drilled shaft and the diversion tunnel so as to form a blind room. The method comprises the following reconstructed facilities: a short pressure water inlet, a derivation conduit section, a current adjusting section, a constriction section, a drilled shaft section, a drilled shaft tunnel connecting section and a diversion tunnel section. The method has the advantages that: the method is suitable for the reconstruction of high-head and mass flow flood discharge tunnel; a stable and effective flood discharge also can be kept in the situation of high water level at the downstream; the newly-built tunnel section occupies a small area with flexible arrangement; thereby the method can greatly reduce the cost of energy dissipating facilities.

Owner:NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

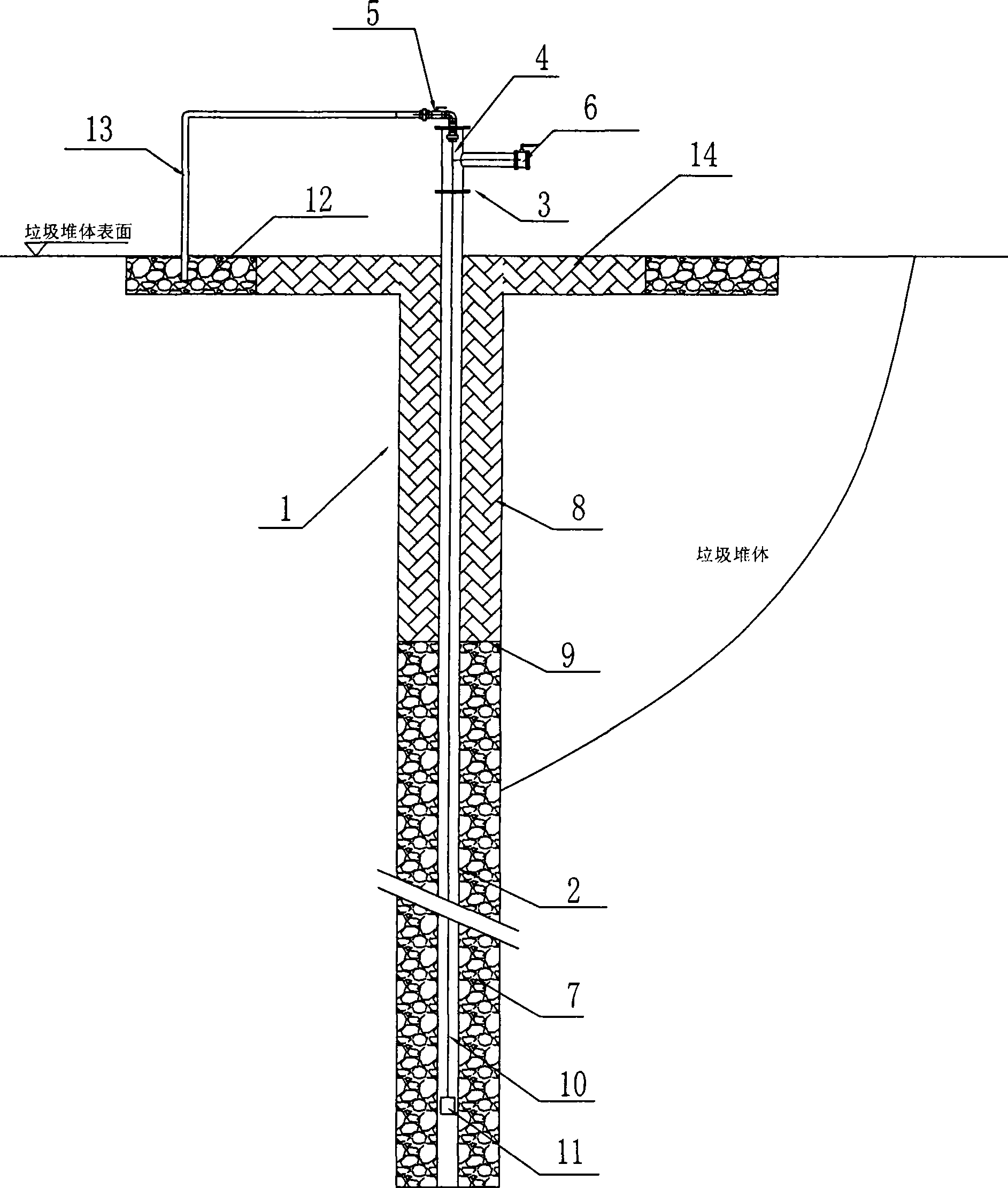

Refuse landfill extraction well and leachate in-situ recharging composite system

InactiveCN101480656AReduce effluxIncrease productionSolid waste disposalEnvironmental engineeringCompound system

The invention relates to an air suction well and percolating liquid original-position recharging compounding system for a refuse landfill field, which is characterized by comprising an air suction drilled shaft, an air suction pipe, a columnar gravel or cobble backfilling layer, a columnar clay backfilling layer, a non-woven fabric layer, a well-internal water discharge pipe, a percolating liquid recharging layer, a recharging pipe, a clay layer for preventing direct recharging. Furthermore, the air suction well and percolating liquid original-position recharging compounding system sucks the percolating liquid through a water discharge pump arranged in the air suction well and recharges the percolating liquid on the spot, thereby not only preventing the refuse landfill field being paved with multiple percolating liquid recharging pipes, but also being beneficial to the degradation of the refuse landfill field and to the increase of the output of landfill gas and the using quantity of the landfill gas of the refuse landfill and effectively decreasing the discharge quantity of the percolating liquid. The invention has the advantages of simple structure, convenient construction, good back percolation effect and low maintenance cost.

Owner:NANJING UNIV

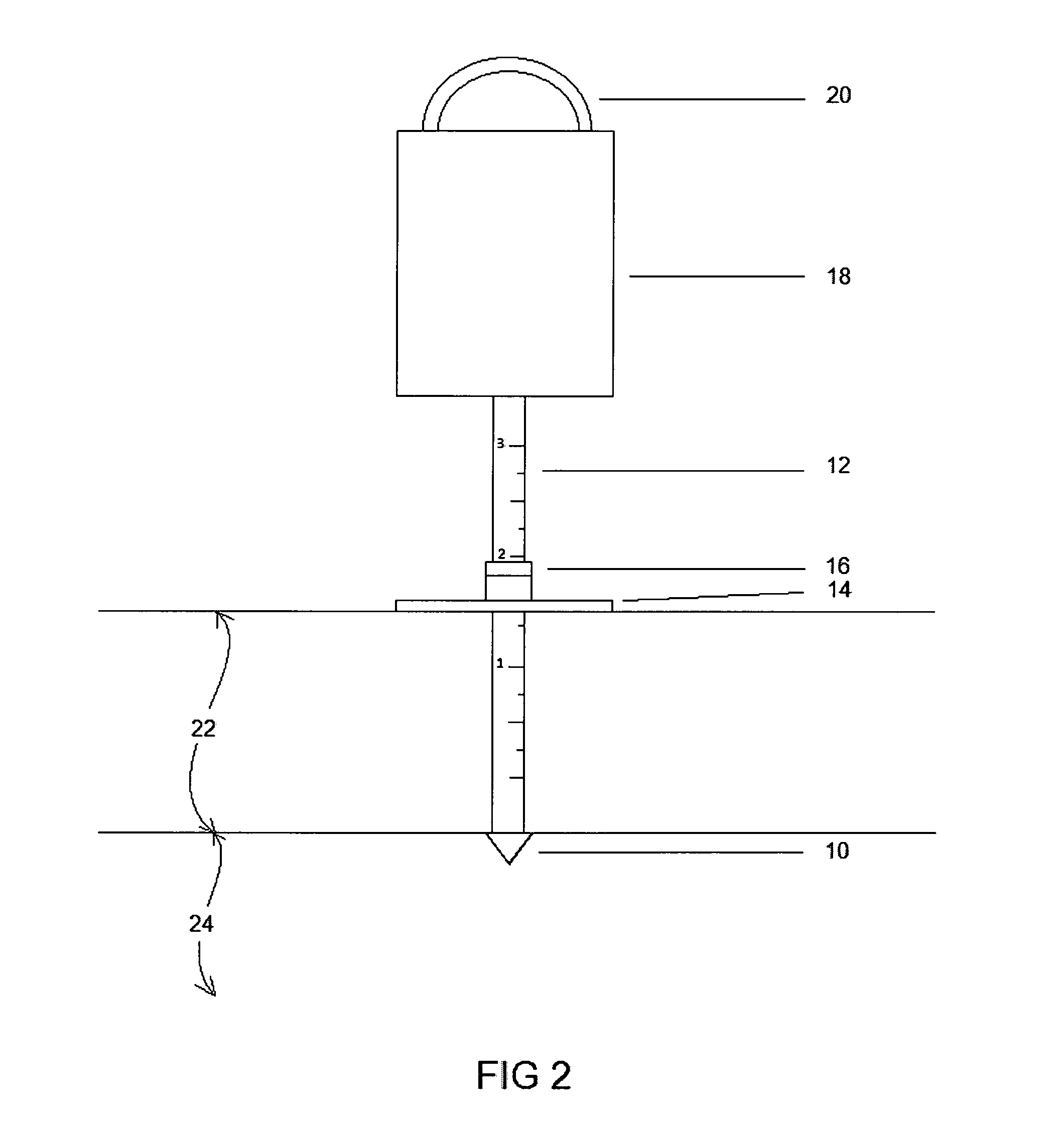

Bore head for microbore operation

Boring apparatus for drilling laser guided microbore tunnels uses a liquid stream to remove soil as slurry and an airstream to conduct the slurry away from the bore head. The cylindrical head houses a drill shaft steered by a pair of remotely controlled rams according to the position of a laser spot on a target fixed close to the end of the drill shaft. Small arcuate steering movements shift the cutter up and down through a first ram alongside the shaft working through a linkage. Side to side steering is provided by a second ram acting directly on the shaft. The components are mounted on an axial base wall which gives repair access and camera view of the target. A drilling platform has rams for advancing the cylindrical head.

Owner:DAVIES RODNEY JOHN

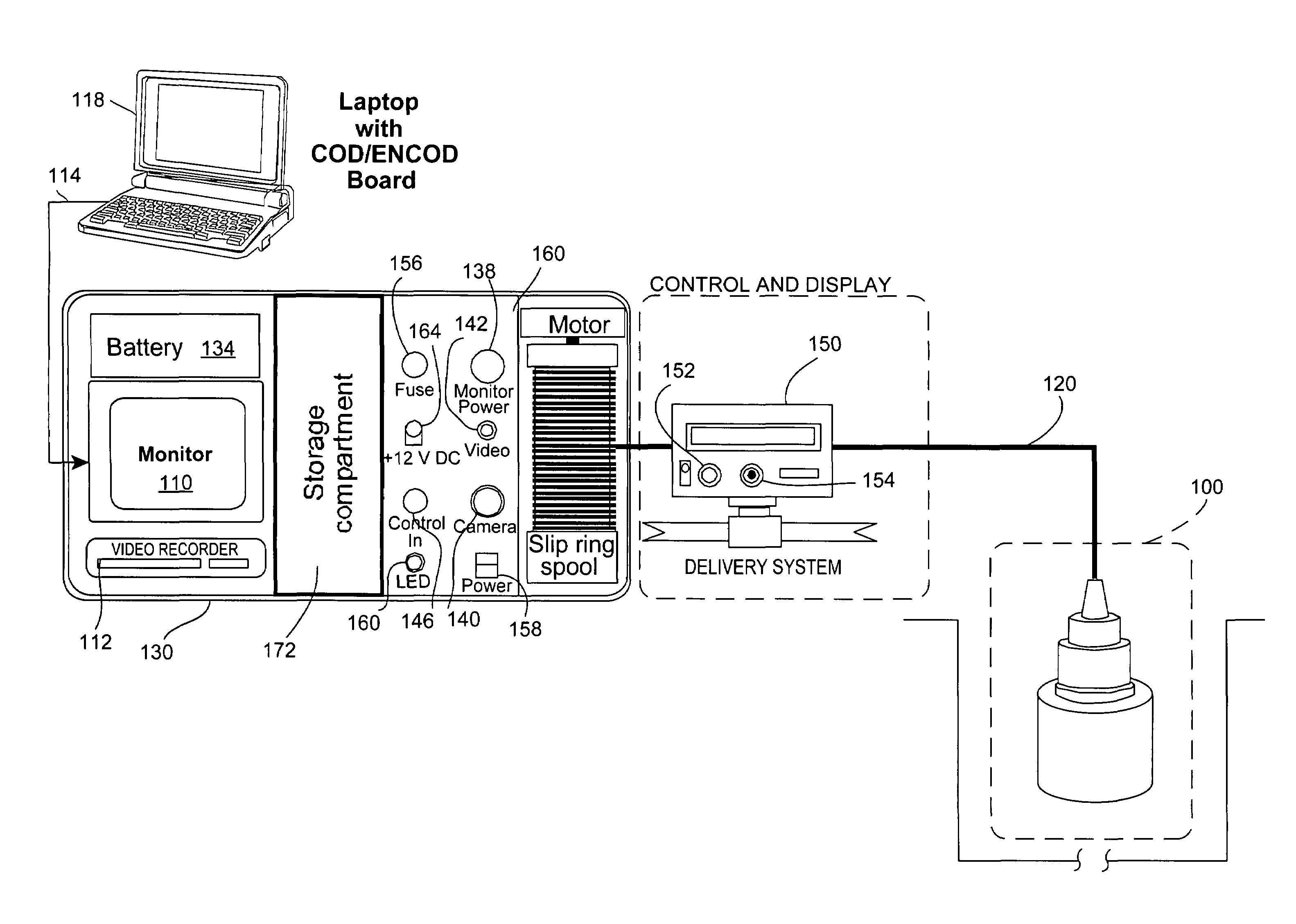

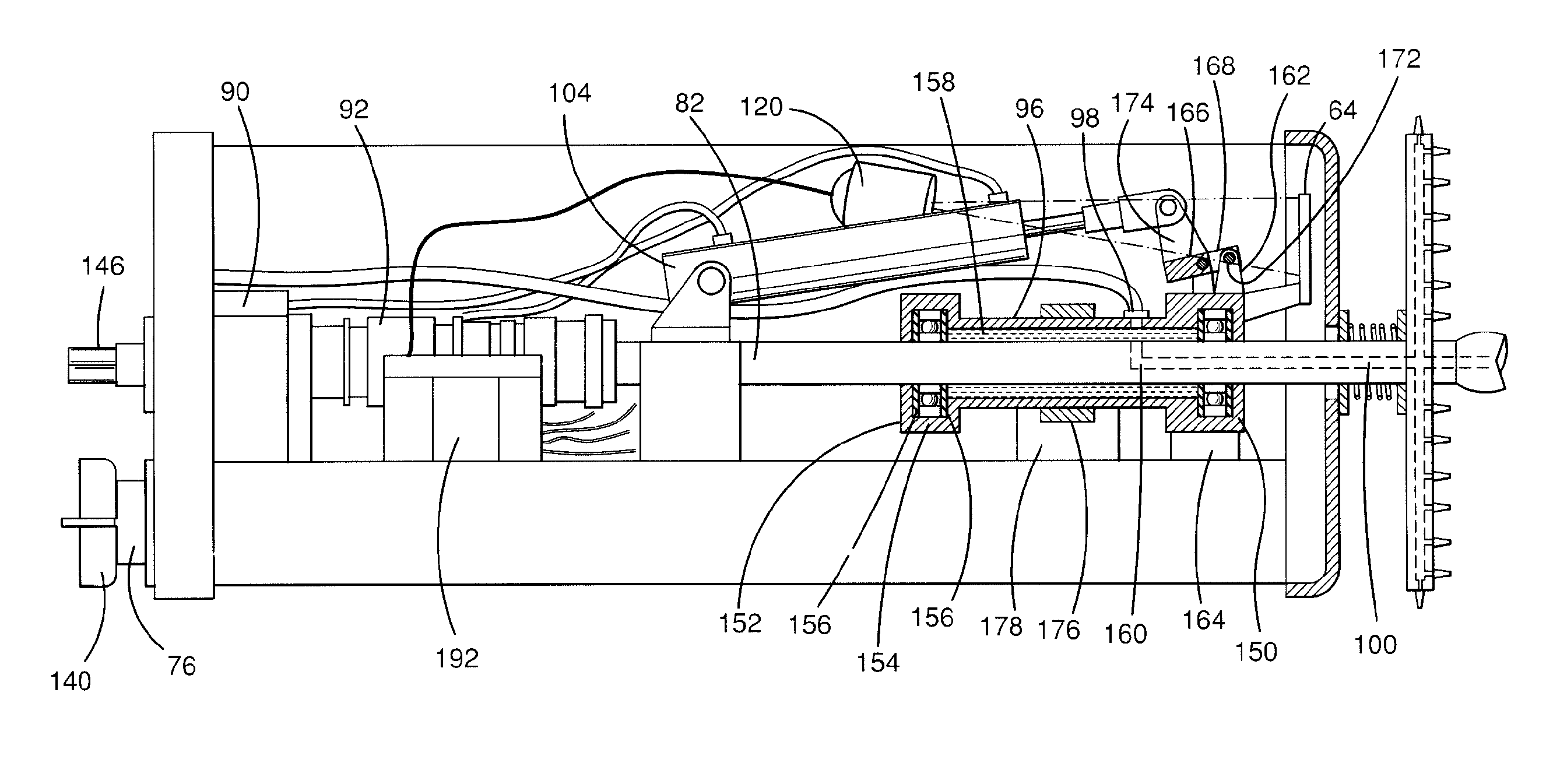

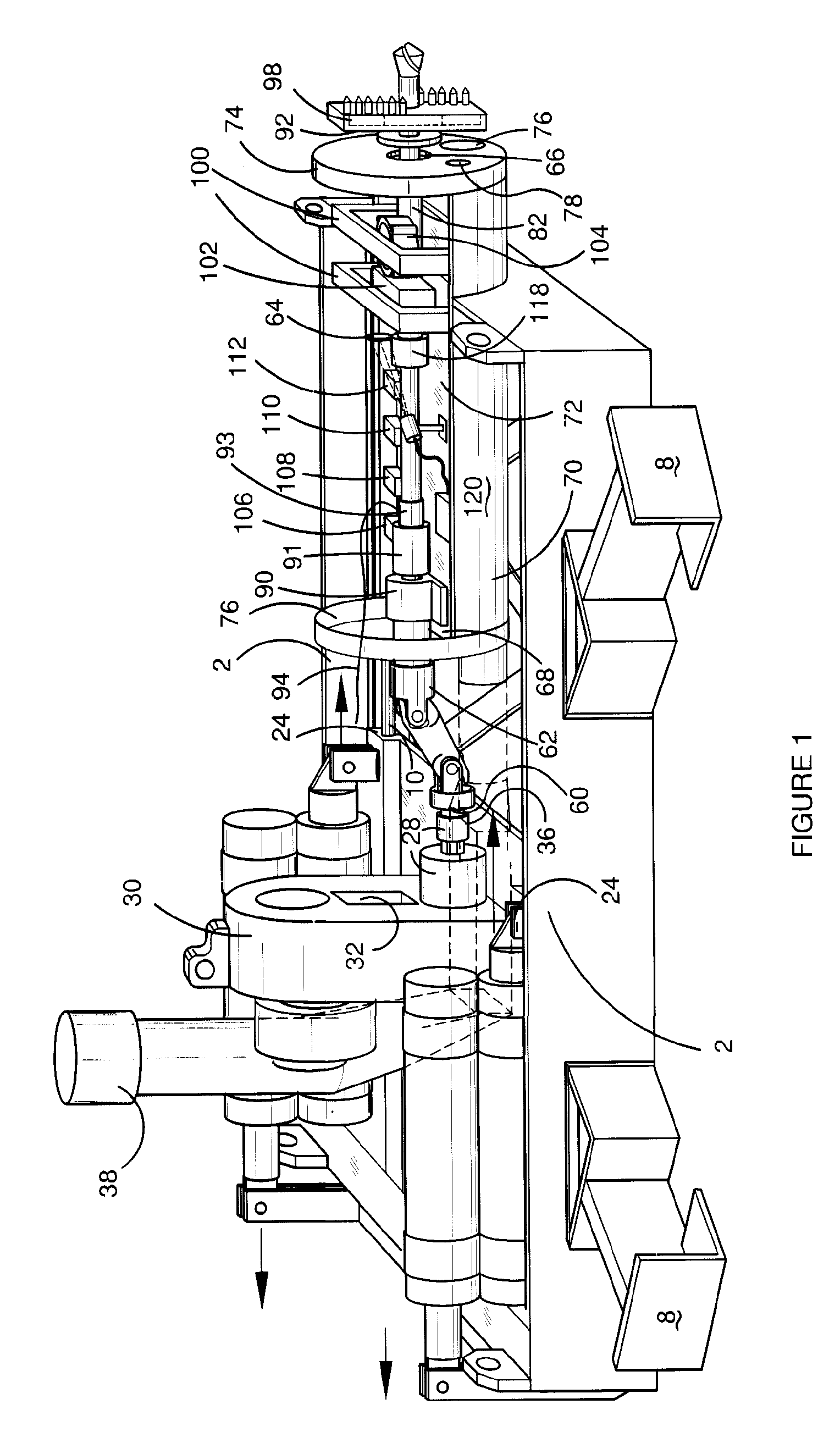

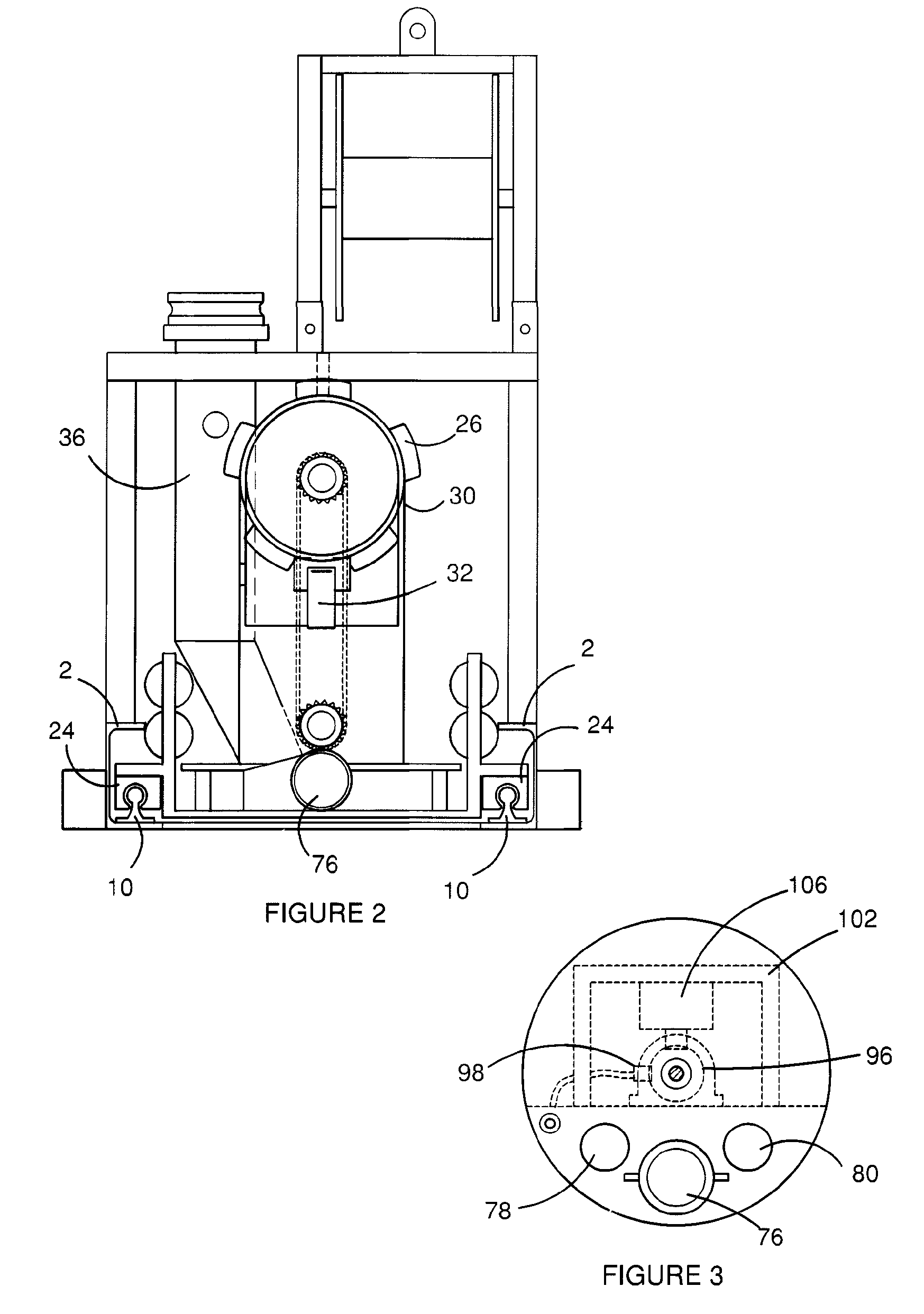

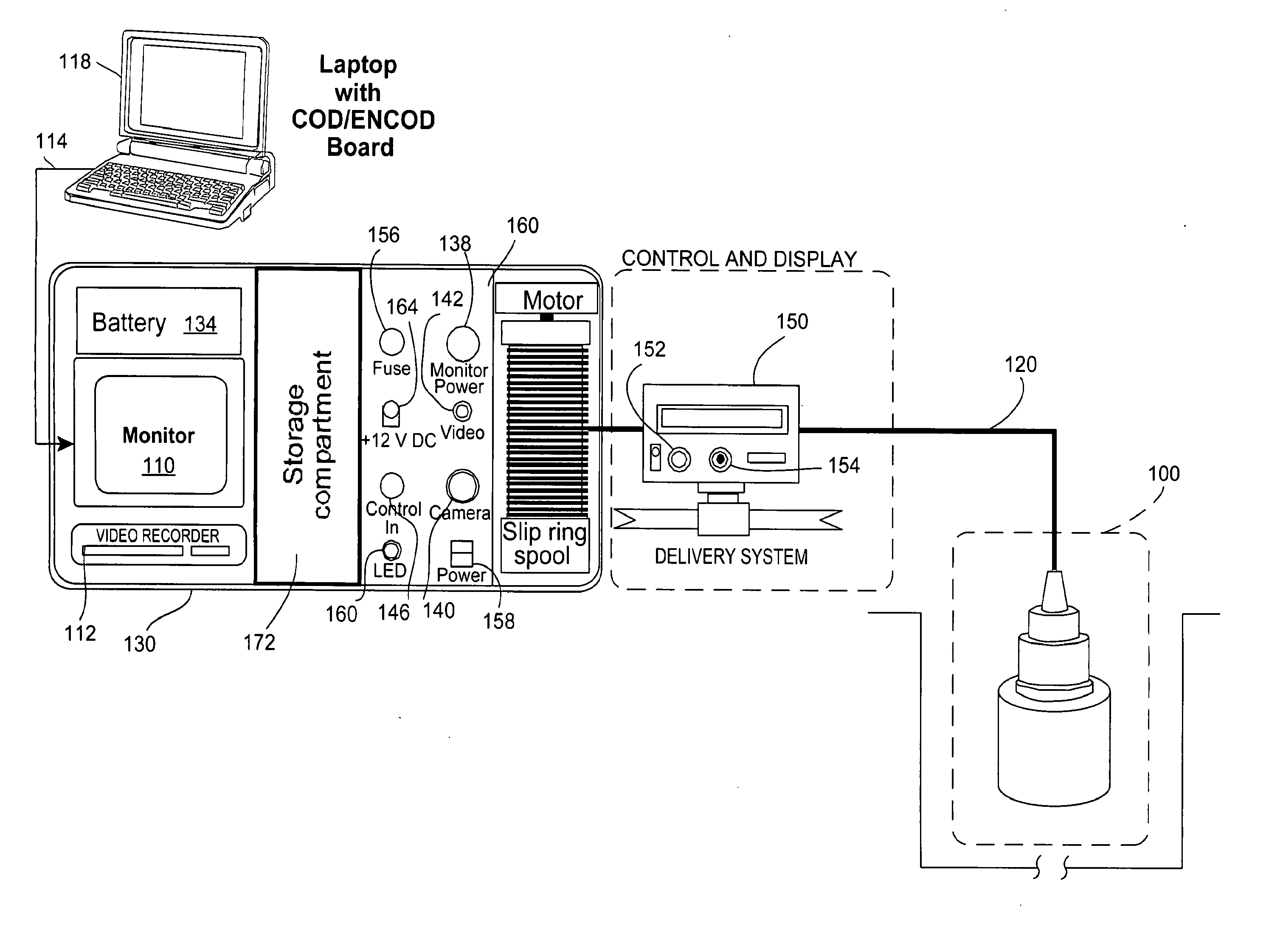

Digital video borescope for drilled shaft inspection

InactiveUS20070127780A1Economical and inexpensiveEfficient in storing and retrievingSurveyConstructionsDigital videoComputer graphics (images)

Visual inspection of an interior surface of a borehole. A housing adapted to be lowered in the borehole supports a portable camera for generating images of a portion of the interior surface of the borehole and a light source for illuminating an area adjacent the camera. A monitor receives signals from the camera and, in response thereto, displays the images generated by the camera. A viewing envelope positioned adjacent the camera defines a viewing area adjacent the camera, particularly for use in visually inspecting slurry-filled boreholes.

Owner:AVER TECH INC

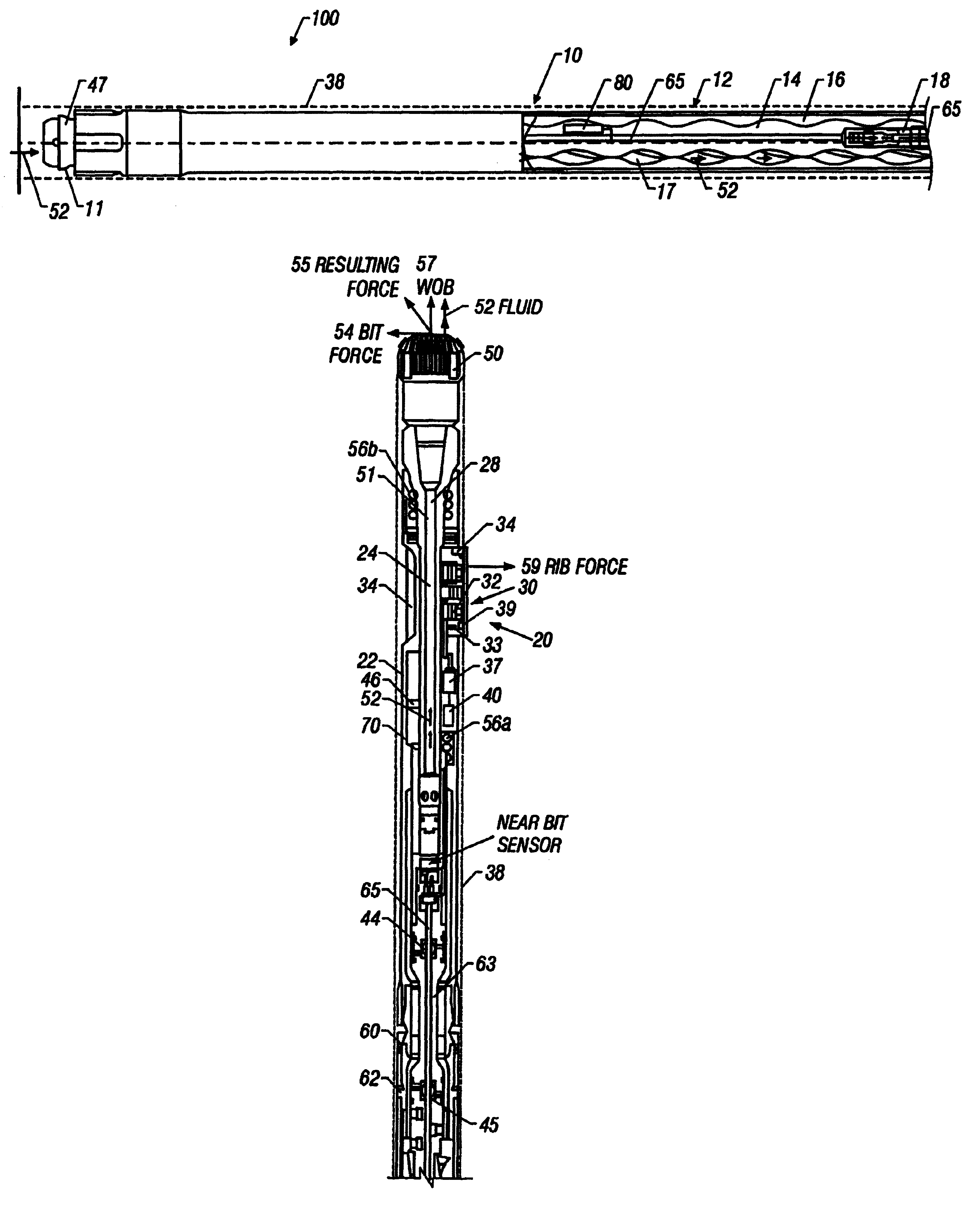

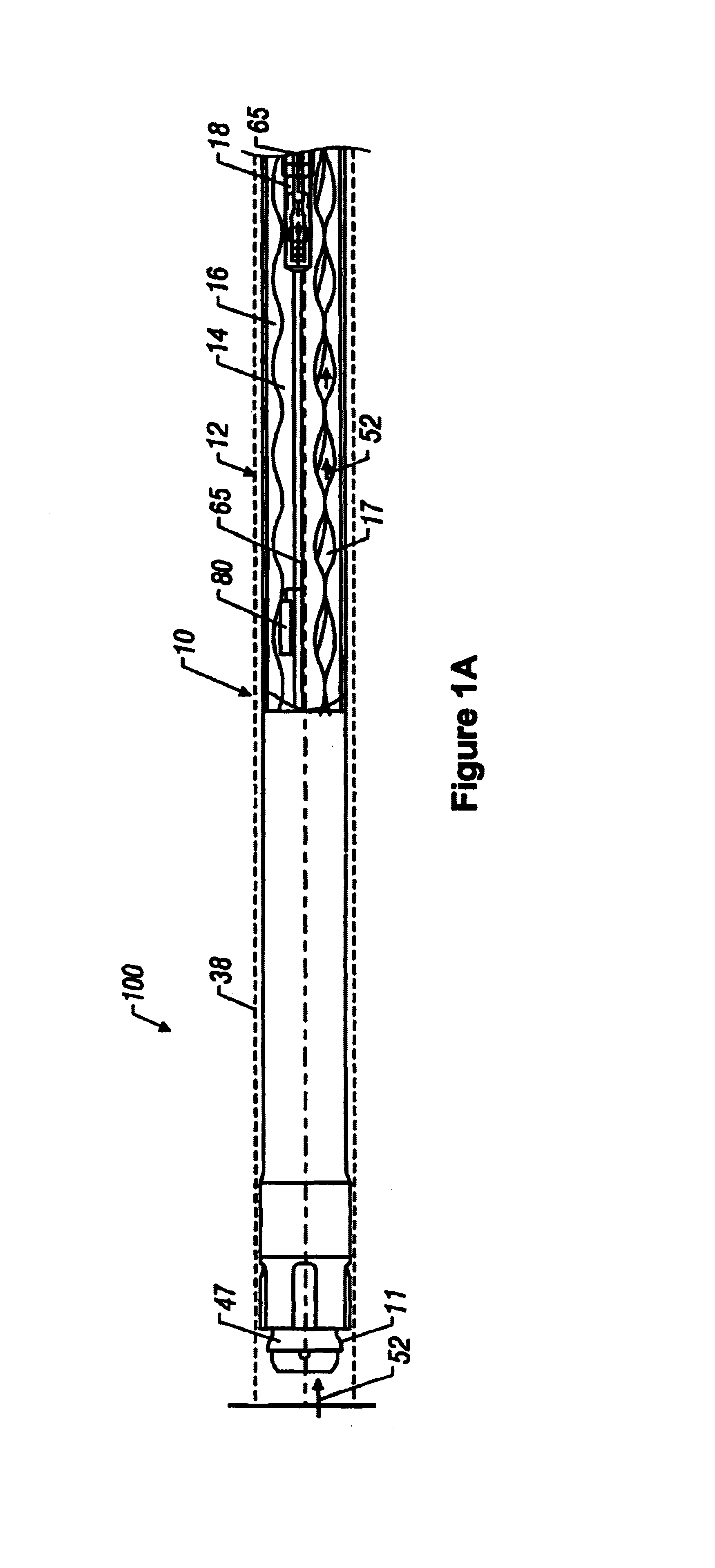

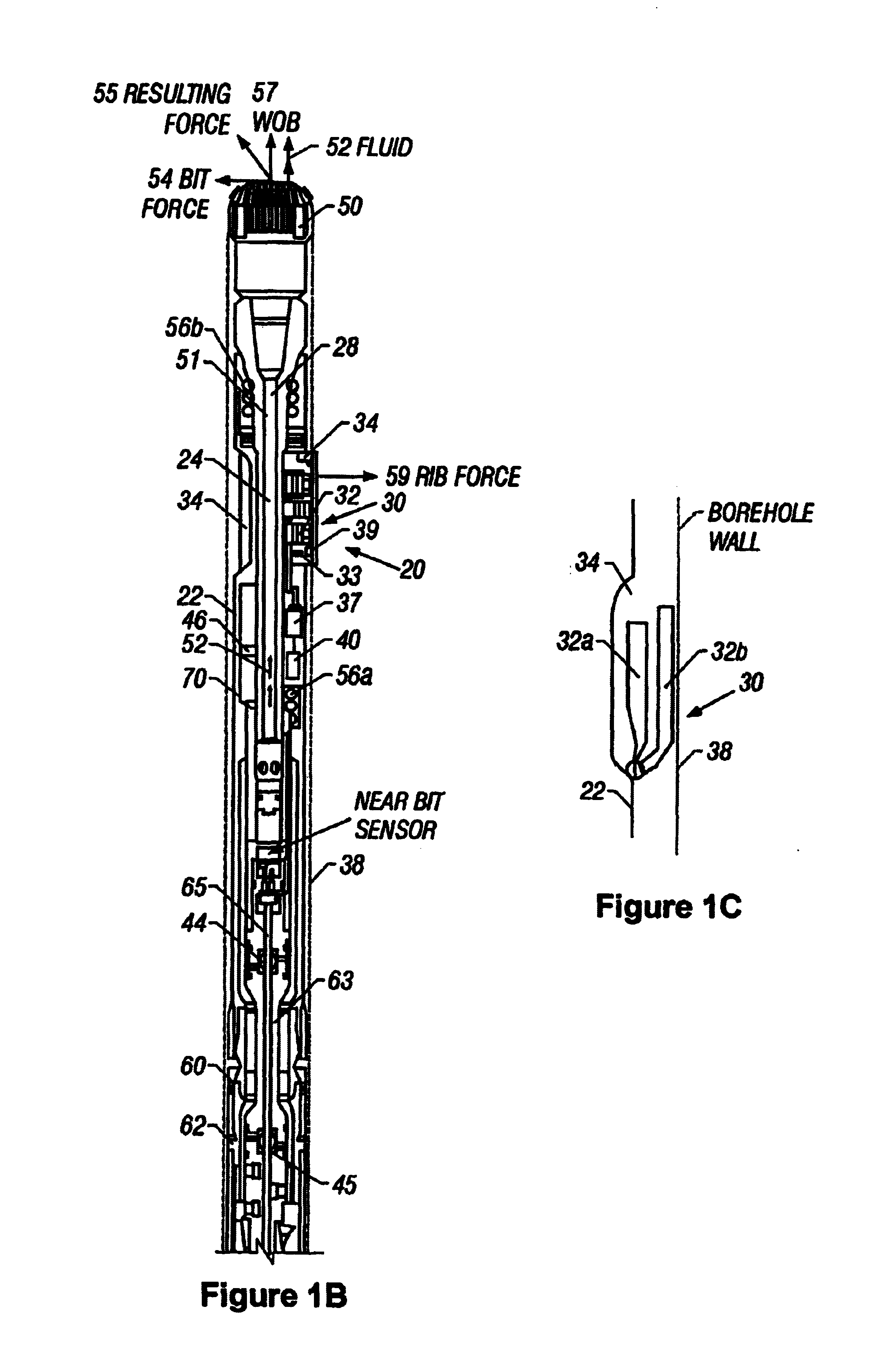

Drilling assembly with a steering device for coiled-tubing operations

The present invention provides a drilling assembly for drilling deviated wellbores. The drilling assembly includes a drill bit at the lower end of the drilling assembly. A drilling motor provides the rotary power to the drill bit. A bearing assembly of the drilling motor provides lateral and axial support to the drill shaft connected to the drill bit. A steering device is integrated into drilling motor assembly. The steering device contains a plurality of force application members disposed at an outer surface of the drilling motor assembly Each force application member is adapted to move between a normal position and a radially extended position to exert force on the wellbore interior when in extended position. A power unit in the housing provides pressurized fluid to the force application members. A control device for independently operating each of the force application members is disposed in the drilling motor assembly. A control circuit or unit independently controls the operation of the control device to independently control each force application member. For short radius drilling, a knuckle joint is disposed uphole of the steering device to provide a bend in the drilling assembly. During drilling of a wellbore, the force application members are operated to adjust the force on the wellbore to drill the wellbore in the desired direction.

Owner:BAKER HUGHES INC

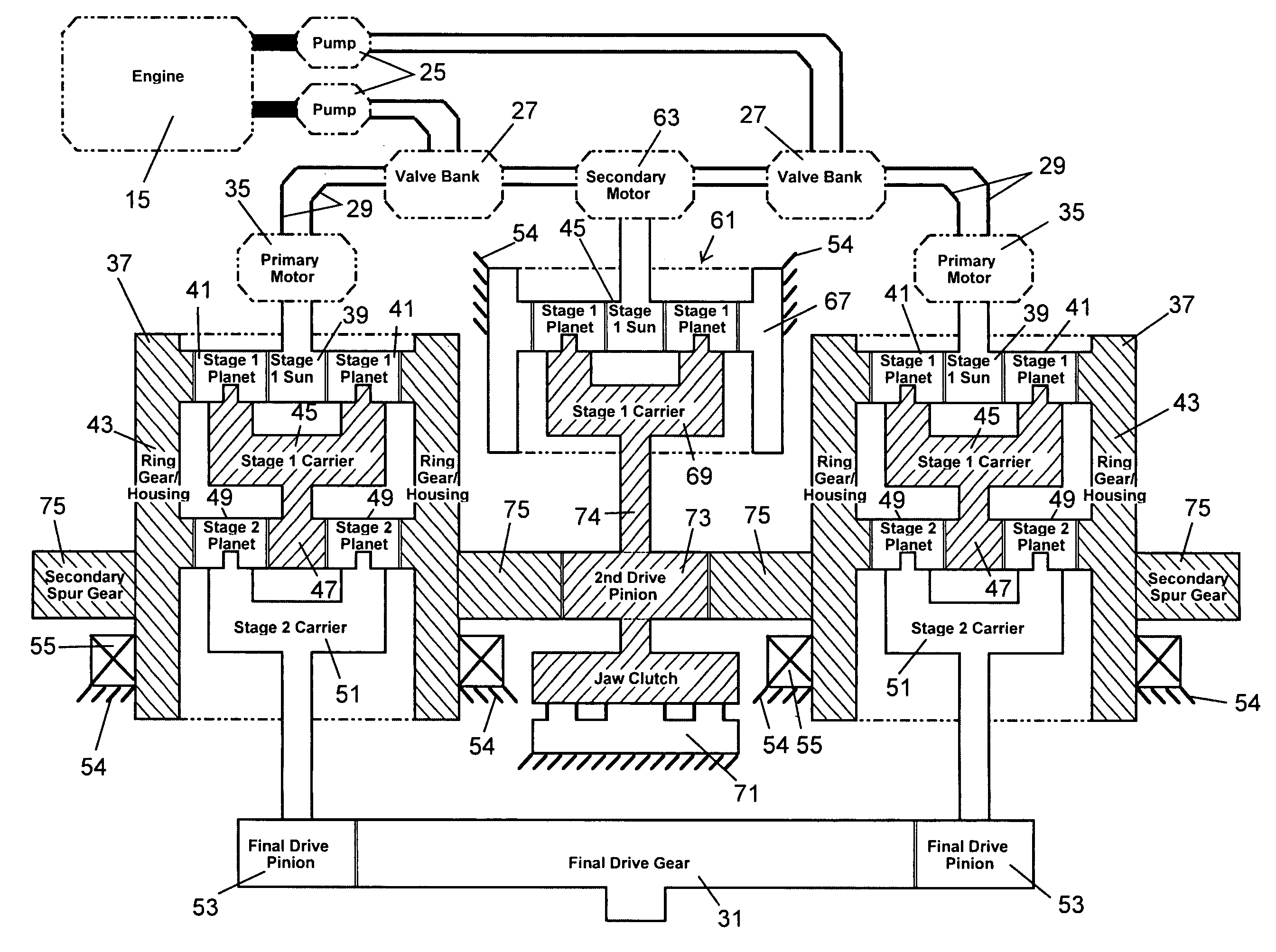

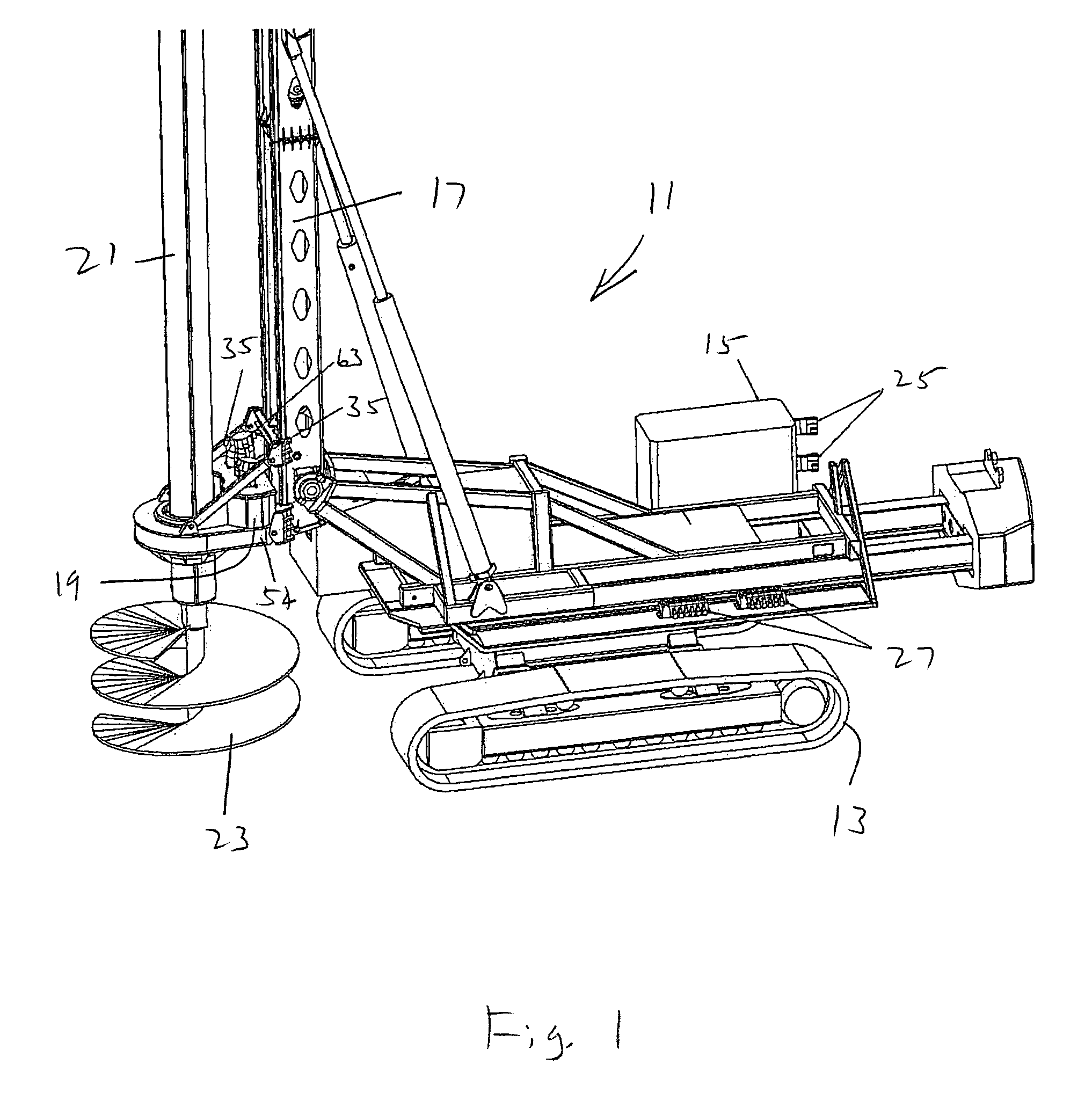

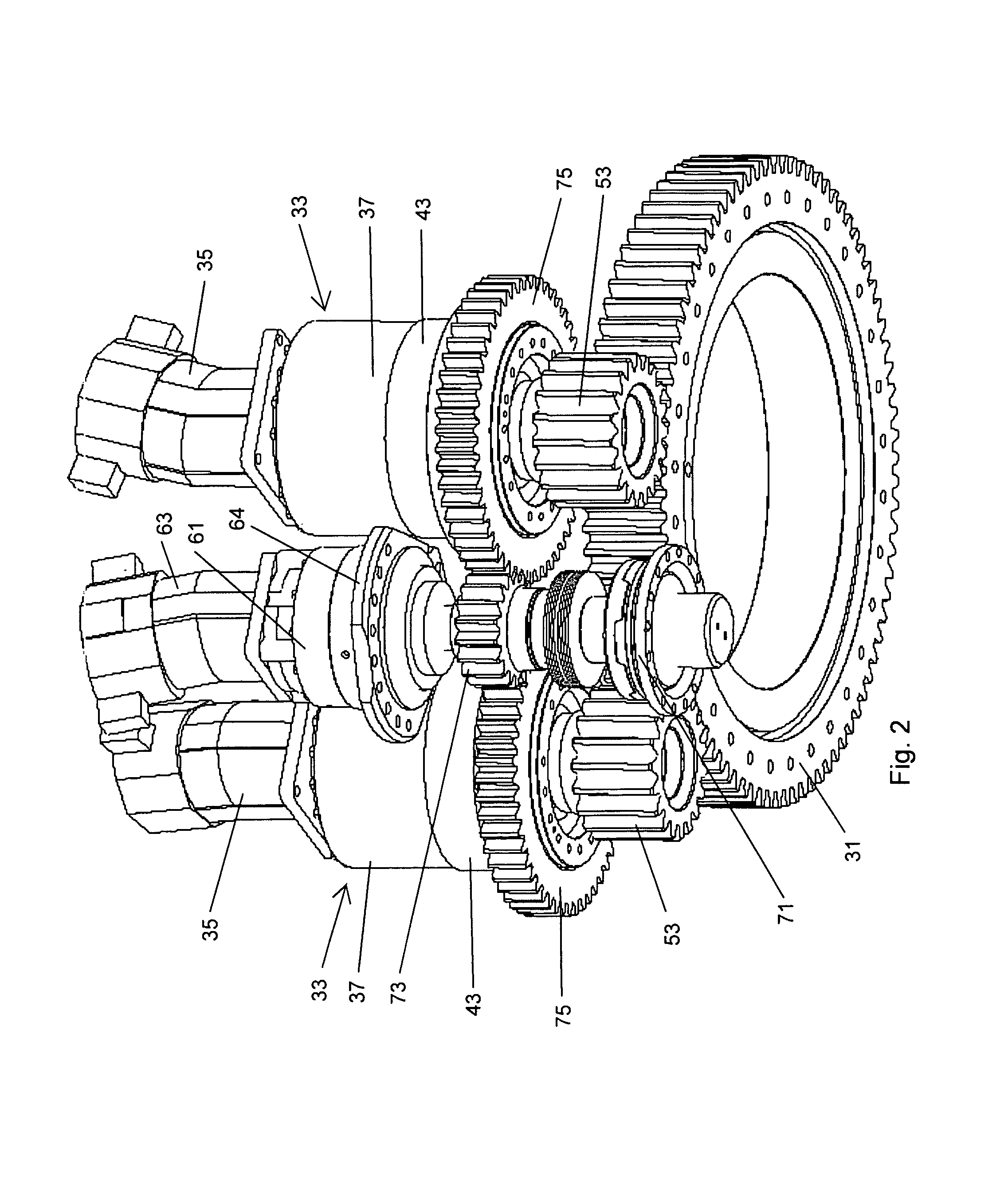

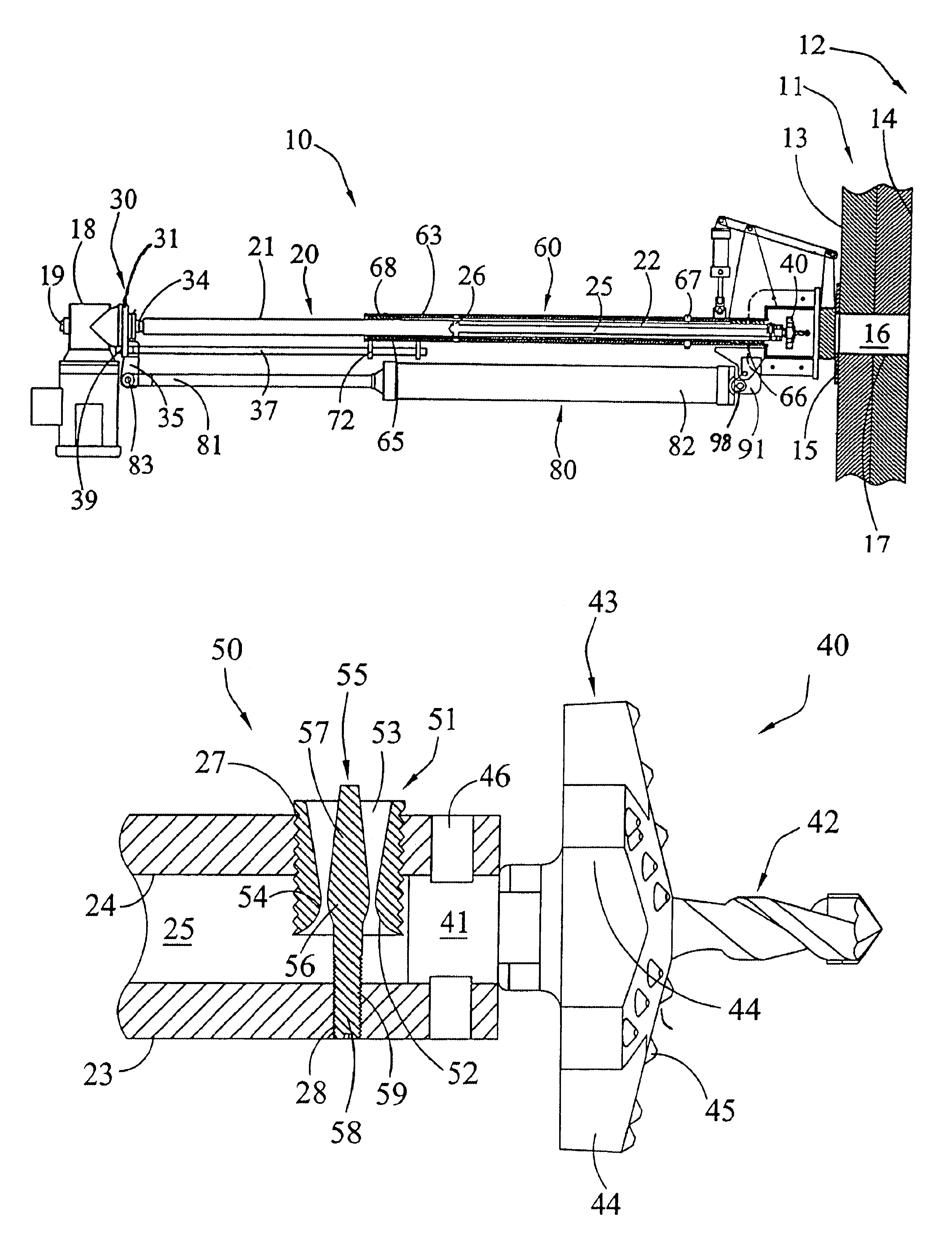

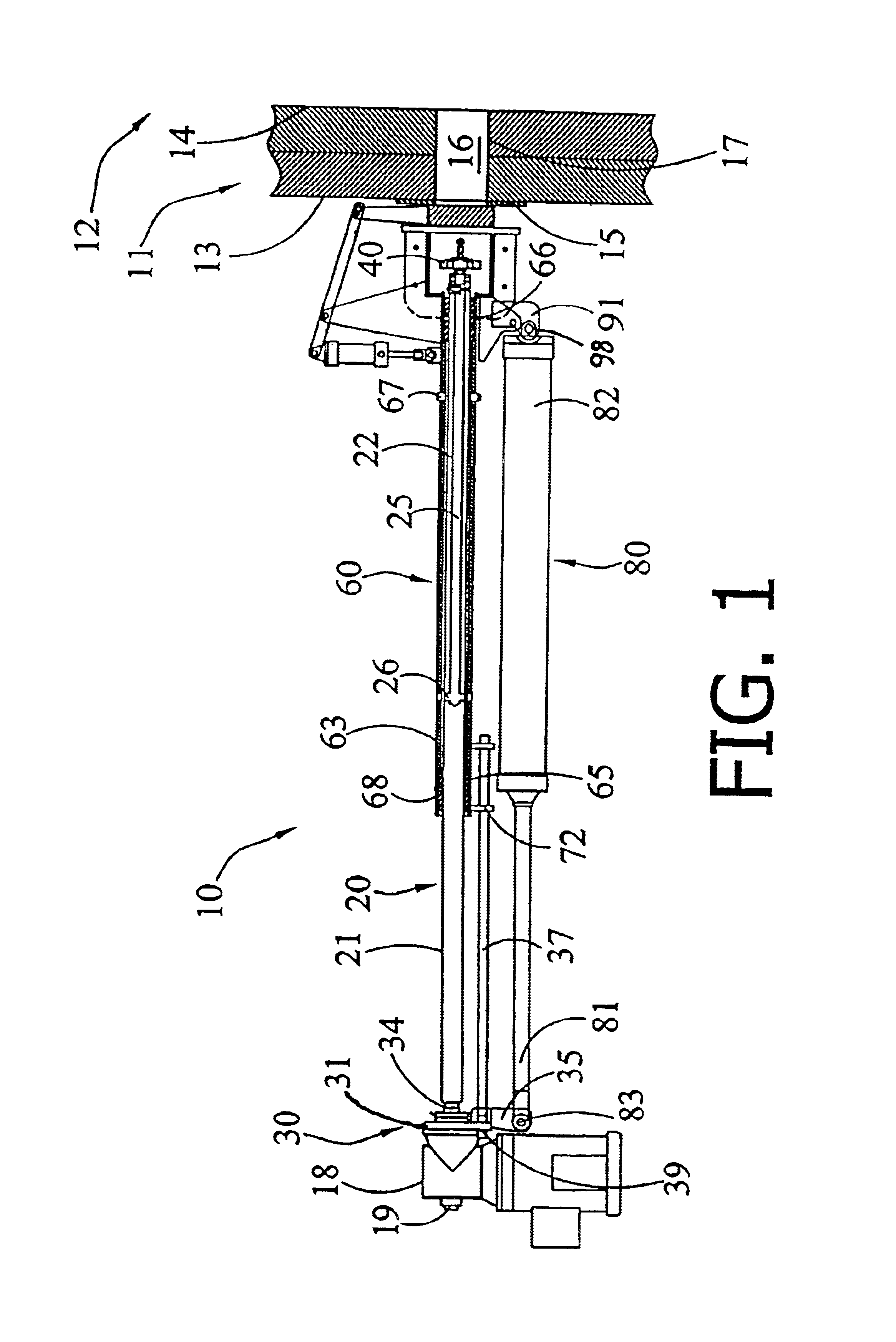

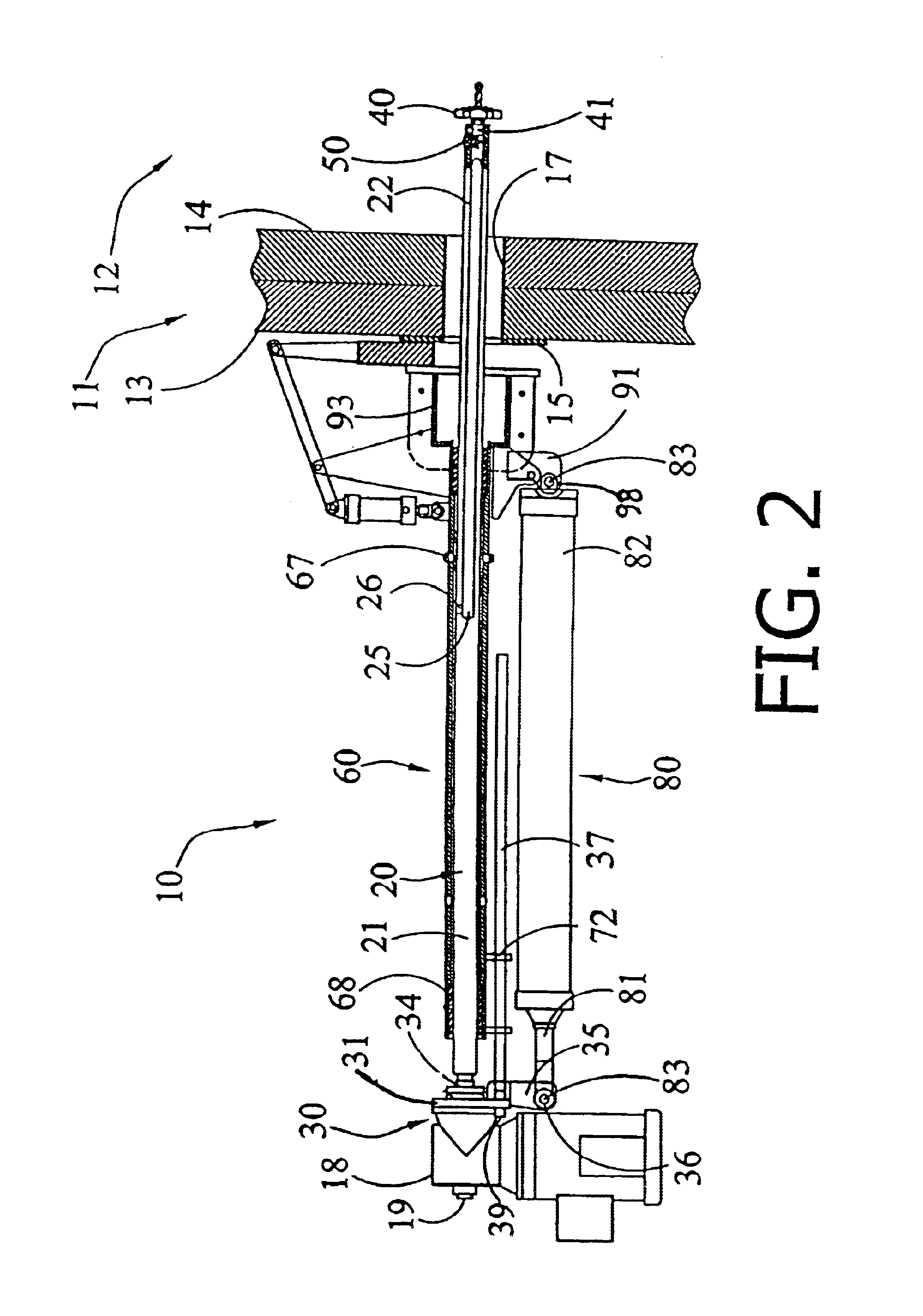

Foundation drilling apparatus and method with continuously variable hydraulic differential rotary table

A drilling machine drills foundation holes known as drilled shafts or bored piles with a drilling tool attached to an end of a kelly. The kelly is rotated with a rotary drive. The rotary drive has a first motor, a final drive gear coupled to the kelly so as to rotate with the kelly and a planetary gear set between the first motor and the final drive gear. A second motor is coupled to the ring gear on the planetary gear set. A clutch can also be connected to the ring gear. The rotary drive allows the drilling tool to be rotated at low drilling speeds and, without stopping rotation or shifting gears, removed from the hole and accelerated to high speeds to discharge spoil. A mid-range is also possible, wherein the drilling tool can process fluids in the hole. Another motor and planetary gear set can be coupled to the final drive gear and to the second motor.

Owner:WATSON INC

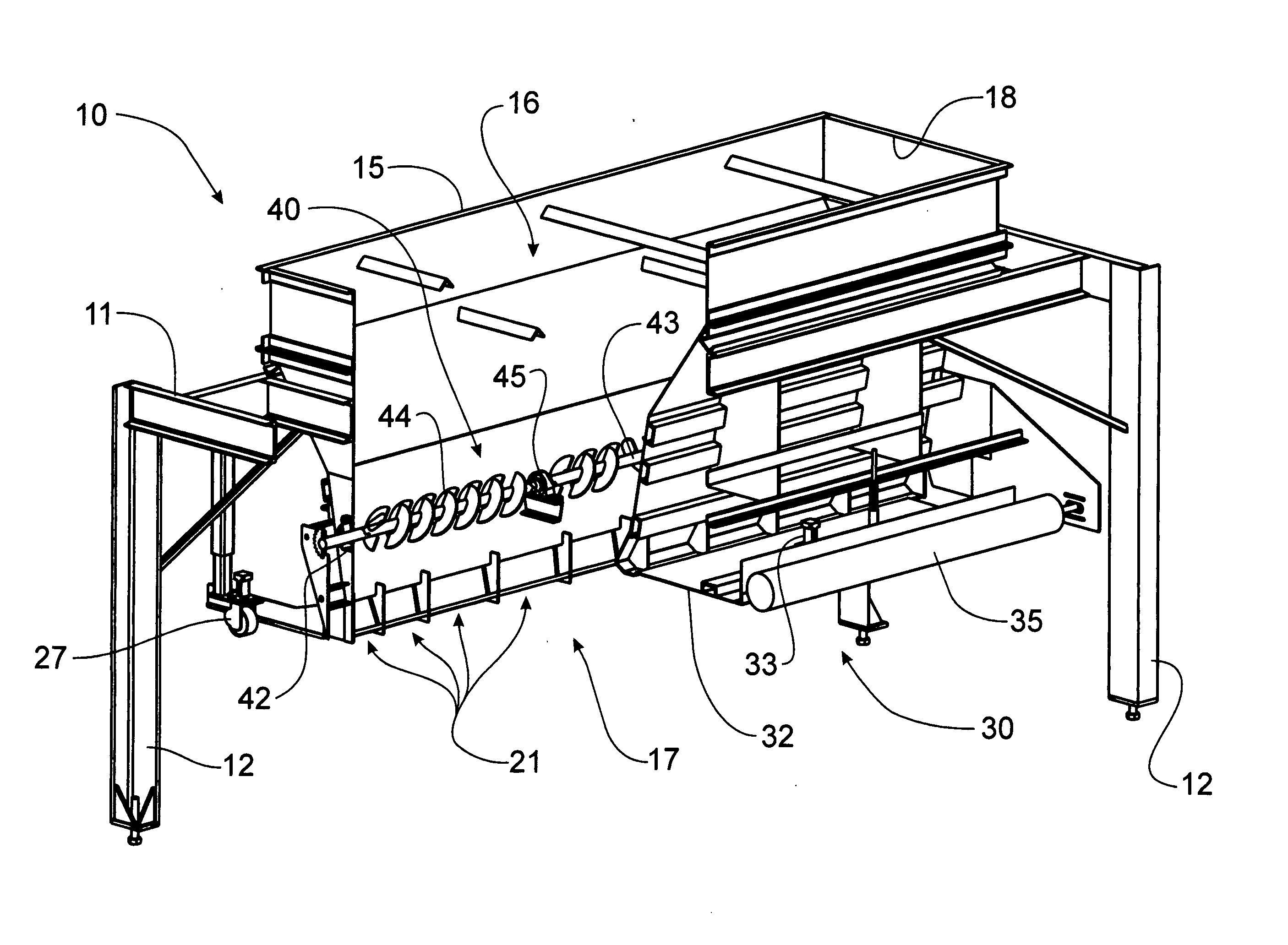

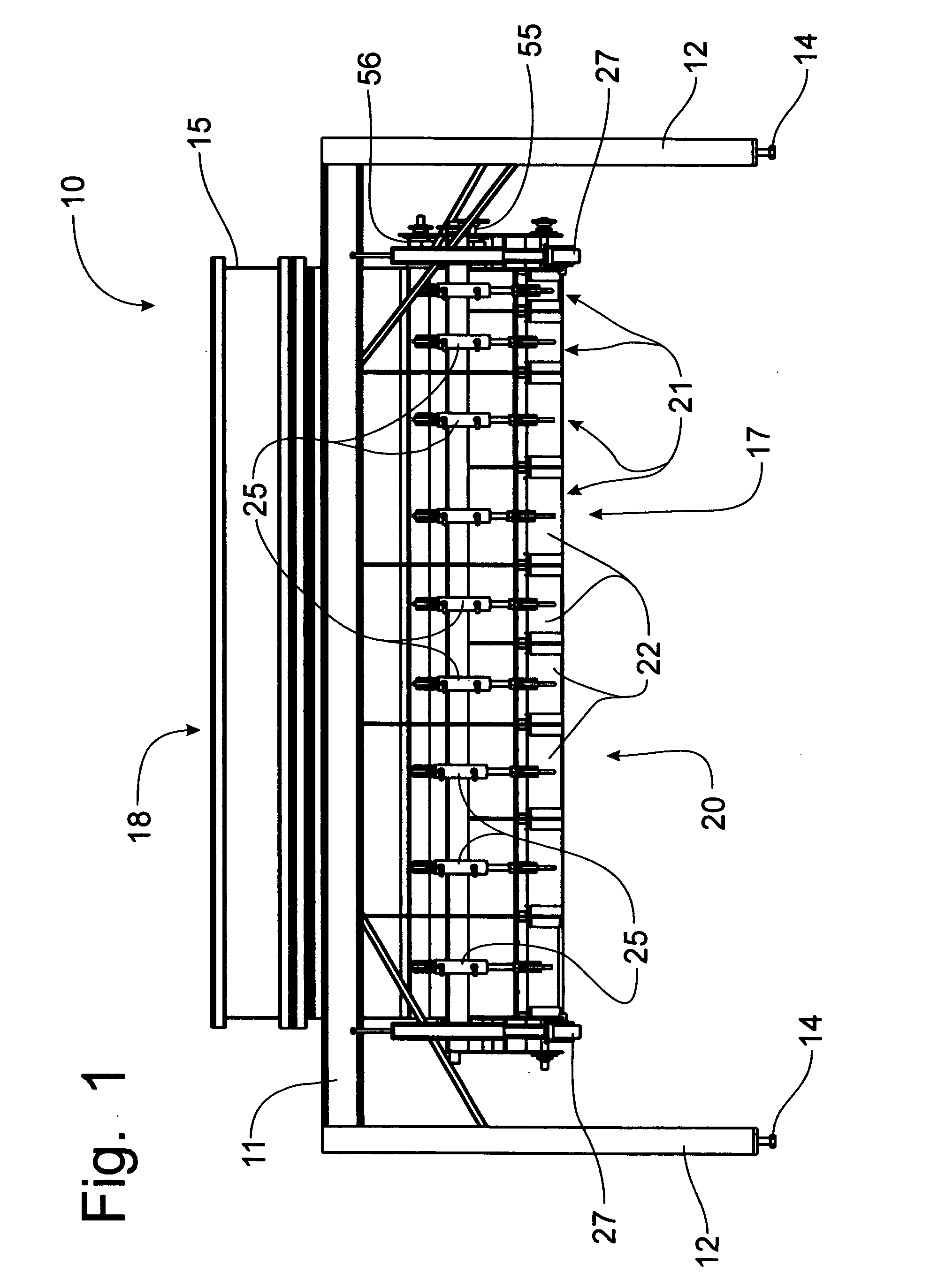

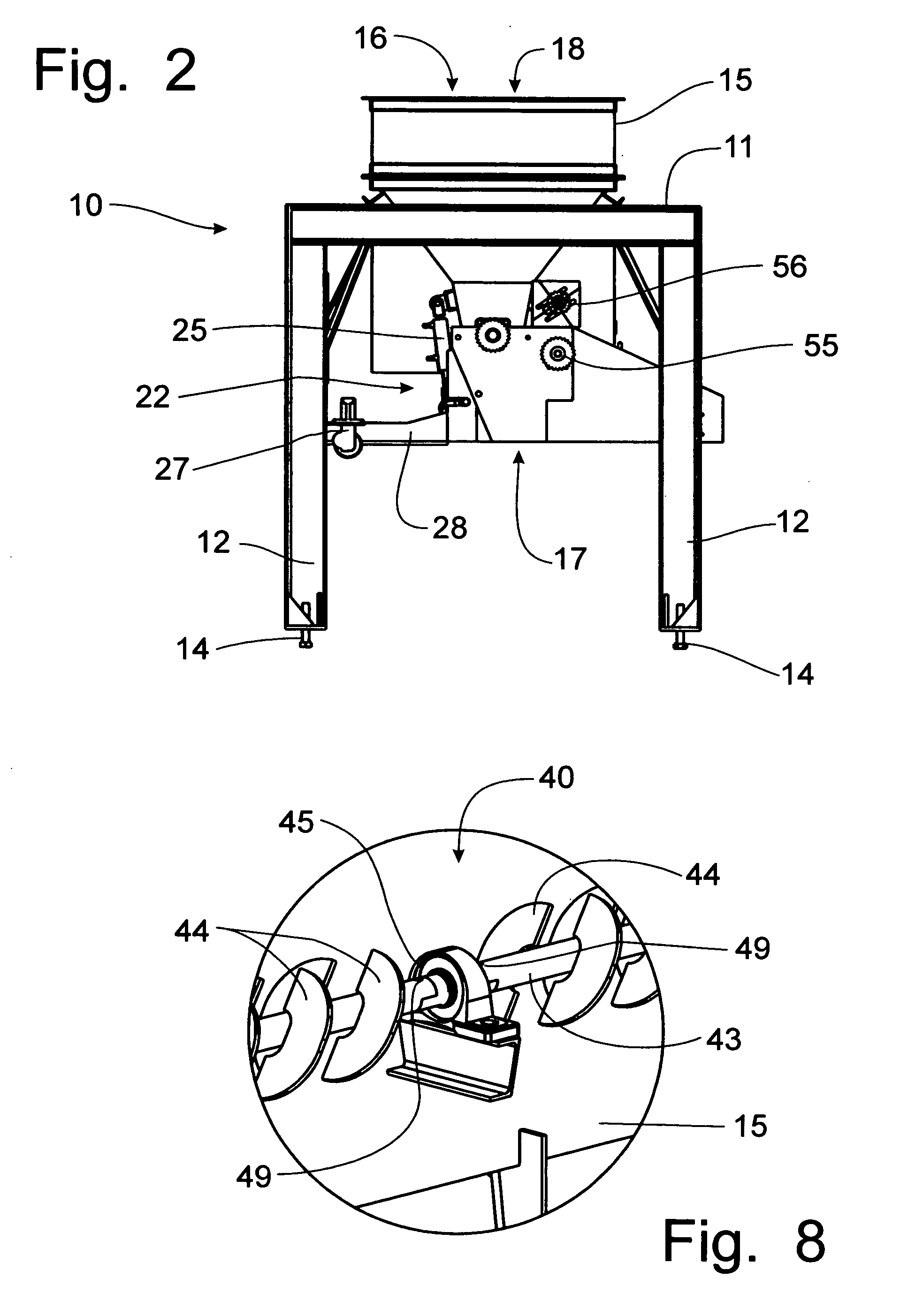

Segmented auger for a concrete dispensing apparatus

InactiveUS20080049543A1Quick removalFast replacementDischarging apparatusMixing operation control apparatusEngineeringMechanical engineering

A segmented auger mechanism is mounted in the hopper of a concrete dispensing apparatus used to distribute a hydrated concrete mixture into a horizontally disposed form to manufacture pre-cast concrete structures, such as concrete wall panels used to form a foundation for a residential or commercial building. The auger mechanism is formed of connected segments that can be individually and independently removed from the concrete structure for service and repair. The auger is rotatably supported by a pair of end bearings supported on the opposing end walls of the hopper of the dispensing apparatus, and by at least one interior bearing rotatably supporting a jack shaft having opposing half-round connecting portions for attachment to a corresponding connecting portion on the auger shaft. Removal of a segment of the auger mechanism facilitates the removal of the entire auger mechanism to minimize the down time of the concrete dispensing apparatus.

Owner:SUPERIOR WALLS OF AMERICA

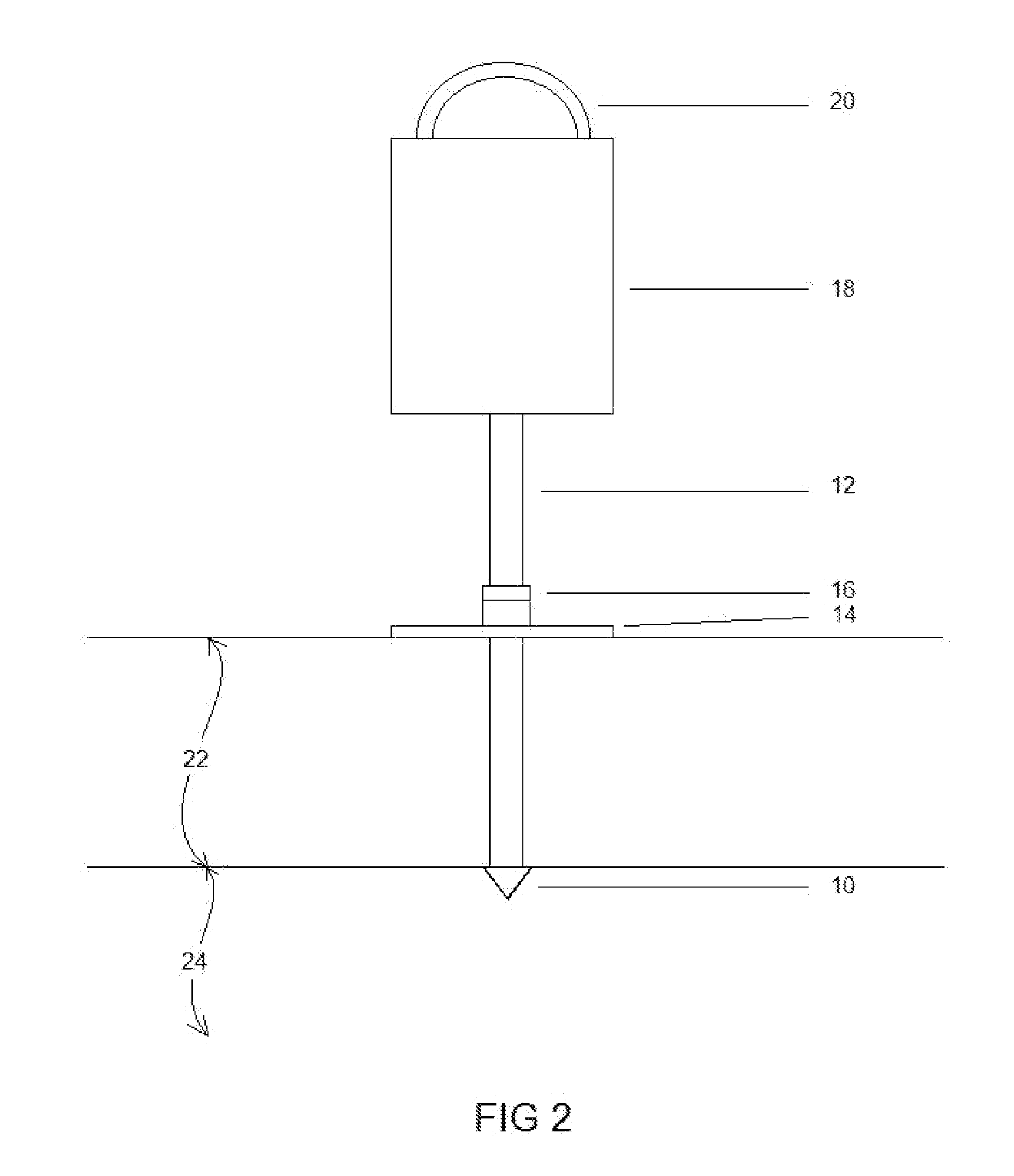

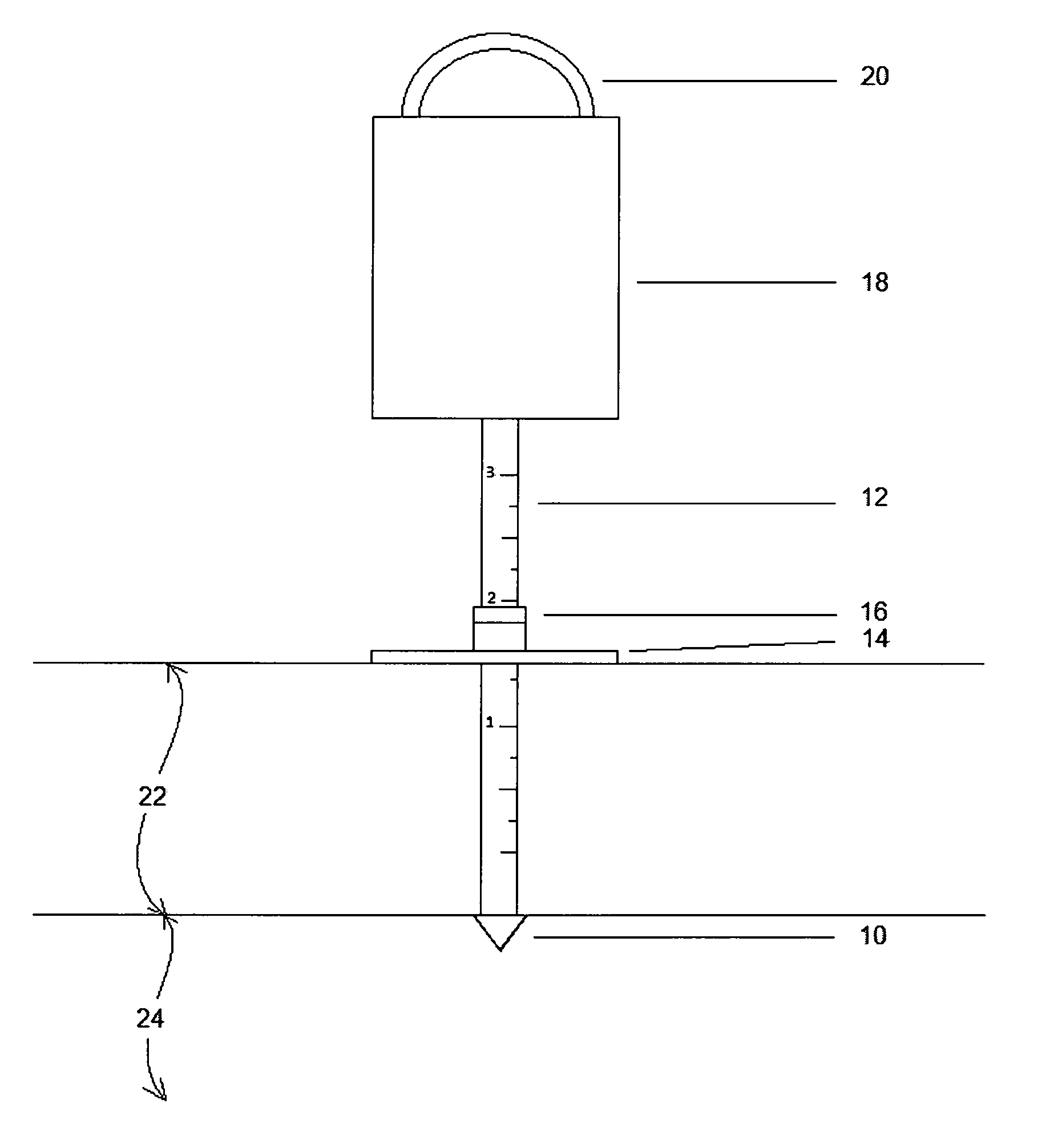

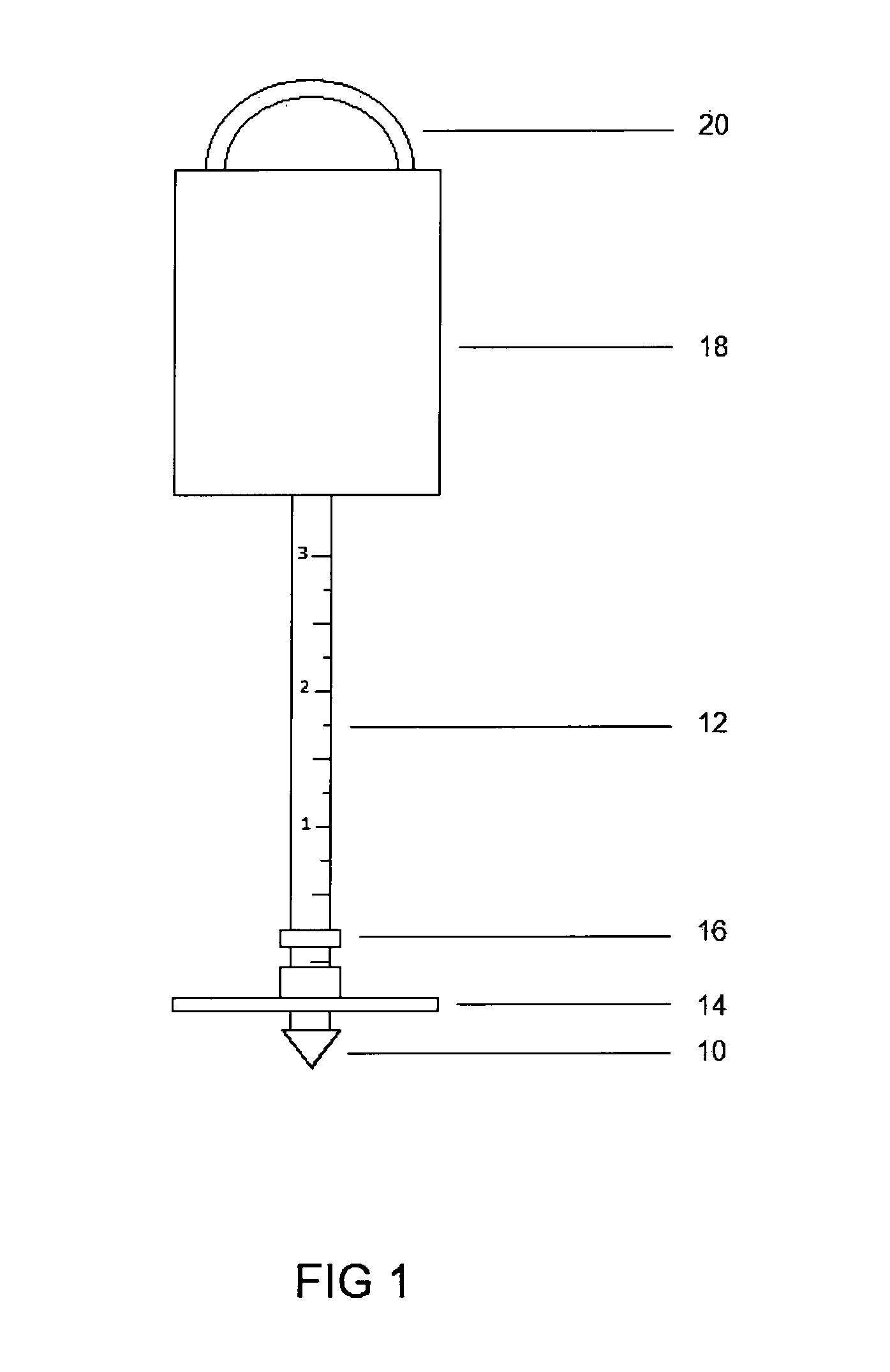

Shaft Sounding Device for Measuring Thickness of Sediments at Base of Drilled Shafts

InactiveUS20160202054A1Simple and reliable processWiden meansSurveyMechanical depth measurementsSounds deviceMechanical engineering

A sounding device for measuring the thickness of sediments at the base of dry or wet drilled shaft excavations for the assessment of drilled shaft bottom cleaning operations. The sounding device provides a simple and reliable means to quantitatively evaluate drilled shaft bottom cleanliness.

Owner:FUNG STEVE WILHELM

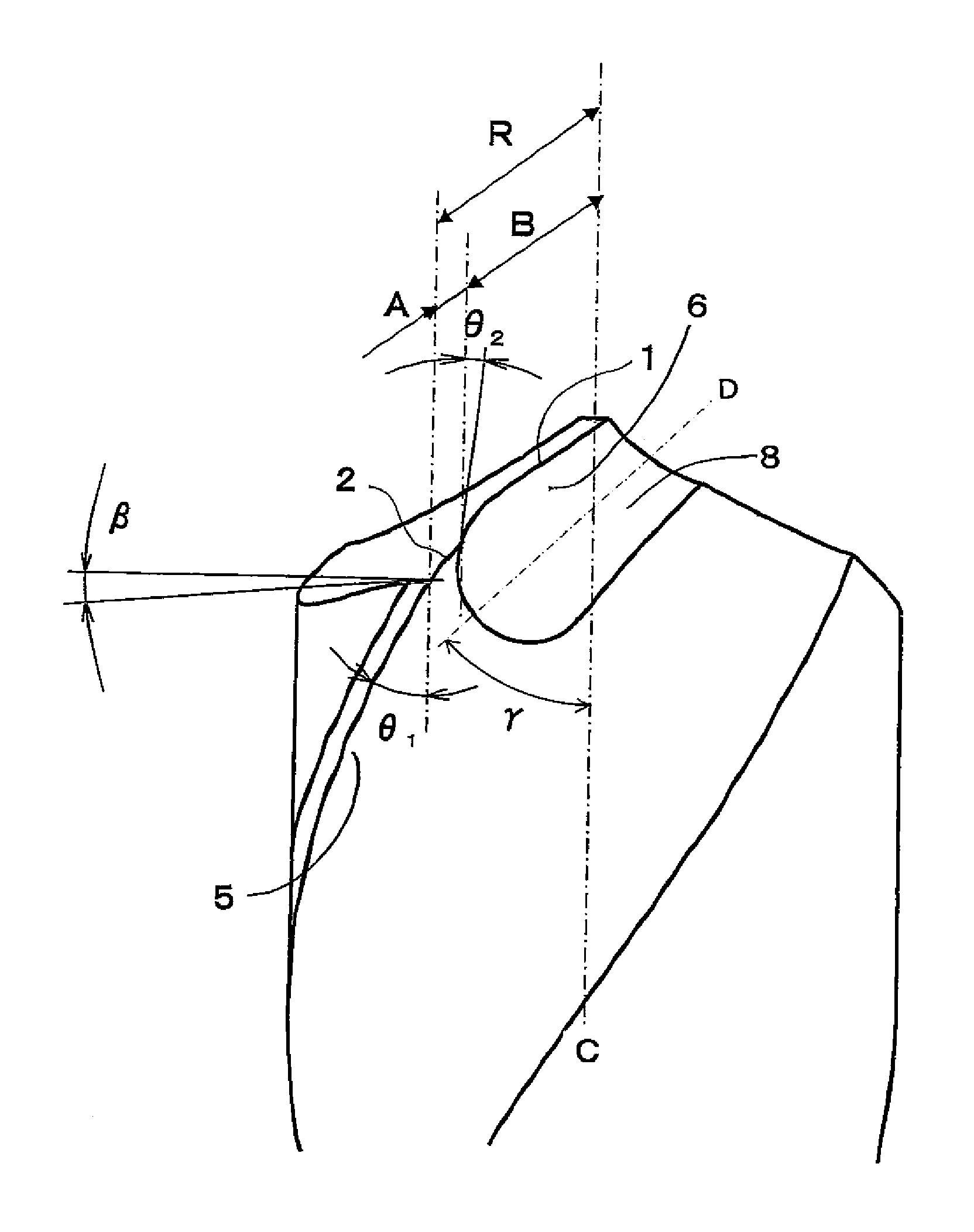

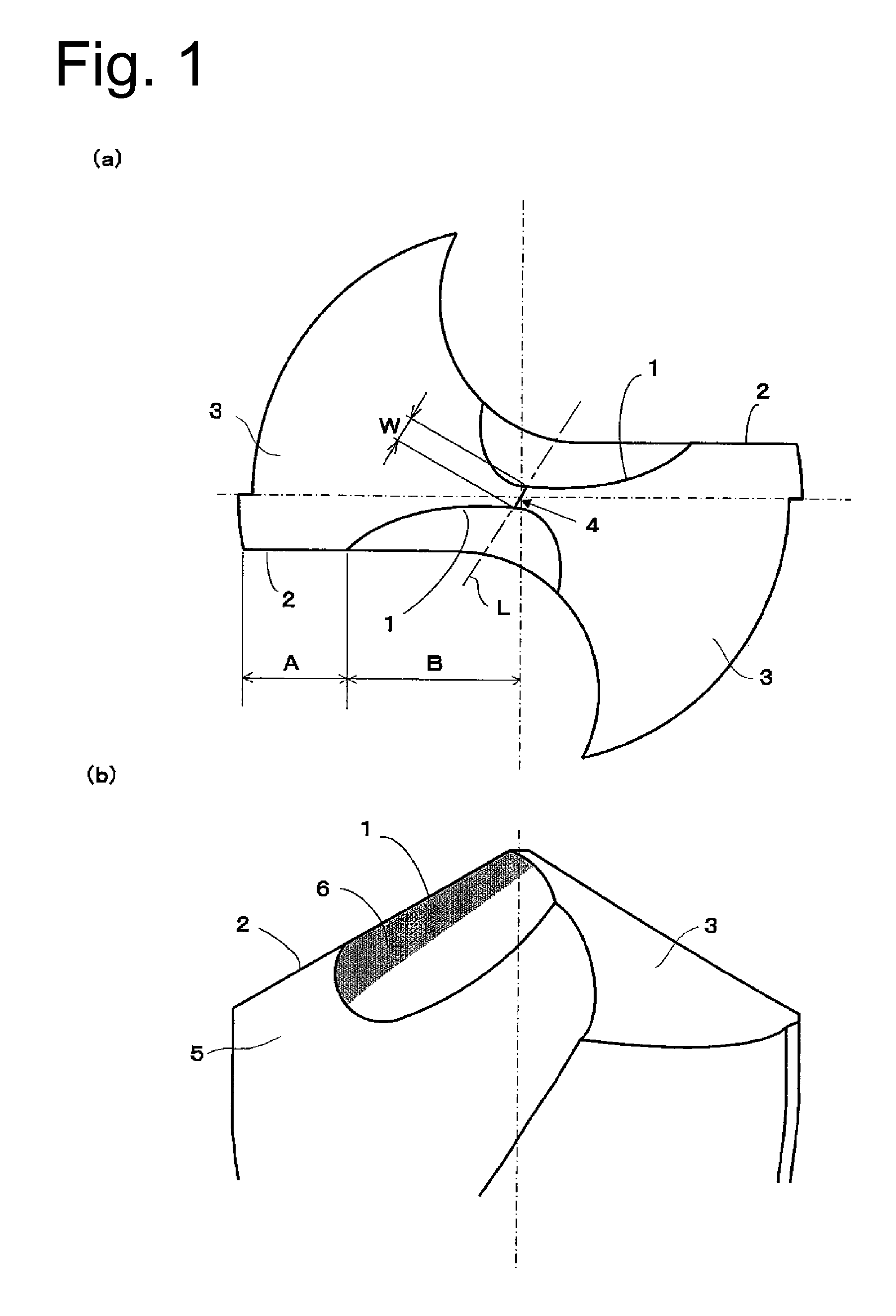

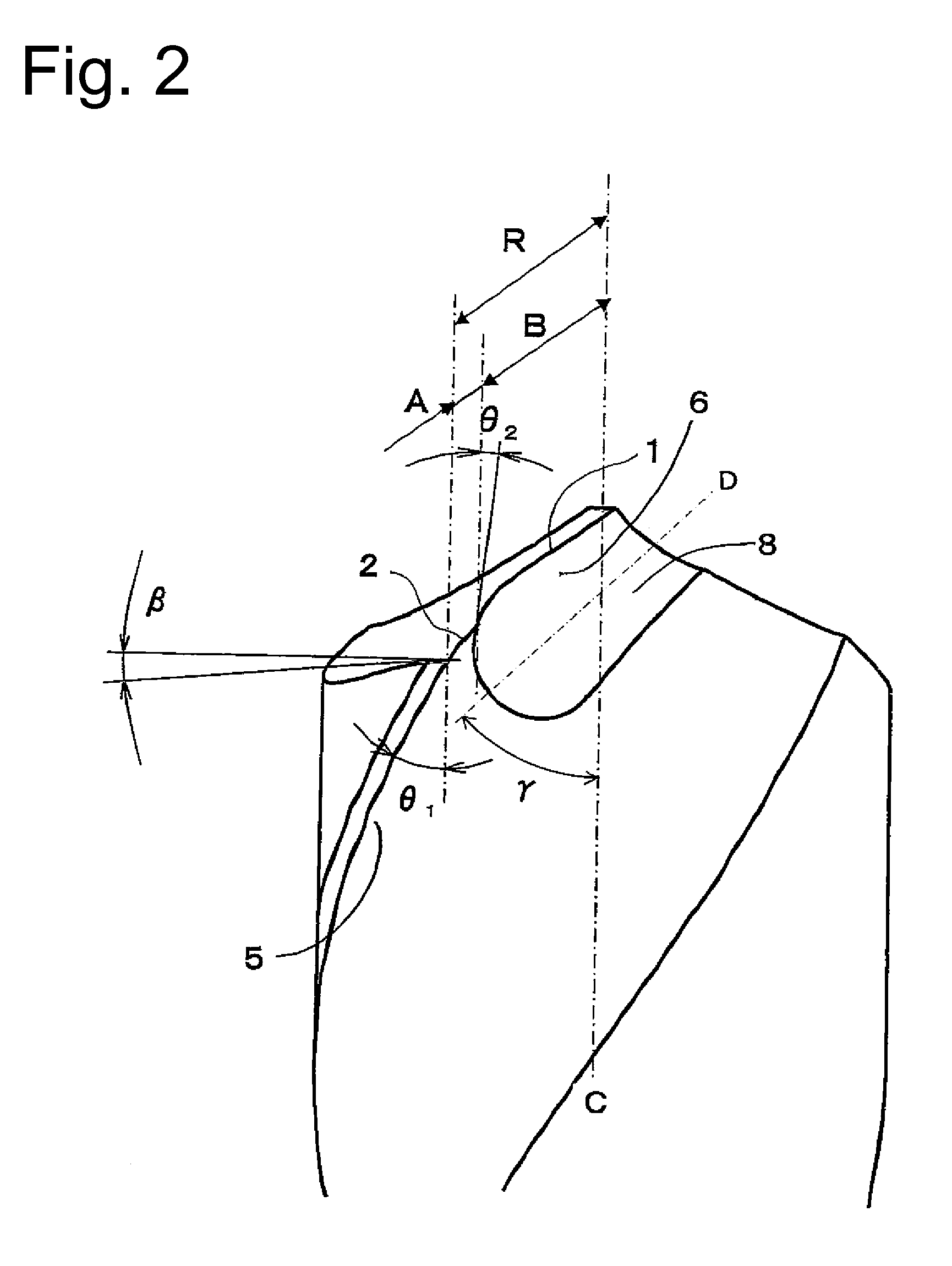

Drill

ActiveUS8579557B2Easy to drillIncrease in the drill's life spanWood turning toolsTransportation and packagingEngineeringHuman power

Owner:BIC TOOL

Borescope for drilled shaft inspection

ActiveUS10677039B1Adjustable lengthIncrease the lengthTelevision system detailsSurveyEngineeringBorescope

A borescope may include a housing including a transparent viewing window, a bumper surrounding at least a portion of a periphery of the transparent viewing window, wherein the bumper is configured to be pressurized by a fluid, and at least one imaging assembly configured to visualize a field of view exterior of the housing through the transparent viewing window.

Owner:AVER TECH INC

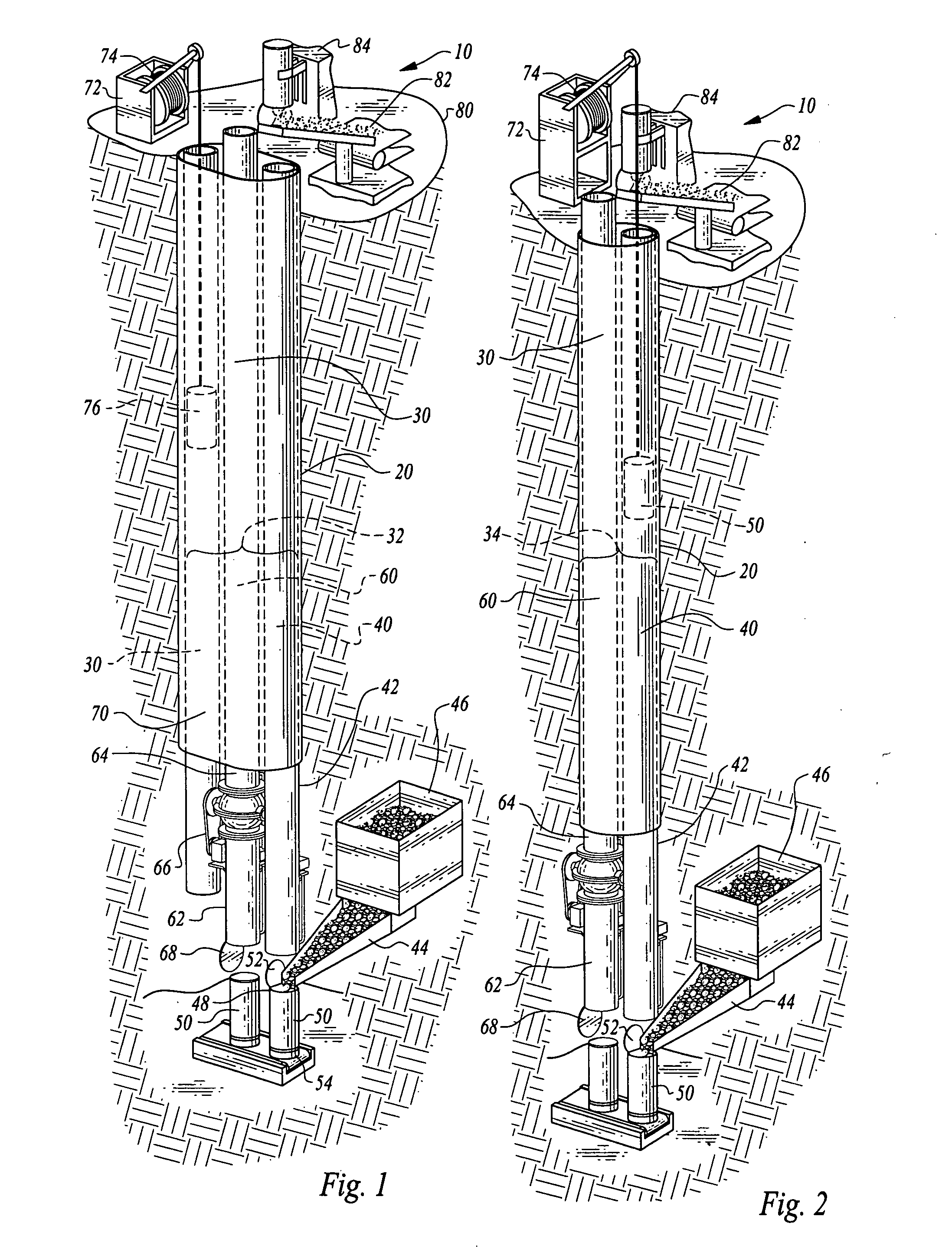

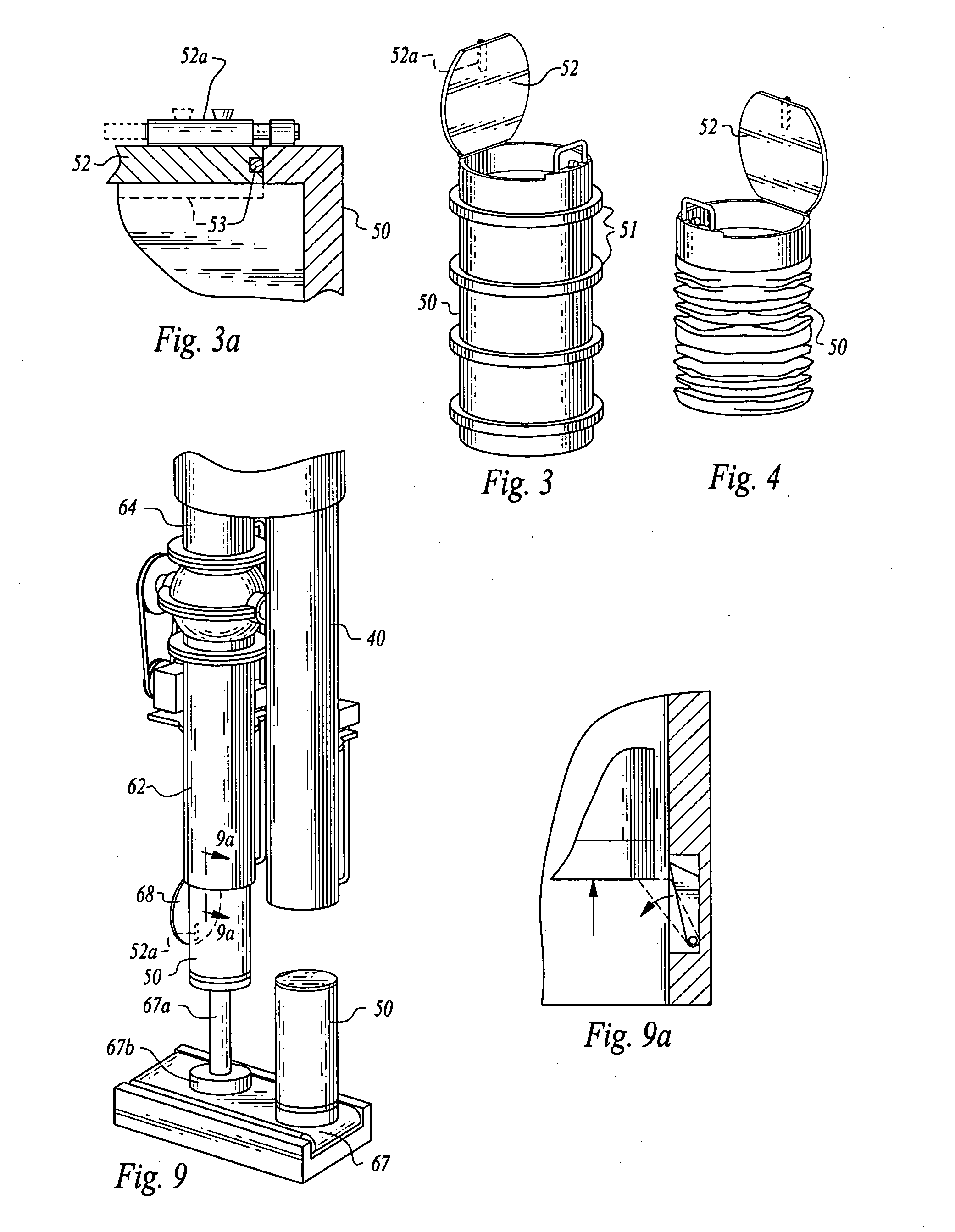

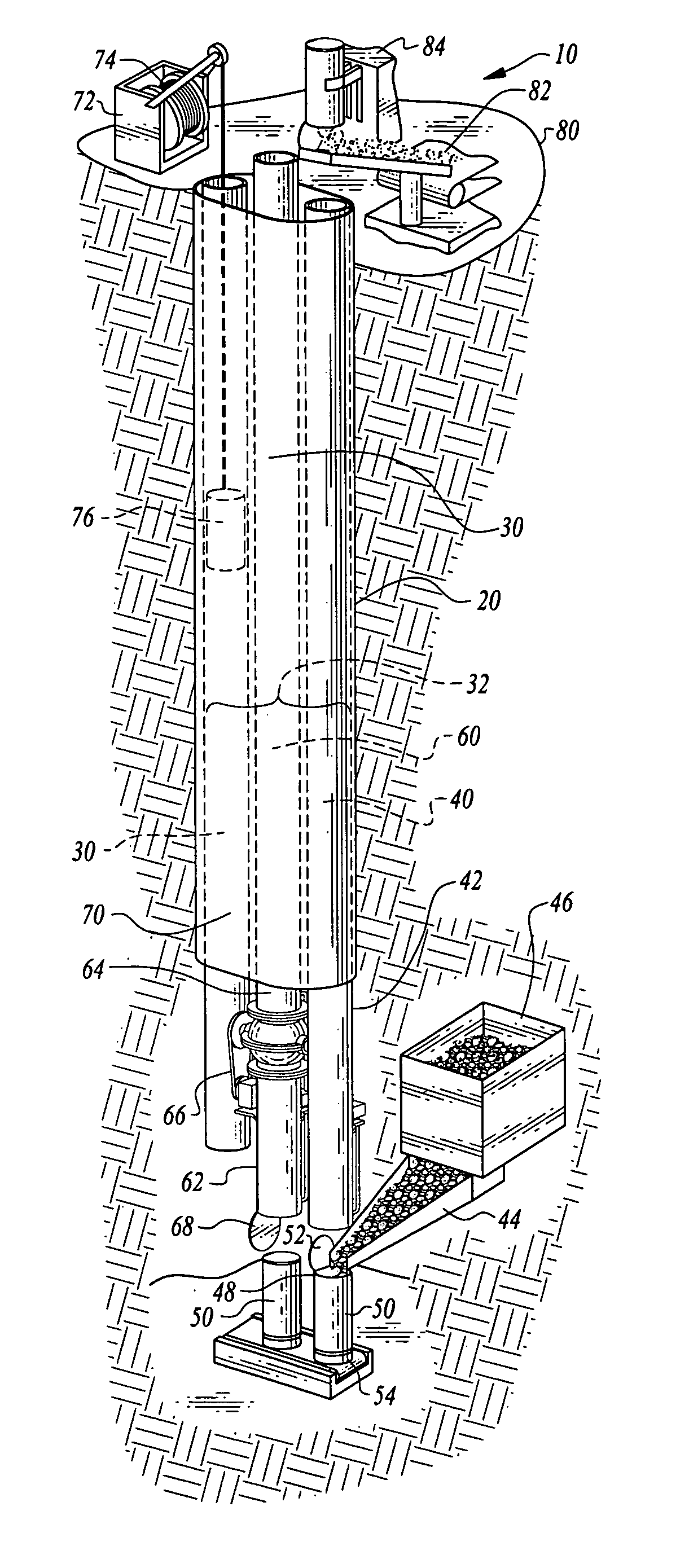

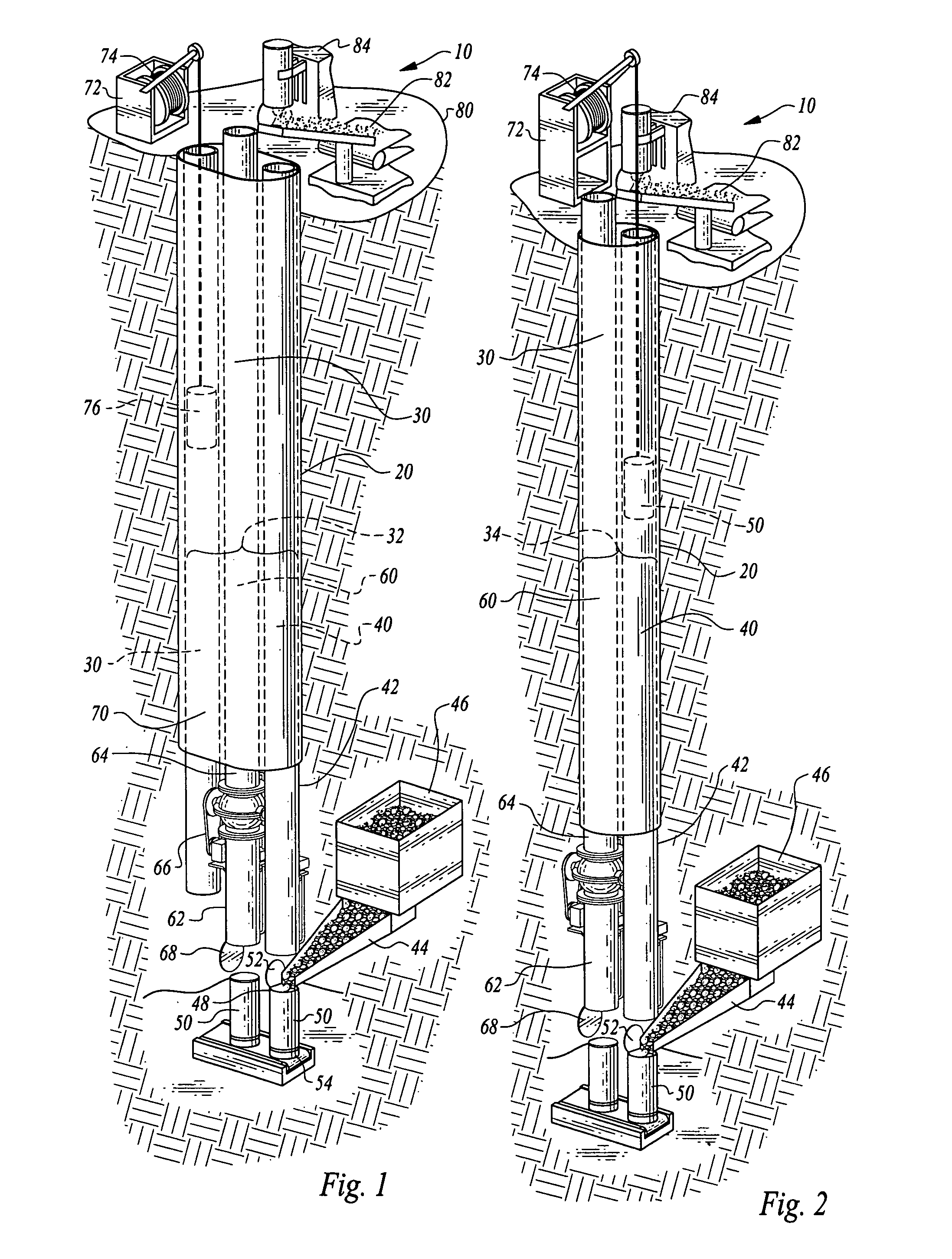

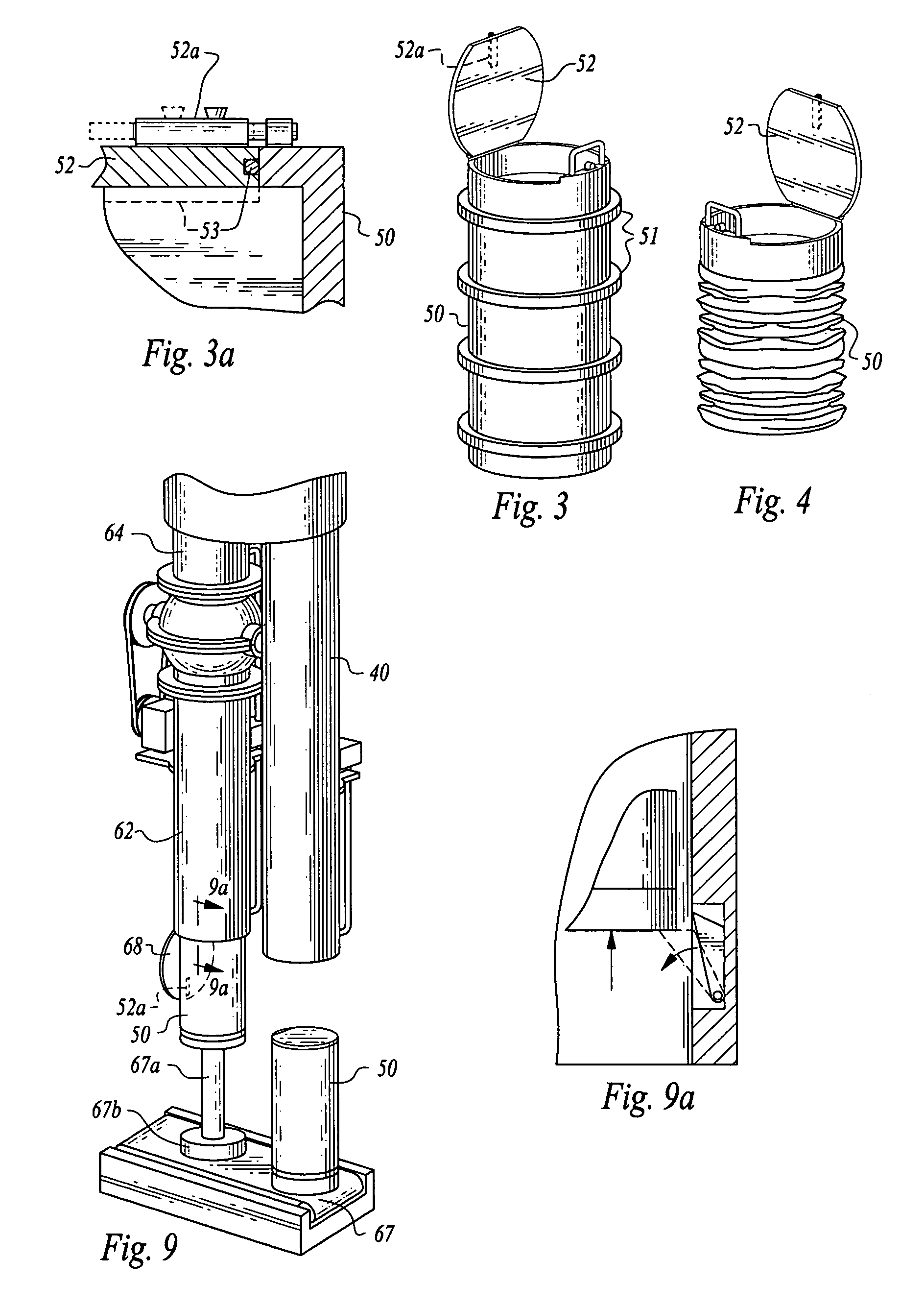

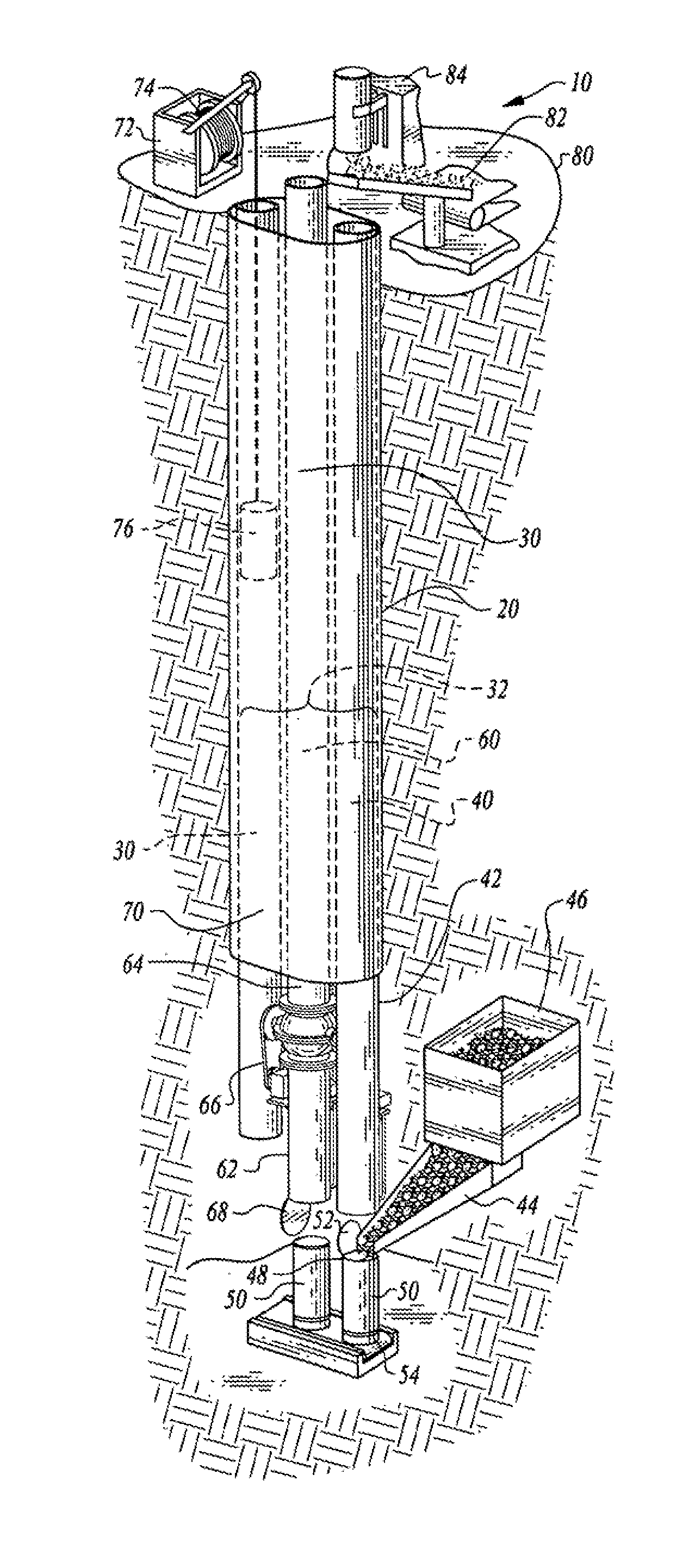

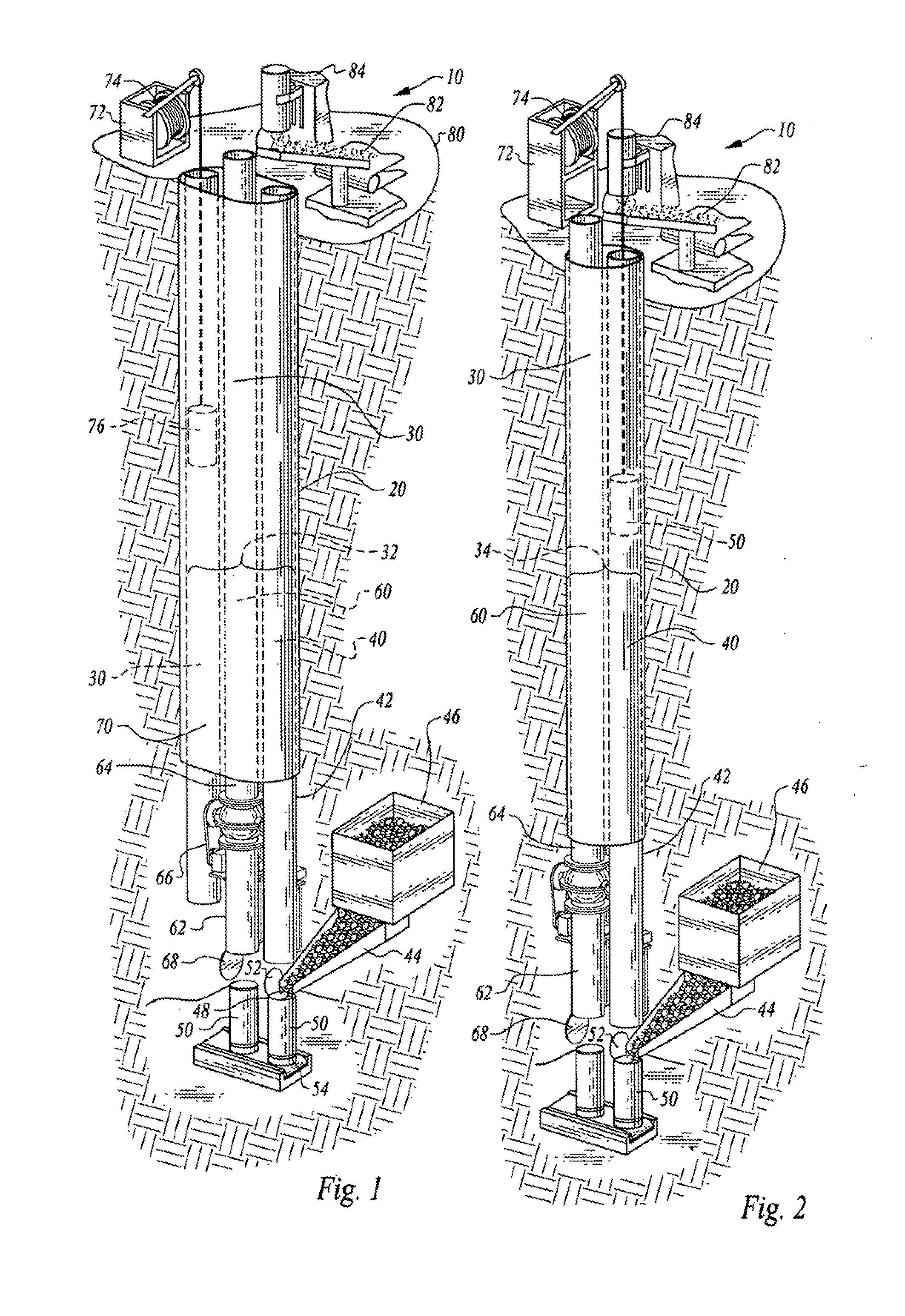

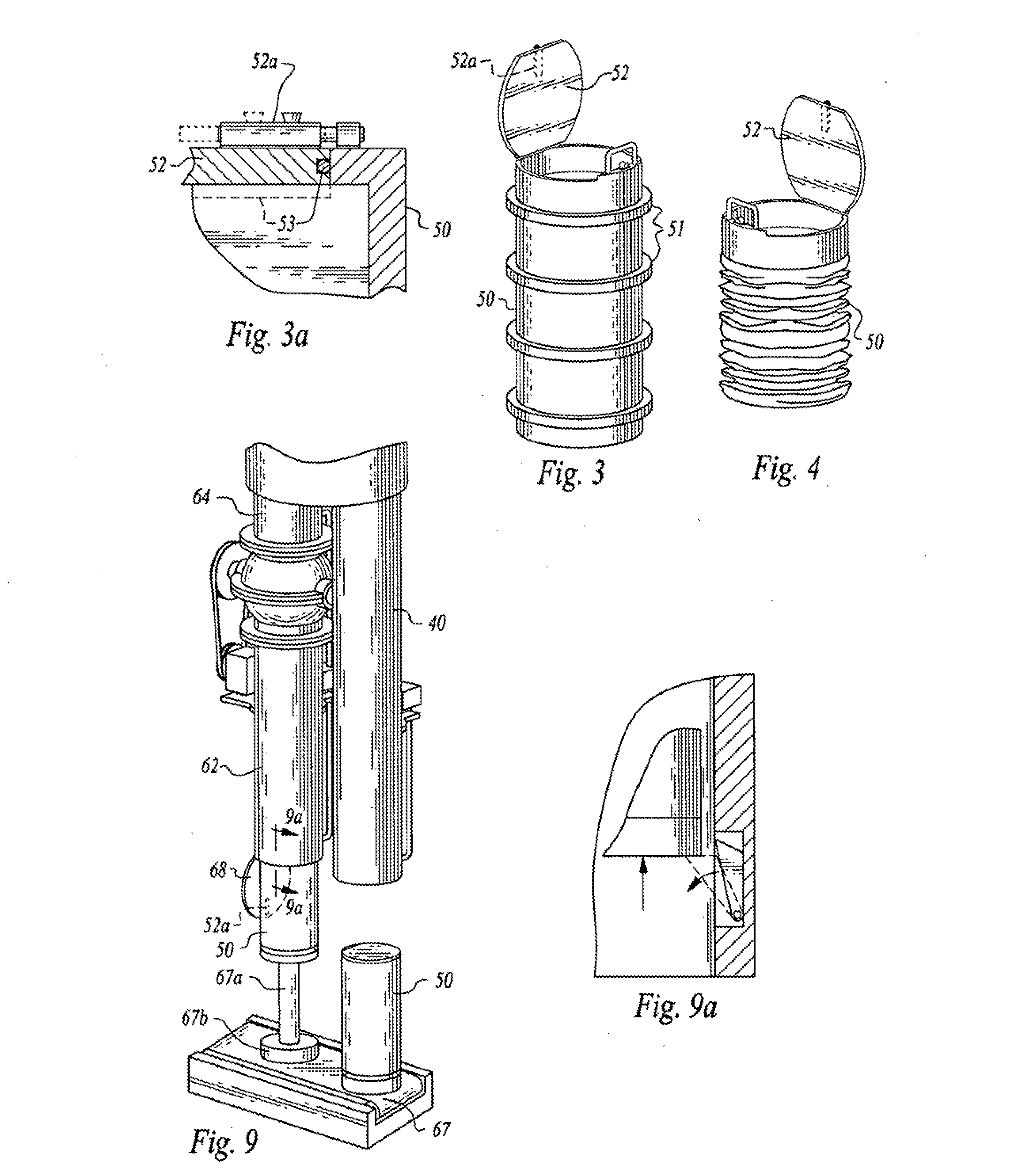

Hydraulic elevation apparatus and method

InactiveUS20070269295A1Control speedPromote sportsBulk conveyorsEarth drilling and miningAbove groundEngineering

The hydraulic elevation apparatus and method of the present invention incorporate a multiple chamber framework internally disposed preferably within at least one single shaft structure, which facilitates movement of object transport containers within the multiple chamber framework. Preferably, fluid elevation is employed to elevate object transport containers and their contents within the multiple chamber framework. Each single shaft structure may be constructed from an existing rehabilitated shaft, or a newly drilled shaft. The present invention may be utilized in vertical or incline lifting environments, and an auxiliary hoist chamber may be incorporated into the multiple chamber framework for use as an alternative to, or in conjunction with, elevating objects by employing fluid elevation. The present invention may be employed in a variety of heavy lifting scenarios, including underground mining or in above ground lifting environments.

Owner:GUENTHER ROSS

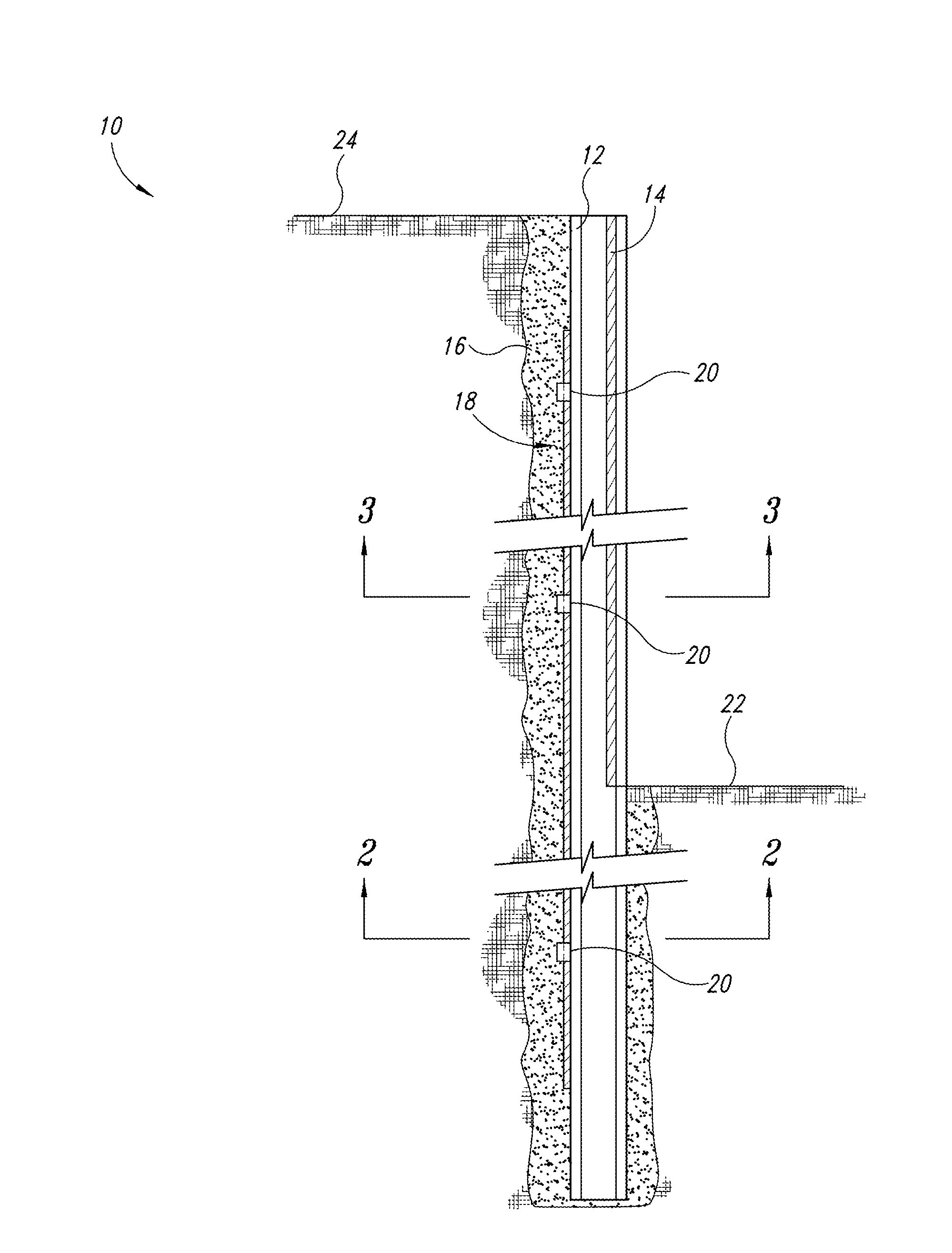

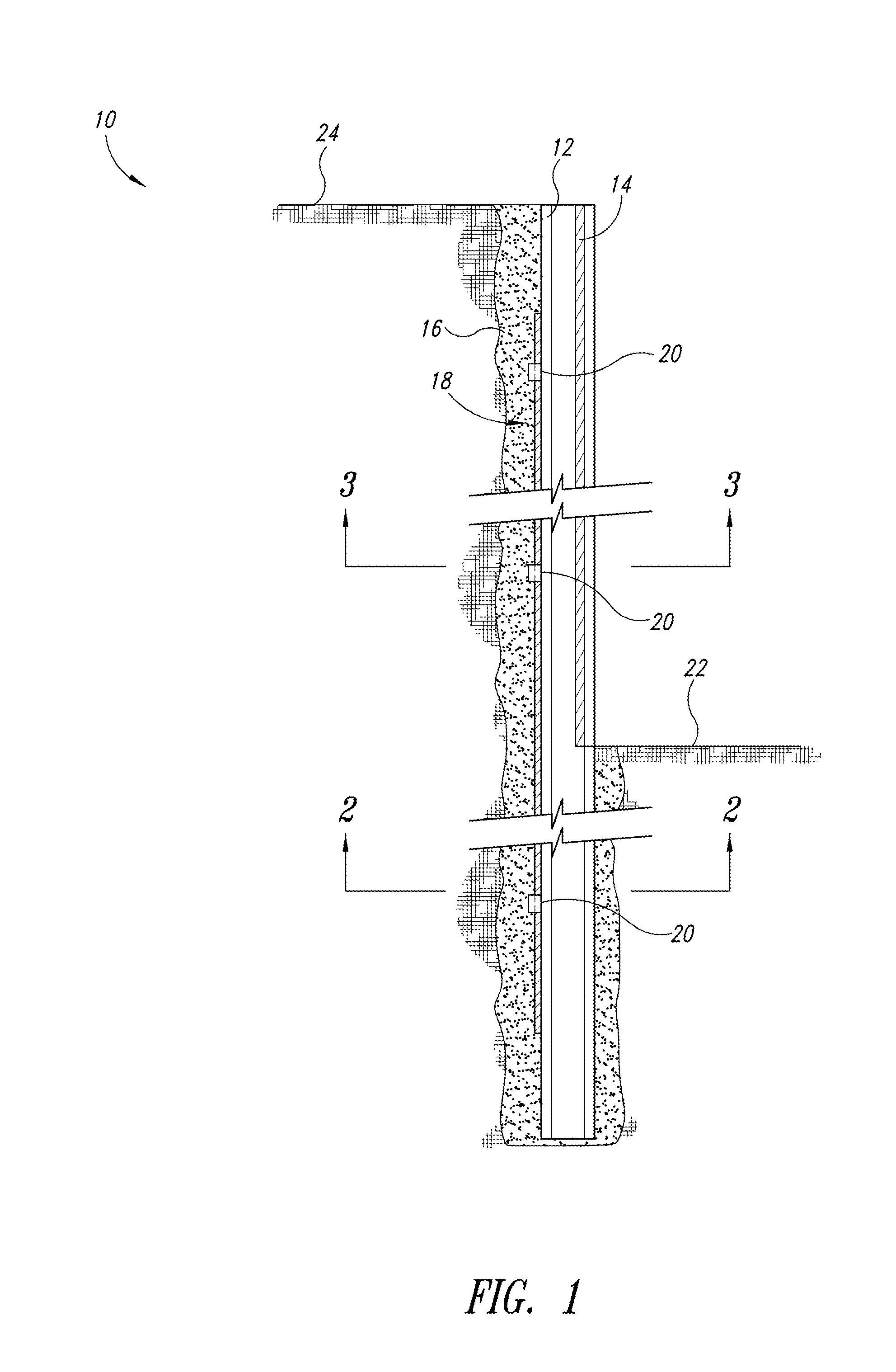

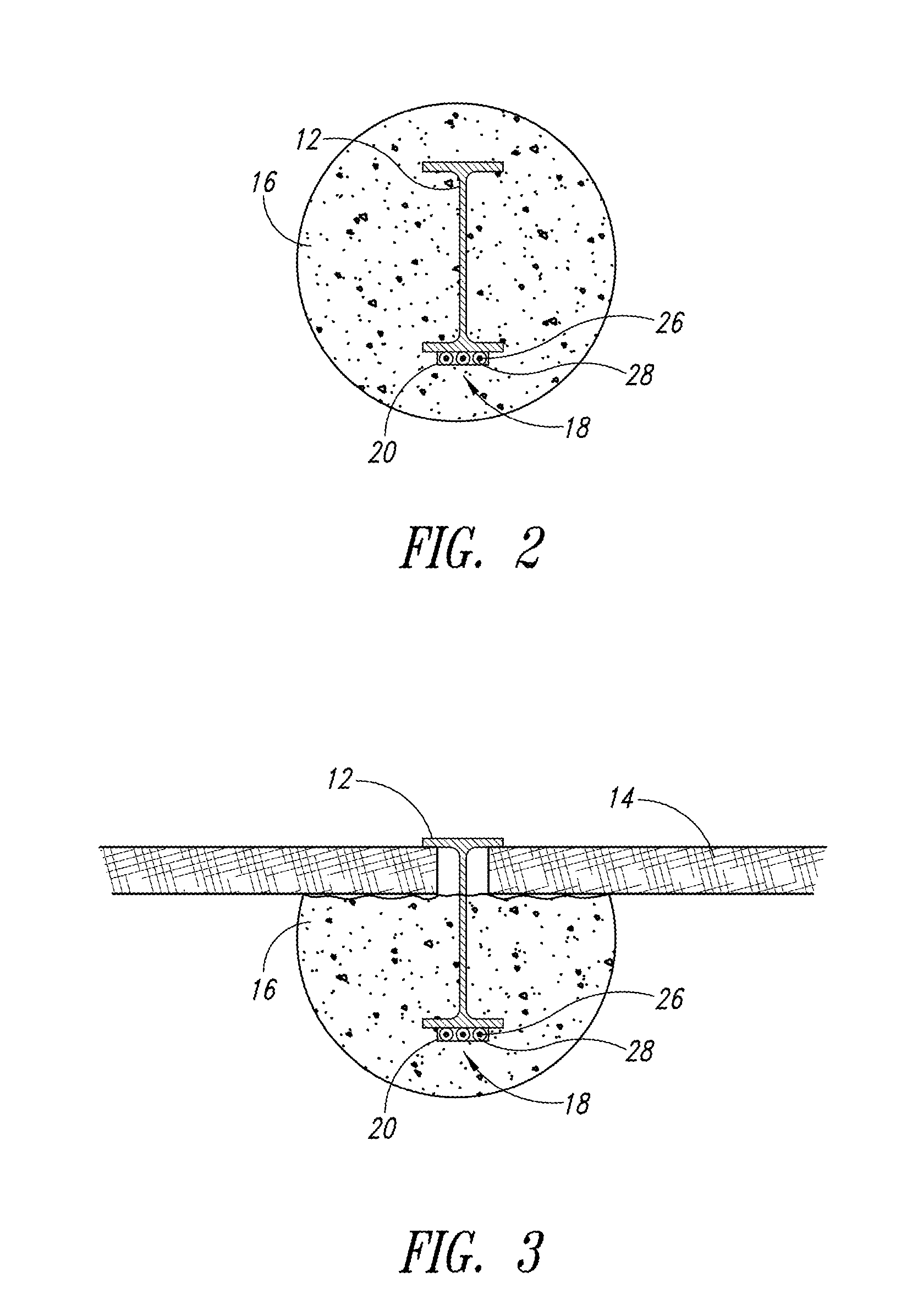

Systems and methods to reinforce excavation walls

ActiveUS20150086278A1Improve carrying capacityIncrease the elastic rangeExcavationsBulkheads/pilesPre stressPre stressing

A soldier pile wall for shoring an excavation site includes a plurality of drilled shafts drilled along an edge of the excavation site, a plurality of soldier piles, each of the plurality of soldier piles being positioned within a respective drilled shaft, and a pre-stressing system coupled to at least some of the plurality of soldier piles. The pre-stressing system is configured to induce stresses to counteract working stresses of the soldier pile wall. Related methods are also provided.

Owner:POST TENSIONING SOLUTIONS

Hydraulic elevation apparatus and method

The hydraulic elevation apparatus and method of the present invention incorporate a multiple chamber framework internally disposed preferably within at least one single shaft structure, which facilitates movement of object transport containers within the multiple chamber framework. Preferably, fluid elevation is employed to elevate object transport containers and their contents within the multiple chamber framework. Each single shaft structure may be constructed from an existing rehabilitated shaft, or a newly drilled shaft. The present invention may be utilized in vertical or incline lifting environments, and an auxiliary hoist chamber may be incorporated into the multiple chamber framework for use as an alternative to, or in conjunction with, elevating objects by employing fluid elevation. The present invention may be employed in a variety of heavy lifting scenarios, including underground mining or in above ground lifting environments.

Owner:GUENTHER ROSS

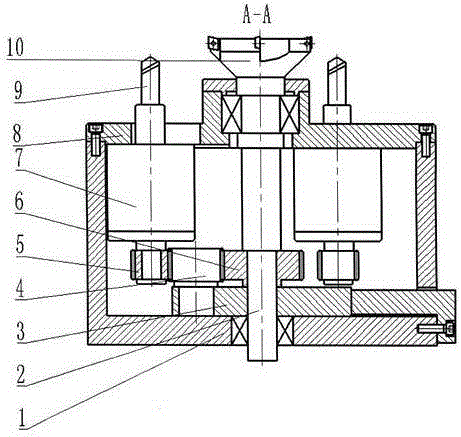

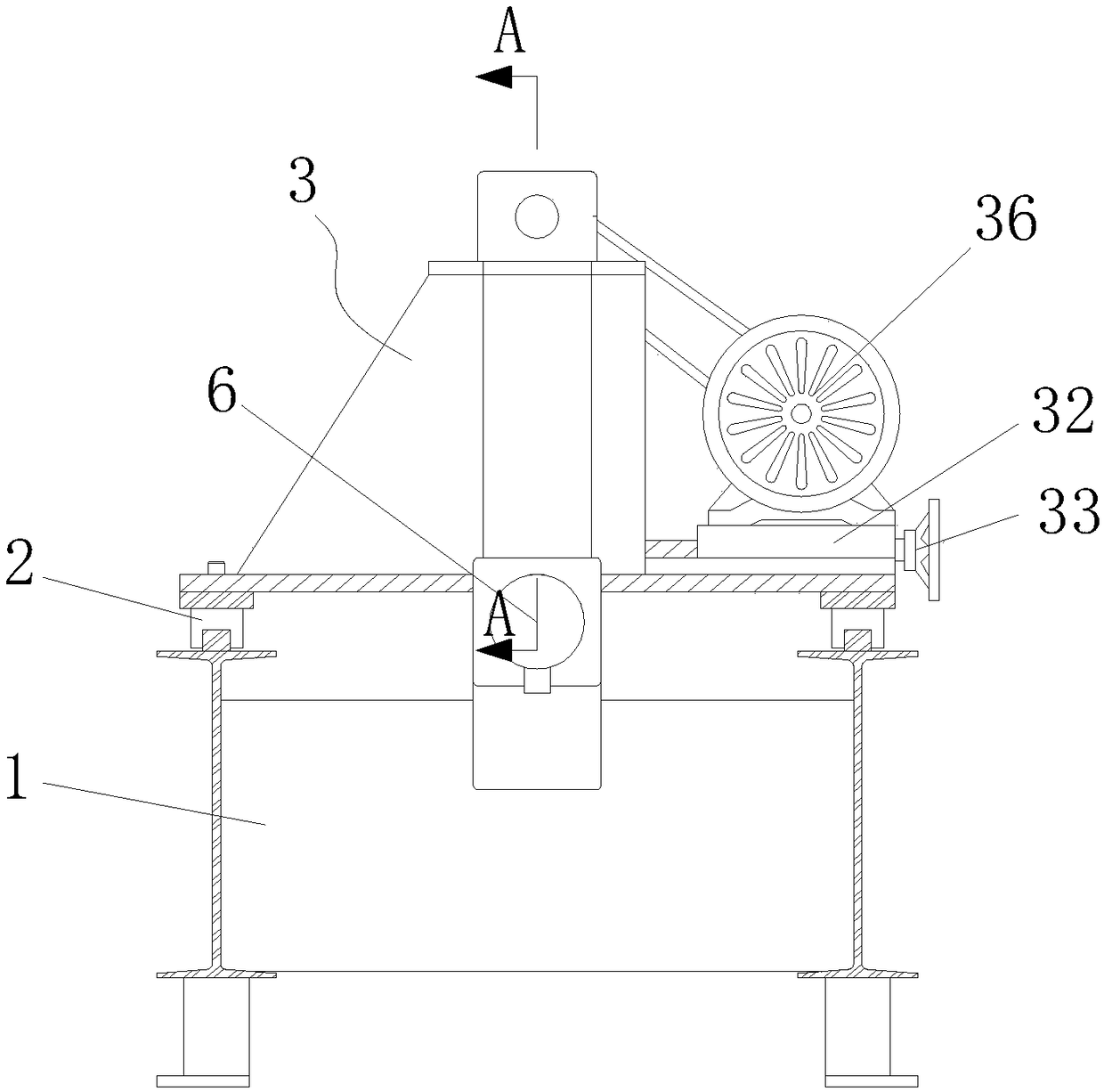

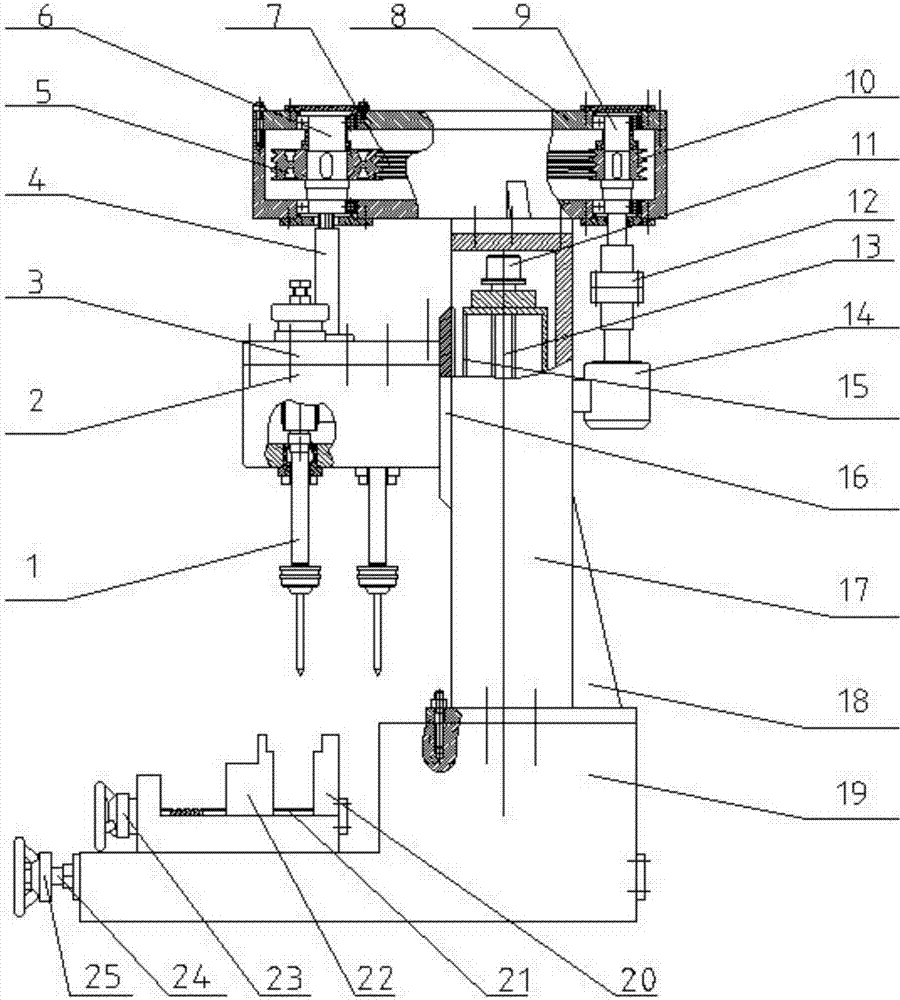

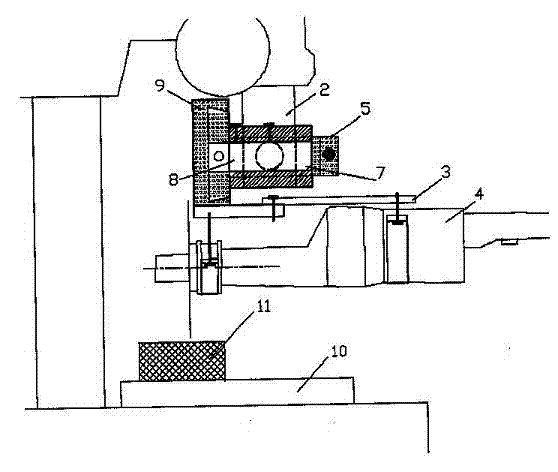

Multi-shaft drilling and milling power head device with adjustable center distance

InactiveCN105215763AReduce transshipment inventoryImprove processing efficiencyOther manufacturing equipments/toolsLarge fixed membersMilling cutterGear wheel

The invention discloses a multi-shaft drilling and milling power head device with adjustable center distance. A main shaft is mounted in the center position of a box body, the middle part of the main shaft is sleeved with a sun gear, boring and milling cutters are mounted at the upper end part of the main shaft and are both in rigid connection, a planet carrier is fixed at the bottom of the box body and is centred through the main shaft, a planetary gear is mounted on the planet carrier, a long hole for fixing the housing of a drilling shaft is formed in a box body cover and the box body cover is fixed through a bolt, a drill bit in rigid connection is assembled at the upper part of the drilling shaft, and a drilling shaft gear is assembled at the lower part of the drilling shaft. The center distance of the drilling shaft of the device is adjustable, therefore, the device can be compatible to all models of spherical surface hole bearing seats within the center distance covering range of the device, the compatibility is good, and the adjustment is easy. By adopting the processing method of milling, the processing efficiency is improved greatly.

Owner:XINXIANG SUNRISE CNC BEARING EQUIP

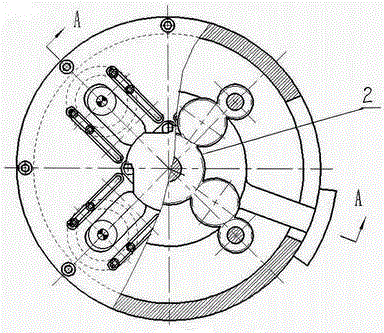

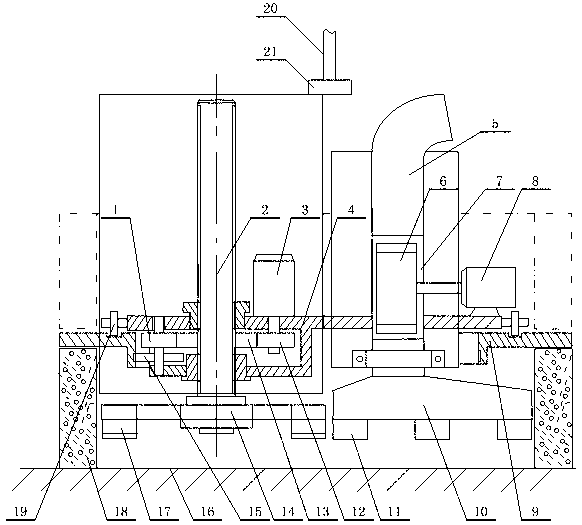

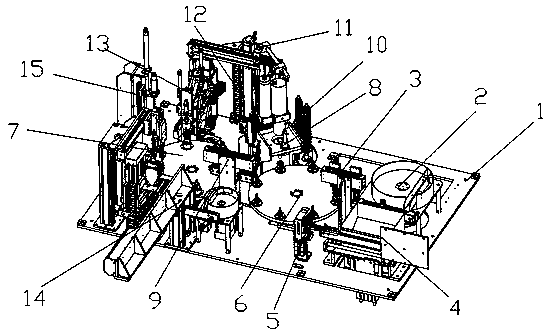

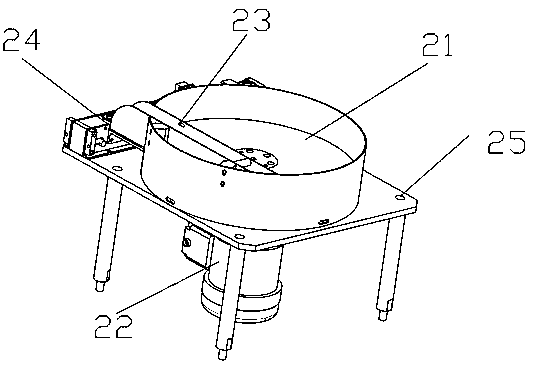

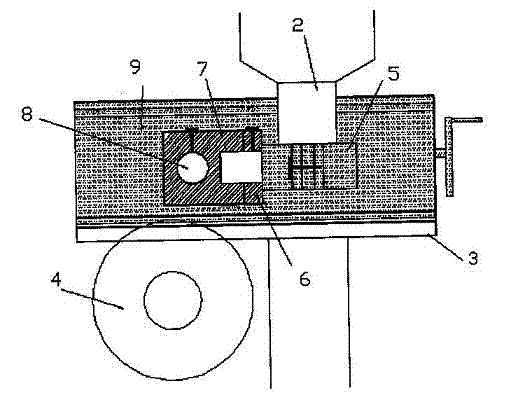

Super-large-aperture pile foundation hole drilling machine

InactiveCN103104190AImprove drilling efficiencyLow costConstructionsDerricks/mastsGear wheelElectric machinery

The invention relates to a super-large-aperture pile foundation hole drilling machine. The super-large-aperture pile foundation hole drilling machine comprises a track rack, a rotary bracket, a drilling machine and a blower, wherein a drilling disc is arranged at the lower part of the drilling machine, drilling heads are distributed on the drilling disc, a drilling shaft is upward arranged at the middle part of the drilling disc, an input gear is sleeved on the drilling shaft, a speed regulating motor is fixed on the rotary bracket, a rotor shaft of the speed regulating motor is connected with a driving gear, the driving gear, the input gear and a bridging gear are sequentially meshed with one another so as to be in transmission, the bridging gear is coaxially connected with a traveling gear, the traveling gear is meshed with the track rack, a suction head is arranged at the lower part of the blower, the lower part of the suction head is connected with slide wanes, a wind power chamber and a wind power transmission pipe are upward arranged at the upper part of the suction head, and a wind wheel is arranged in the wind power chamber. According to the super-large-aperture pile foundation hole drilling machine, super-large apertures can be formed in one step through drilling, and driven-in pile foundations are firm and are difficultly damaged; and the hole drilling efficiency is high, and the cost is low, so that the super-large-aperture pile foundation hole drilling machine is applicable to large-scale popularization and use.

Owner:CHINA UNIV OF MINING & TECH

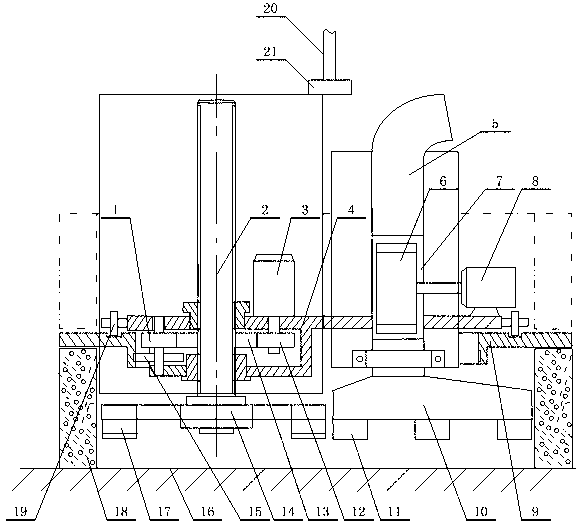

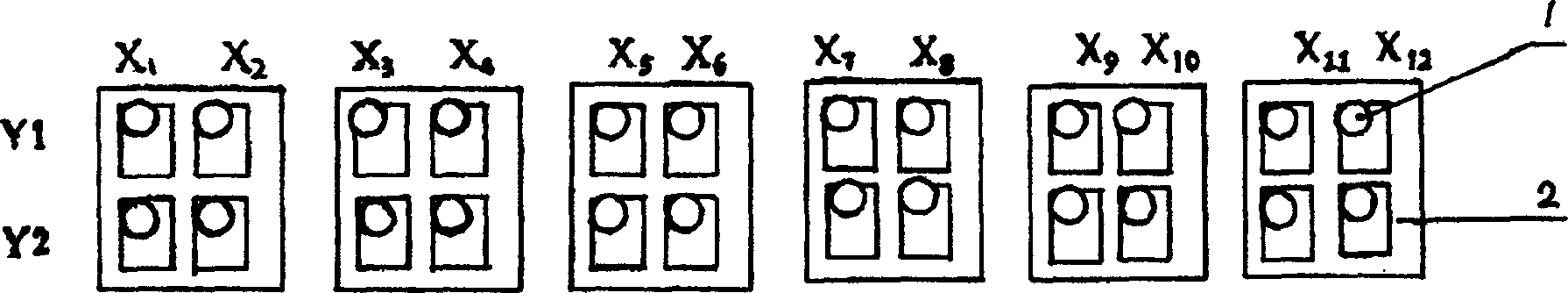

Array method for drill spindles of printed circuit board drilling machine or forming machine

InactiveCN1593824ALow investment costImprove drilling efficiencyPrinted circuit manufactureBoring/drilling machinesMolding machinePrinted circuit board

Then invention relates to a kind of arraying method for print circuit board drill or auger spindle of molding machine. It arrays auger spindles in matrix, which is to array auger spindles in several rows and in several lines which both are moveable. The invention improve the drilling efficiency, save the cost and time for drilling, solve the production choke point and cut down the cost of the drilling machine or the molding machine.

Owner:UNIMICRON TECH SHEN ZHEN

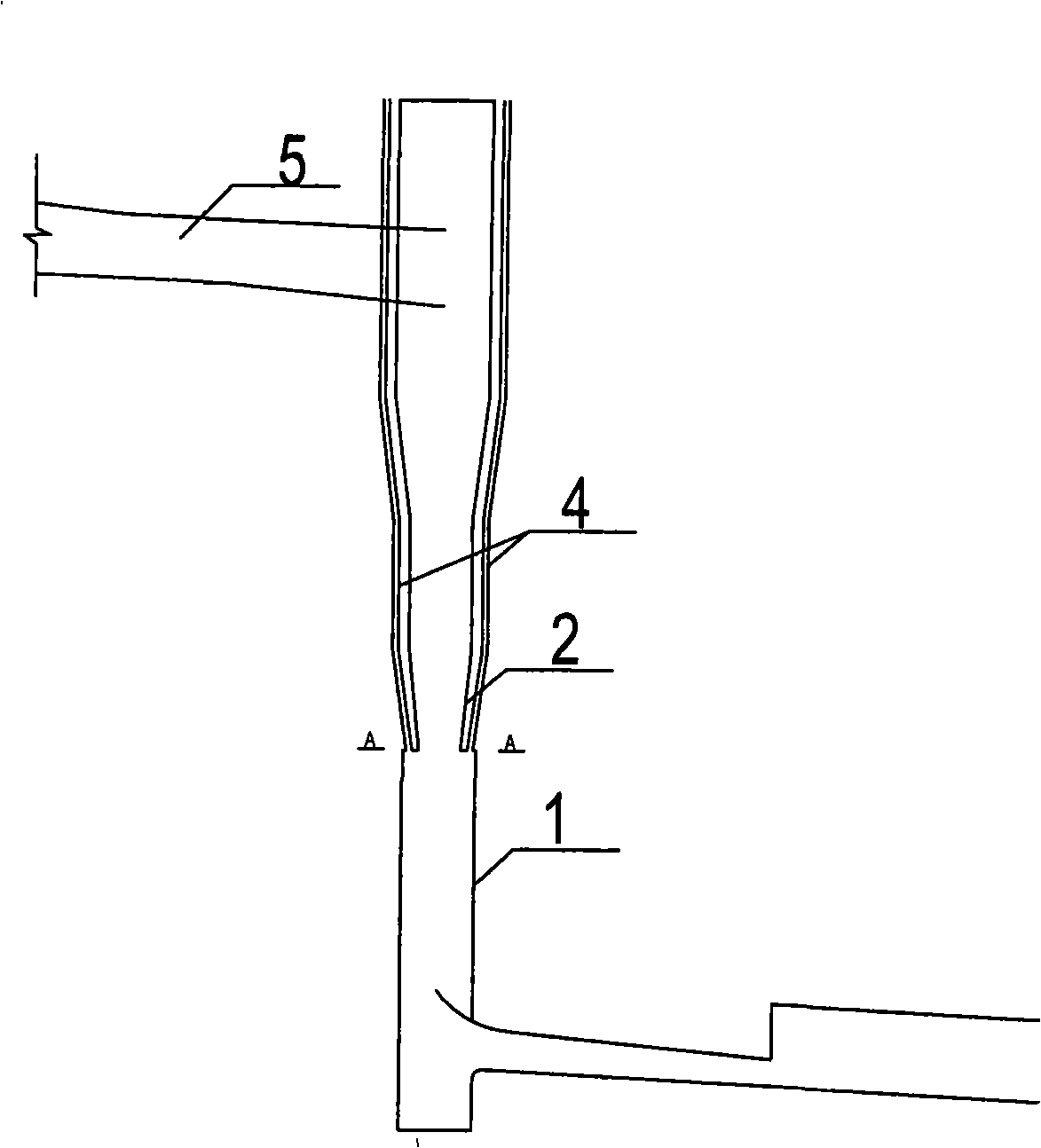

Application of polyurea as drilled shaft underground excavating tunnel water-proof material

InactiveCN101408110AAchieve waterproof effectGood anti-seepageUnderground chambersTunnel liningEngineeringWear resistance

The invention relates to an application which adopts polyurea as a waterproof material in concealed excavation tunnel of a vertical shaft. The application comprises the following steps: the polyurea is coated on a geotextile surface so as to obtain a seamless and integral polyurea geotextile compound which is used as a waterproof film and attached on the inner wall of the tunnel by a mechanical fixing mode so as to lead the permeated water to enter into a drainage system at the periphery of the tunnel. Compared with the prior art, the invention has the following advantages: (1) a structure which adopts polypropylene material to make woven fabric as base cloth and is coated with a polyurea layer is adopted and the whole protecting film is seamless and integral and has the characteristics of good permeability resistance, corrosion resistance, wear resistance and aging resistance and the like; (2) the waterproof film is attached on the inner wall of the tunnel in the mechanical fixing mode so as to lead the permeated water to enter into the drainage system at the periphery of the tunnel, thus avoiding leakage; and (3) the construction is simple, convenient and easy to implement.

Owner:SHANGHAI WEIKAI CHEM

Kiln cleaning apparatus

Owner:MARTIN ENG

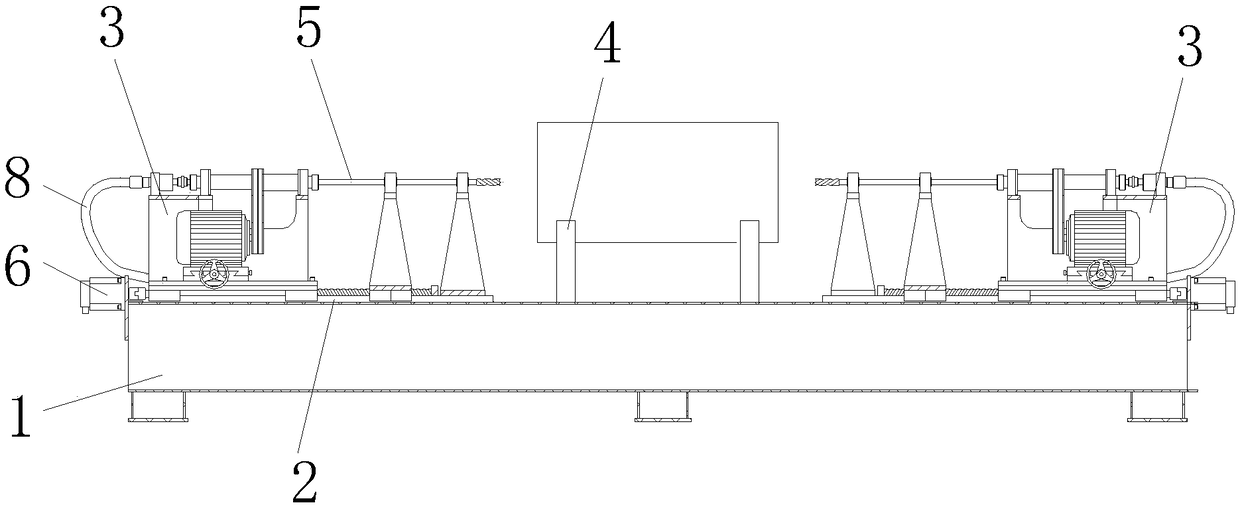

Super-large-aperture pile foundation hole drilling machine

InactiveCN103104191AImprove drilling efficiencyLow costConstructionsDerricks/mastsGear wheelElectric machinery

The invention relates to a super-large-aperture pile foundation hole drilling machine. The super-large-aperture pile foundation hole drilling machine comprises a track rack, a rotary bracket, a drilling machine and a blower, wherein a drilling disc is arranged at the lower part of the drilling machine, drilling heads are distributed on the drilling disc, a drilling shaft is upward arranged at the middle part of the drilling disc, an input gear is sleeved on the drilling shaft, a speed regulating motor is fixed on the rotary bracket, a rotor shaft of the speed regulating motor is connected with a driving gear, the driving gear, the input gear and a bridging gear are sequentially meshed with one another so as to be in transmission, the bridging gear is coaxially connected with a traveling gear, the traveling gear is meshed with the track rack, a suction head is arranged at the lower part of the blower, the lower part of the suction head is connected with slide wanes, a wind power chamber and a wind power transmission pipe are upward arranged at the upper part of the suction head, and a wind wheel is arranged in the wind power chamber. According to the super-large-aperture pile foundation hole drilling machine, super-large apertures can be formed in one step through drilling, and driven-in pile foundations are firm and are difficultly damaged; and the hole drilling efficiency is high, and the cost is low, so that the super-large-aperture pile foundation hole drilling machine is applicable to large-scale popularization and use.

Owner:XUZHOU UNIV OF TECH

Ultra-long deep woodworking drilling machine and implementing method thereof

InactiveCN108501121ASecure center pointGuaranteed accuracyStationary drilling machinesBark-zones/chip/dust/waste removalFixed frameEngineering

The invention discloses an ultra-long deep woodworking drilling machine. The ultra-long deep woodworking drilling machine comprises a drilling machine support and a wood fixing frame fixed to the upper surface of the drilling machine support. A guide rail is welded to the upper surface of the drilling machine support and located on each side of the wood fixing frame, each guide rail is in slidingconnection with a moving assembly, a hollow drill shaft assembly is rotationally connected above each moving assembly through a bearing pedestal, the end, different from the wood fixing frame, of eachdrill shaft assembly is connected with a water pipe, and a hollow twist drill bit is connected to the end, close to the wood fixing frame, of each drill shaft assembly. The invention further discloses an implementing method of the ultra-long deep woodworking drilling machine. Water is injected into lengthened drill rods through high-pressure water pumps and sprayed out from water outlet holes inthe front ends of the twist drill bits, wood chips generated due to drilling are washed from inside to outside through the high-pressure water and conveyed out of ports of holes, and thus the deep holes can be drilled at a time.

Owner:东阳市尚德电器机械有限公司

Hydraulic elevation apparatus and method

InactiveUS20100303560A1Control speedPromote sportsBulk conveyorsEarth drilling and miningAbove groundEngineering

The hydraulic transportation apparatus and method of the present invention incorporate a multiple chamber framework internally disposed preferably within at least one single shaft structure, which facilitates movement of object transport containers within the multiple chamber framework. Preferably, fluid elevation is employed to elevate and lower object transport containers and their contents within the multiple chamber framework. Each single shaft structure may be constructed from an existing rehabilitated shaft, or a newly drilled shaft. The present invention may be utilized in vertical or incline lifting environments, and an auxiliary hoist chamber may be incorporated into the multiple chamber framework for use as an alternative to, or in conjunction with, elevating objects by employing fluid elevation. The present invention may be employed in a variety of heavy lifting scenarios, including underground mining or in above ground lifting environments.

Owner:GUENTHER ROSS

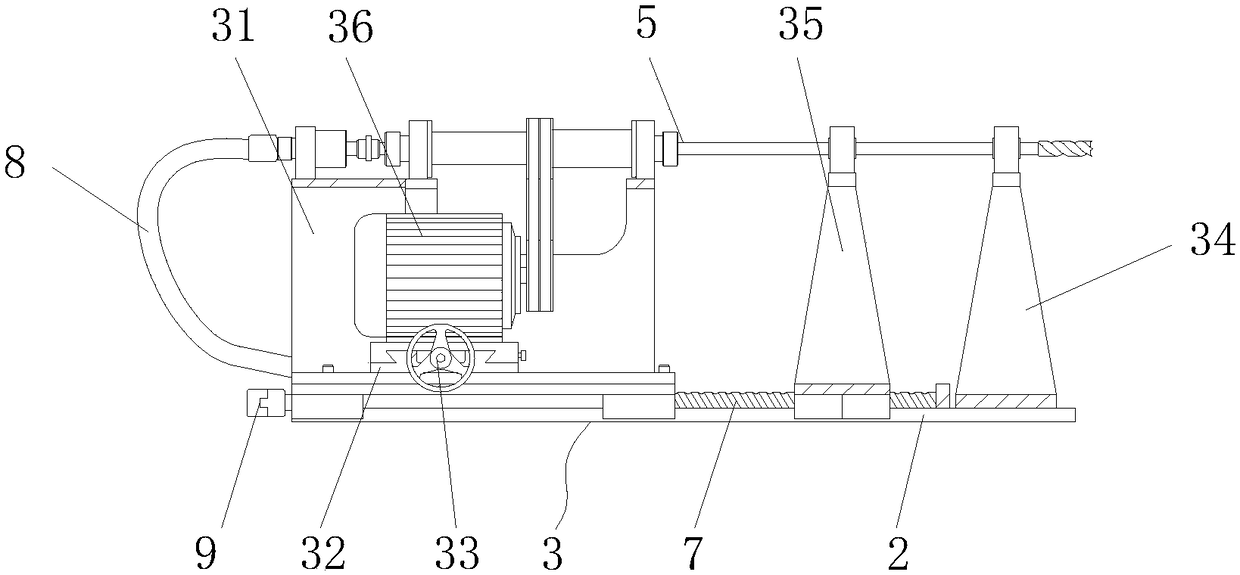

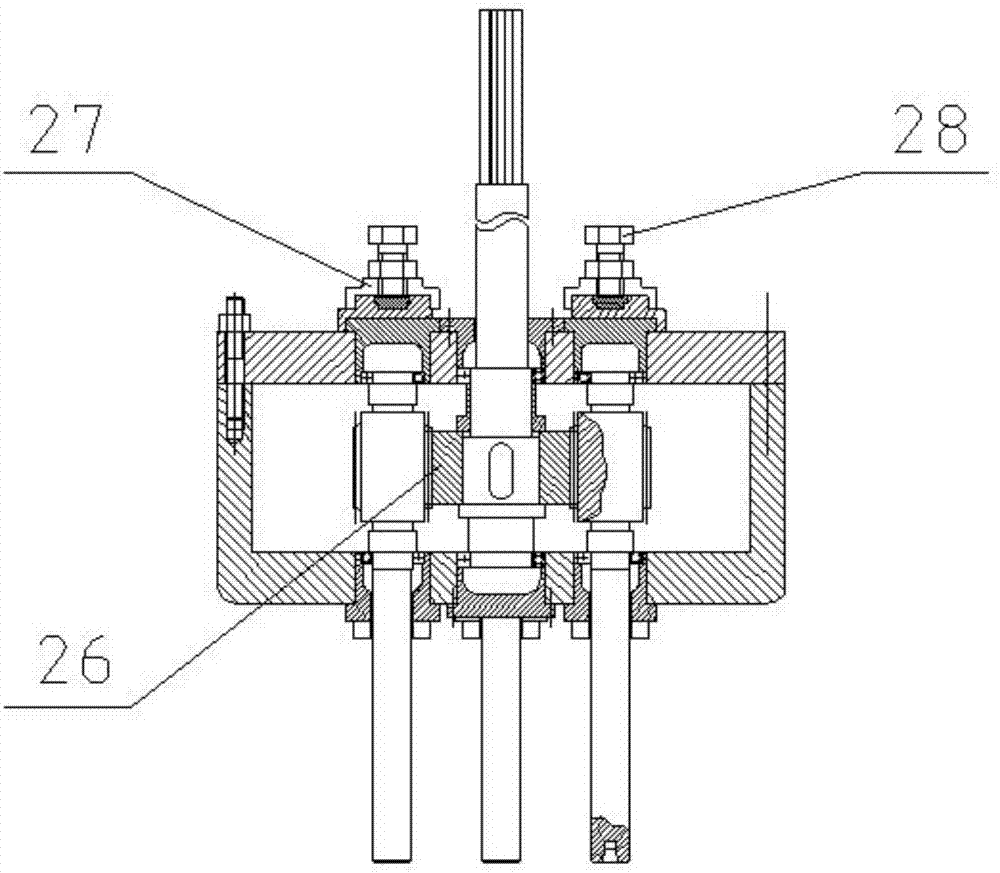

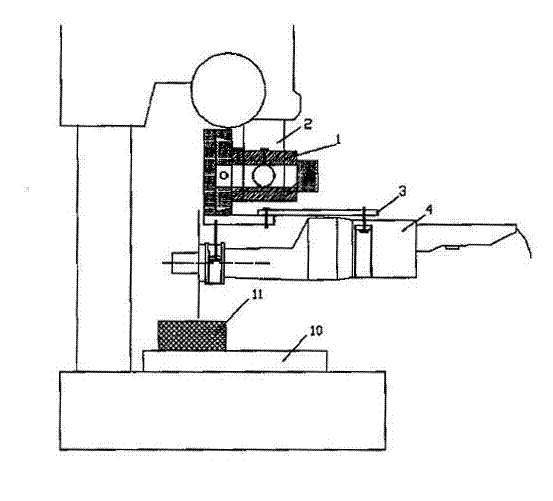

Vertical multi-spindle drilling machine with adjustable spacing

PendingCN107398576AWith self-locking functionEnsure safetyBoring/drilling machinesGear wheelCoupling

The invention discloses a vertical multi-spindle drilling machine with an adjustable spacing. The vertical multi-spindle drilling machine comprises a main motor, an elastic coupling, belt driving components, a main shaft, gear spacing adjusting devices, linear modules, a rack, a supporting rib plate and workpiece clamping and adjusting devices, wherein the main motor is connected with the belt driving components by the elastic coupling; the belt driving components are connected with the corresponding gear spacing adjusting devices by the main shaft; the gear spacing adjusting devices are fixed on the corresponding linear modules; the linear modules are fixed on the rack; the rack is fixed on the workpiece clamping and adjusting devices; and the supporting rib plate is used for supporting and fixing the rack. According to the vertical multi-spindle drilling machine with the adjustable spacing, provided by the invention, the spacing between drill spindles is flexibly adjusted according to the required hole distance, the working efficiency of the drilling machine is improved, and the service life of the drilling machine is prolonged; and the vertical multi-spindle drilling machine with the adjustable spacing has the advantages of simple structure, convenience and flexibility in operation and wide application range.

Owner:QINGDAO UNIV OF SCI & TECH

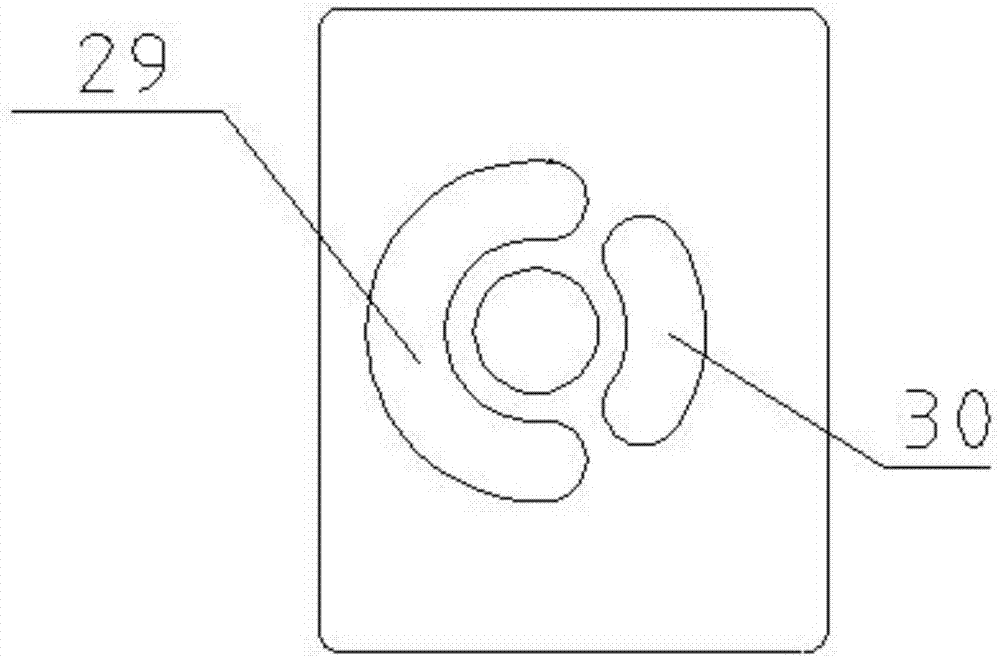

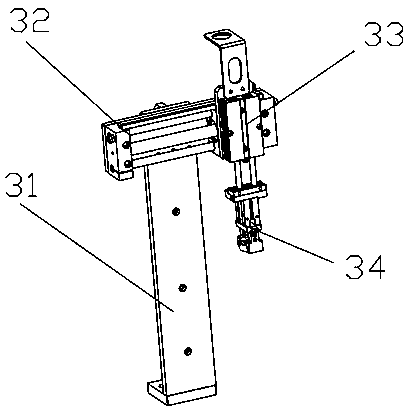

Full-automatic assembling process for crane drill bit drill spindle

ActiveCN111590293AIncrease productivityImprove pass rateMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a full-automatic assembling process for a crane drill bit drill spindle. The full-automatic assembling process comprises the following steps of S1, feeding and conveying a shaft sleeve; S2, clamping, rotating and moving the shaft sleeve; S3, jacking, feeding and conveying a rotating shaft; S4, clamping, rotating and moving the rotating shaft, and combining the rotating shaft and the shaft sleeve into an assembly I; S5, compressing and positioning the assembly I; S6, feeding and grinding a drill bit; S7, assembling the drill bit and the assembly I into an assembly II; S8, splicing a screwdriver head and the assembly II into an assembly III; S9, feeding and conveying a shaft cap; S10, assembling the shaft cap and the assembly III into an assembly IV; and S11, laminating the shaft cap of a finished drill bit drill spindle. Through adoption of the full-automatic assembling process, all accessories of the drill bit drill spindle are assembled into a finished productaccording to a set sequence; automatic assembling operation of the drill bit drill spindle is achieved; the assembling quality and efficiency of the drill bit drill spindle are improved; and good market application value is achieved.

Owner:深圳市中科创想科技有限责任公司

Portable assembly precision joint cutting processing device

InactiveCN102476343ASimple structureCombination principle is not complicatedPreparing sample for investigationGrinding machinesBench grinderEngineering

The invention relates to the field of mechanical test methods for engineering applications and the technical field of joint cutting processing, in particular to a portable assembly precision joint cutting processing device, which comprises a metal snap ring, a rotary shaft seat, a fixed shaft seat, an assorted revolving shaft and a small-sized one-way walking workbench. A method disclosed by the invention comprises (1) an installation step: fixing the metal snap ring on a drill spindle of a drilling and milling machine, adjusting to a required angle, and clamping; and (2) a working step: clamping a sanding machine by using a fixing device, tightly fixing an entire combine device on the drill spindle according to the operating step (1), arranging the sanding machine fixing device on a cross-shaped workbench, fixing a test piece on a cross-shaped workbench on the lower part of the drilling and milling machine, adjusting a joint cutting position on the test piece according to the bidirectional walking function of the workbench, fixing a diamond marble sheet on the sanding machine, starting the sanding machine, and shaking a small workbench in the combined device to complete joint cutting.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Shaft sounding device for measuring thickness of sediments at base of drilled shafts

InactiveUS9441962B2Safe, simple, reliable and quantitativeSimple and reliable processMechanical depth measurementsEarth material testingEngineeringSounds device

A sounding device for measuring the thickness of sediments at the base of dry or wet drilled shaft excavations for the assessment of drilled shaft bottom cleaning operations. The sounding device provides a simple and reliable means to quantitatively evaluate drilled shaft bottom cleanliness.

Owner:FUNG STEVE WILHELM

Extrusion auger with removable auger segments and removal tool

InactiveUS20050185503A1Improve structural strengthEasy and safe disassemblyDrill bitsDisloding machinesEngineeringMechanical engineering

There is provided an extrusion auger having auger segments that are removable from an auger shaft and that include a recess to facilitate removal of the auger segments. A pulling tool is also provided to engage the recess of the auger segment and to facilitate the removal of auger segment from the auger shaft in an axially forward direction. The auger segment includes an access way to provide access to the recess and the recess includes an engaging surface. The pulling tool includes a flanged end that can pass through the access way of the auger segment and contact the engaging surface of the auger segment. The recess of the auger segment may be located in a bore of the auger hub such that the pulling tool can be advanced along a keyway in the auger shaft, rotated to pass the flanged end of the pulling tool through the access way, and pulled axially forward to contact the engaging surface.

Owner:J C STEELE & SONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com