Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce lint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

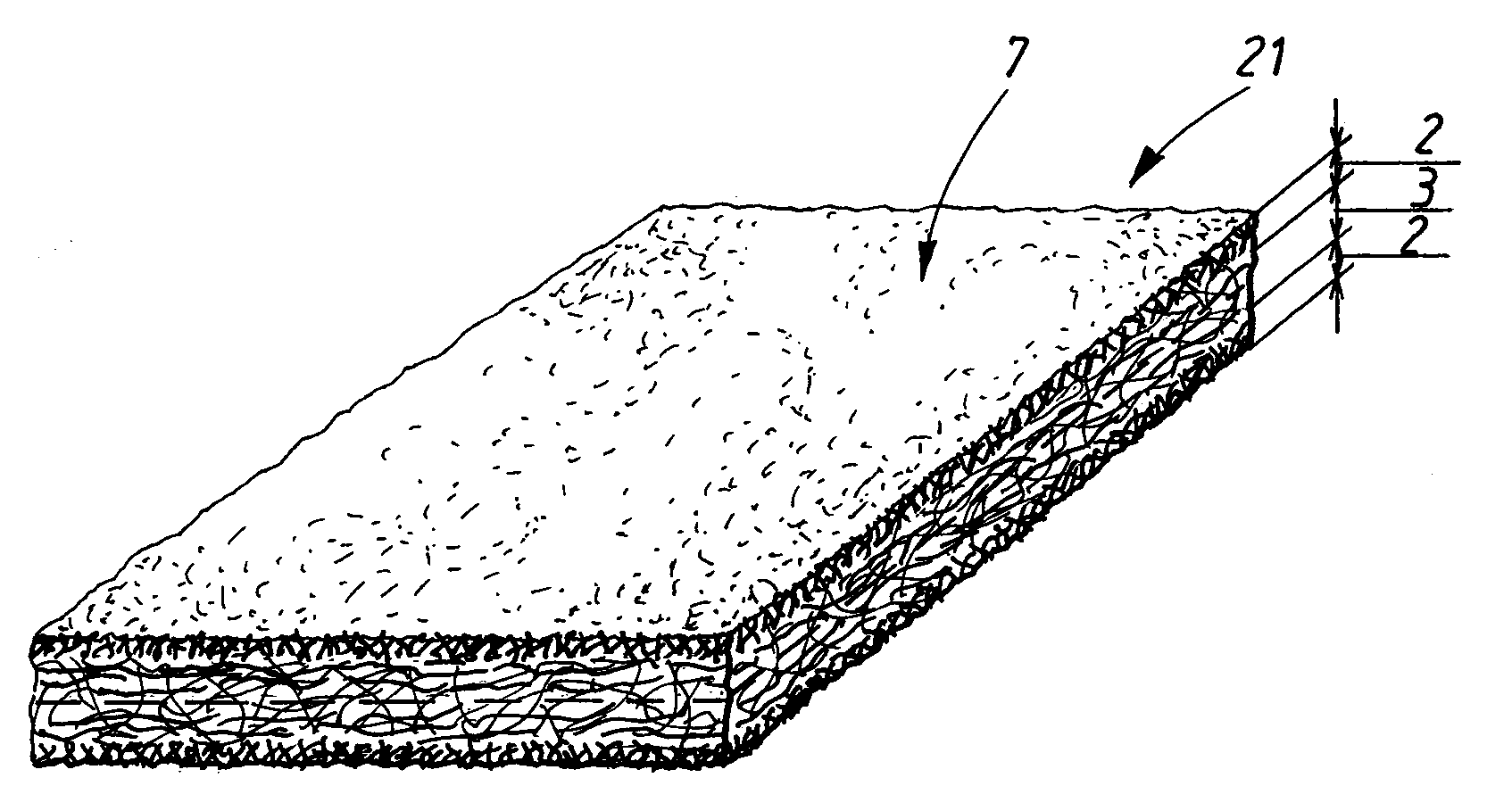

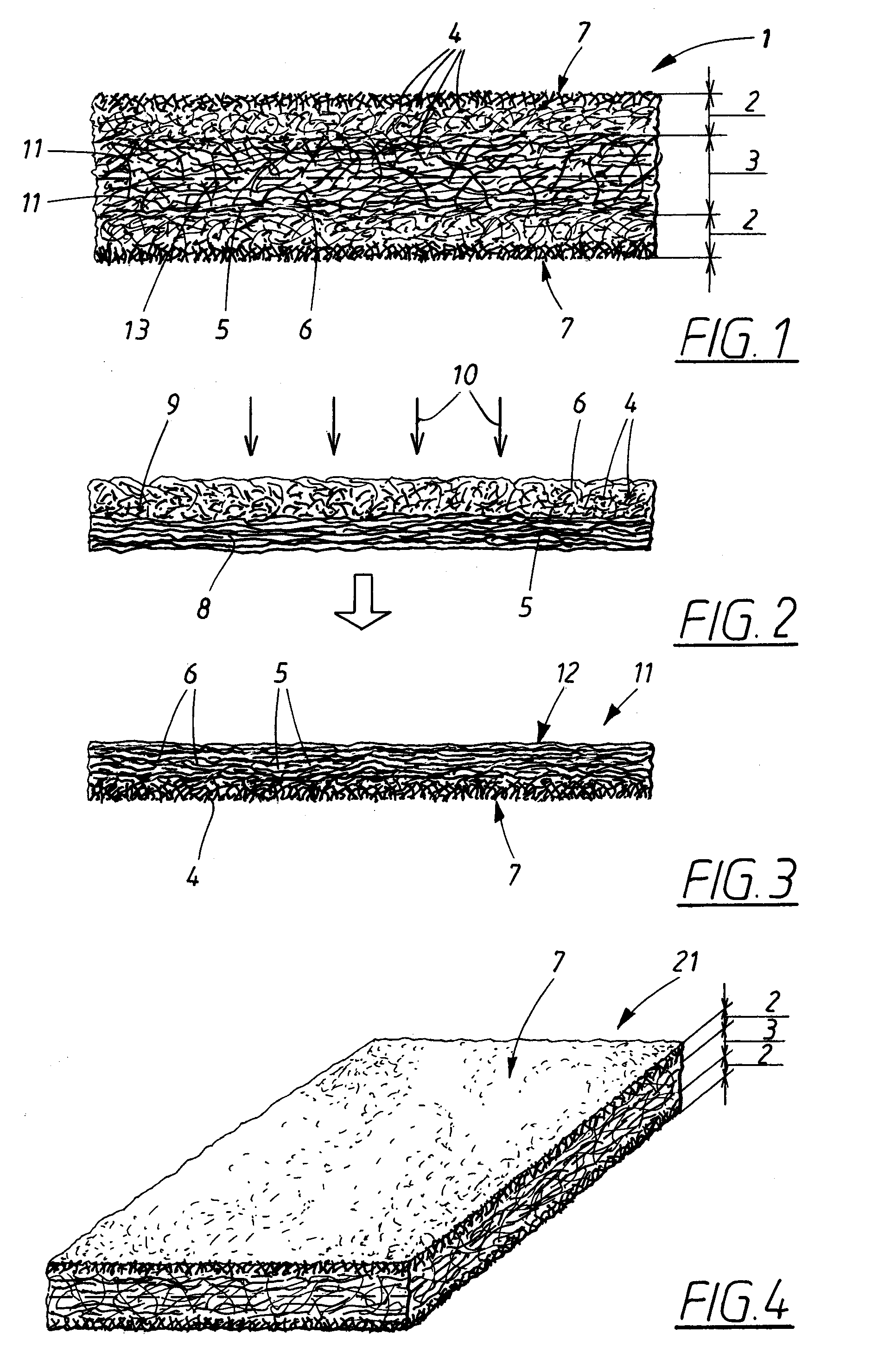

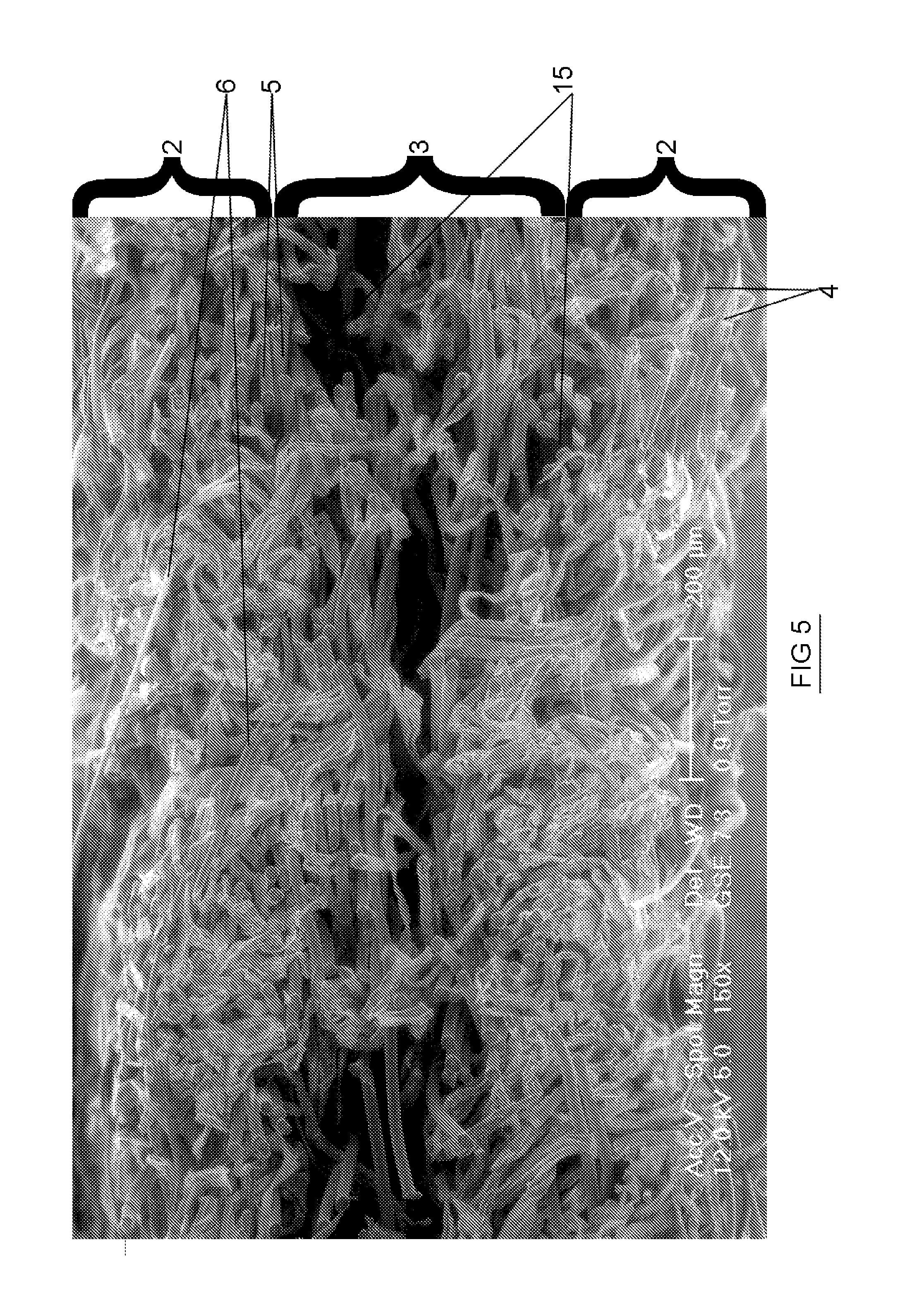

Laminate having improved wiping properties and a method for producing the laminate

ActiveUS20100203306A1Reduce lintingIncrease tensile strengthWarp knittingCleaning machinesLayered structureEngineering

Owner:ESSITY HYGIENE & HEALTH AB

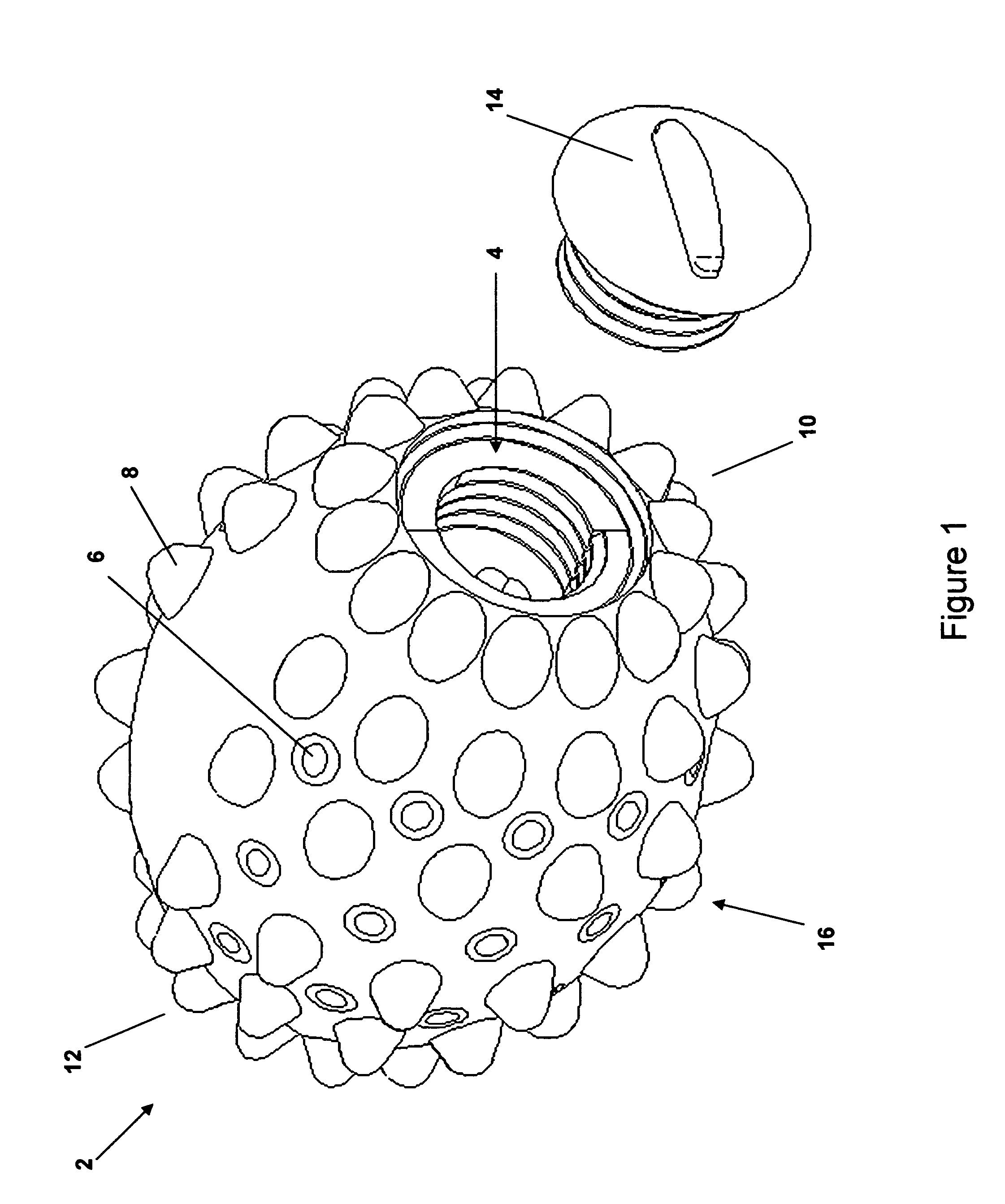

Environmentally sensitive multi-use apparatus for administering and dispensing laundry additives

ActiveUS8460395B2Increase air circulationFaster drying timeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsLaundryBiomedical engineering

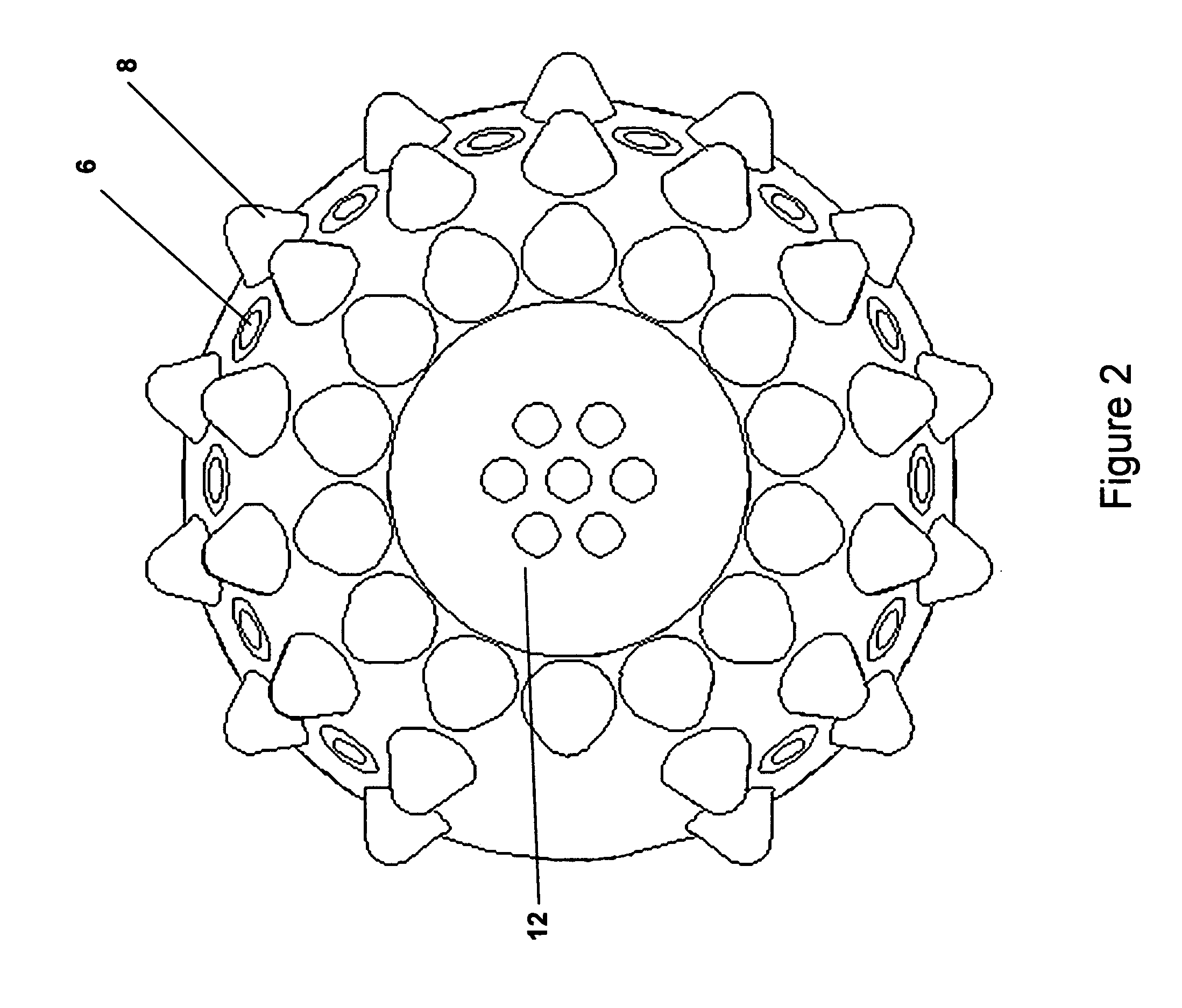

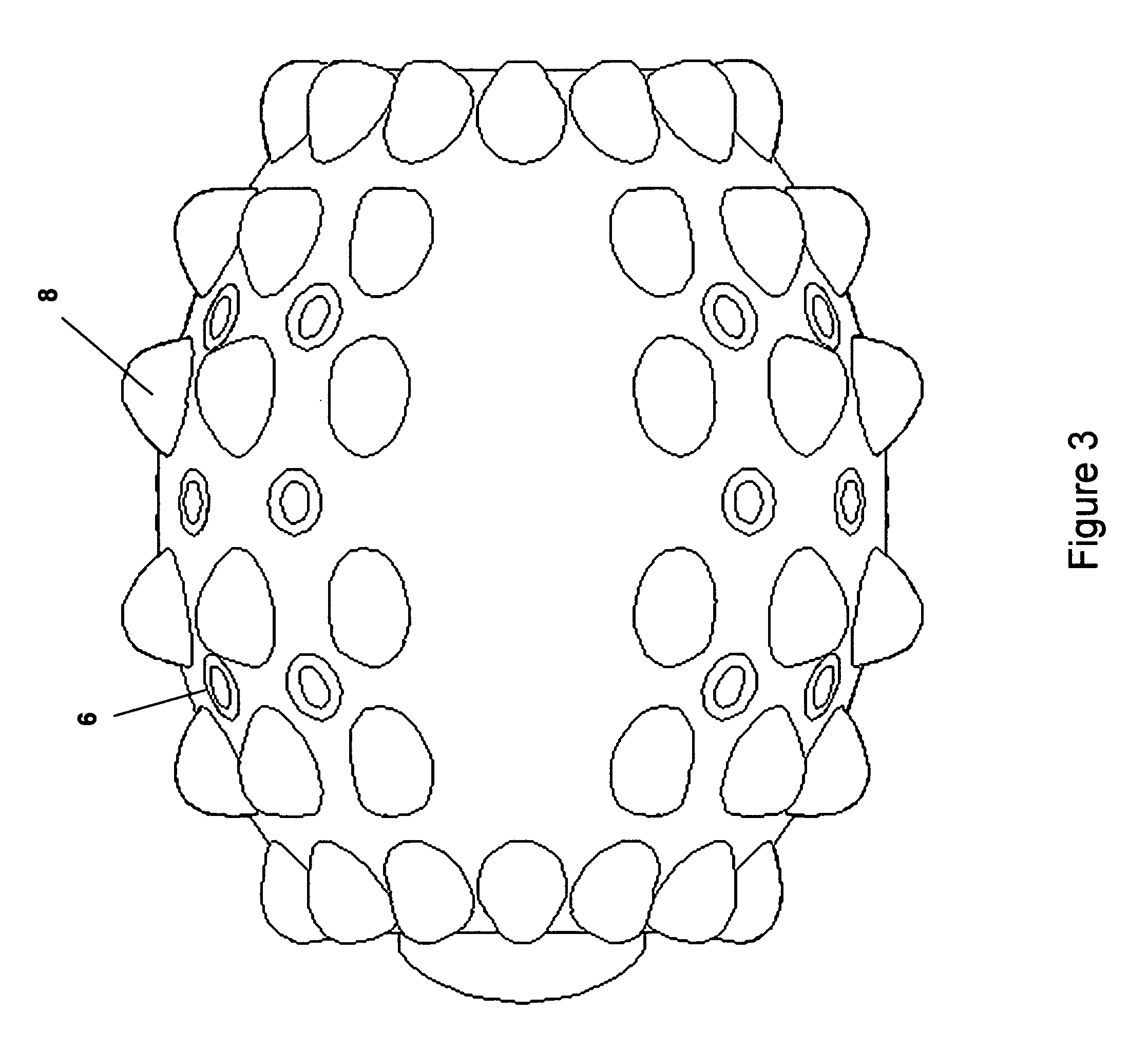

Devices for delivering reusable environmentally friendly laundry additives to a plurality of wash cycles and drying cycles are provided. The devices include a container that has an inner chamber and a plurality of apertures and protrusions located on an exterior surface thereof. The apertures are configured to allow the laundry additive to leave the inner chamber and interact with clothing during a plurality of wash cycles and drying cycles. The protrusions are configured to make contact with, and soften, clothing during the drying cycles. The container is configured to receive the laundry additive by a user of the device, prior to placing the device in a first wash or drying cycle, and effectively disperse and administer said additives.

Owner:SMULOWITZ MARC S

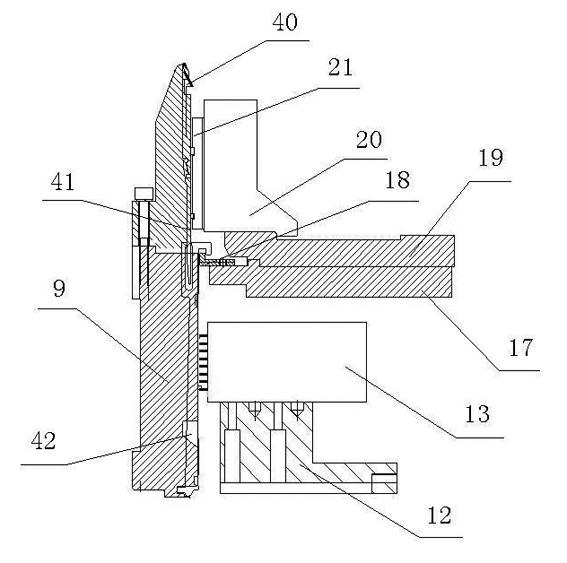

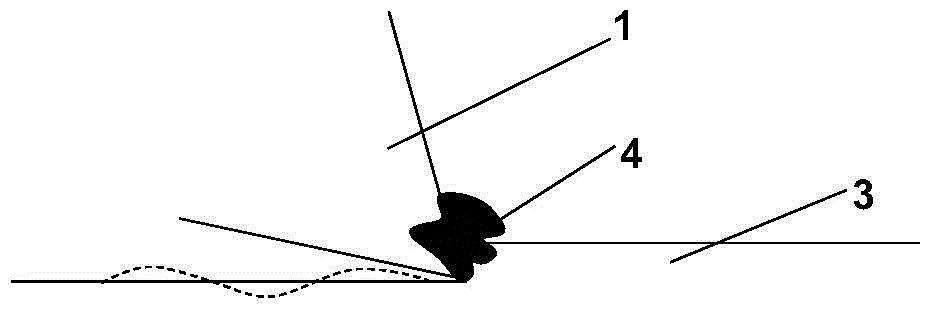

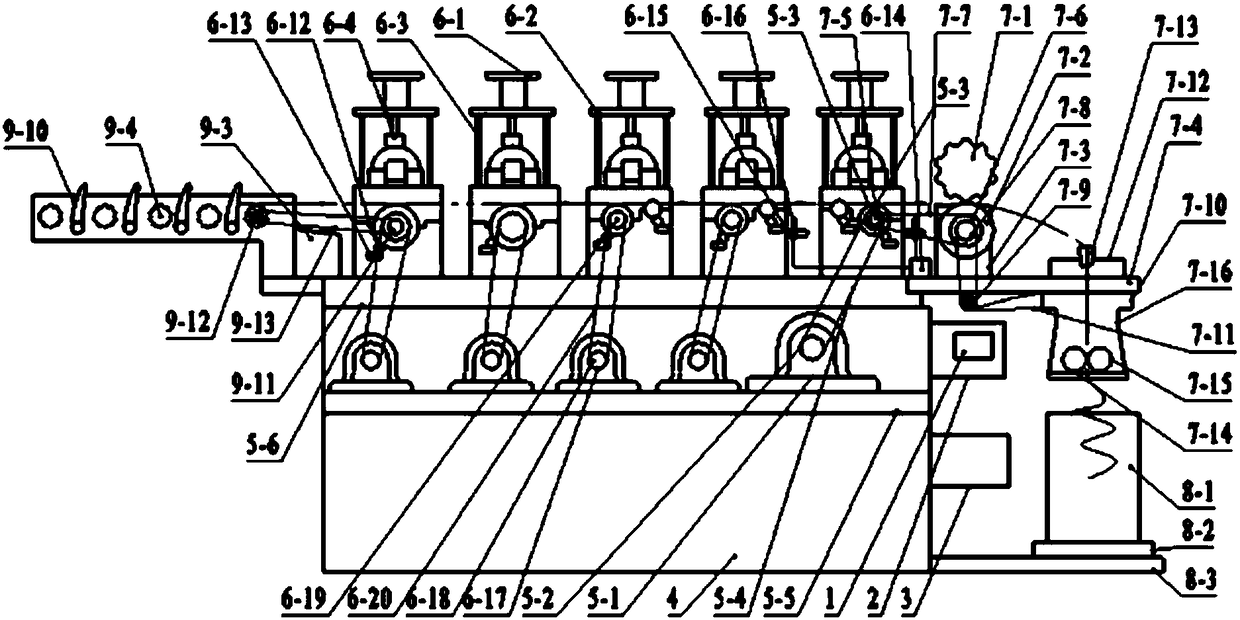

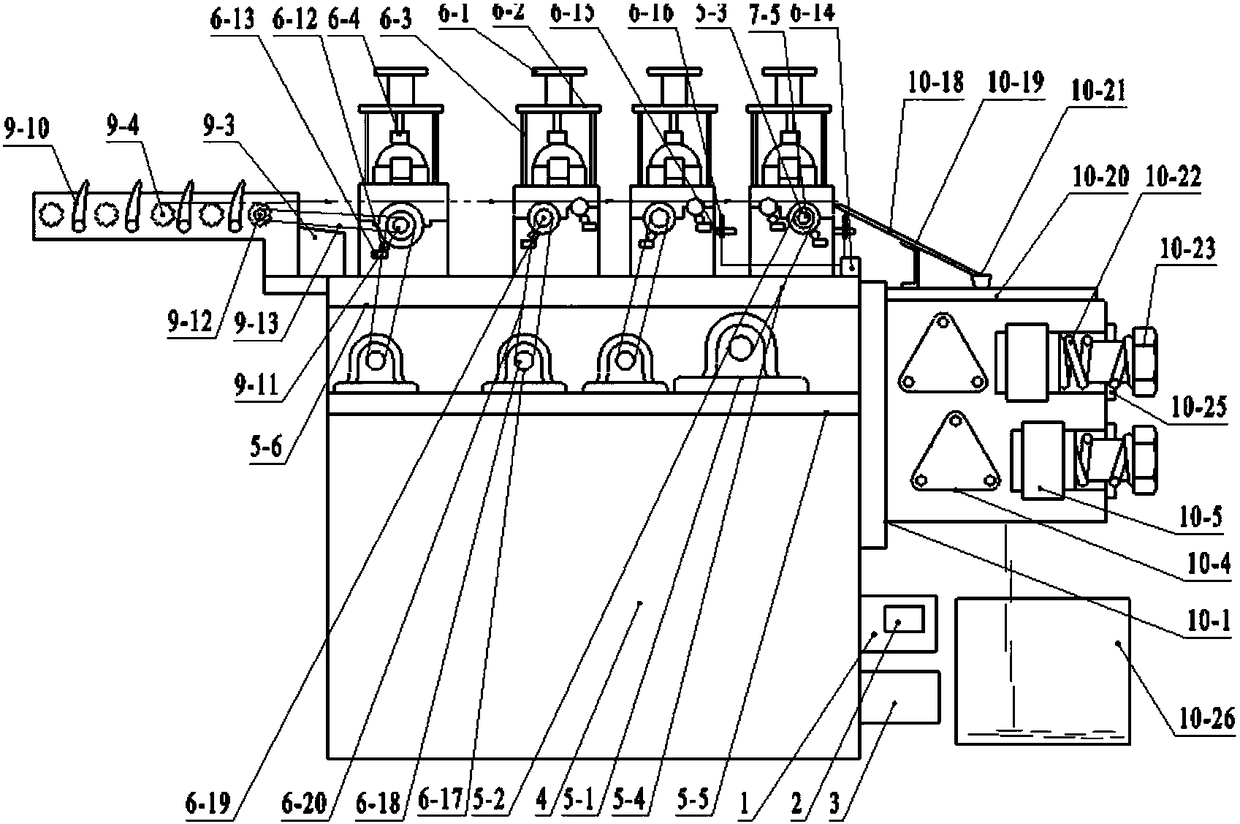

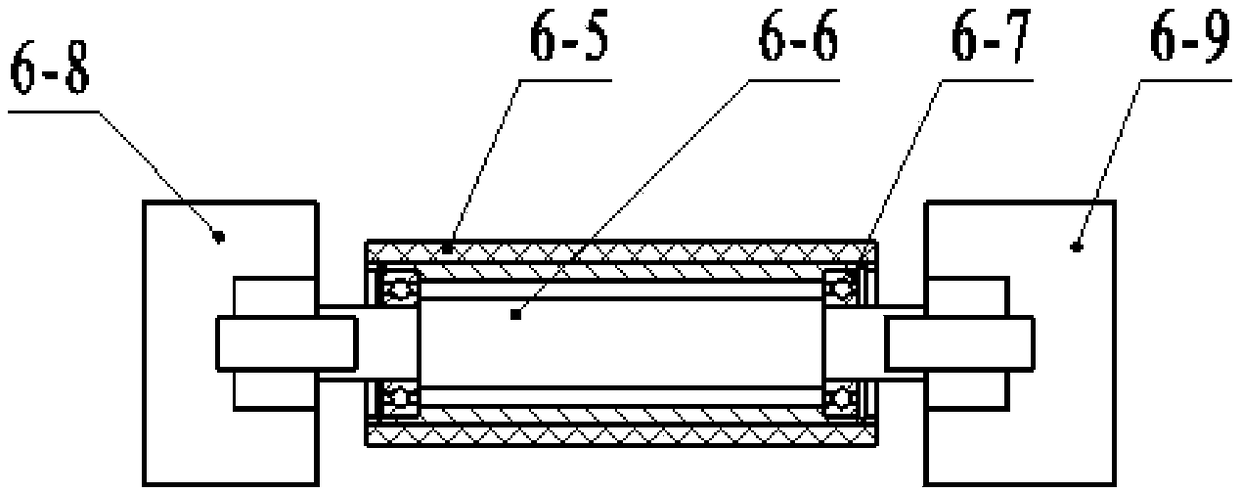

Concave-convex loop-cutting computer jacquard machine

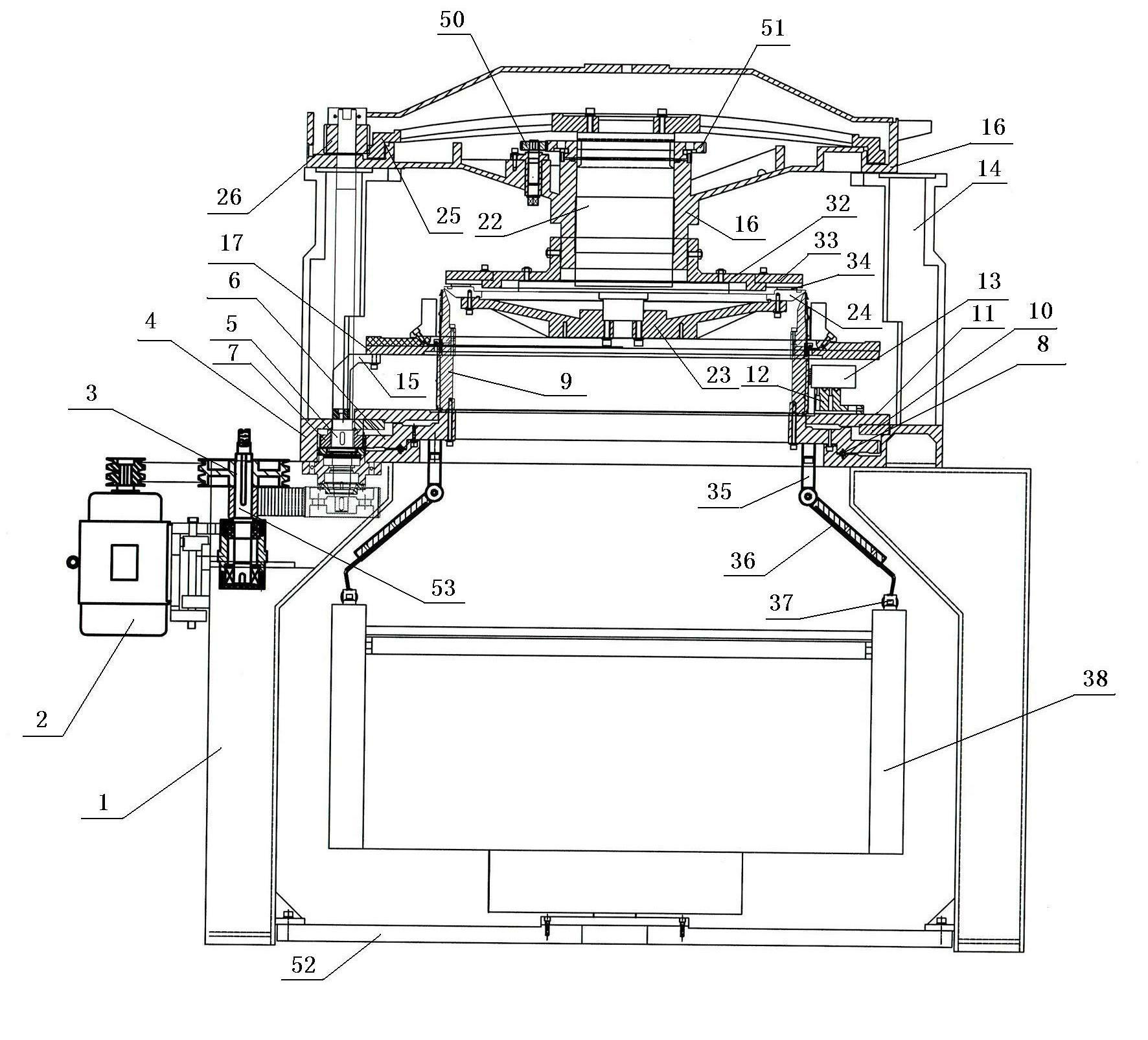

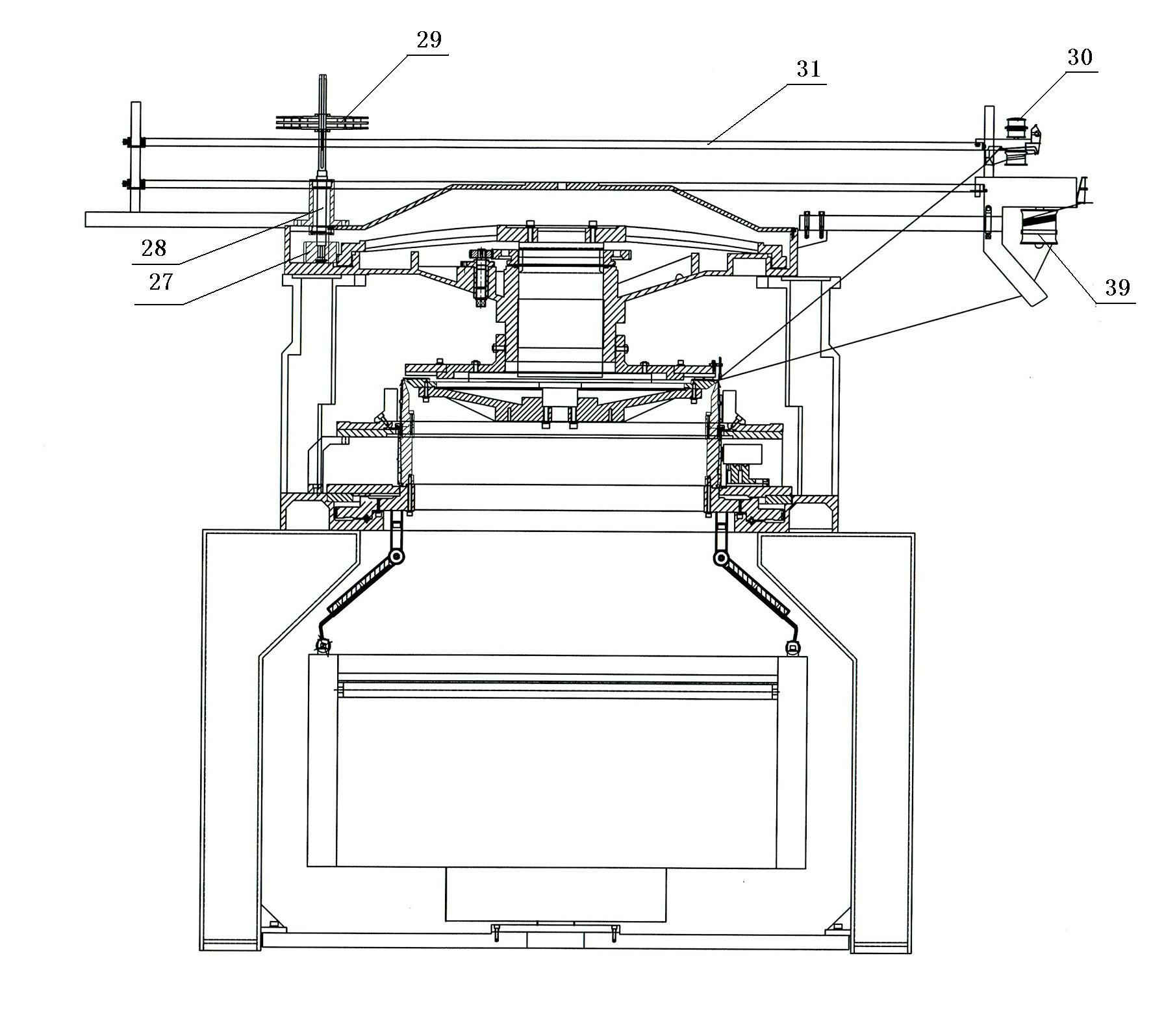

The invention relates to a concave-convex loop-cutting computer jacquard machine; a stand is connected with a driving motor and a large disc; a lower needle cylinder is fixed on a gear of the large disc; a needle selection device is fixed on a bracket of the needle selection device; a reset mountain corner is fixed on a bottom loop of the reset mountain corner; a bottom loop of a saddle is also fixed on the bottom loop of the reset mountain corner; the saddle is fixed on the bottom loop of the saddle; a cutter mountain corner is fixedly arranged on a first sliding block in the saddle; the cutter mountain corner comprises a first mountain corner group and a second mountain corner group; the depth of a kinking point of a first wool hooking mountain corner of the first mountain corner group is more than that of the kinking point of a second wool hooking mountain corner of the second mountain corner group; the gear of the large disc is connected with two connecting rods which are arranged in a symmetrical way; the connecting rods are connected on a connecting piece; the connecting piece is connected on a cloth rolling machine by a cavel; and the cloth rolling machine is driven to rotate by the gear of the large disc through the connecting rods. Due to the reasonable design of the structure and the change for the arrangement way of the cutter mountain corner, the concave-convex loop-cutting computer jacquard machine can realize computer knitting and is capable of molding once, and a concave-convex wool fabric with bright colors can be processed according to the need.

Owner:LIANYUNGANG YUANFENG MACHINERY

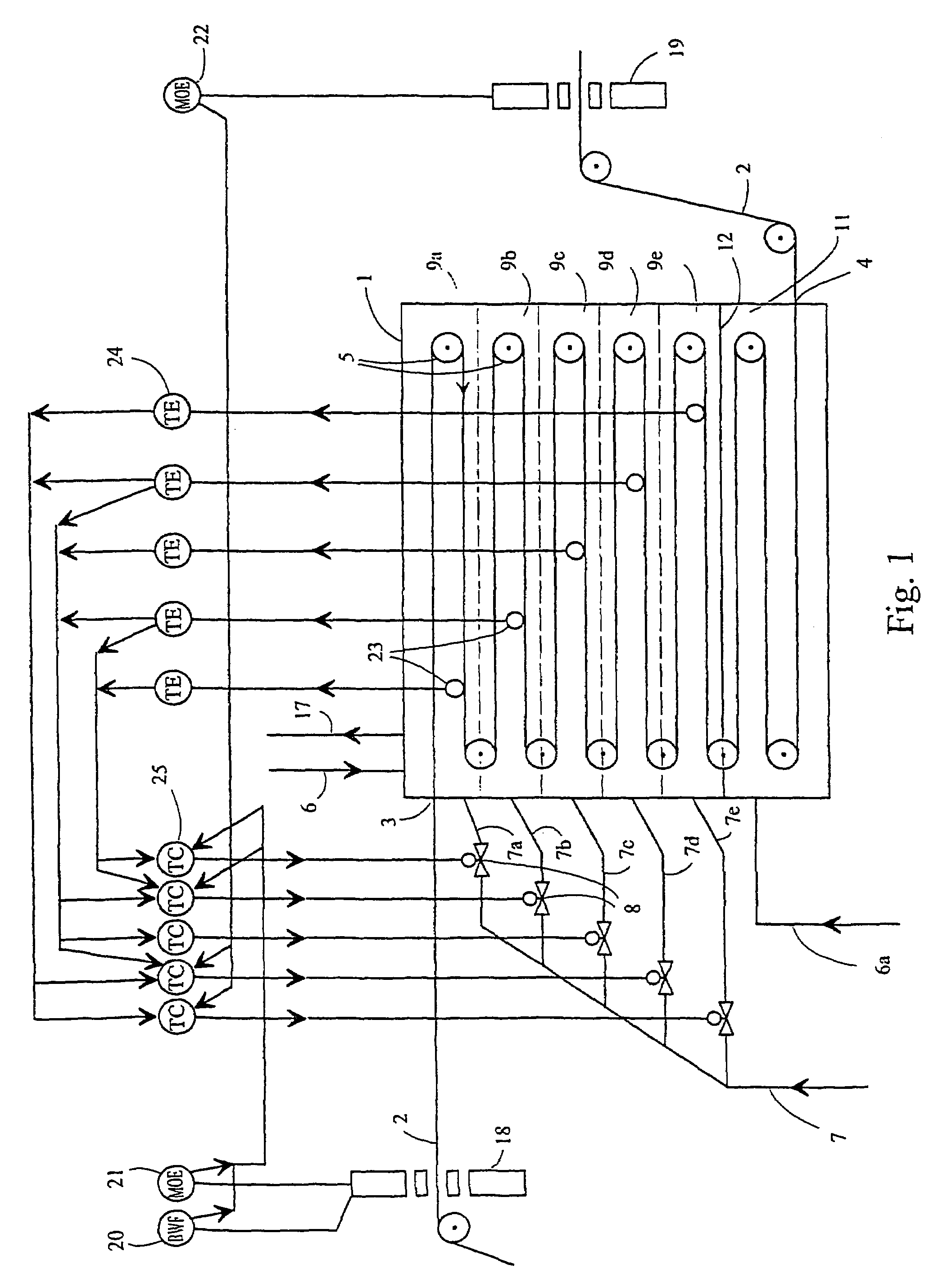

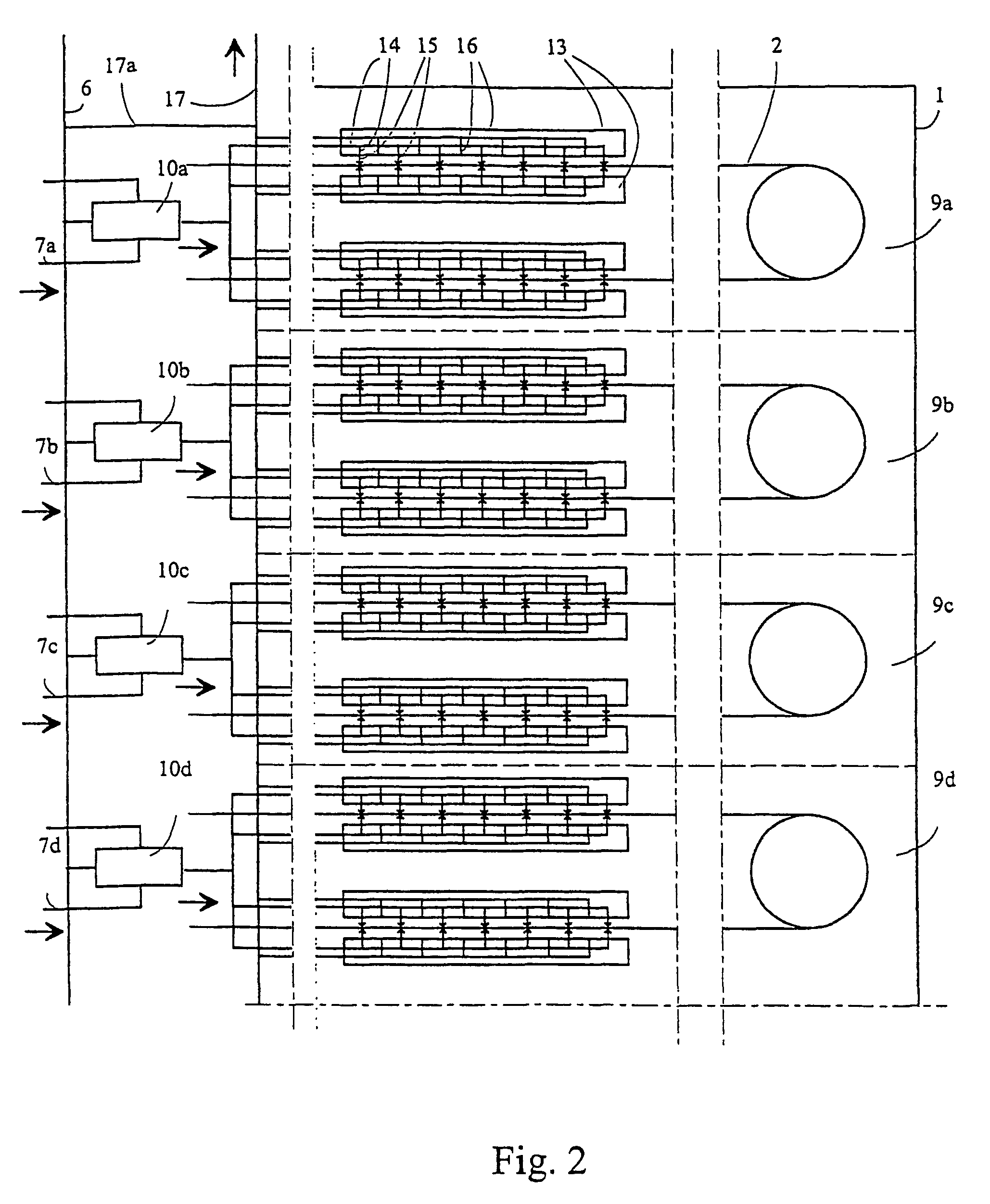

Method and equipment for drying a pulp web using hot air of different temperatures

InactiveUS7325331B2Impair it qualityEnergy lossDrying using combination processesDrying solid materials with heatIndoor airEngineering

The invention relates to a method for drying a fibre-based pulp web (2), and to a drying box (1) used in the method. According to the invention, the drying box (1) contains drying zones (9a-9e), to each one of which hot drying air can be blown independently so that the web can be dried in the various zones at different temperatures. The temperature of the first zone (9a) can thus be lower than that of one or more subsequent zones (9b-9e) to prevent the water in the incoming wet web from boiling. The last zone in the drying box (1) can be a separate cooling zone (11), wherein the web is cooled by indoor air from outside the box. The temperatures can be adjusted by adjusting, with the aid of valves (8), the pressure of the steam, which heats the drying air that is fed into the various zones (9a-9e), on the basis of the temperatures measured by the sensors (23) for the various zones and of the basis weight and moisture measurements carried out on the web (2) that goes into the box (1) and comes out of the box.

Owner:VALMET TECHNOLOGIES INC

Pea protein beverage and preparation method thereof

ActiveCN109965019AInhibit aggregationEvenly dispersedMilk substitutesFood scienceFlavorVegetable oil

The invention discloses a pea protein beverage and belongs to the technical field of food processing. The pea protein beverage comprises, by mass, 0.7-6.0% of pea protein powder, 2-8% of white sugar,0.5-6.0% of vegetable oil, 0-1% of enzymolyzed oat powder, 0.5-6.0% of coconut cream, 0.2-0.4% of a compound emulsifying and thickening agent, 0.03% of sodium tripolyphosphate, 0.05-2% of powdery essence and the balance of water. The pea protein beverage is prepared by selectively using the proper compound emulsifying and thickening agent and other formula ingredients. A preparation method is simple, reasonable, easy in operation and convenient to implement, and the pea protein beverage prepared by the method is excellent in color, high in stability, soft and refreshing in taste, uniform in suspension in the shelf life of 12 months, free of layering, water separation and precipitation, nourishing, balanced in matching, rich in flavor and suitable for instant drinking by people at all ages.

Owner:HEBEI BROS ILONG FOOD TECH LLC +1

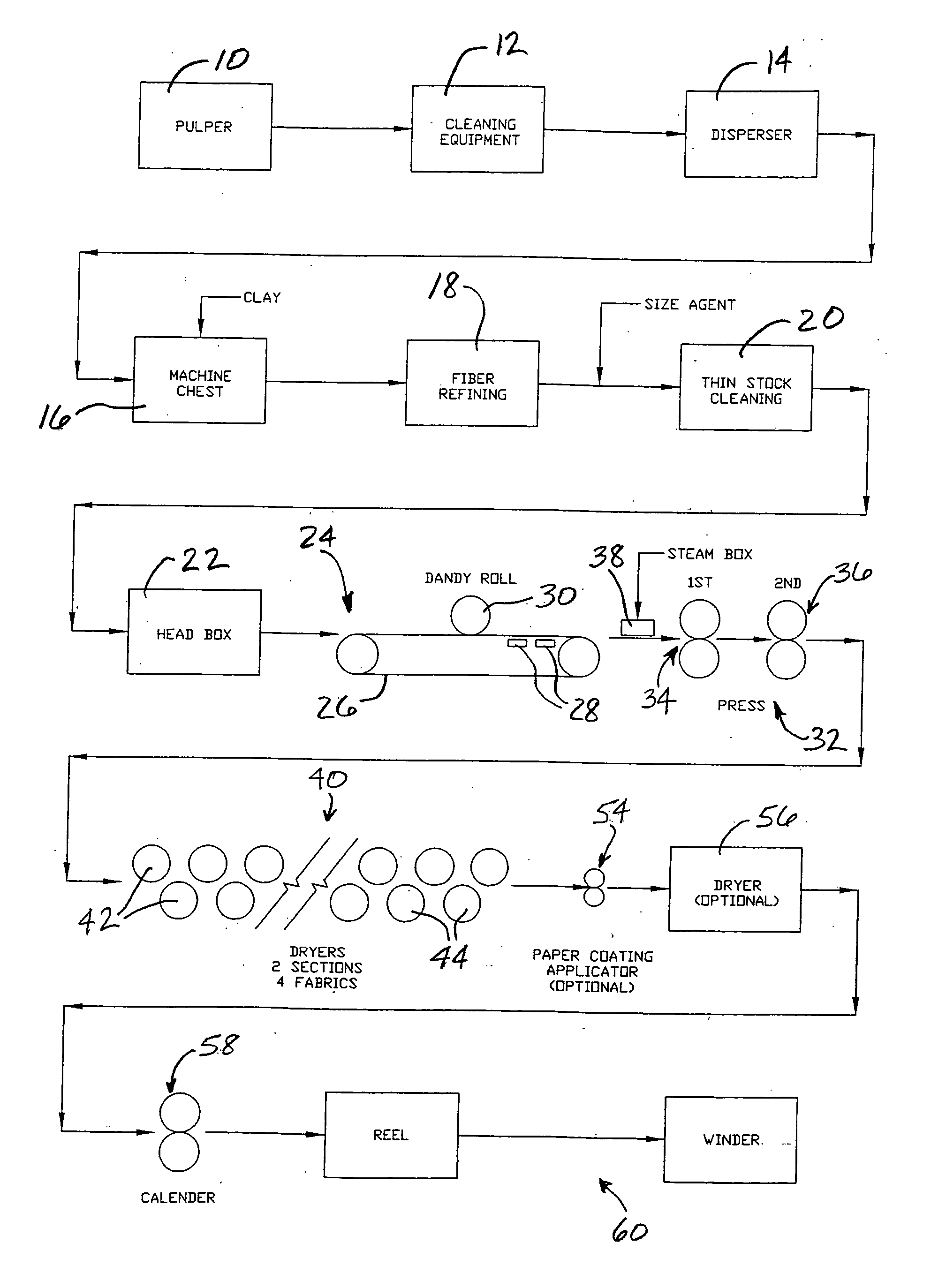

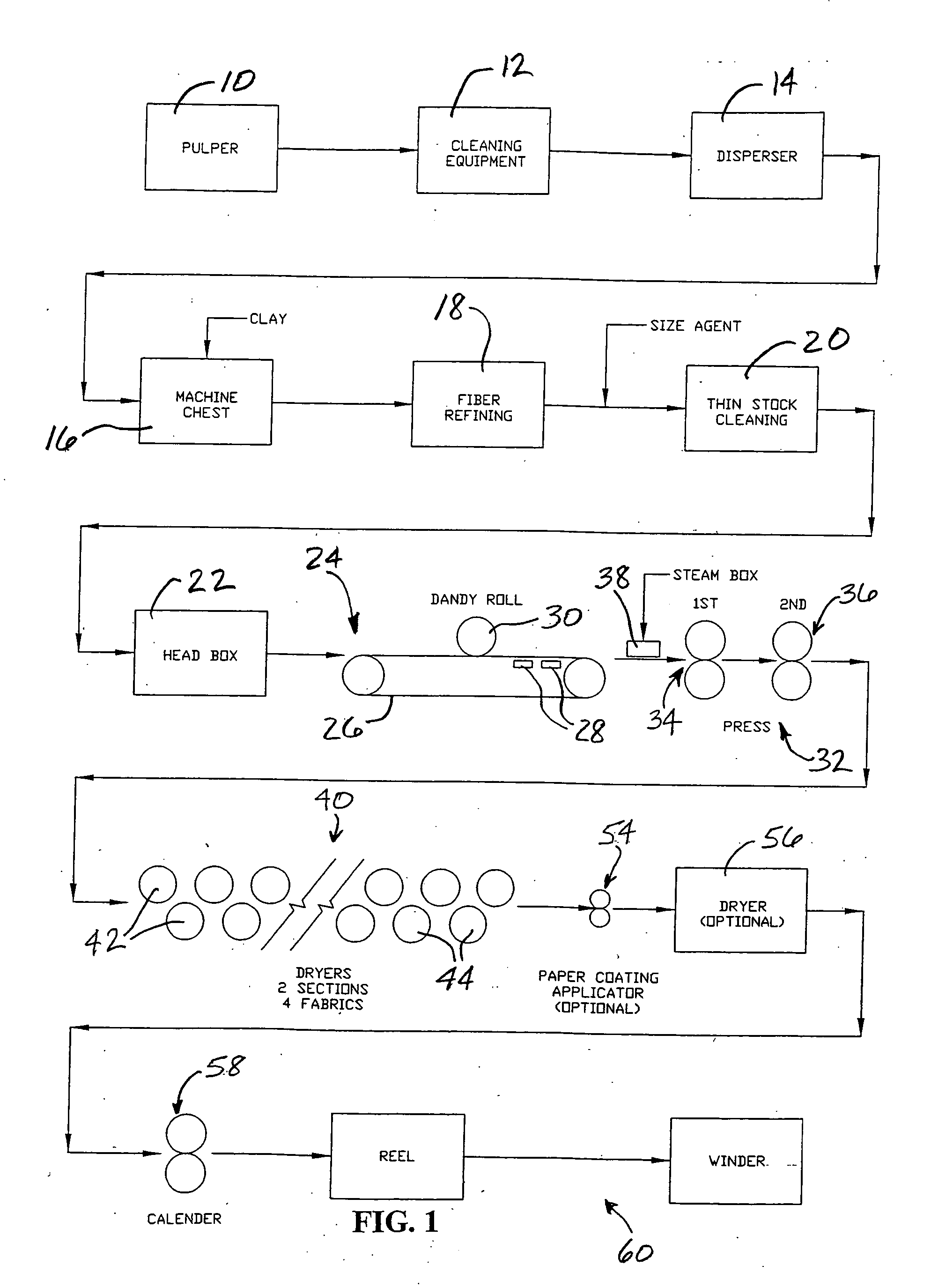

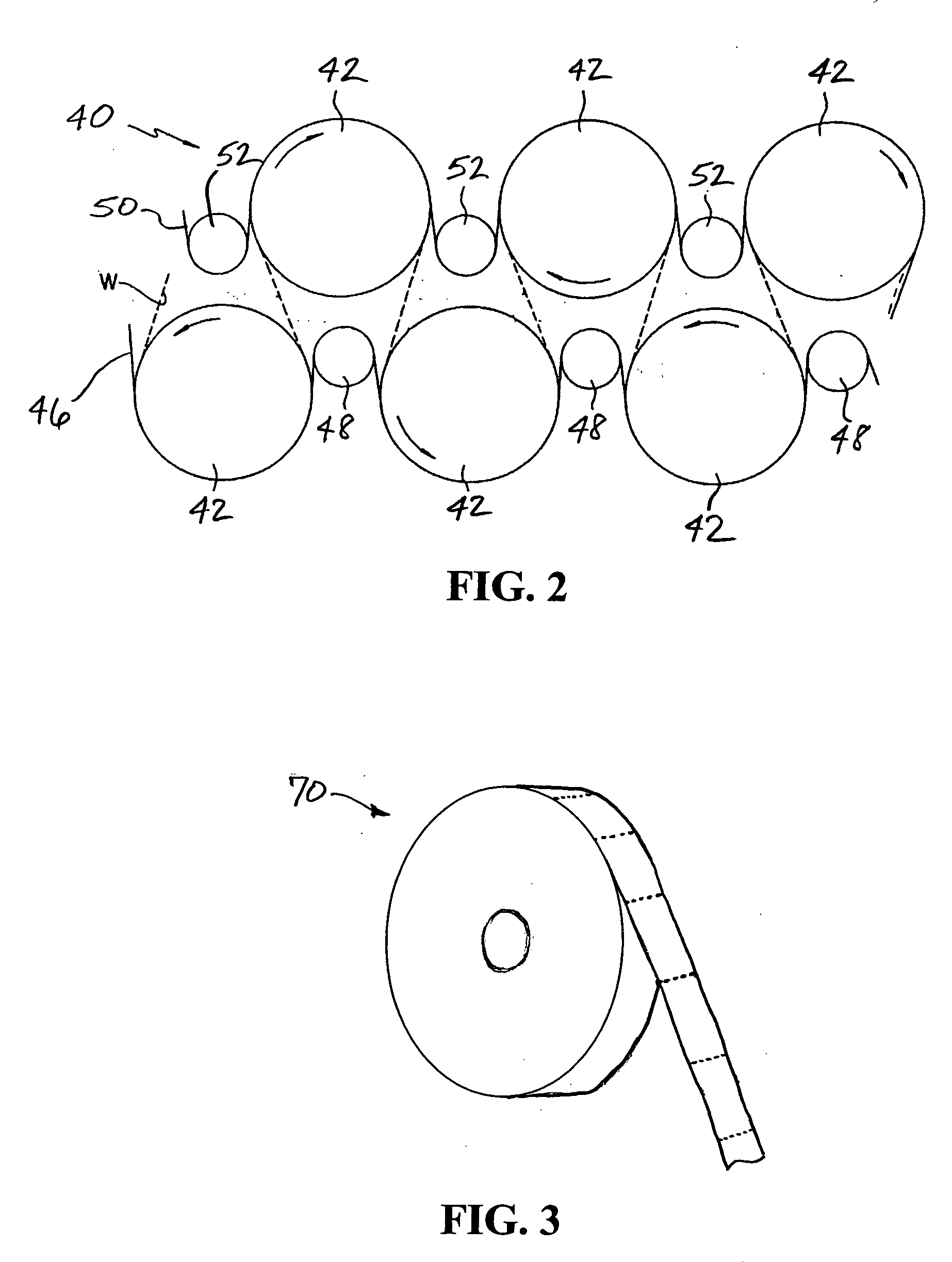

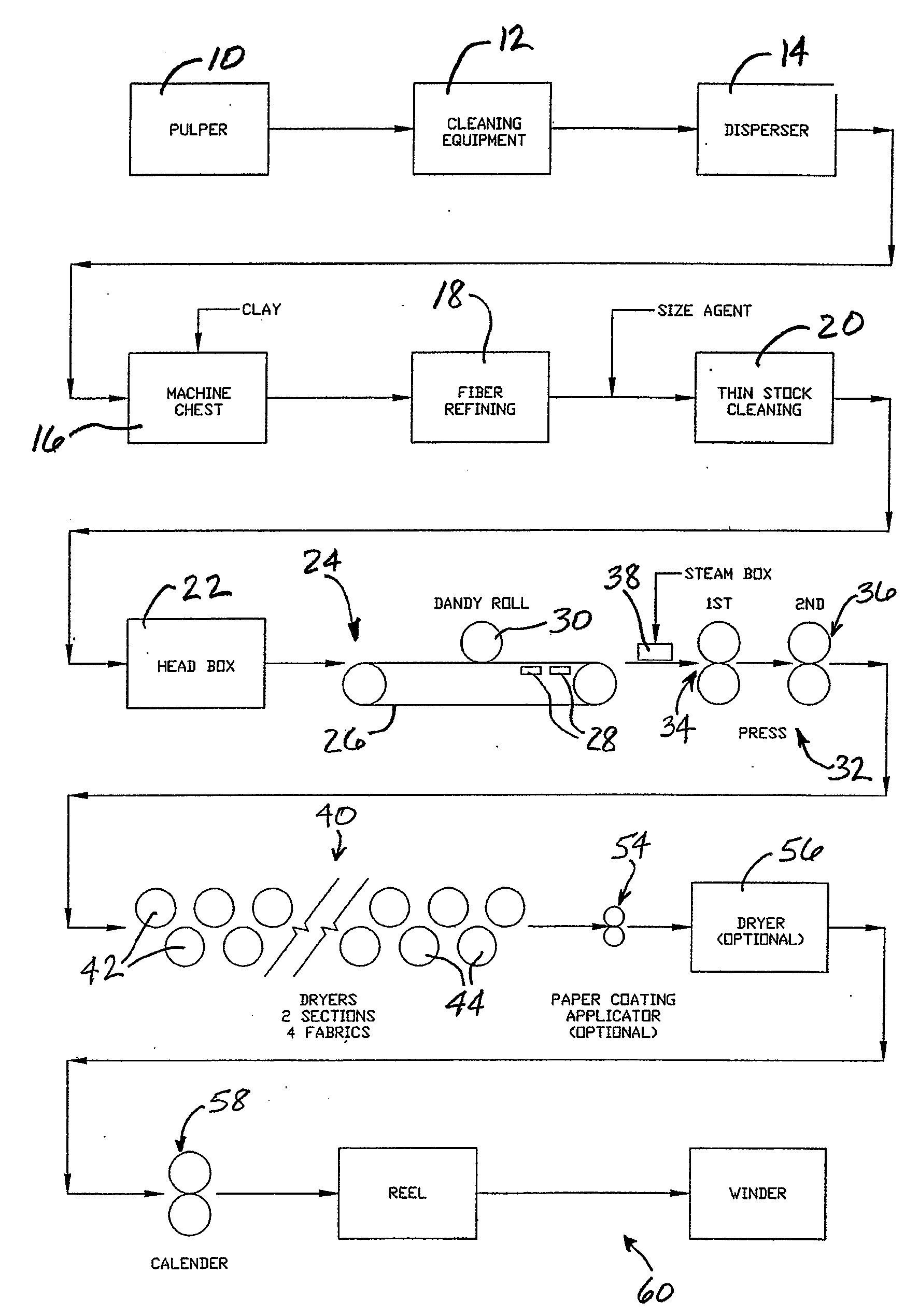

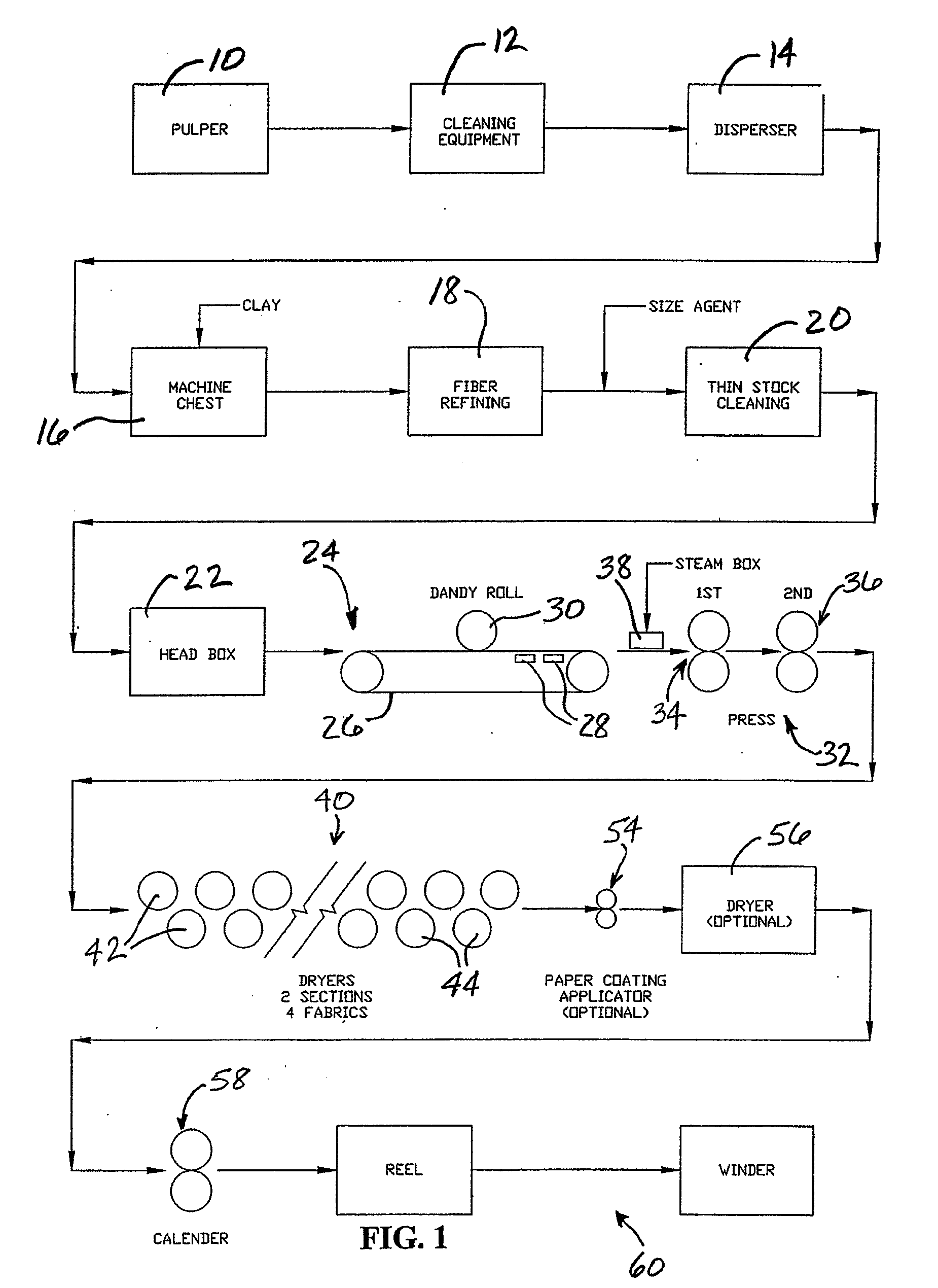

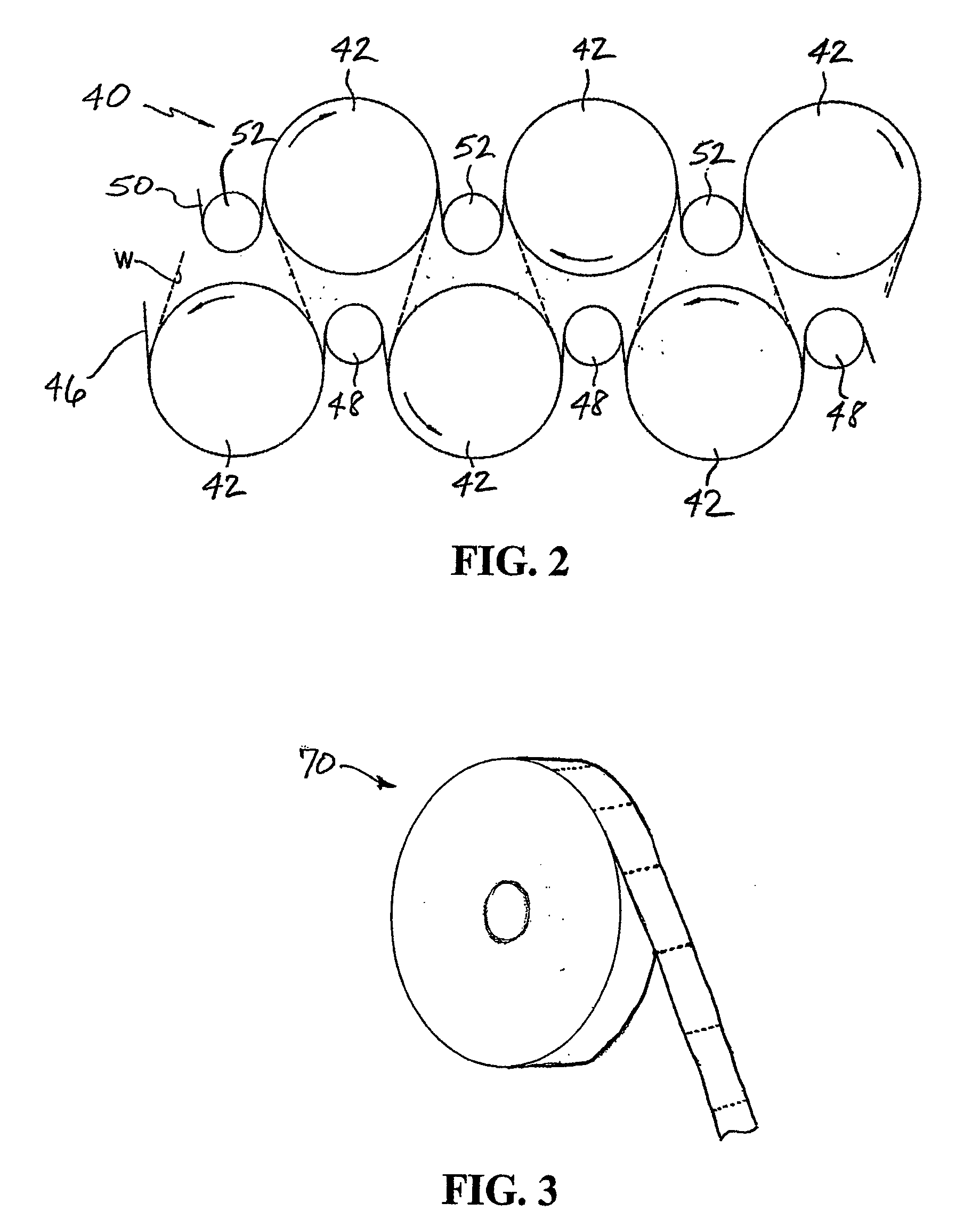

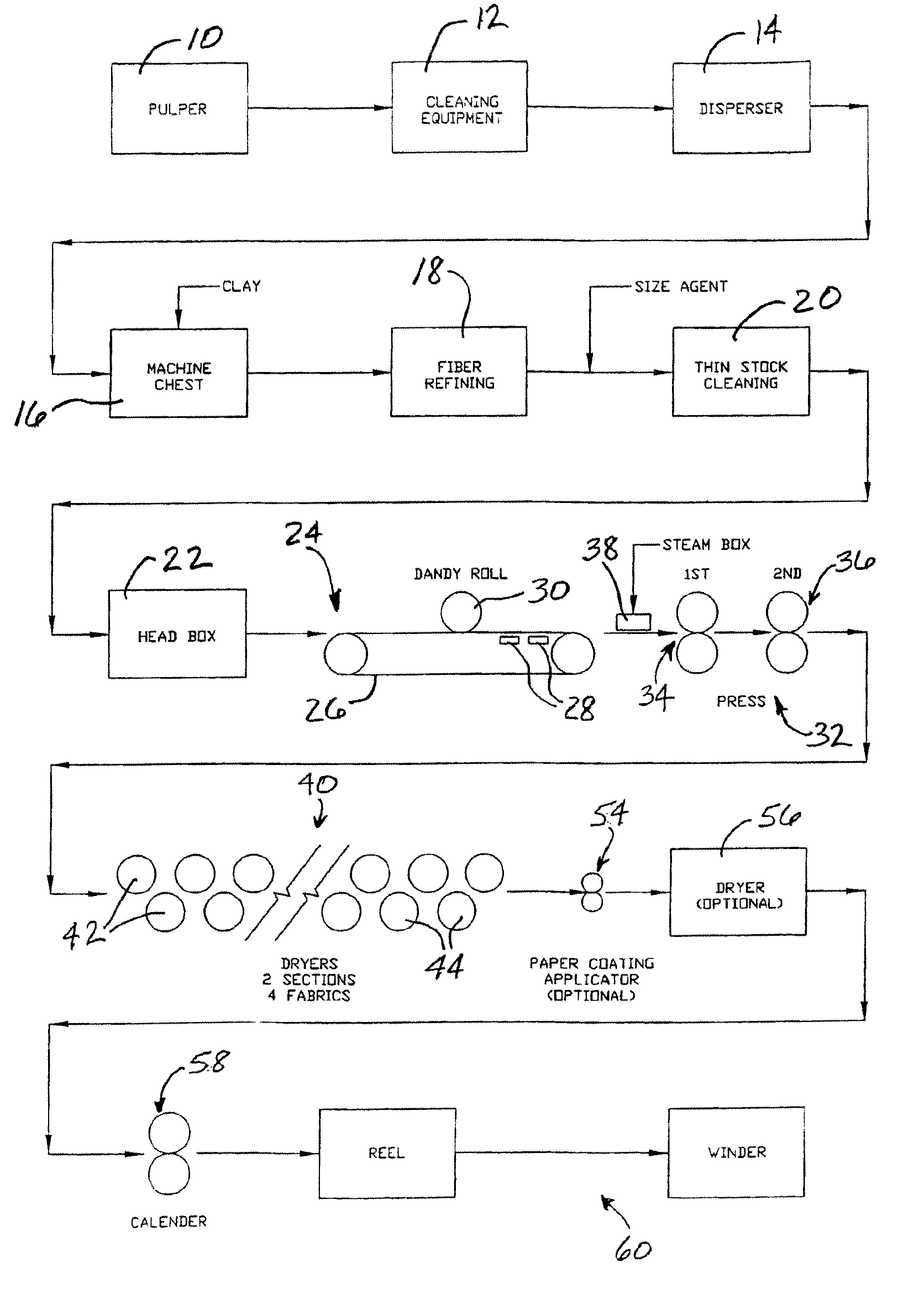

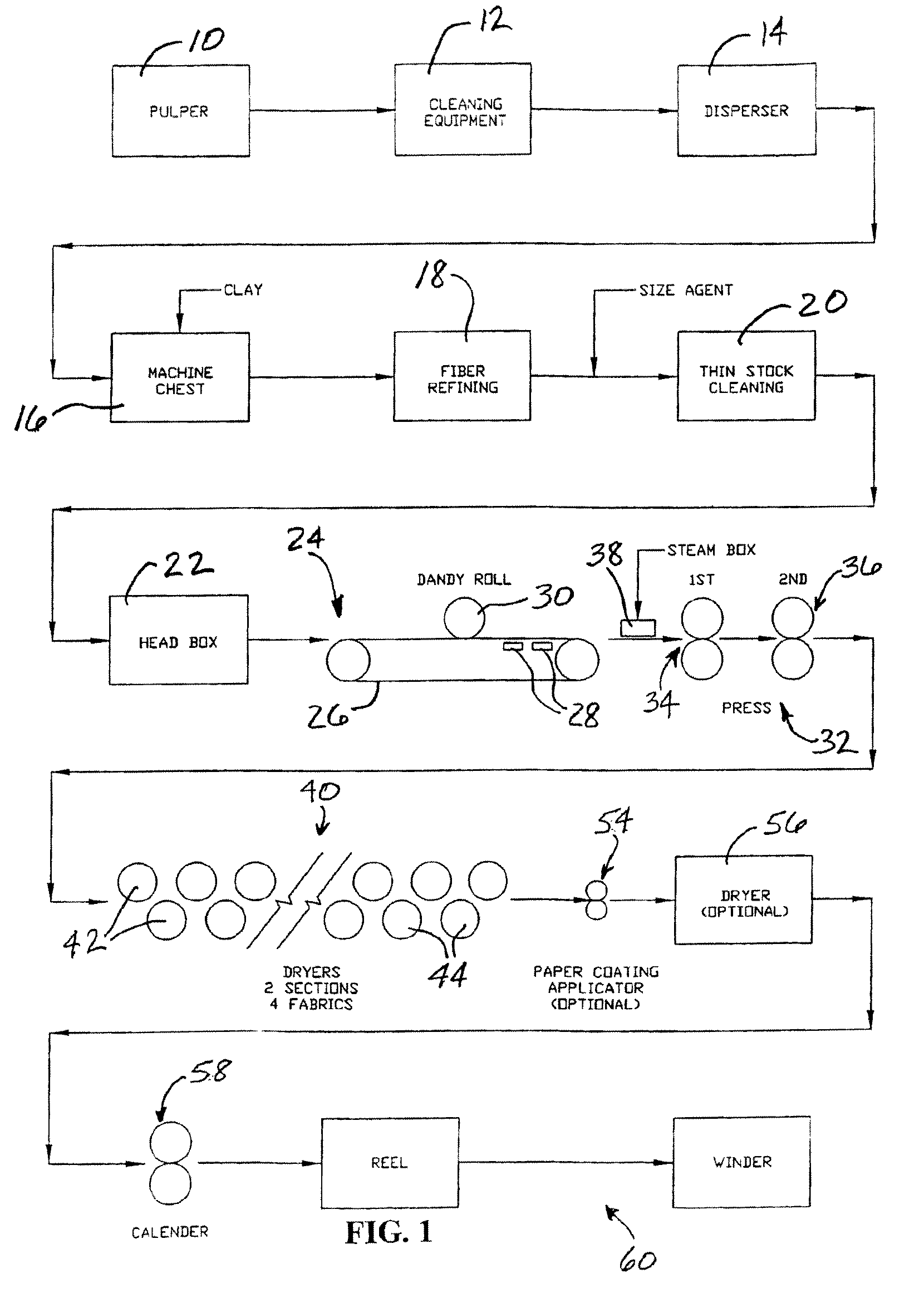

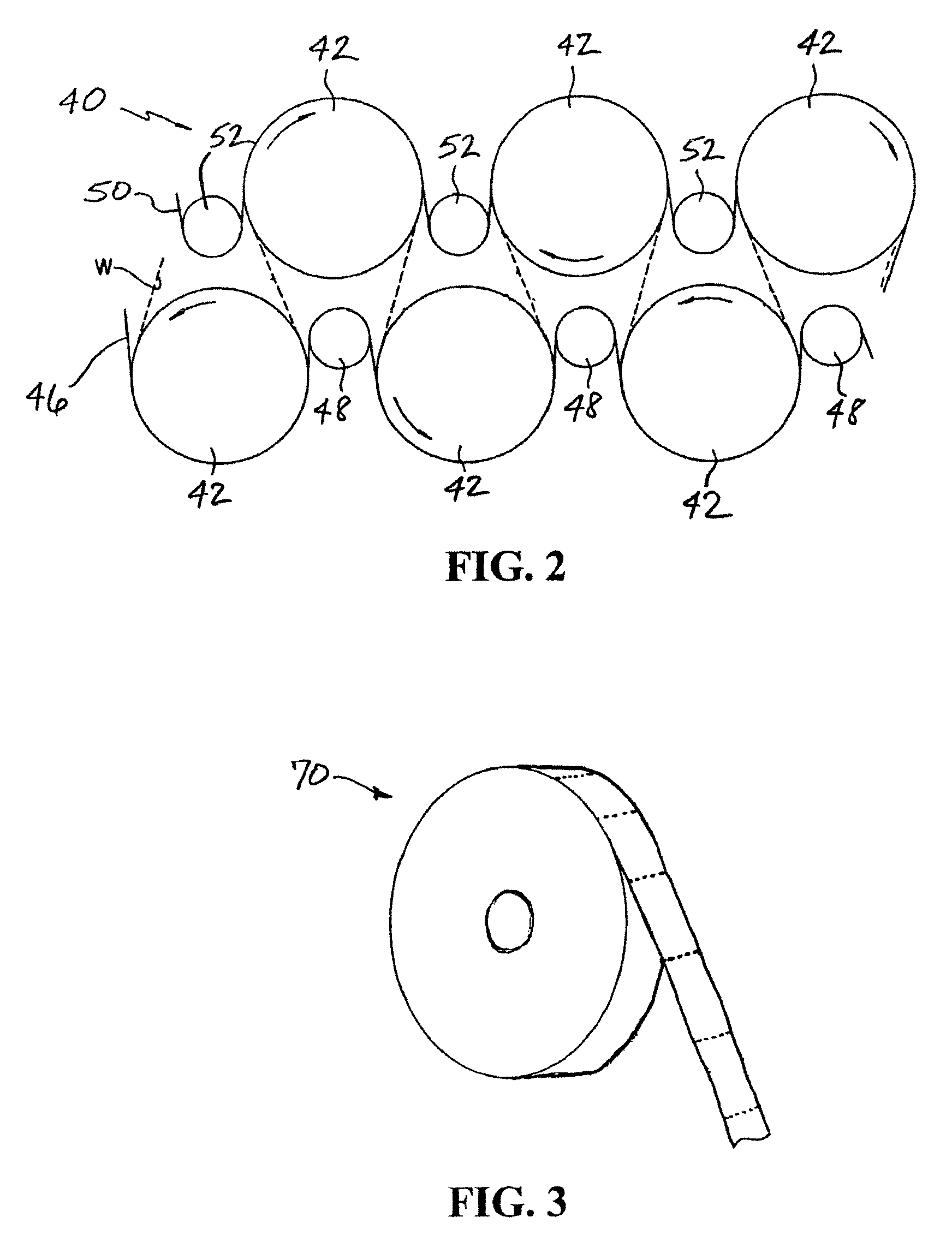

Recycled white ticket stock and method of making same

InactiveUS20050279472A1Increase stiffnessReduce dustSpecial paperPaper recyclingFiberSolid bleached board

A ticket stock and manufacturing process wherein a pulp is formulated from a blend of recycled furnishes, with added starch for enhancing sheet stiffness and reducing linting and dusting on cut edges of the stock, and clay or other opacifier for enhancing opacity of the stock. A preferred pulp comprises a blend of recycled solid bleached sulfate plate stock, recycled coated soft white, and recycled ground wood furnish such as newsprint or the like. In one embodiment, the blend comprises about 25-50 wt. % recycled solid bleached sulfate plate stock, about 25-50 wt. % recycled coated soft white, and about 15-25 wt. % recycled ground wood furnish. The furnish blend is repulped with minimal mechanical refining, is treated with steam injection for hydrating and softening the fibers, and is formed into a web that is pressed, dried, and soft calendered. The caliper of the resulting stock is about 7 to 9 points.

Owner:SONOCO DEV INC

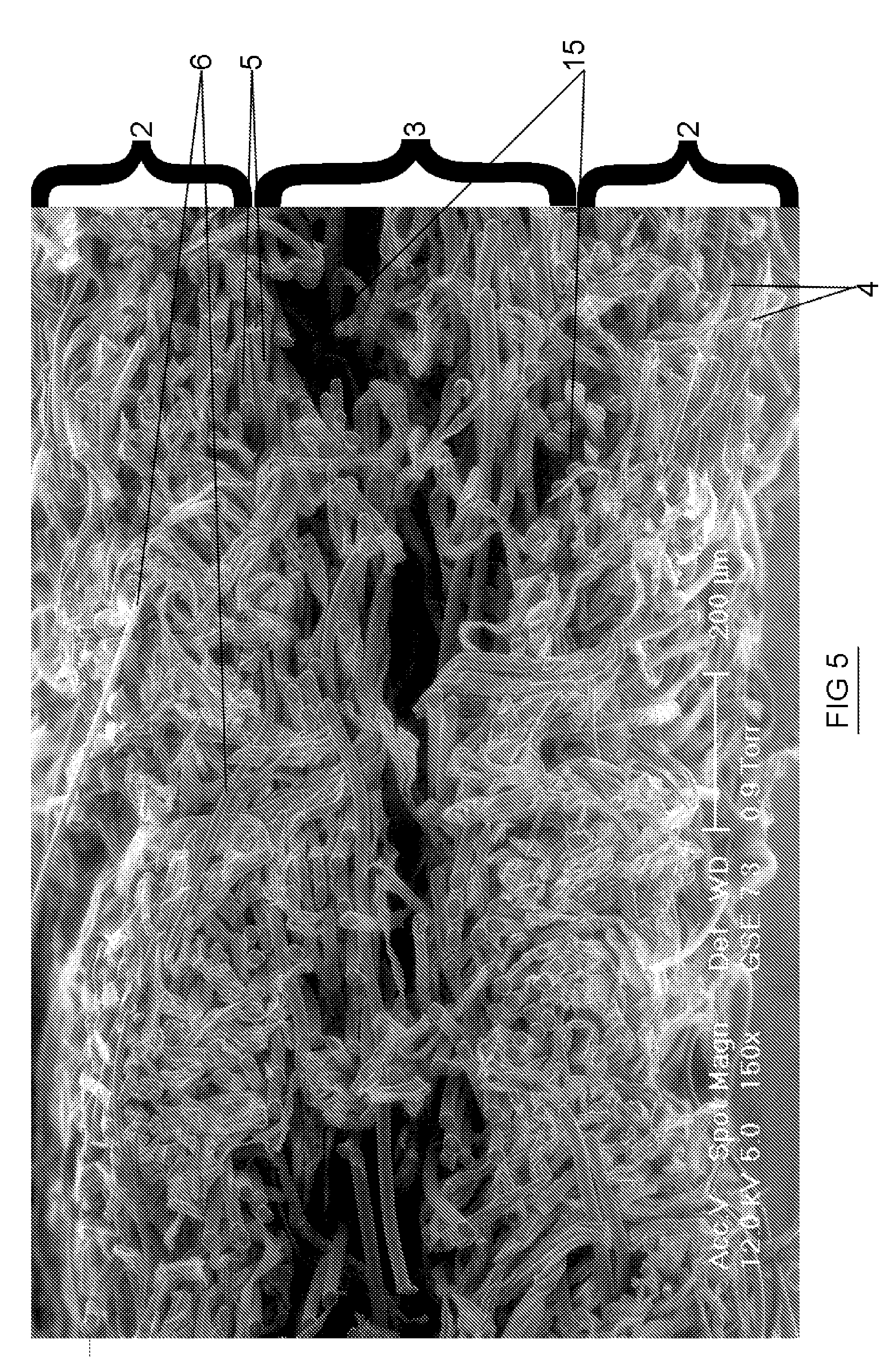

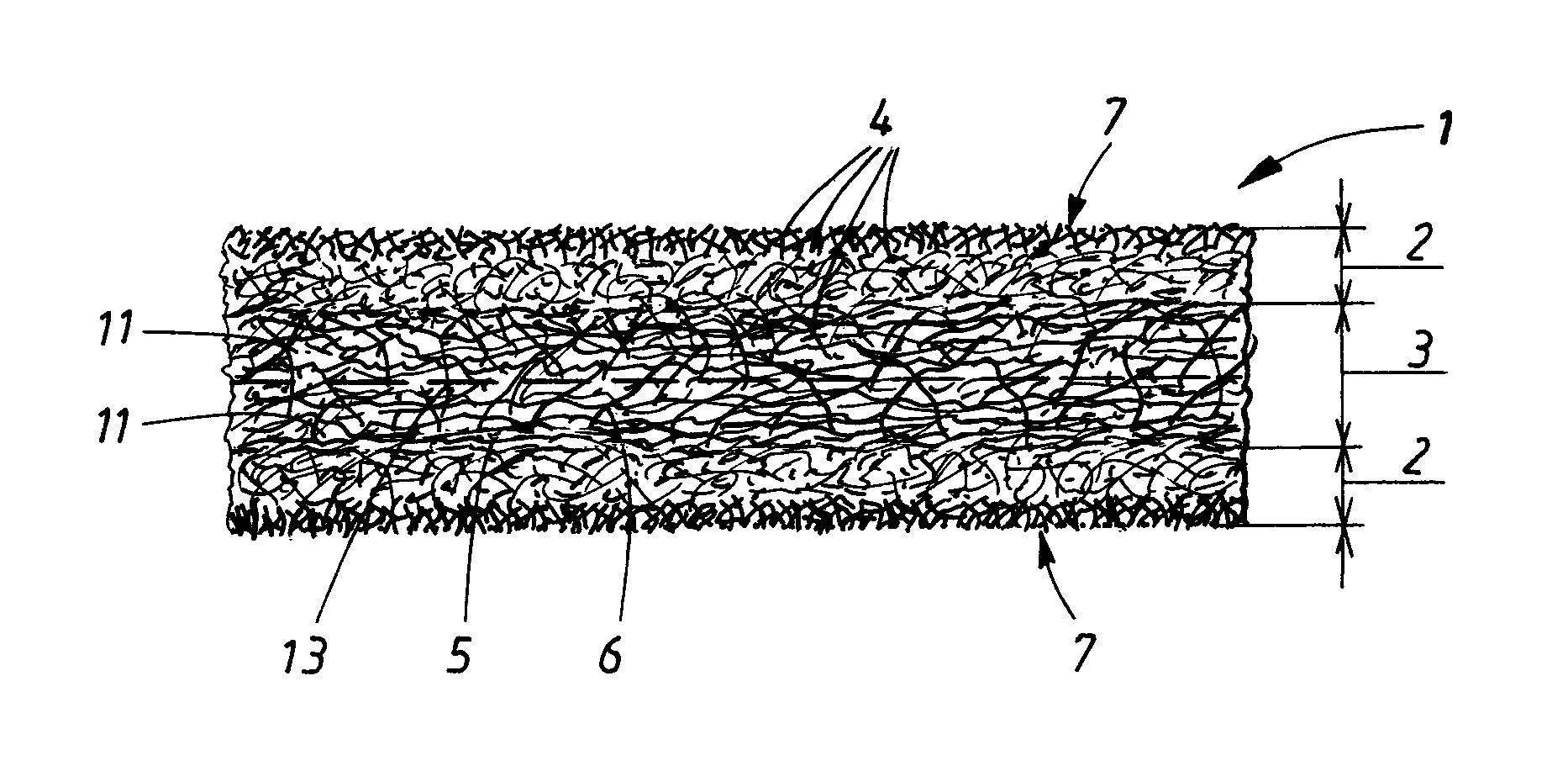

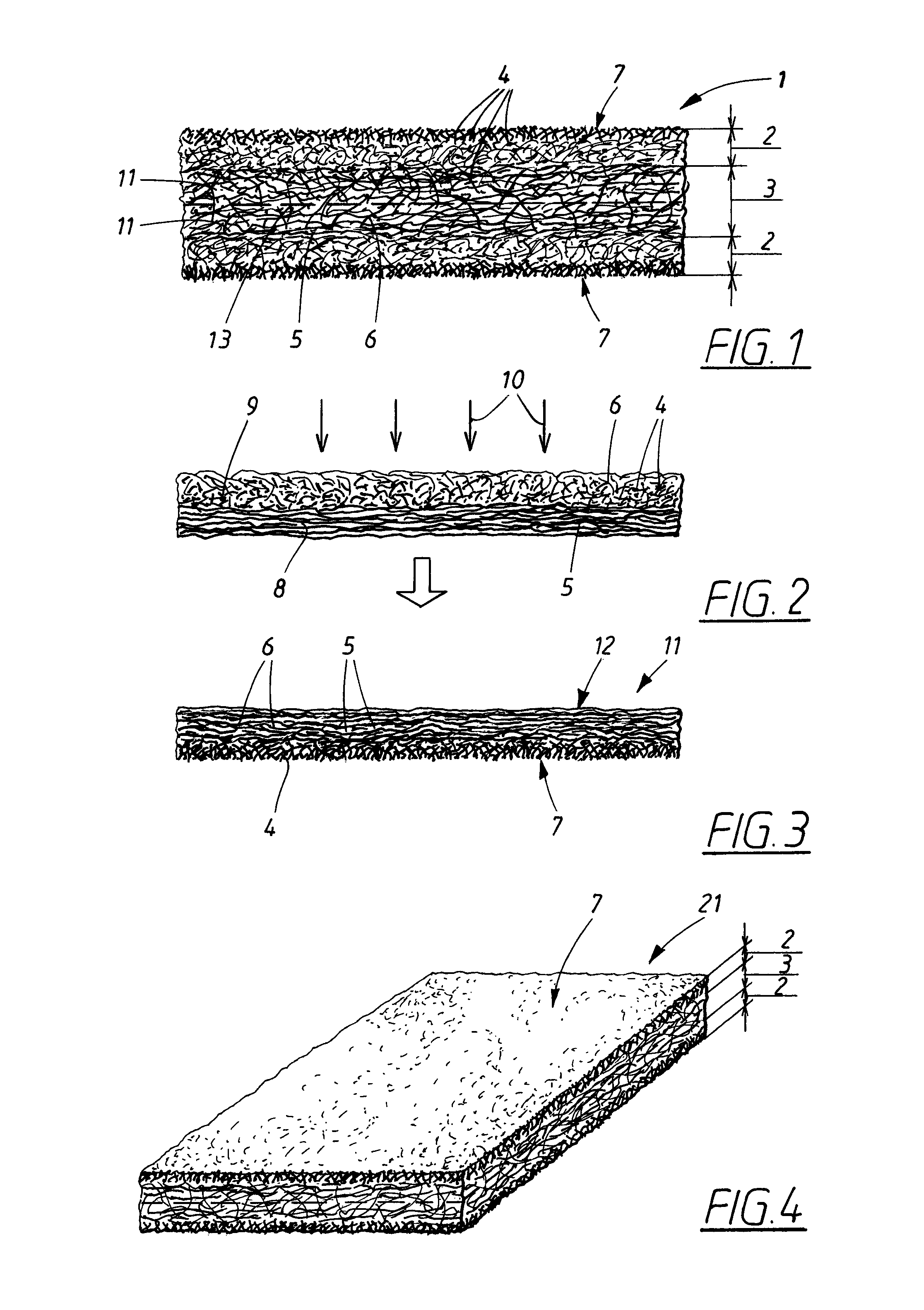

Laminate having improved wiping properties and a method for producing the laminate

ActiveUS8906816B2High tensile strengthReduce lintWarp knittingCleaning machinesFiberMaterials science

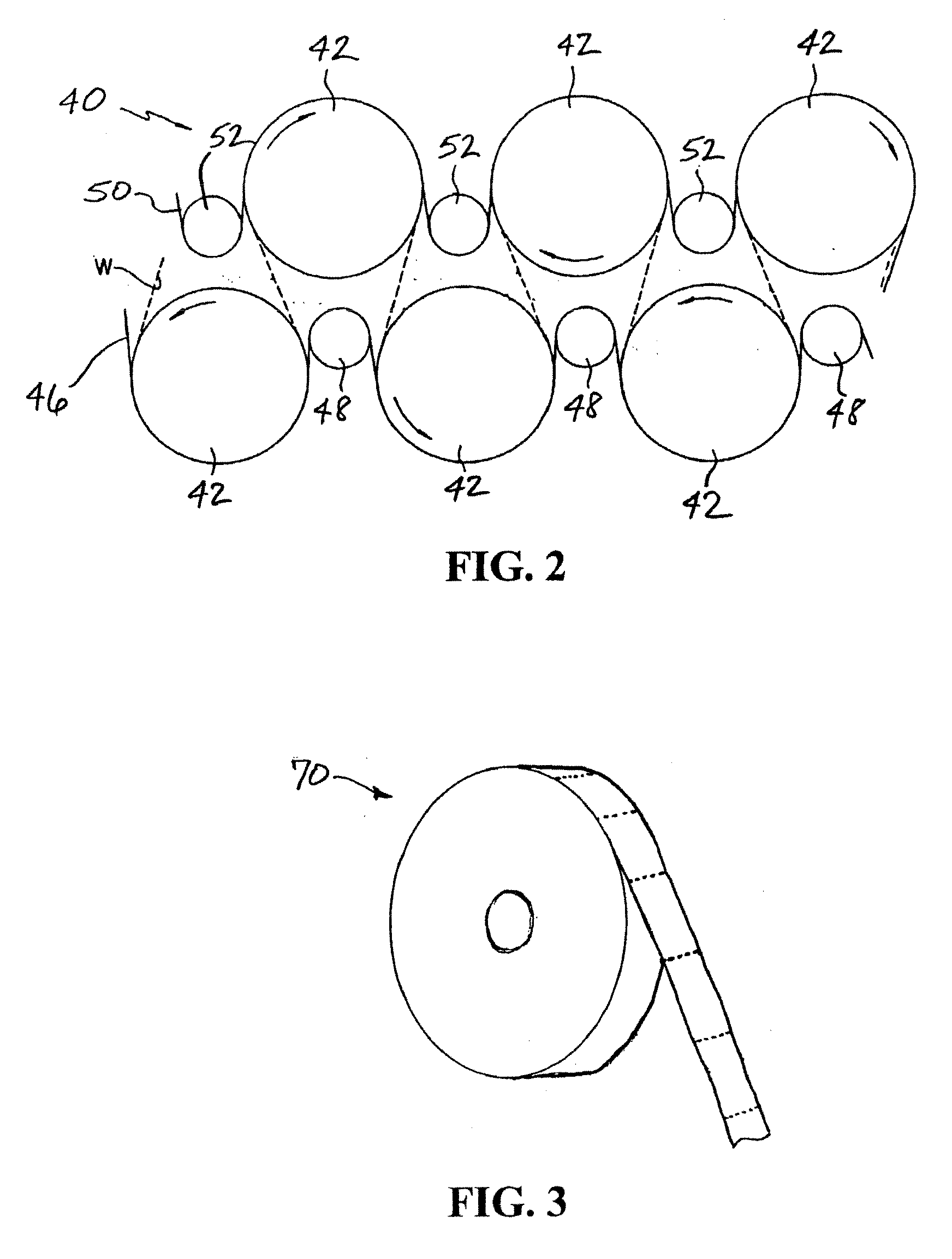

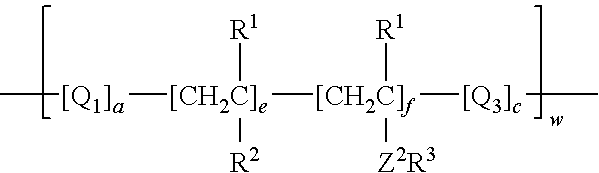

A sheet of wiping material has a first outer surface and a second outer surface and a core region between the surfaces. The wiping material includes absorbent fibers and non-absorbent fibers. The wiping material has a stratified structure with a fiber gradient and a higher ratio of absorbent fibers to non-absorbent fibers at the outer surfaces of the wiping material than in the core region. A method of producing the wiping material is described.

Owner:ESSITY HYGIENE & HEALTH AB

Blended yarn spinning method

The invention discloses a blended yarn spinning method. Blended yarn is composed of cashmere, synthetic fiber and viscose acetal fiber, and spinning is finished through manual blending, blowing, cotton carding, drawing and roving. The method has the advantages that manual blending is adopted for mixing of fiber, and the nonuniformity of cashmere in finished yarn is solved; the process that carding is conducted more times than striking in the blowing and cotton carding processes, anti-static coating powder is added, damage to cashmere fiber and fleece falling are reduced, and the phenomenon that cashmere winds the cylinder and doffer easily is solved; the twist of roving is increased, and the defects that adhering, breakage and loosening, caused by the features that the crispation number of cashmere is reduced, and the fiber is smooth, in the processing process are overcome.

Owner:NANTONG YUEDA KNITTING GARMENT

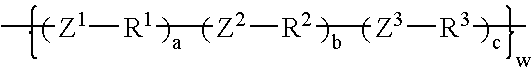

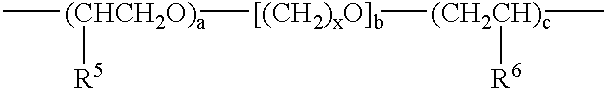

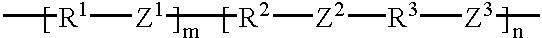

Modified condensation polymers containing azetidinium groups in conjunction with amphiphilic hydrocarbon moieties

InactiveUS6896769B2Imparting softnessReduced strengthNatural cellulose pulp/paperMechanical working/deformationPolyamideCondensation polymer

Modified condensation polymers containing azetidinium groups, such as polyamide epichlorohydrin (PAE) resins, can be combined with amphiphilic hydrocarbons containing polyethers into a single molecule to provide several potential benefits, depending upon the specific combination employed, including: (a) wet strength aids that impart softness; (b) softeners that do not reduce wet strength: (c) wet strength with improved wet / dry strength ratio; (d) surface feel modifiers with reduced linting and sloughing; (e) wet strength aids with controlled absorbency; (f) wet strength aids with controlled decay rate after wetting; and (g) Yankee dryer additives that provide surface protection and adhesion with controlled release properties.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Spinning method for blended gauze

The invention relates to the field of making of gauze, in particular to a spinning method for blended gauze. The blended gauze is composed of cashmere, synthetic fibers and EKS fibers. Spinning is completed through the steps of manual blending, blowing, cotton carding, drawing, roving, spinning and spooling. The method comprises the following specific spinning steps of raw material selection, combing, drawing, roving, spinning and spooling. In the roving step, a powder antistatic coating further needs to be added. The nonuniformity of the cashmere in resultant yarn is solved. Damage to cashmere fibers and fibering off of the cashmere fibers are reduced, and the problem that the cashmere is prone to be wound around a cylinder and a doffer is solved. The human body can be kept warm and dry, and the functions of deodorizing, smell removing and PH value adjustment are achieved.

Owner:安徽天峰纺织有限公司

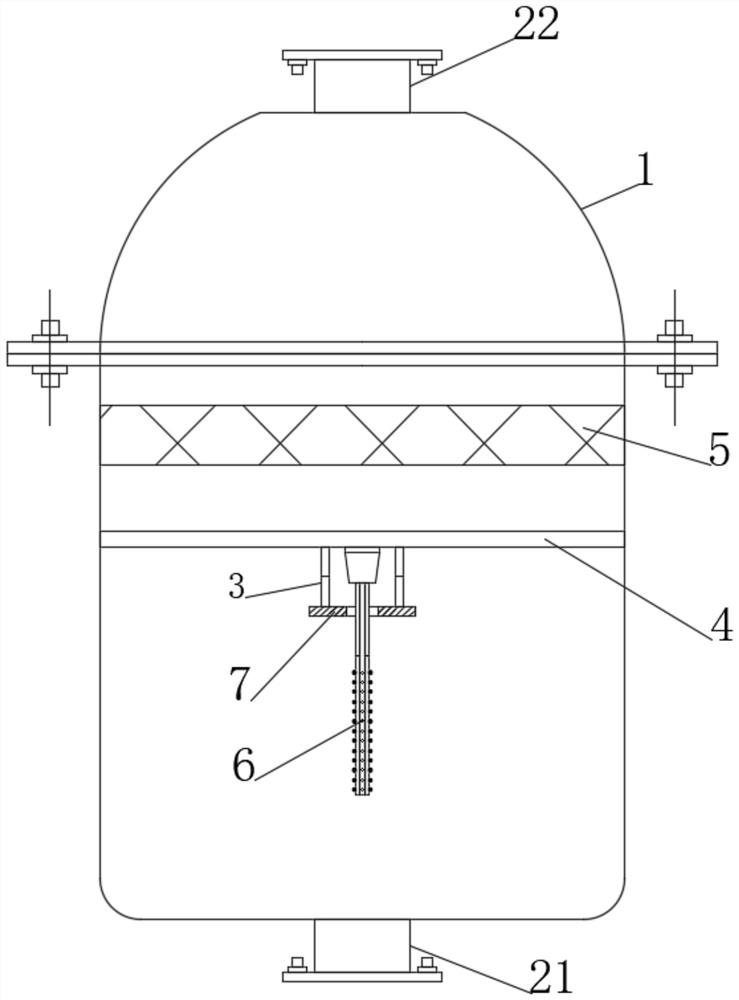

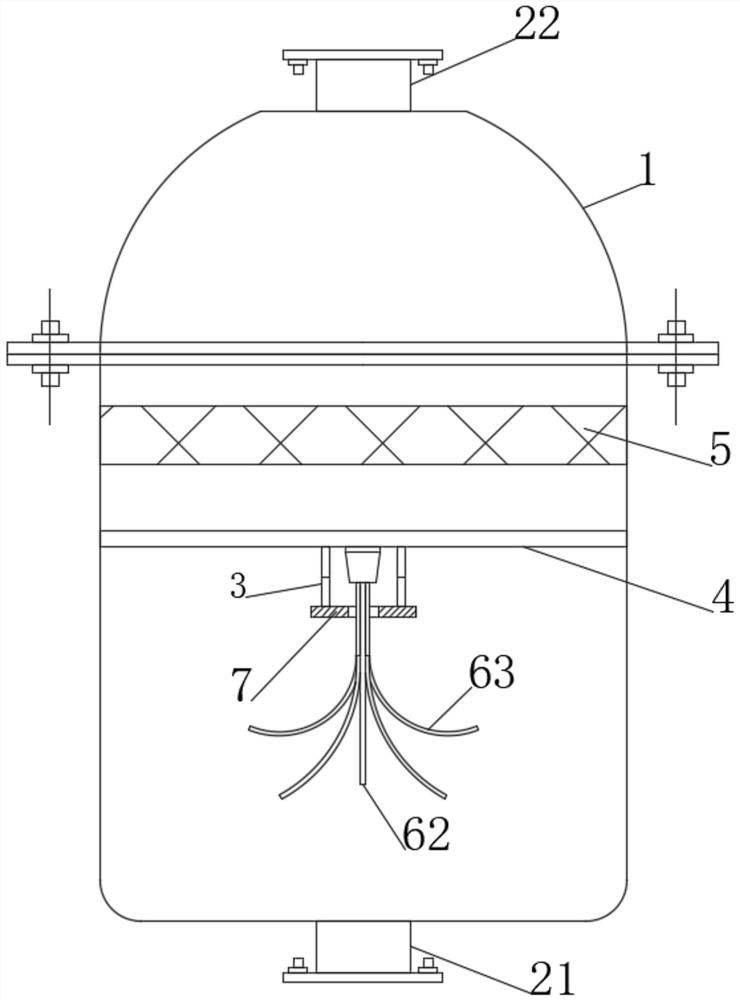

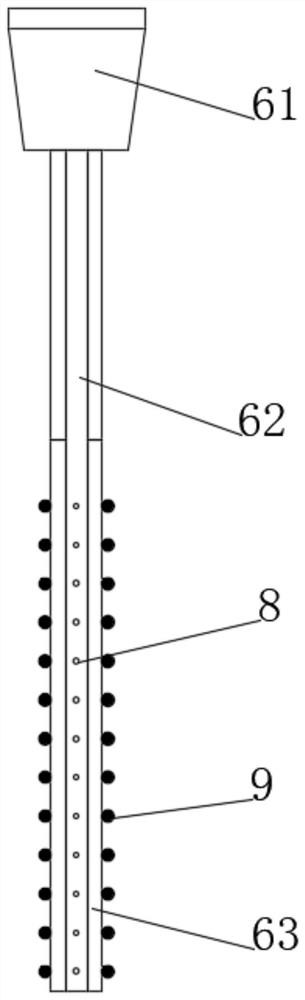

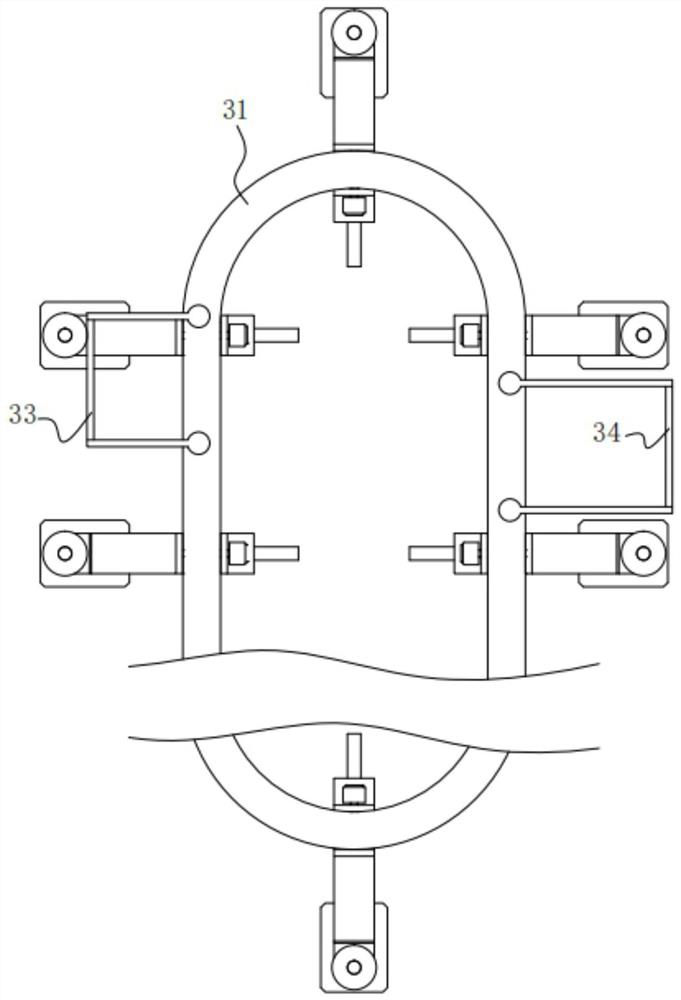

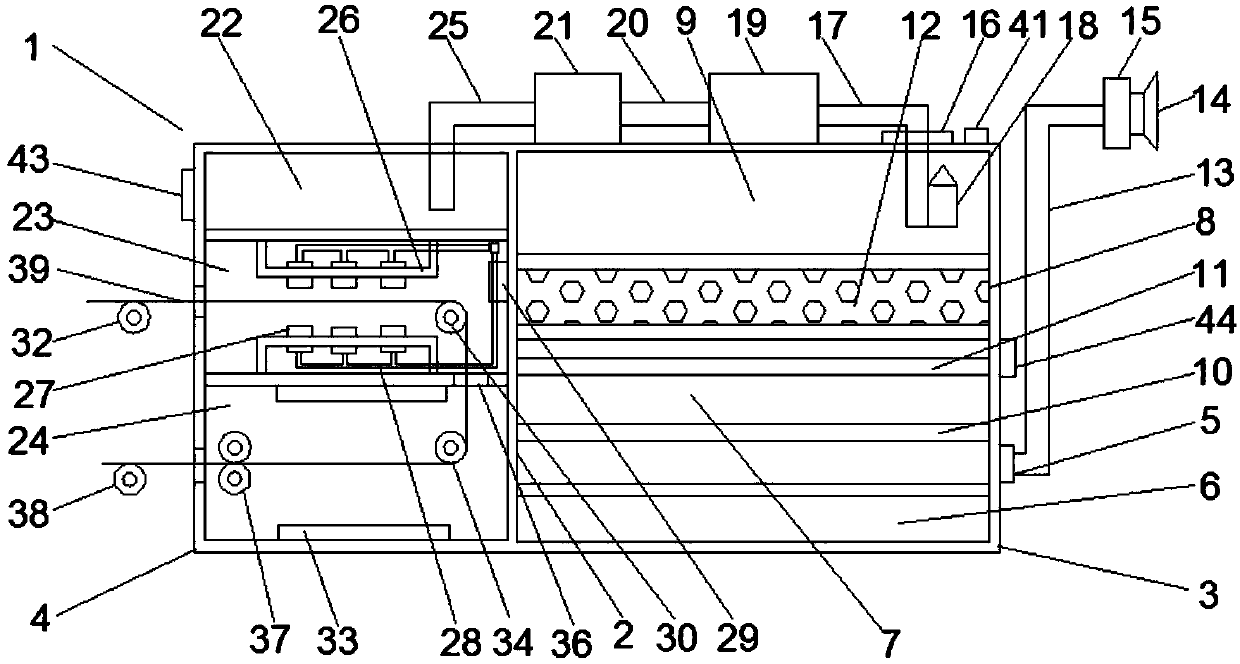

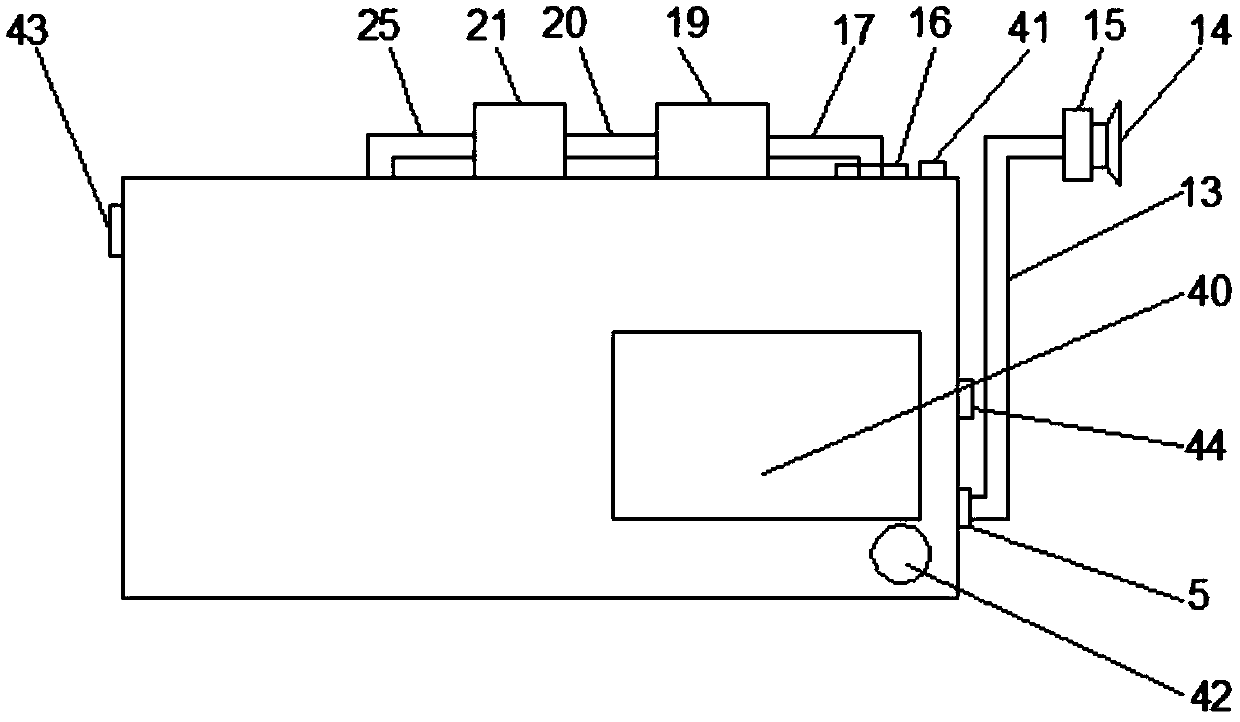

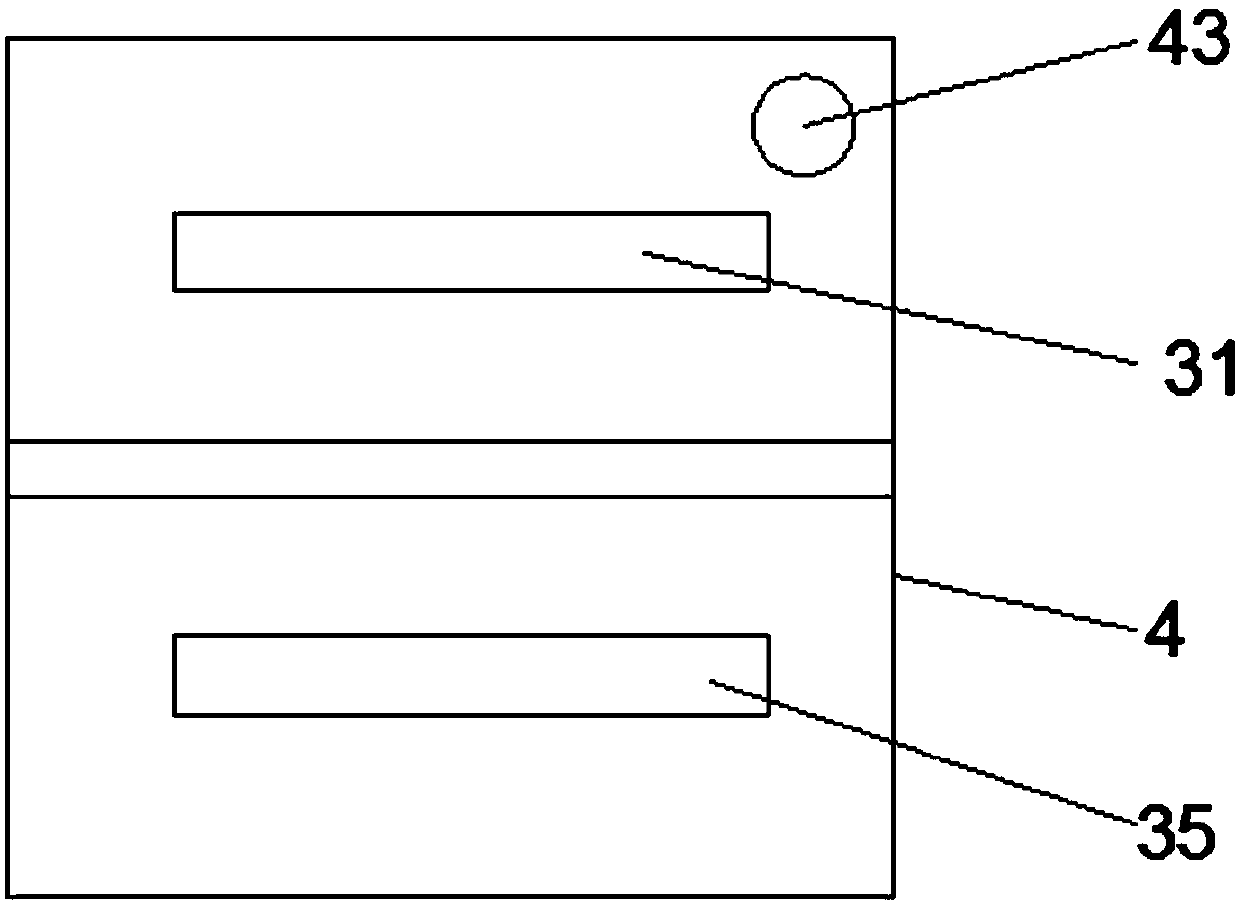

Self-expanding umbrella skirt-shaped printing and dyeing waste gas treatment device

InactiveCN111905503AIncrease reachReduce lintCombination devicesEnvironmental engineeringMechanical engineering

The invention discloses a self-expanding umbrella skirt-shaped printing and dyeing waste gas treatment device, which belongs to the field of waste gas treatment, and is characterized in that when theself-expanding umbrella skirt-shaped printing and dyeing waste gas treatment device is used, a self-expanding interception column is controlled to rotate, the self-expanding interception column is outwards expanded and unfolded under the action of centrifugal force, and meanwhile, by matching the effect of a point pull rope, an umbrella skirt-shaped net surface structure can be formed between theself-expanding interception column and the expanded self-expanding interception column, so that most impurities such as batting in the waste gas can be intercepted when the waste gas is in contact with the filtering assembly; when batting cleaning is needed, the electromagnet is controlled to be powered off, the self-expanding interception column stops rotating, and through the effect of the batting discharging ring; the point pull rope can carry the interception batting to be separated from the self-expansion interception column, so that the difficulty of separating the batting from the self-expansion interception column is effectively reduced; meanwhile, the protection effect on the filtering assembly is effectively improved, the damage rate of the filtering assembly is effectively reduced, and the waste gas treatment cost input is reduced.

Owner:段孝辉

Infrared-Absorbing Ticket Stock and Method of Making Same

InactiveUS20080035291A1High level of IR absorptionEnhanced infrared absorptionNon-fibrous pulp additionSpecial paperFiberSulfate

A ticket stock and manufacturing process wherein a pulp is formulated from a blend of recycled printed papers, with added starch for enhancing sheet stiffness and reducing linting and dusting on cut edges of the stock. A preferred pulp comprises a blend of printed solid bleached sulfate plate stock, printed white groundwood-free paper, and printed groundwood paper such as printed newsprint or the like. In one embodiment, the blend comprises about 25-50 wt. % printed solid bleached sulfate plate stock, about 15-40 wt. % printed white groundwood-free paper, and about 15-40 wt. % printed groundwood paper. The printed papers are repulped with minimal mechanical refining, treated with steam injection for hydrating and softening the fibers and breaking up inks into fine particles, and formed into a web that is pressed, dried, and soft calendered. The caliper of the resulting stock is about 7 to 9 points.

Owner:SONOCO DEV INC

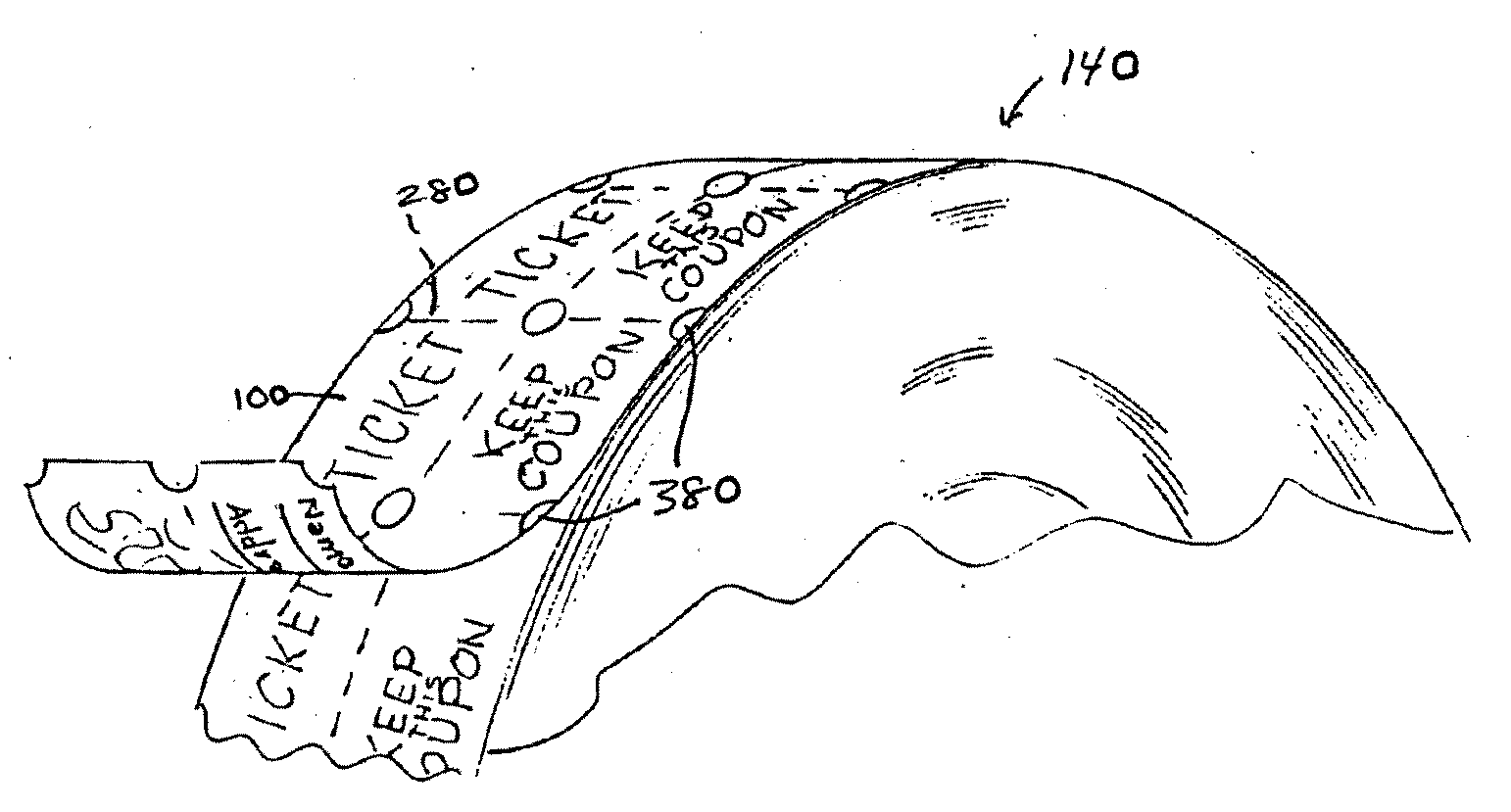

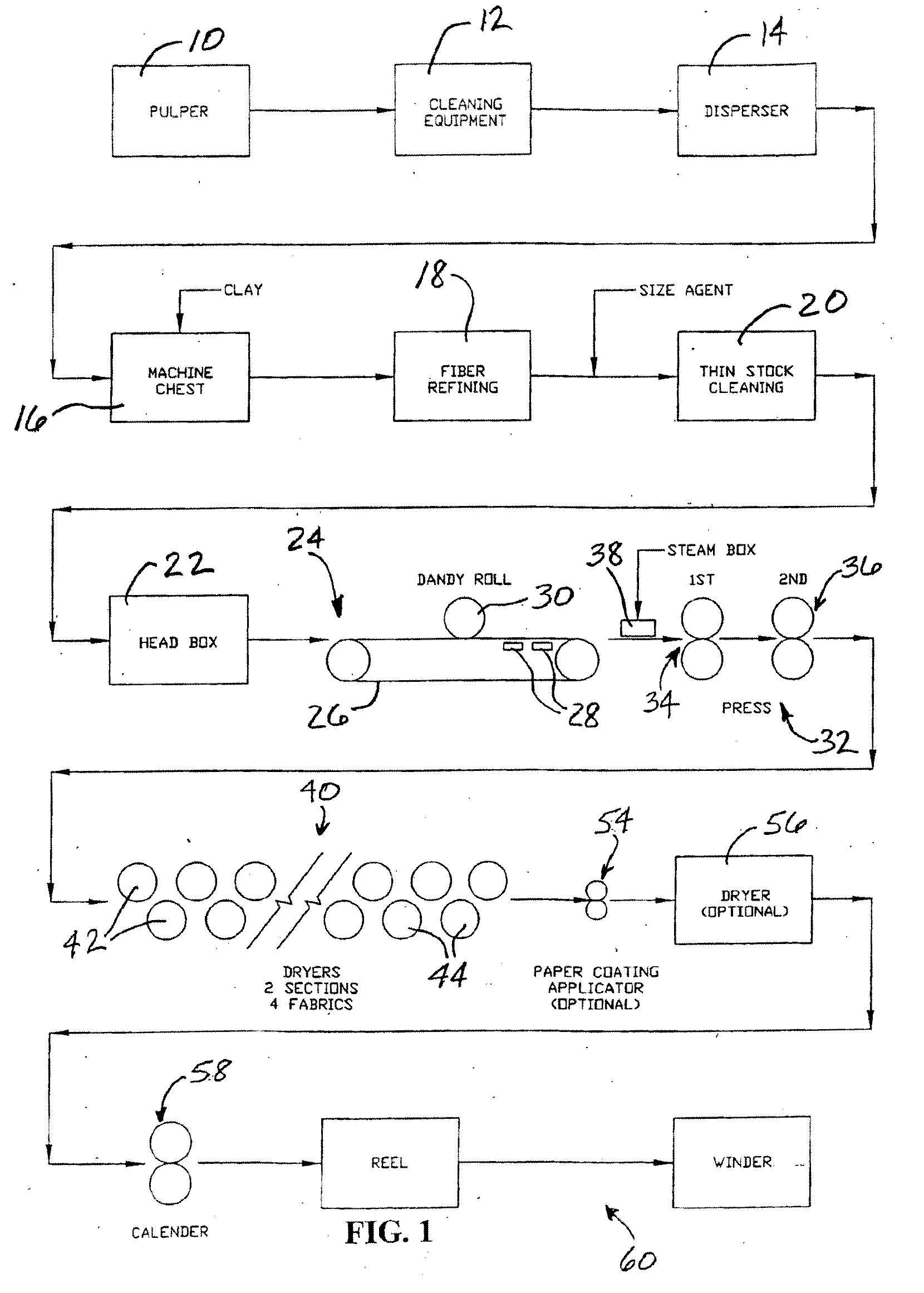

High Opacity Tickets

ActiveUS20080149289A1Good flexibilityGood printabilityNatural cellulose pulp/paperSpecial paperFiberCard stock

A ticket stock and manufacturing process wherein a pulp is formulated from a blend of recycled furnishes, with added starch for enhancing sheet stiffness and reducing linting and dusting on cut edges of the stock, and clay or other opacifier for enhancing opacity of the stock. A preferred pulp comprises a blend of recycled solid bleached sulfate plate stock, recycled coated soft white, and recycled ground wood furnish such as newsprint or the like. In one embodiment, the blend comprises about 25-50 wt. % recycled solid bleached sulfate plate stock, about 25-50 wt. % recycled coated soft white, and about 15-25 wt. % recycled ground wood furnish. The furnish blend is repulped with minimal mechanical refining, is treated with steam injection for hydrating and softening the fibers, and is formed into a web that is pressed, dried, and soft calendered. The caliper of the resulting stock is about 7 to 9 points and provides a ticket for use in prize redemption in family entertainment centers, arcades, location-based entertainment centers, amusement parks, and similar establishments. The ticket may also be used to conduct drawings, raffles and give-a-ways. The ticket may be formed from a sheet of reply card stock paper having a caliper characteristic in the range of 5 and 11 points.

Owner:INDIANA TICKET

Process for incorporating poorly substantive paper modifying agents into a paper sheet via wet end addition

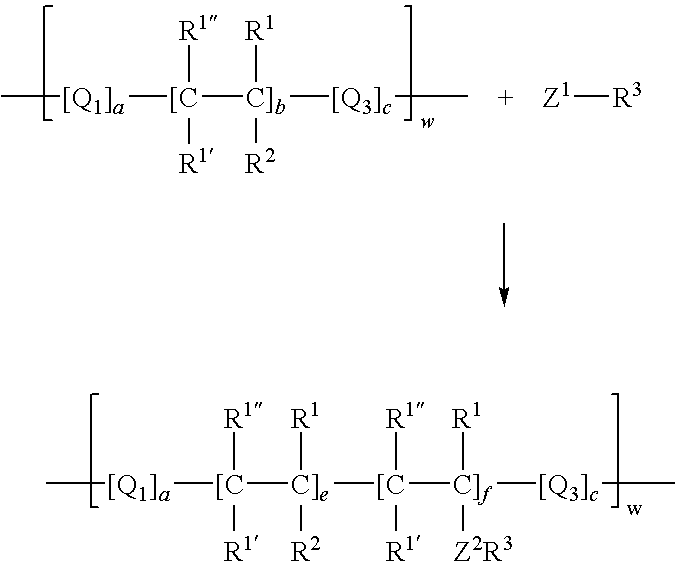

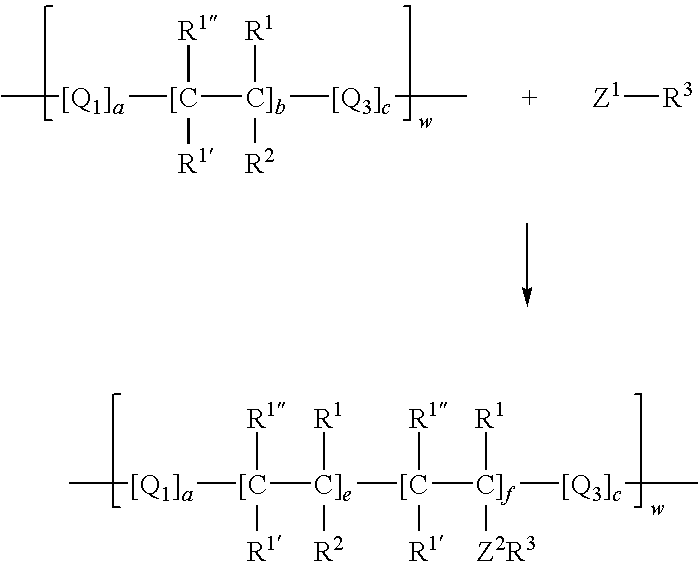

InactiveUS7678232B2Imparting softnessReduced strengthNon-fibrous pulp additionNatural cellulose pulp/paperHydrogenCellulose fiber

Synthetic co-polymers having moieties capable of forming hydrogen bonds, ionic bonds, or covalent bonds with cellulose fibers and paper modifying moieties capable of modifying a paper sheet are disclosed. These synthetic co-polymers are derived from the reaction of an aldehyde functional polymer and an aldehyde reactive paper modifying agent containing a non-hydroxyl aldehyde reactive functional group.

Owner:KIMBERLY-CLARK WORLDWIDE INC

High opacity tickets

Owner:INDIANA TICKET

Milling cutter

ActiveCN104400096AIncrease the lengthReduce processing burdenMilling cuttersMilling cutterMetallic materials

A milling cutter comprises a handle part for clamping the milling cutter, a cutting part and at least two slots, wherein the cutting part at least comprises two edge parts; each edge part comprises a continuous curve edge; a starting point of the curve edge is arranged close to the end surface of the cutting part. The milling cutter is specifically designed for continuously milling non-cascading metal and nonmetal materials; when the milling cutter is used for machining the special cut materials, the service life of the milling cutter can be greatly prolonged and the machining cost can be reduced.

Owner:SHANGHAI JINGREN LASER TECH

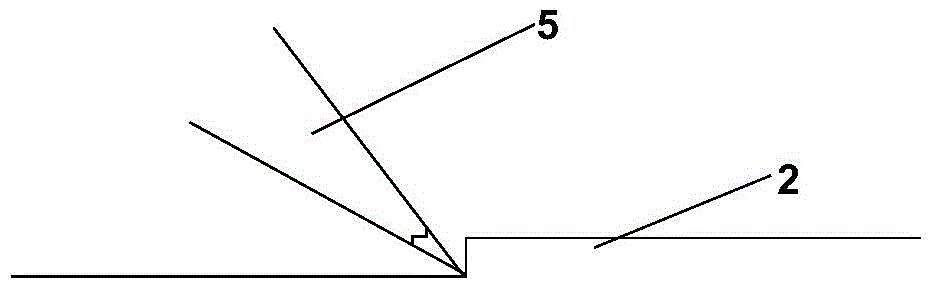

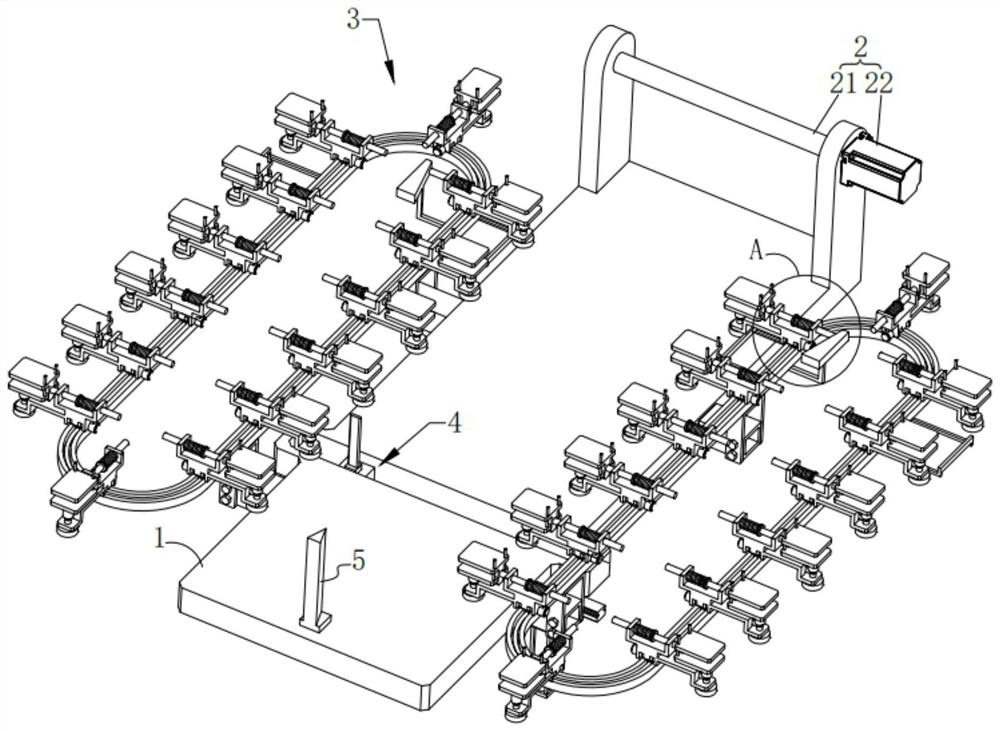

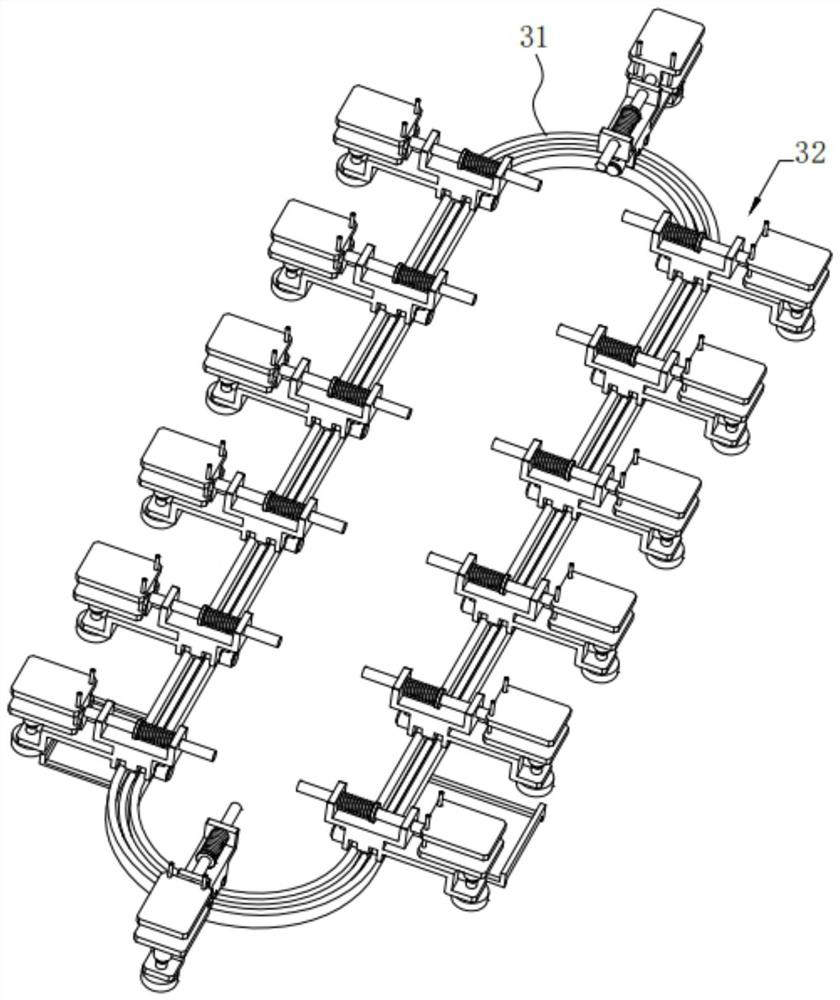

Towel cutting and forming device

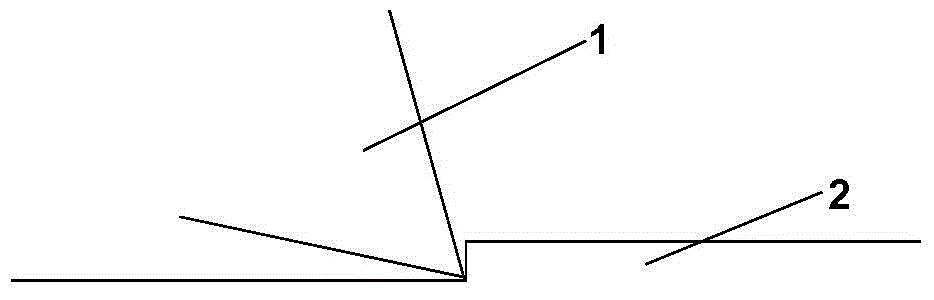

ActiveCN113106734AAvoid processing efficiency impactGuaranteed processing efficiencySevering textilesEngineeringBlade knife

The invention provides a towel cutting and forming device. The towel cutting and forming device comprises a support, an unwinding mechanism, two conveying mechanisms, a segmented cutting mechanism and a single-blade knife; the unwinding mechanism is arranged at the end of the support; the two conveying mechanisms are oppositely arranged, and the ends, close to the unwinding mechanism, of the two conveying mechanisms are feeding ends; each conveying mechanism comprises an annular guide rail, walking clamping assemblies, a friction plate I, a friction plate II and a slope plate; the segmented cutting mechanism is arranged at the bottom of the support; a cutting part of the segmented cutting mechanism penetrates through the support and can conduct longitudinal displacement; and the single-blade knife is arranged at the discharging ends of the conveying mechanisms. Towels wound into rollers are clamped and conveyed through the conveying mechanisms, the walking clamping assemblies reciprocate along the corresponding annular guide rails, then the towels can be circularly clamped, and the machining efficiency is guaranteed; and in addition, the conveyed towels are cut into long strips through the segmented cutting mechanism, and then the long strips are separated through the single-blade knife, so that feeding and cutting are again avoided, and one-time cutting forming is achieved.

Owner:安徽省伊贝雅纺织股份有限公司

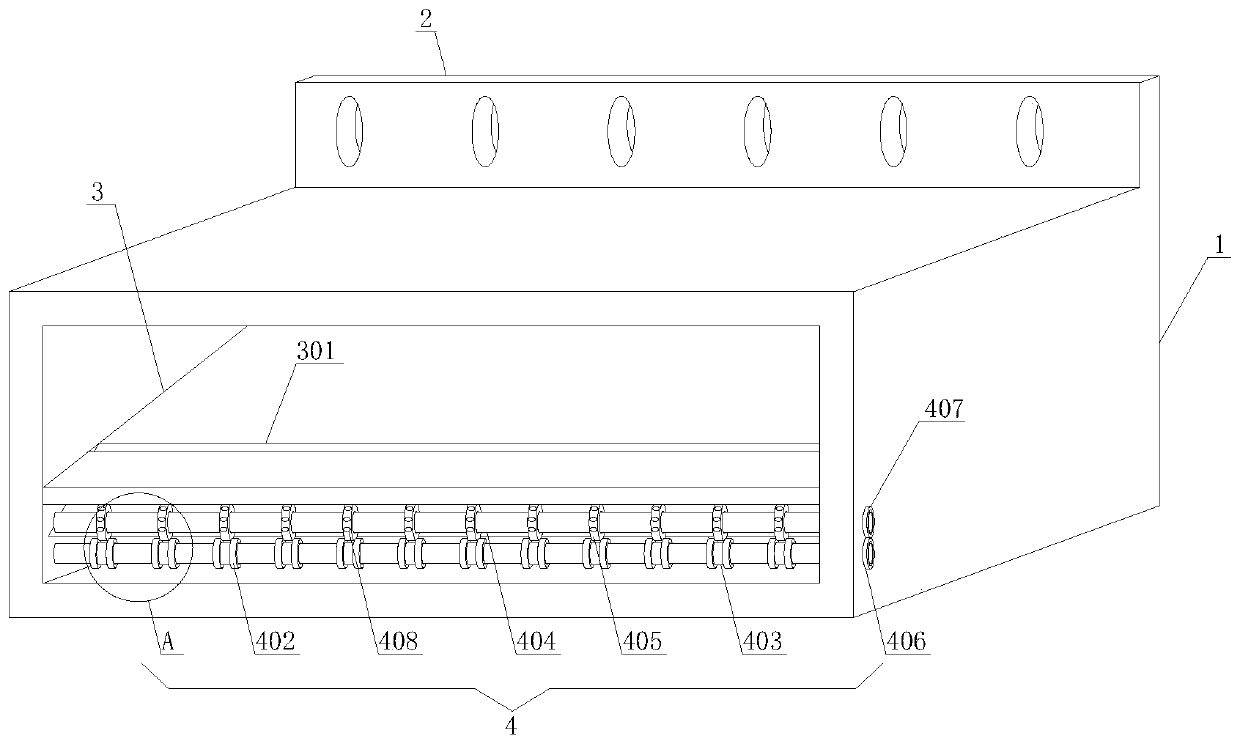

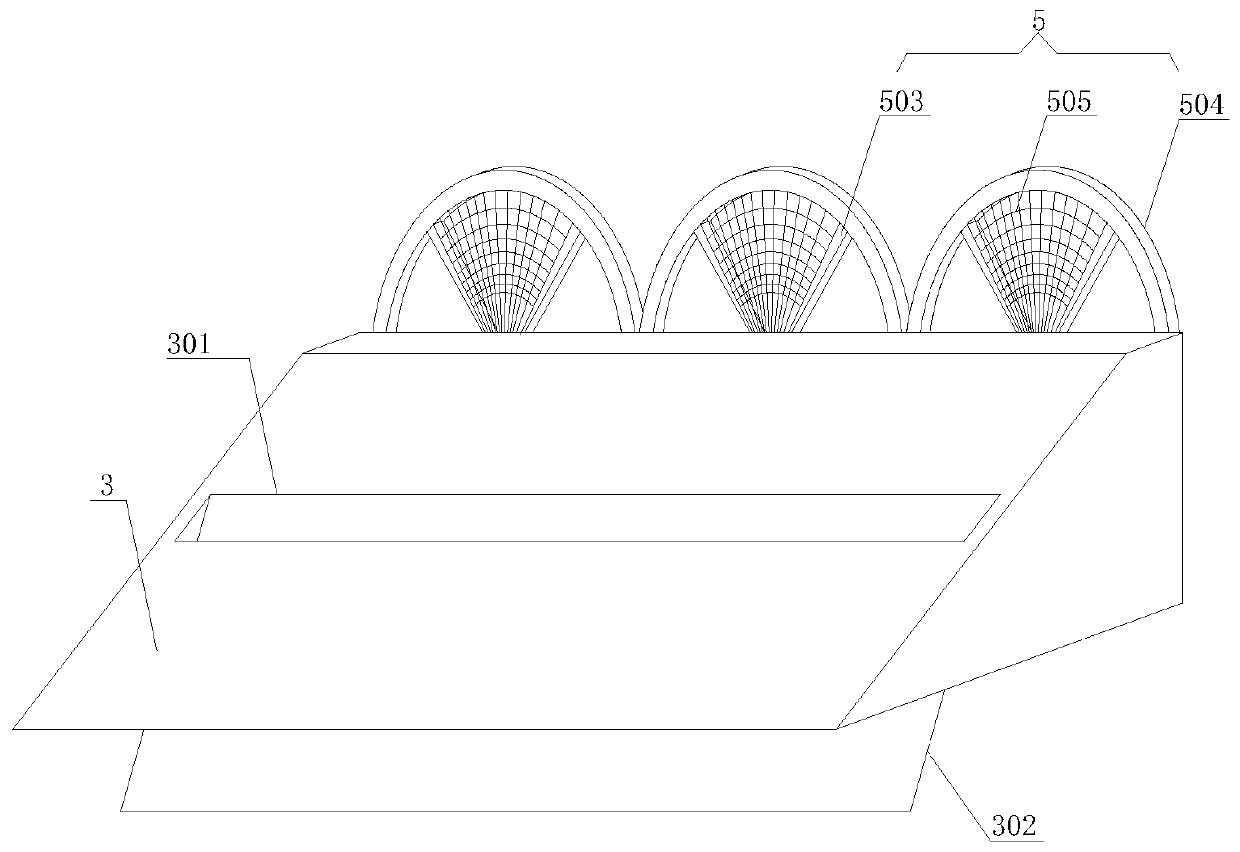

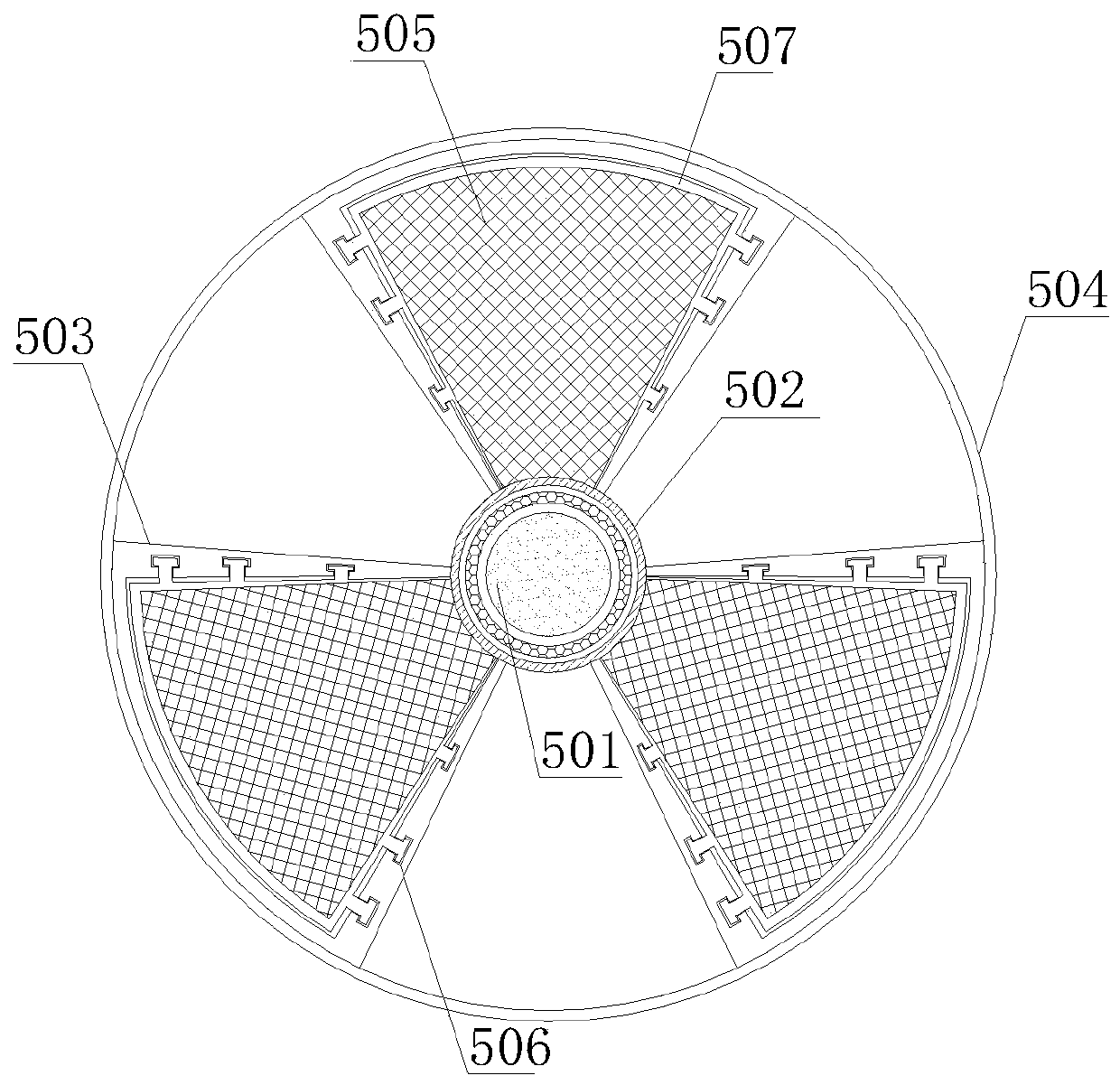

Textile dust collecting equipment for textile machine

InactiveCN110420903APurify the production environmentImprove qualityFilament handlingDirt cleaningYarnEngineering

The invention discloses textile dust collecting equipment for a textile machine. The textile dust collecting equipment comprises a butting box, a dismounting and mounting plate, an air draft table, ayarn guide mechanism and a fluff collecting mechanism, wherein the bottom of the dismounting and mounting plate is fixedly welded to the back side of the top of the butting box, the two sides of the air draft table are fixedly welded to the inner wall of the butting box, the yarn guide mechanism is arranged at the bottom of the front side of an inner cavity of the butting box, and the fluff collecting mechanism is arranged on the back side of the air draft table. According to the textile dust collecting equipment for the textile machine, collecting and cutting-off of fluff adhered to yarn or not broken is carried out from a yarn inlet, so that on one hand, the amount of the fluff floating in the air can be reduced, the production environment is purified, on the other hand, the quality of the woven products can be improved, and the economic benefits of textile production can be improved; and the rotating speed of the fluff collecting mechanism can be accelerated continuously along withthe increase of the collection amount of the fluff, certain attraction force can be increased to better suck the floating fluff, and on the other hand, the generated wind power can be used for blowingand cooling the textile equipment.

Owner:宁波市鄞州智伴信息科技有限公司

Dedusting and humidifying device for spinning workshop

ActiveCN107653558AImprove air qualityQuality improvementCombination devicesLiquid/gas/vapor removalEngineeringTextile

The invention discloses a dedusting and humidifying device for a spinning workshop. The device includes a box body, the box body is internally provided with a longitudinal clapboard which partitions an accommodating cavity of the box body into a purifying box and a humidifying box, a filtering solution is stored in the purifying box, one side of the purifying box is provided with a water inlet andan air inlet separately, the purifying box is provided with a sediment tank, a first filtering layer, a second filtering layer and a clarification layer from bottom to top sequentially, the sedimenttank is positioned on the bottom of an inner cavity of the purifying box, an accommodating cavity of the first filtering layer is internally provided with coarse grilles and fine grilles separately, the fine grilles are positioned above the coarse grilles, an accommodating cavity of the second filtering layer is filled with suspended fillers, and the air inlet is formed opposite to the first filtering layer. The device has the advantages that the air quality of the spinning workshop is effectively improved, static potential dangers of textiles are eliminated, the structure is simple, and the practicability is high.

Owner:HAIAN QI HONG TEXTILE TECH CO LTD

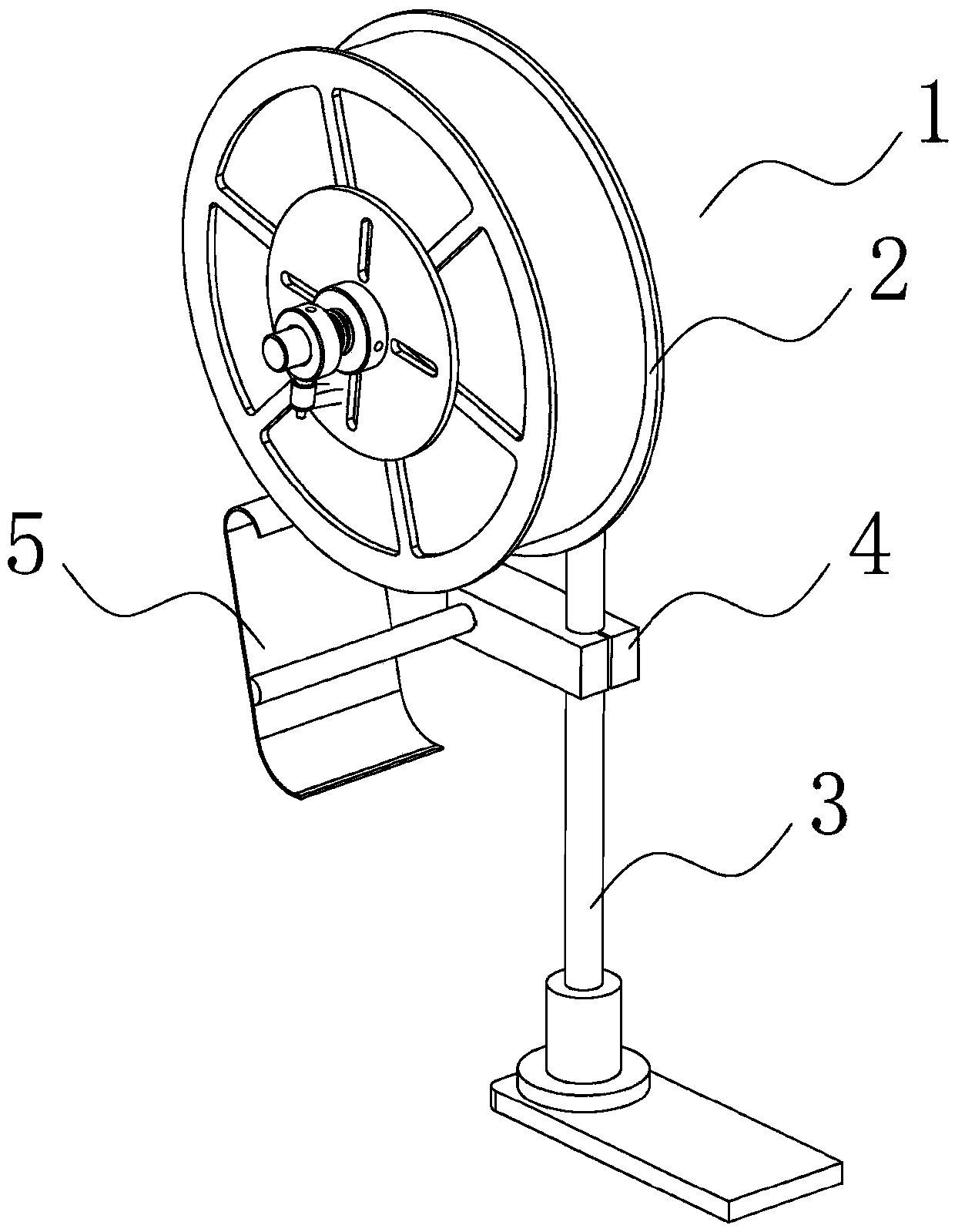

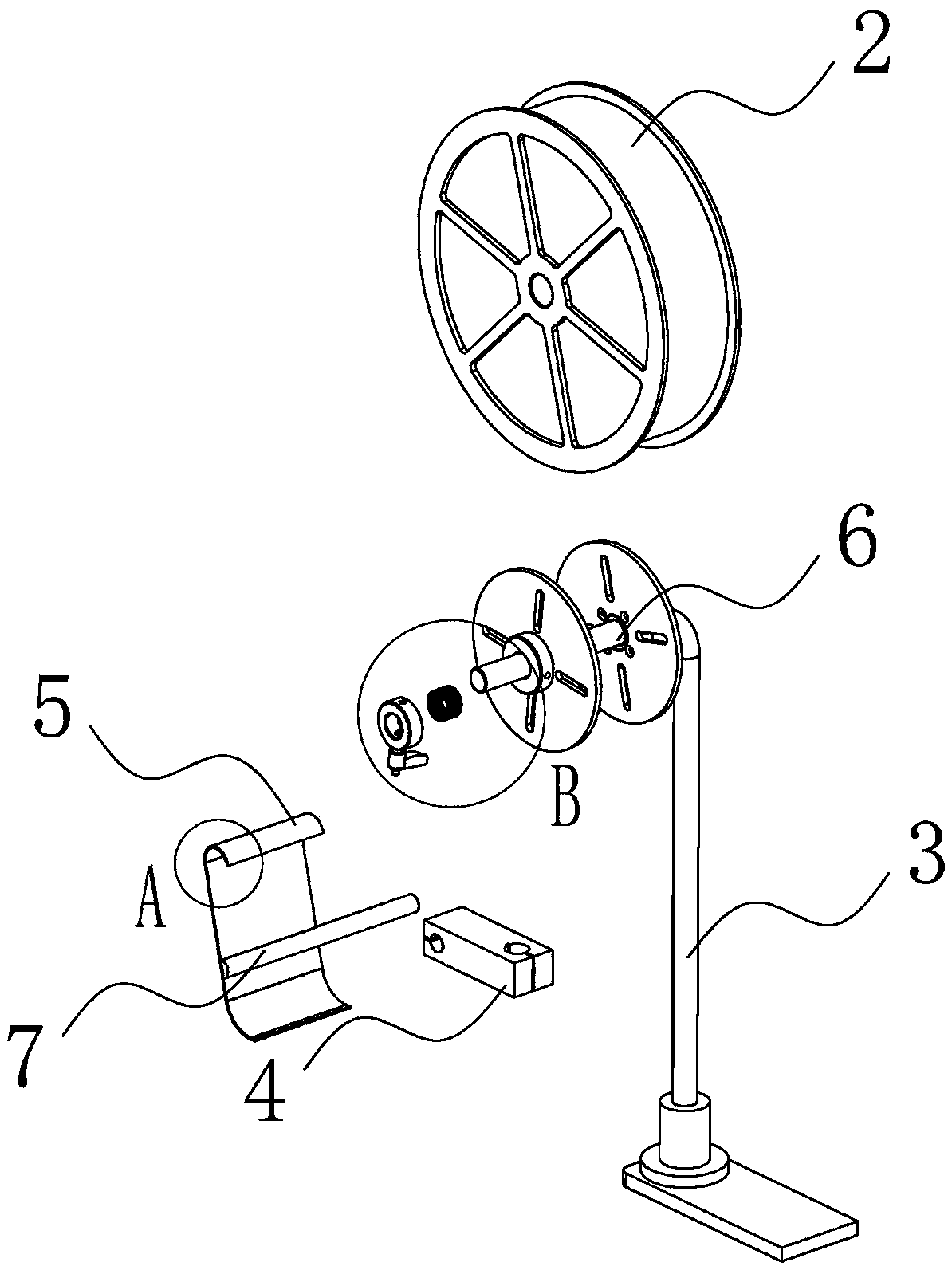

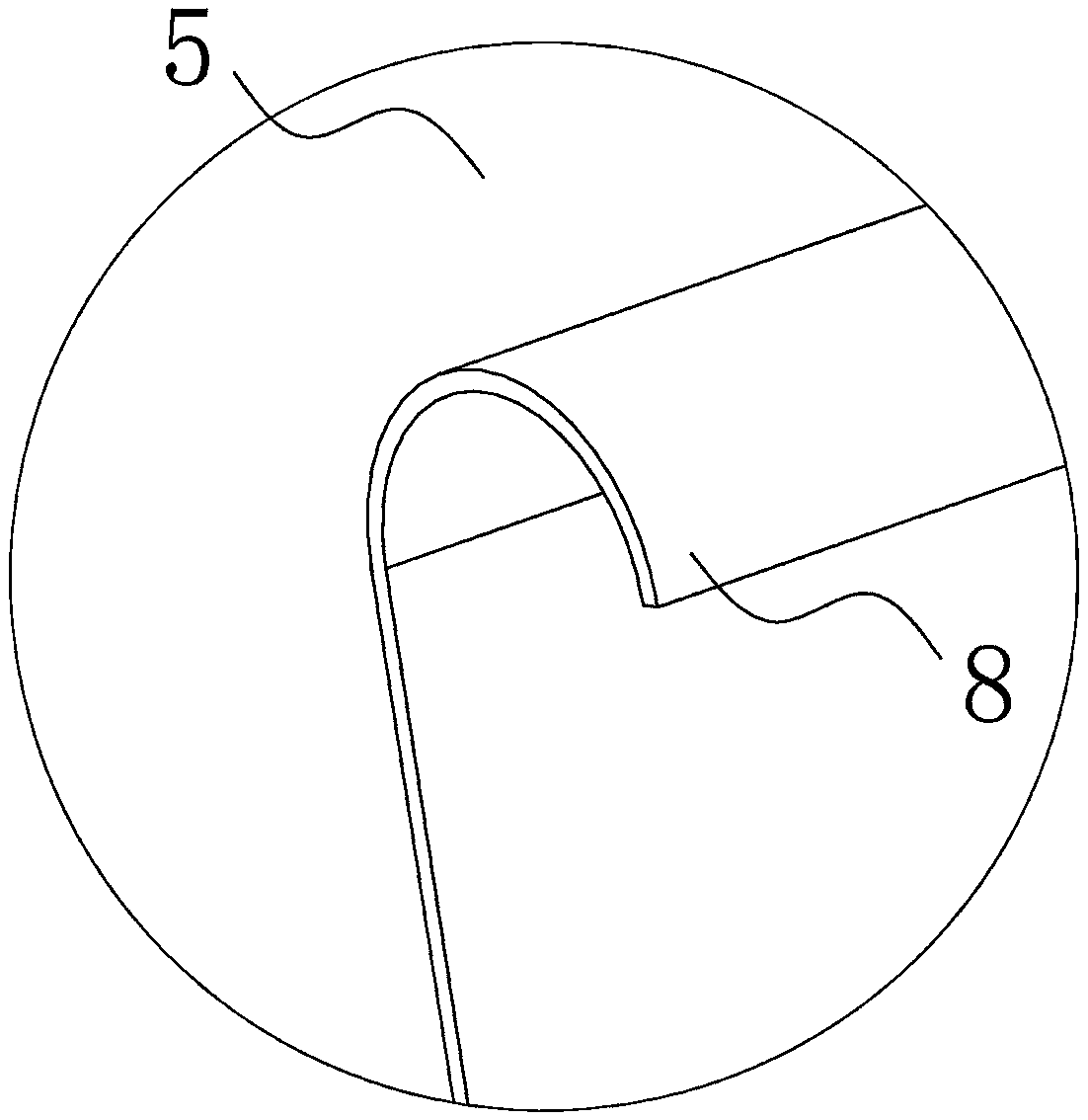

Yarn take-up device used for colored spun yarn processing

The invention discloses a yarn take-up device used for colored spun yarn processing. The yarn take-up device comprises a yarn take-up disc and a supporting column; a rotating disc is arranged on the upper portion of the supporting column, the yarn take-up disc is sleeved with the rotating disc, a hanging disc is hung on the supporting column, a yarn combing disc is installed at one side of the hanging disc, a turnover connecting column is welded to the middle of the yarn combing disc, and a scraper blade is arranged at the top of the yarn combing disc; a rotating shaft penetrates through the middle of the rotating disc, springs sleeve the two ends of the rotating shaft respectively, and a clamping block is arranged at each end of the rotating shaft. The yarn combing disc can be made to swing up and down around the turnover connecting column so that the scraper blade at one end of the yarn combing disc can fit the yarn take-up disc, the scraper blade is used for scraping fluff and thread residue on yarn taken up by the yarn take-up disc, it is ensured that the outer surface of the yarn taken up by the device is cleaner, and the fluff and impurities on the yarn are reduced. The yarntake-up device is convenient to operate, and all members are connected flexibly.

Owner:HUBEI ENG INST

Cashmere blending method for reducing card neps with design and color

The invention discloses a cashmere blending method for reducing card neps with design and color, and relates to the field of cashmere blending of cashmere industries. The method is characterized by comprising the following steps that step one, pre-carding is carried out on 20% of hue cashmere; step two, laying-up and opening are carried out on carded hue cashmere and remaining dyed cashmere; stepthree, oil water is added; and step four, bin transferring is carried out for maintenance. The cashmere blending method for reducing the card neps with the design and color has the advantages that (1)laying-up once and opening twice are carried out on the carded hue cashmere and other hue cashmere, a preliminary blending process is omitted, the frequency of opening is reduced, thereby protectingthe length of a cashmere fiber, reducing the time and labor, and improving the production efficiency; (2) the card neps of the pre-carded fiber are obviously reduced during spinning, spun yarns have no card nep, no card nep picking link exists during knitting production, thereby improving the working efficiency and ensuring the inherent quality and appearance quality of cashmere products; (3) during all production processes from spinning to knitting, energy conservation and consumption reduction are achieved, and the production efficiency is improved.

Owner:NINGXIA RONGCHANG CASHMERE IND GROUP

Slivering and crude oil

InactiveCN1558019AIncreased head break rateLate shaping effectFibre treatmentOil and greaseFatty alcohol

The top making and wool mixing oil consists of refined vegetable oil and refined animal oil as basic material, emulsifier and antistatic agent. The refined vegetable oil is methyl fatty ester, the refined animal oil as basic material is methyl fatty ester, the emulsifier is emulsifier NP or fatty alcohol-polyoxyetheleneether, and the antistatic agent is octadecyl phosphate. The present invention makes wool fiber no shortening.

Owner:徐维青

Slivering and crude oil

InactiveCN1242113CIncreased head break rateLate shaping effectFibre treatmentOil and greaseFatty alcohol

The top making and wool mixing oil consists of refined vegetable oil and refined animal oil as basic material, emulsifier and antistatic agent. The refined vegetable oil is methyl fatty ester, the refined animal oil as basic material is methyl fatty ester, the emulsifier is emulsifier NP or fatty alcohol-polyoxyetheleneether, and the antistatic agent is octadecyl phosphate. The present invention makes wool fiber no shortening.

Owner:徐维青

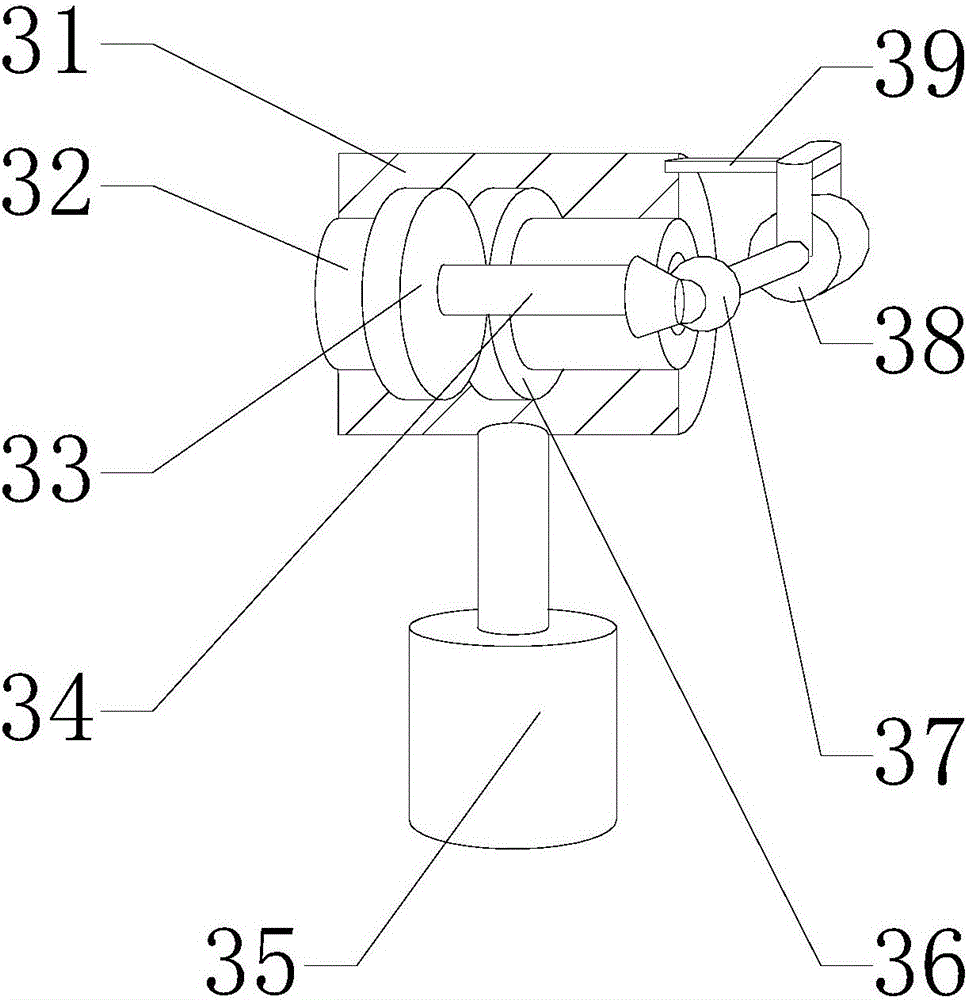

Twist setting mechanism

The invention provides a twist setting mechanism. The twist setting mechanism comprises a bundling wheel, a first gear, a first bevel gear, a second gear, a second bevel gear, a pulley, a slide wheel, a first circular gear, a motor and a second circular gear. The first gear is mounted on the bundling wheel, the front end of the first gear is connected with the second gear, the first gear is in gear mesh with the second gear, the second bevel gear is connected to the rear end of the first bevel gear which is fixed to the right end of the second gear, the first bevel gear is in gear mesh with the second bevel gear, the pulley is mounted at the rear end of the second bevel gear, and automatic bundling can be realized by the design. The second circular gear is connected to the lower end of the first circular gear which is fixed to the front end of the slide wheel, the first circular gear is in gear mesh with the second circular gear, the second circular gear is mounted on the motor, and an acceleration function is achieved by the design. The twist setting mechanism has advantages of convenience in use and operation, availability for bundling, acceleration promotion, high stability and high reliability.

Owner:重庆节之道竹业有限公司

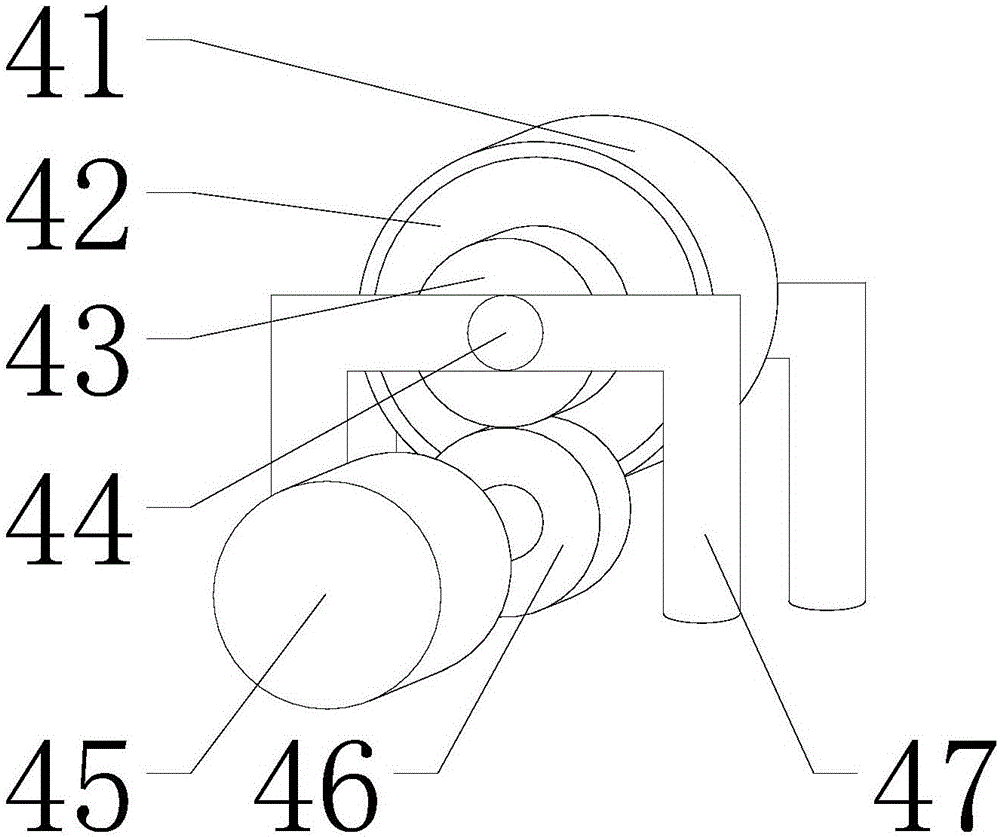

Acetate fiber pull-apart device and production method

The invention provides an acetate fiber pull-apart device and a production method. The pull-apart device comprises a rack; a man-machine control mechanism, a roller feed mechanism, a drafting press mechanism and a removable fiber output mechanism are arranged on the rack; the roller feed mechanism, the drafting press mechanism and the fiber output mechanism are synchronously driven by a main transmission mechanism, and the roller feed mechanism and the fiber output mechanism are installed at the two ends of the rack respectively. Acetate fibers are fed in parallel through the roller feed mechanism, the drafting press mechanism is installed between the roller feed mechanism and the fiber output mechanism for sequentially straightening and pulling apart the acetate fibers to form strip-shaped acetate fibers with different lengths, the acetate fibers are bundled through the fiber output mechanism, and the acetate fibers in different forms are output through different mechanical structuresand operation modes of the fiber output mechanism. By proposing the novel device and method, pull-apart forming of strip-shaped fibers from acetate fiber tows is realized in production, and the cohesion of the fibers is further increased.

Owner:HAIAN GUOYANG MACHINERY TECH CO LTD +1

Pretreatment method of viscose fibers and processing method of terylene-viscose blended knitting yarn

The invention provides a pretreatment method of viscose fibers, which comprises the following steps: (a) spreading a layer of viscose fibers, and spraying a water and crude oil mixer of 30-50 DEG C; (b) packing the viscose fibers, and stacking in a storehouse without ventilation; (c) and opening the viscose fibers to dry in the air. The invention also provides a processing method of terylene-viscose blended knitting yarn, which comprises the following steps: pretreating viscose fibers, opening and cleaning the cotton, combing the cotton, making ribbons, spinning coarse yarn, spinning fine yarnand winding bobbins. The processing method overcomes the defects of poor evenness, much filoplume, obvious defects, uneven and obviously different strength and the like so as to effectively enhance the quality of the yarns and meet the requirements of high-grade knitted fabrics.

Owner:JIANGYIN CITY HUAXIAO TEXTILE

Water-soluble fiber and high-count cashmere yarn spinning process

The invention relates to a water-soluble fiber and high-count cashmere yarn spinning process. The process comprises the following specific steps of (1) firstly opening cashmere, adding oil and water,then preliminarily mixing the cashmere and water-soluble fibers, and feeding a mixture into a mixing willow for full mixing; (2) processing the mixture obtained in the step (1) into rough yarns by using a carding machine, and controlling the temperature of a carding workshop to be 24-26 DEG C and the humidity to be 60-65%; (3) drafting and twisting the rough yarns obtained in the step (2) by a spinning frame to form spun yarns, winding the spun yarns into yarn ears, controlling the temperature of the carding workshop to be 20-30 DEG C and the humidity to be 60-65%, and controlling the draft multiple of the spun yarns to be 1.30-1.35; and (4) performing bobbin replacement and winding on the spun yarns by using a bobbin winder, and removing relatively thin or thick slivers at the same time.According to the process, on one hand, the spinning process is improved, and on the other hand, the water-soluble fibers are modified, so that the cashmere and the water-soluble fibers can be uniformly mixed in the wool mixing stage, after the water-soluble fibers are removed through water washing, the slivers can be uniform, and the wearability of a product is good.

Owner:ZHEJIANG MAGLIA CASHMERE FAMILY CO LTD

milling cutter

ActiveCN104400096BIncrease the lengthReduce processing burdenMilling cuttersMilling cutterMetallic materials

A milling cutter comprises a handle part for clamping the milling cutter, a cutting part and at least two slots, wherein the cutting part at least comprises two edge parts; each edge part comprises a continuous curve edge; a starting point of the curve edge is arranged close to the end surface of the cutting part. The milling cutter is specifically designed for continuously milling non-cascading metal and nonmetal materials; when the milling cutter is used for machining the special cut materials, the service life of the milling cutter can be greatly prolonged and the machining cost can be reduced.

Owner:SHANGHAI JINGREN LASER TECH

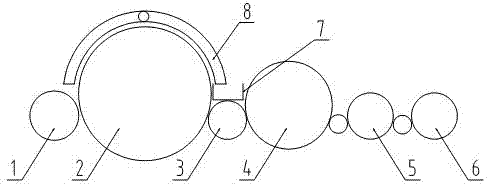

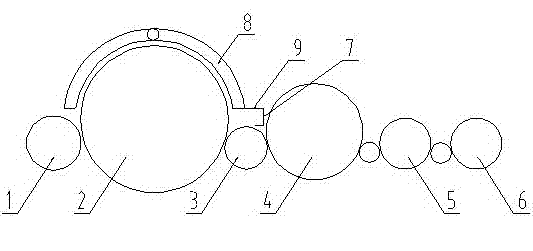

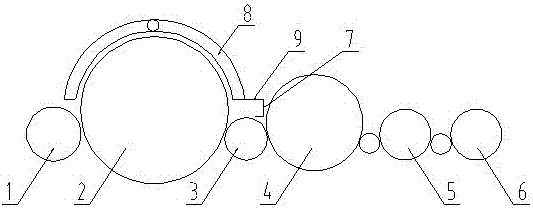

Carding machine deflector

The invention relates to a flow guiding device of a combing machine and belongs to the technical field of textile machinery. The flow guiding device comprises a large cylinder (2) and a second chest cylinder (4), wherein a flow guiding cover (8) is arranged above the large cylinder (2); a combing roller (3) is arranged between the large cylinder (2) and the second chest cylinder (4); an impurity receiving groove (7) is arranged above the combing roller (3); a first half part of the impurity receiving groove (7) is cut open; a wind shield cover (9) is arranged at the top of the impurity receiving groove (7); and the wind shield cover (9) is connected with the flow guiding cover (8). In the flow guiding device of the combing machine provided by the invention, the first half part of the impurity receiving groove (7) is cut open; and the top of the impurity receiving groove (7) is provided with the wind shield cover (9), which contributes to guiding out the air stream in the large cylinder, thus a web gets well, neps are reduced, and the operation rate and made-up rate are improved.

Owner:JIANGSU ZHENXIN IND

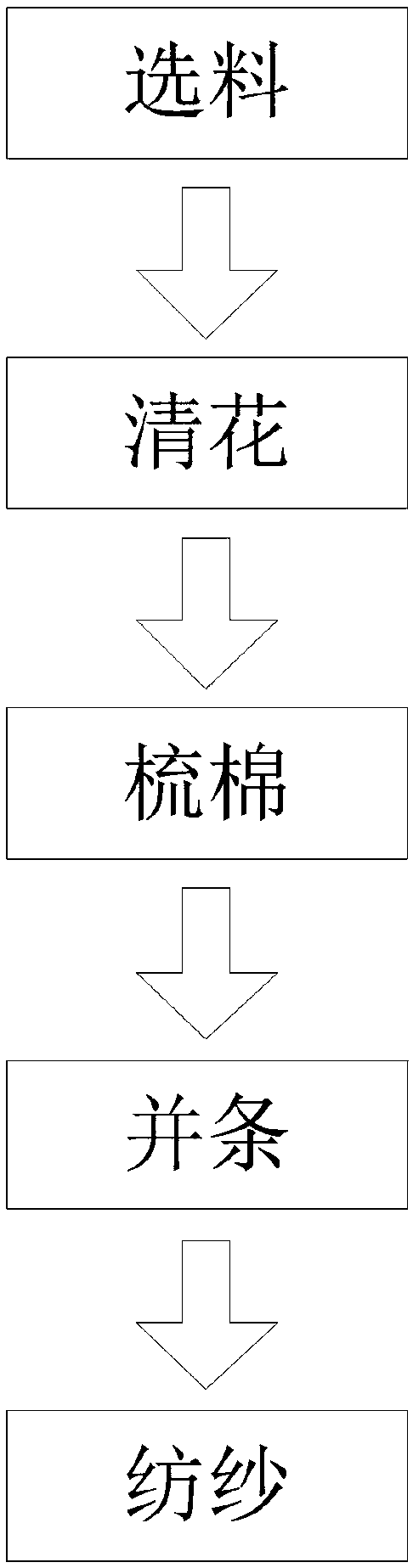

Spinning process of cashmere blended yarn

InactiveCN111270367ASolve the easy winding cylinderSolve the phenomenon of DofferYarnYarnPolymer science

An embodiment of the invention discloses a spinning process of a cashmere blended yarn. The process comprises the steps of material selection, wherein the following raw materials in percentage by massare selected: 50-60% of cashmere in the blended yarn, 20-30% of synthetic fibers in the blended yarn and 15-20% of viscose fibers in the blended yarn; cotton cleaning; cotton carding, wherein combednoil fiber rolls are treated with a cotton carding machine to obtain cotton fiber slivers; drawing, wherein drawing is performed for three times; and spinning, wherein a full-automatic rotor spinningmachine is adopted, the cotton slivers obtained by the drawing process are fed into the rotor spinning machine, and air spinning is performed to obtain a cotton yarn product. Compared with the prior art, the spinning process has the following beneficial effects: the spinning process of the cashmere blended yarn is capable of reasonably matching the raw materials, thereby effectively reducing hairiness of the yarn; and a multi-combing and less-beating process is adopted, so that damage of cashmere fibers and cashmere falling are reduced, and the phenomenon that the cashmere easily winds a cylinder and a doffer is eliminated.

Owner:湖北妙虎纺织有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com