Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153 results about "Blade knife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

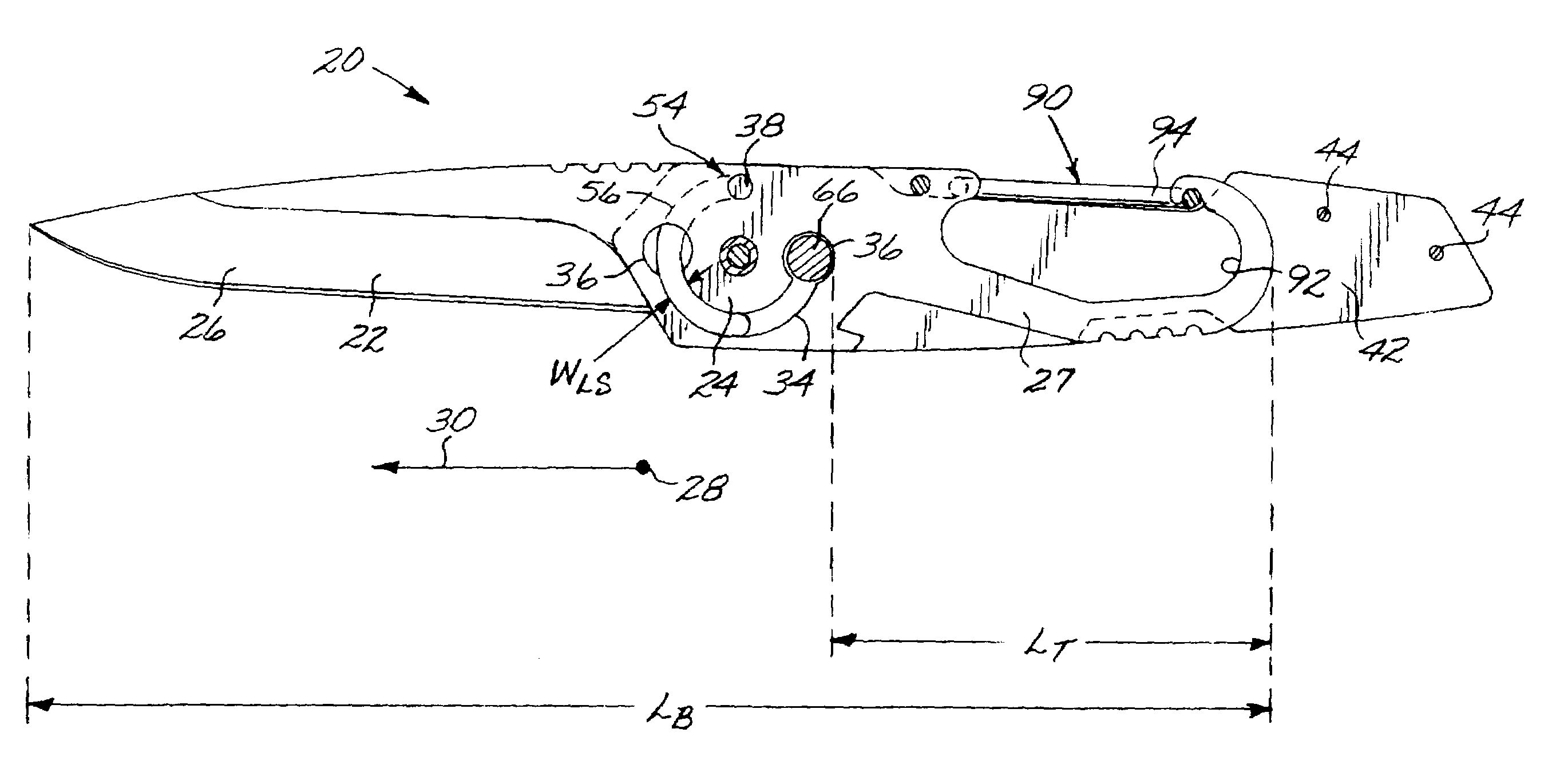

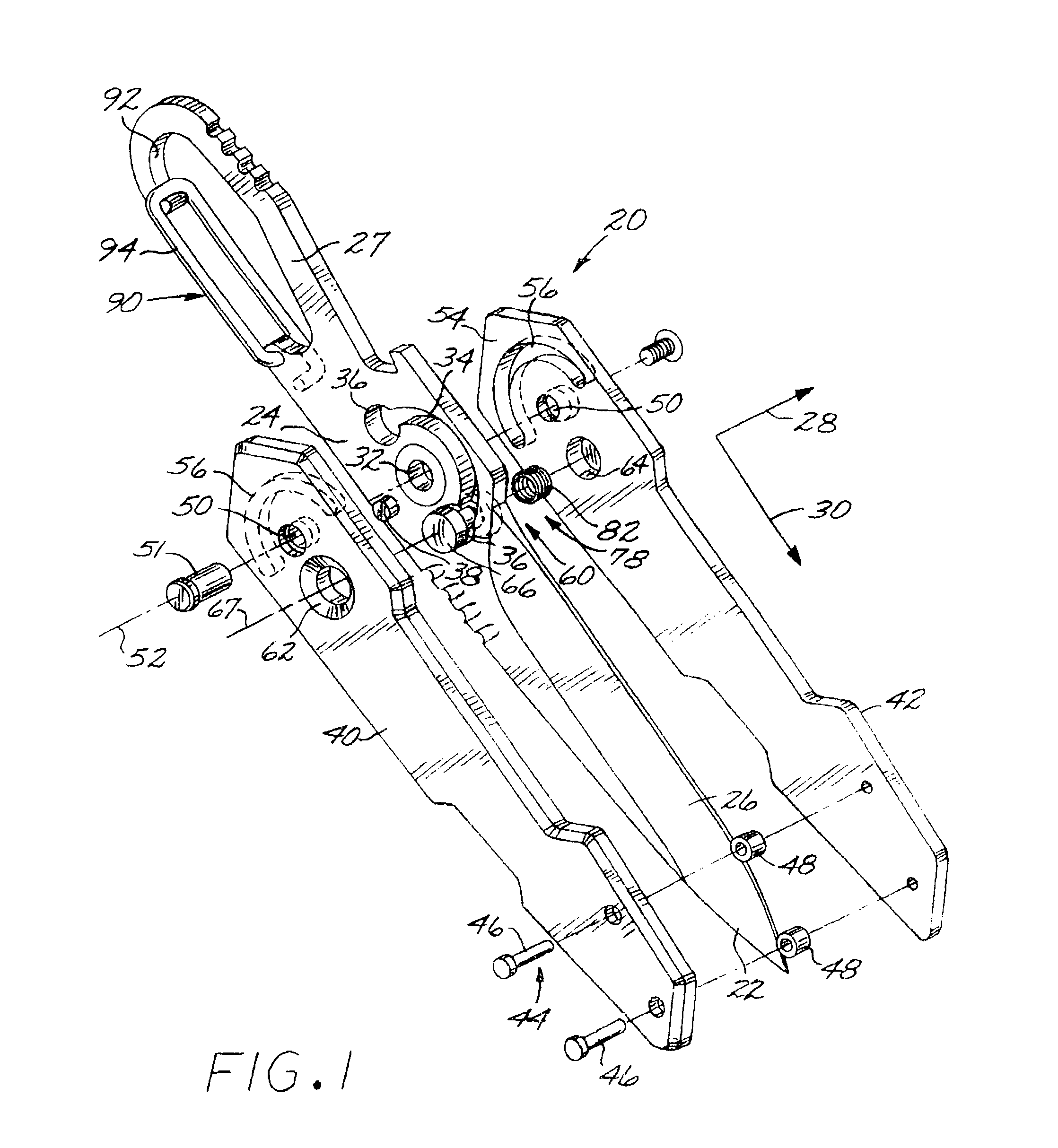

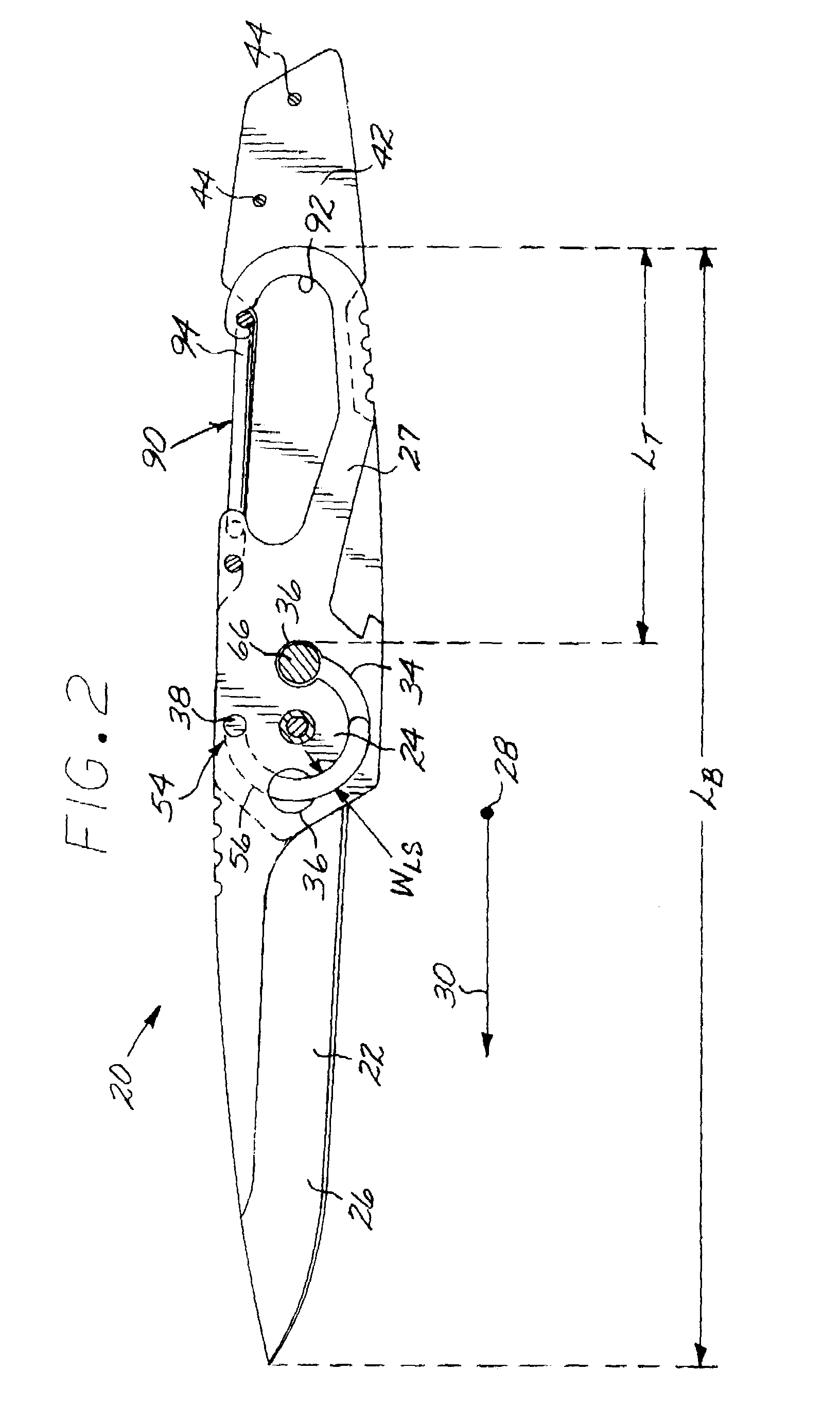

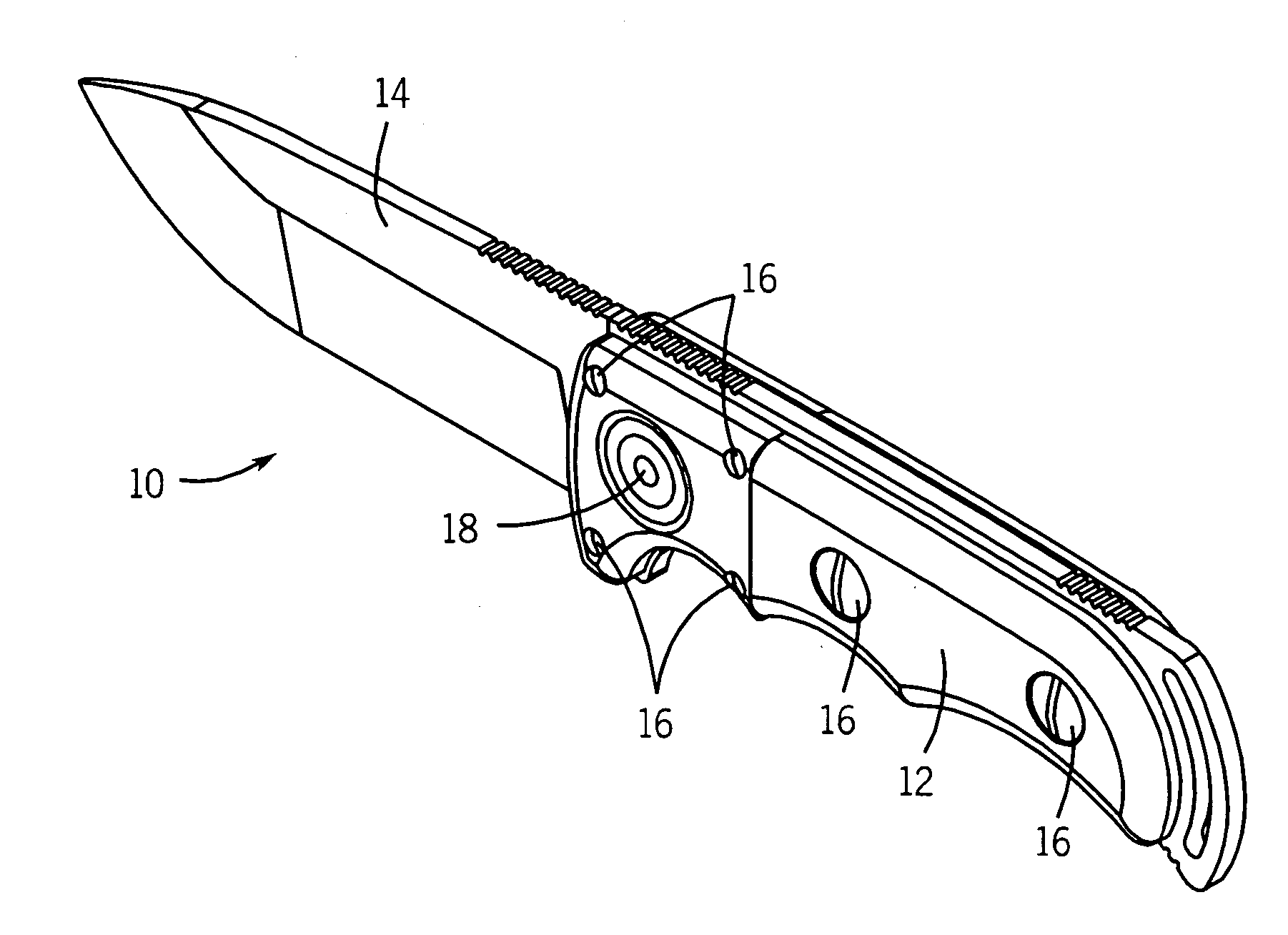

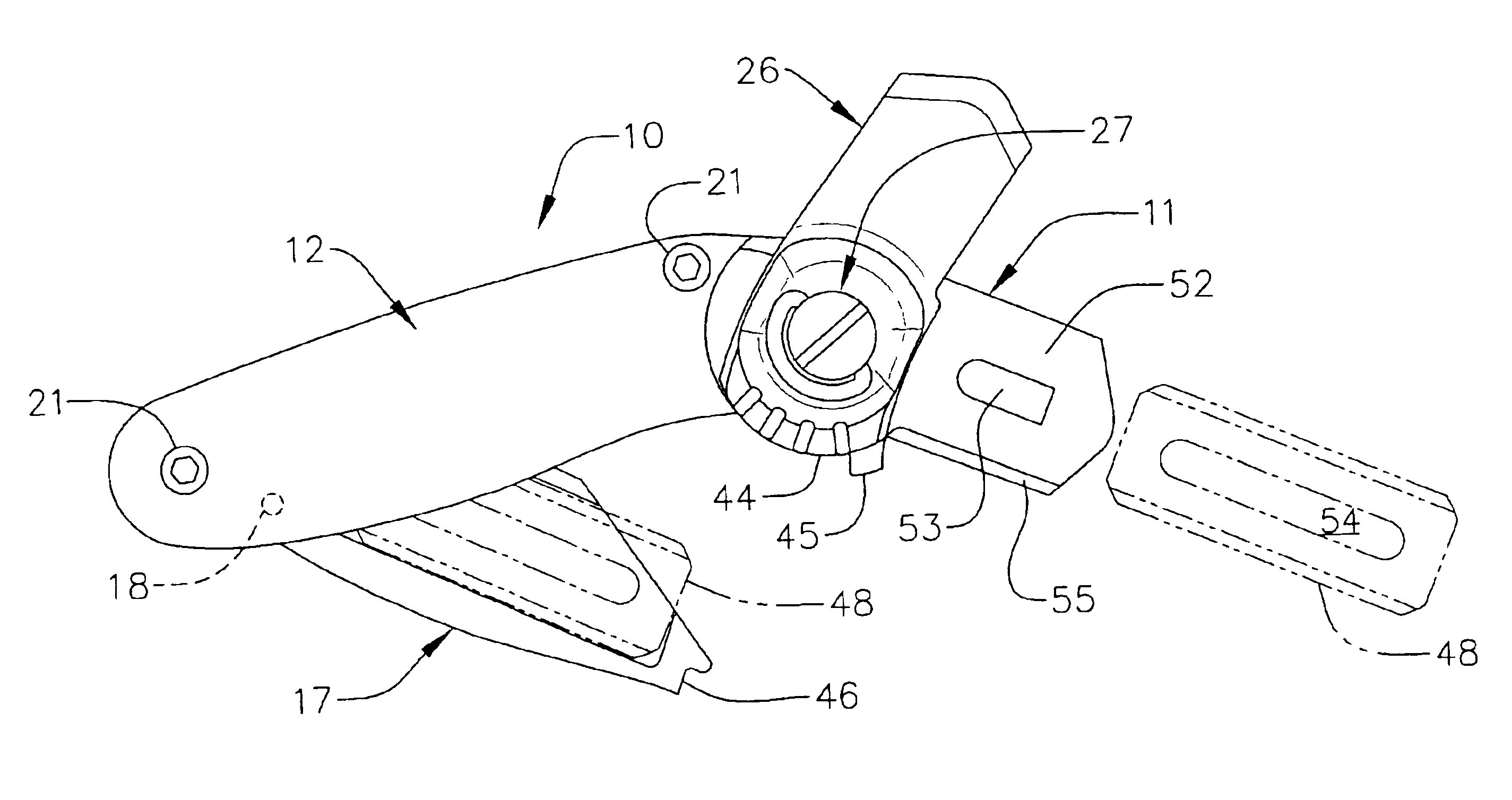

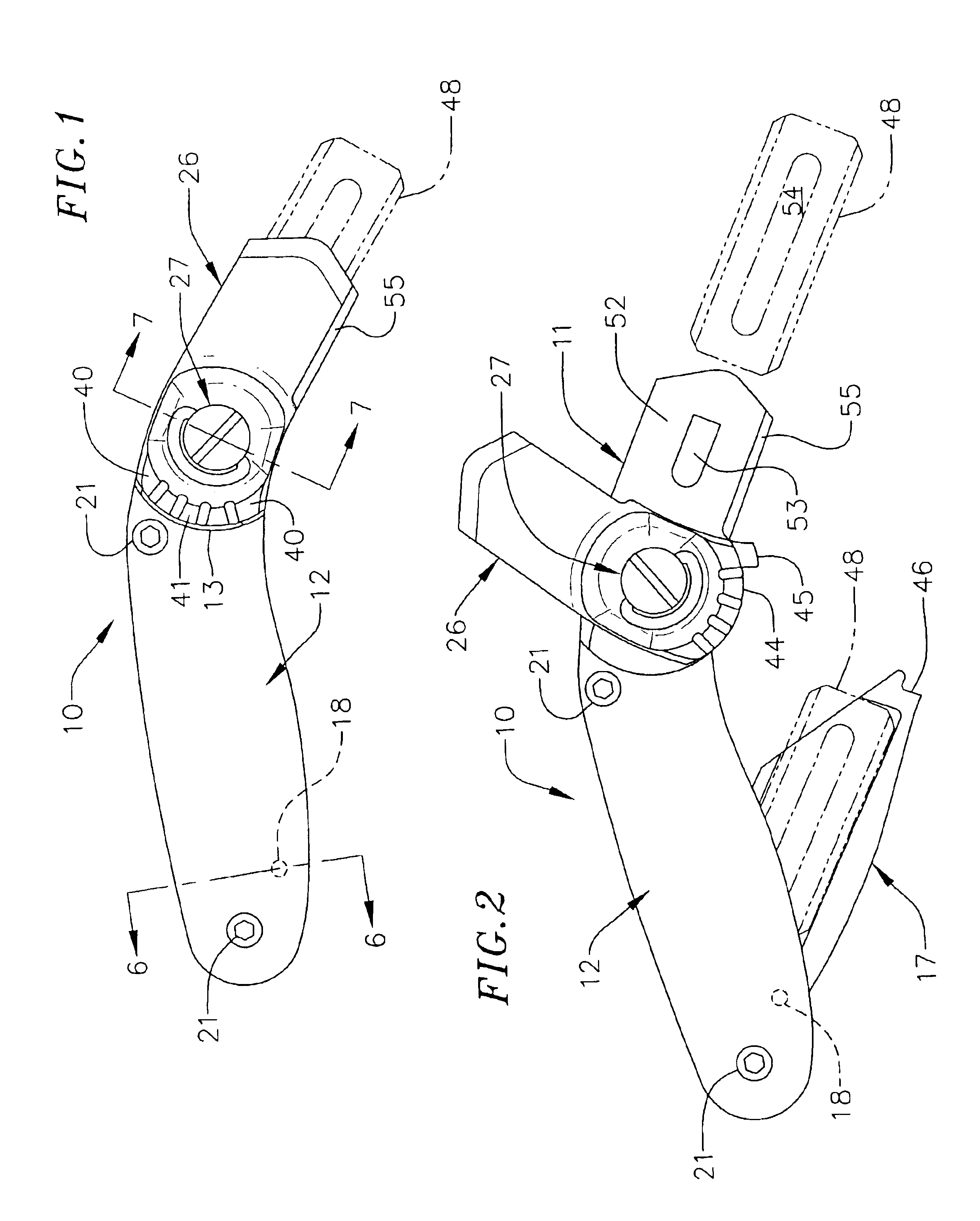

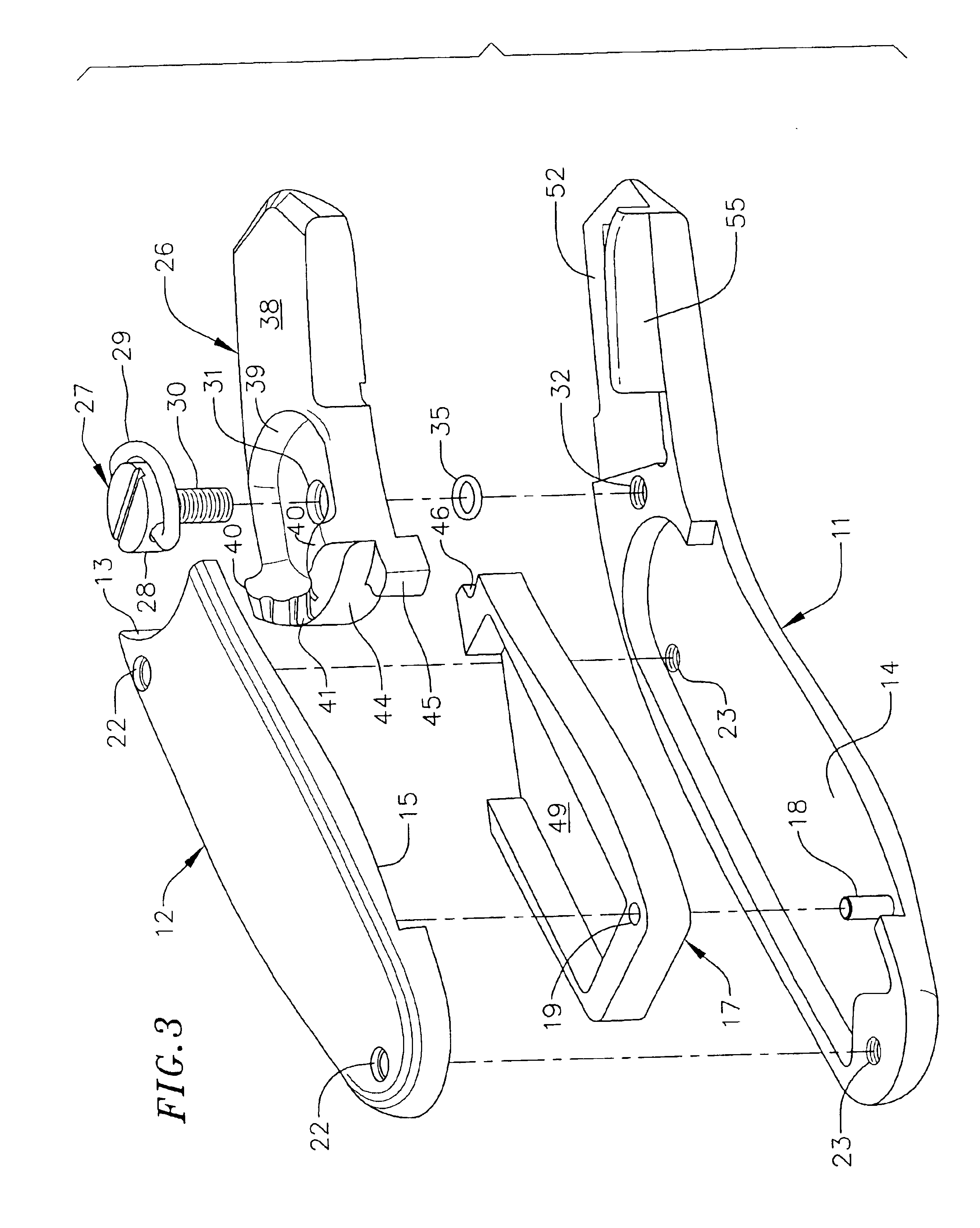

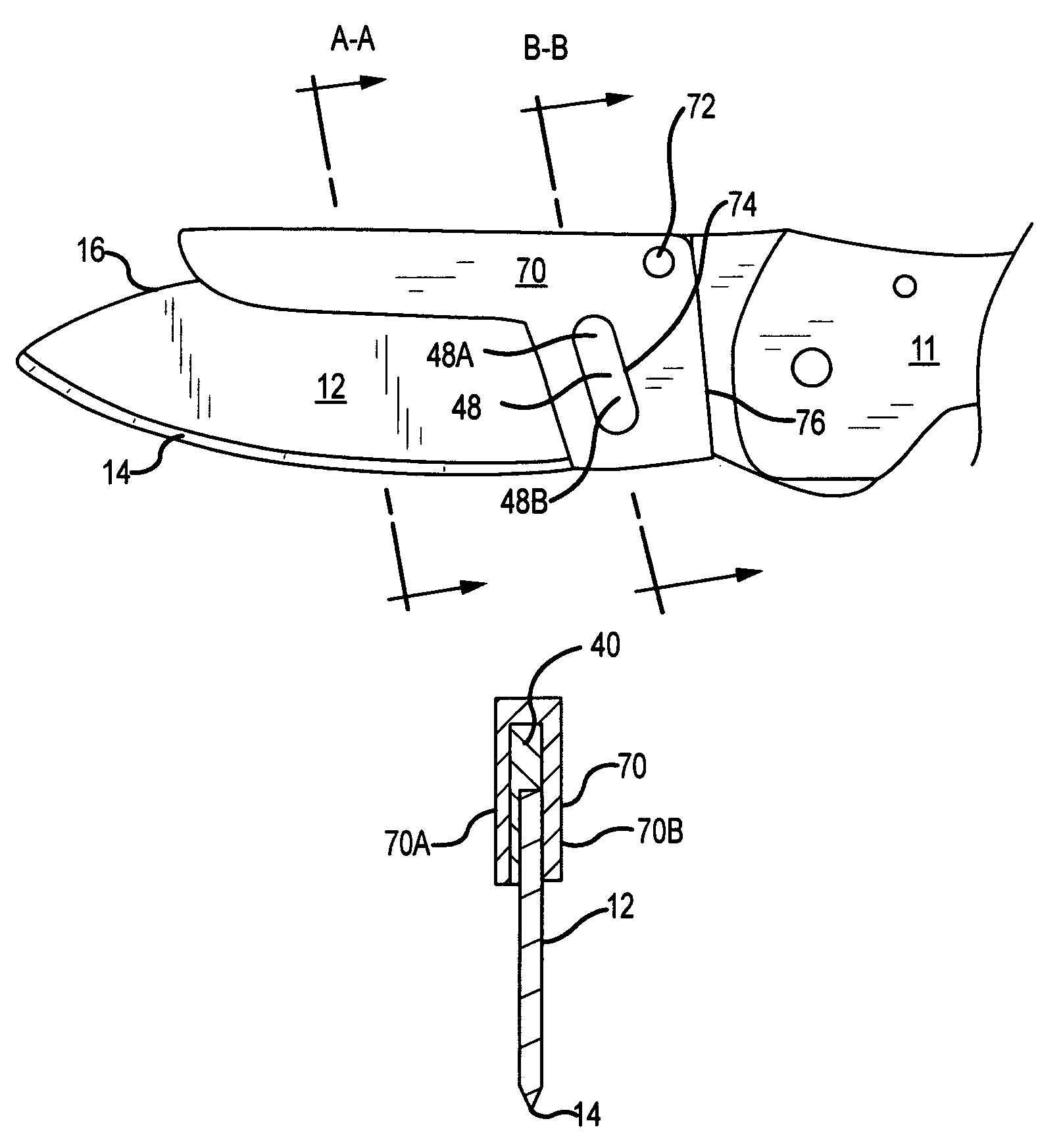

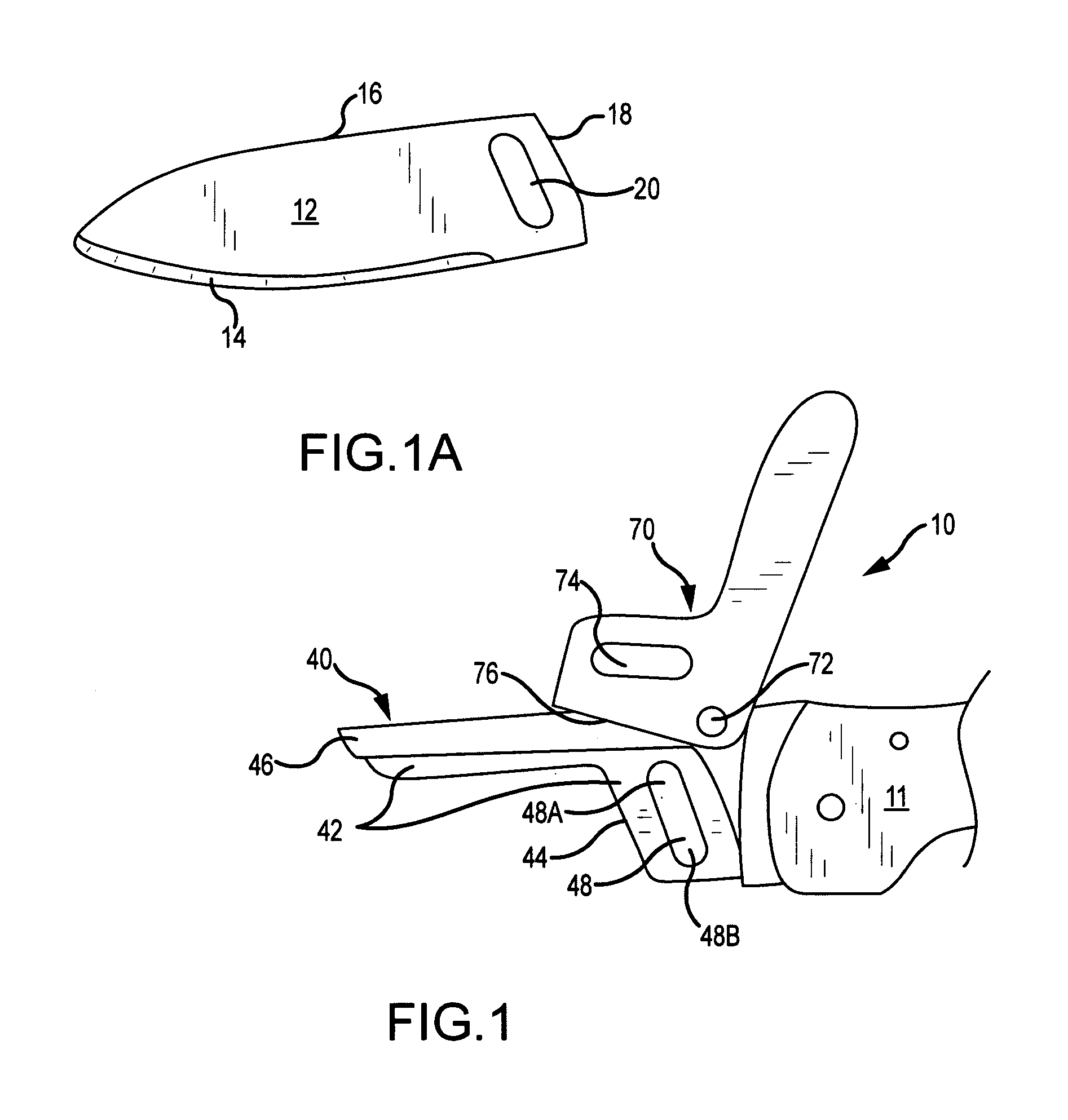

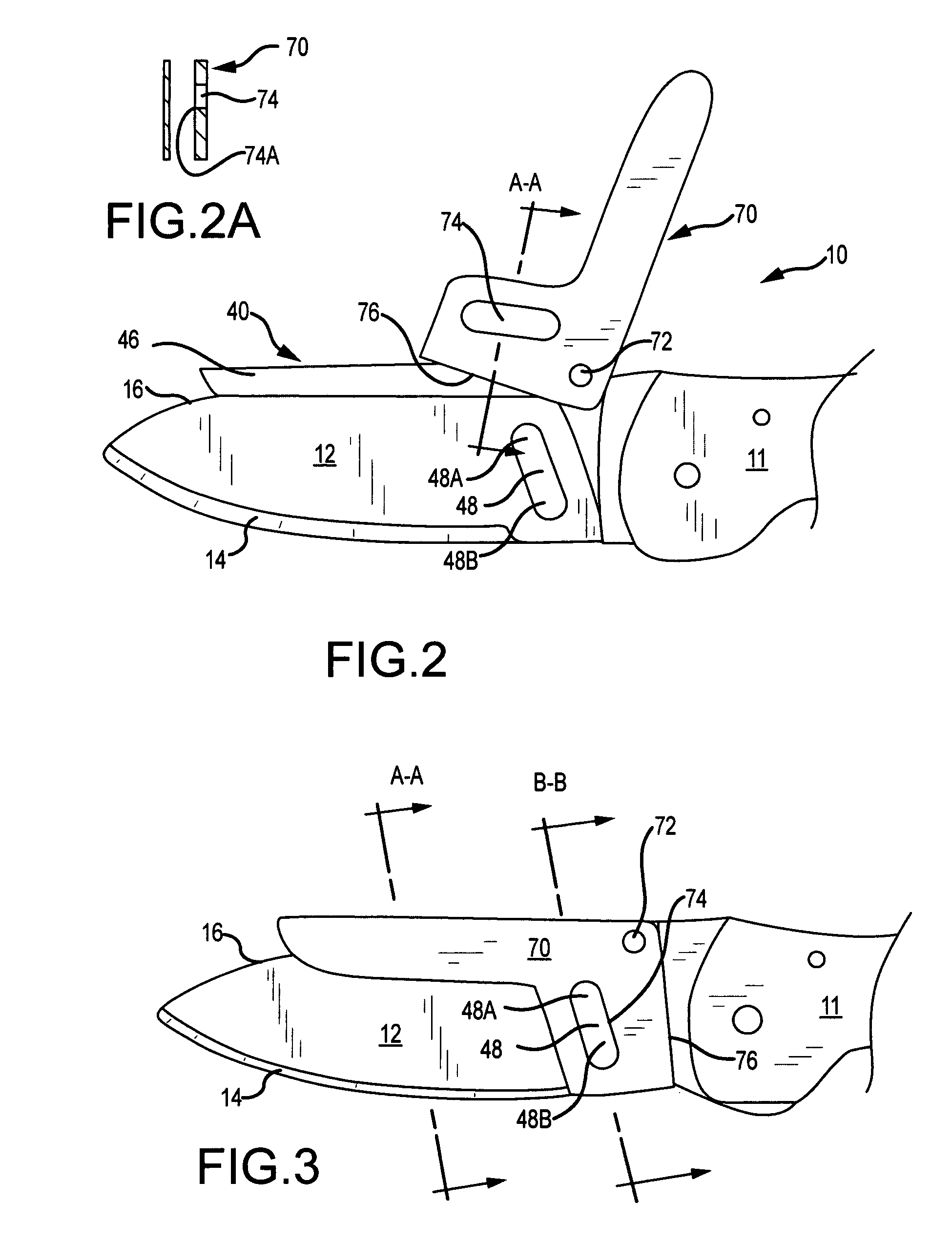

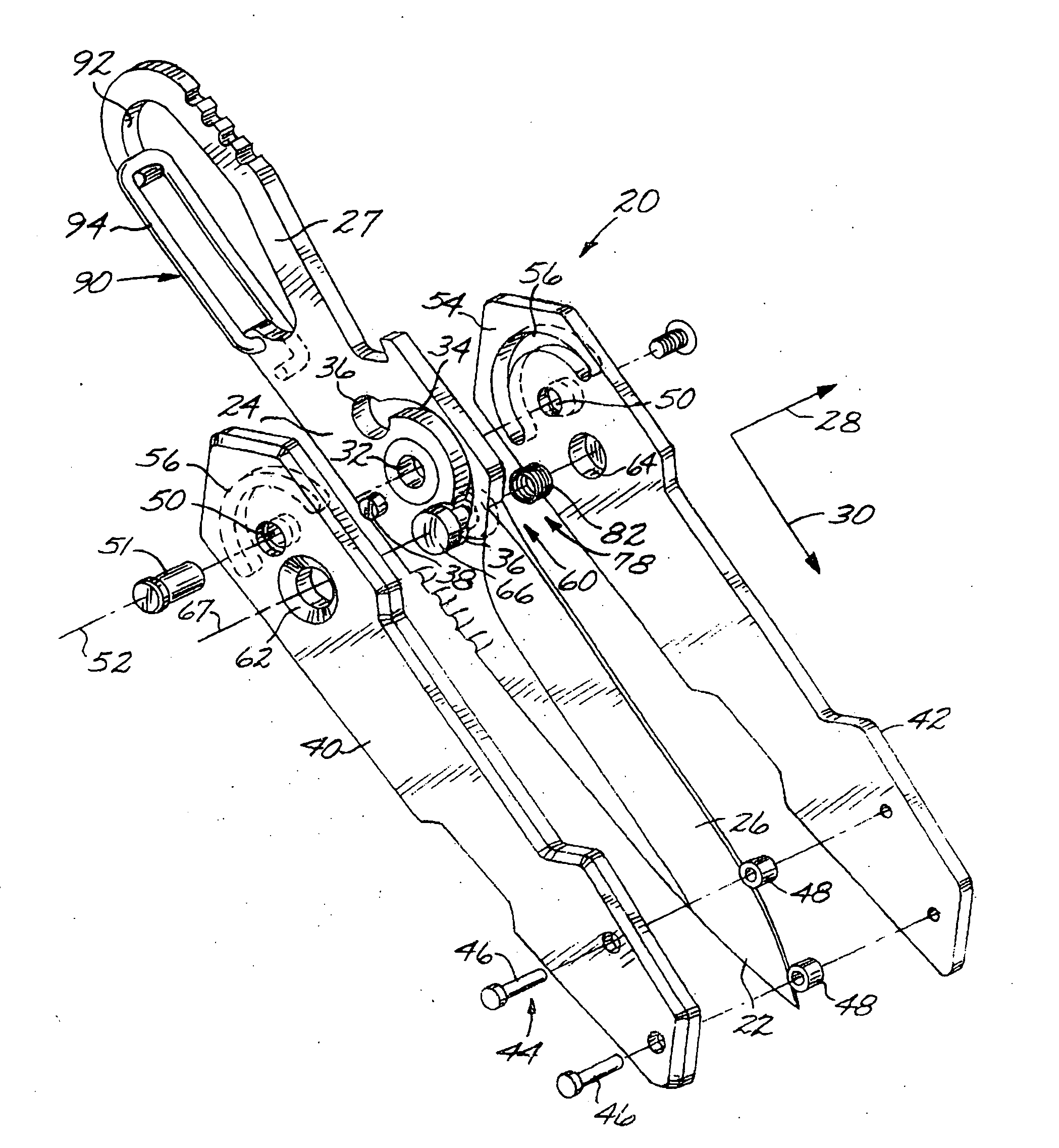

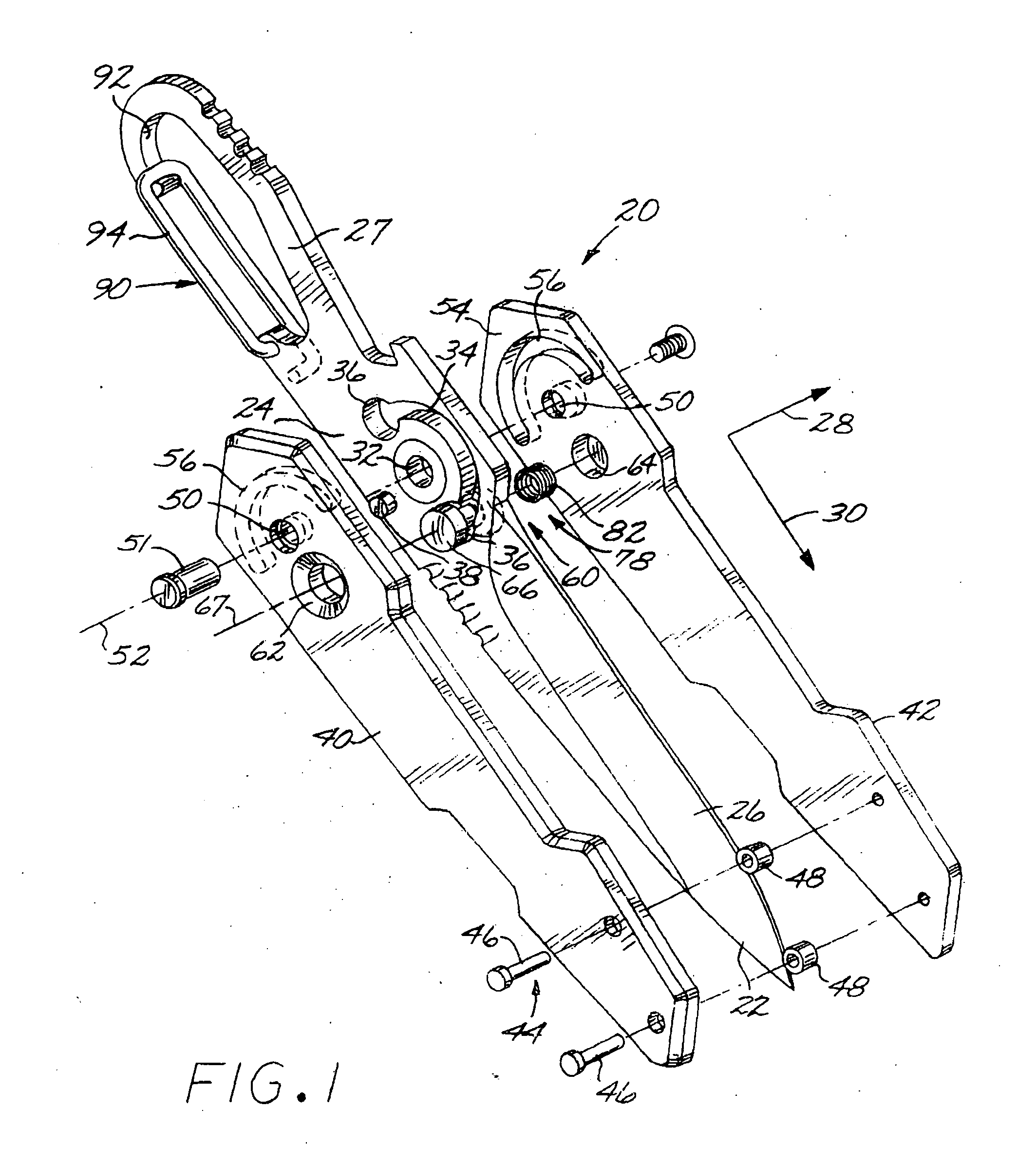

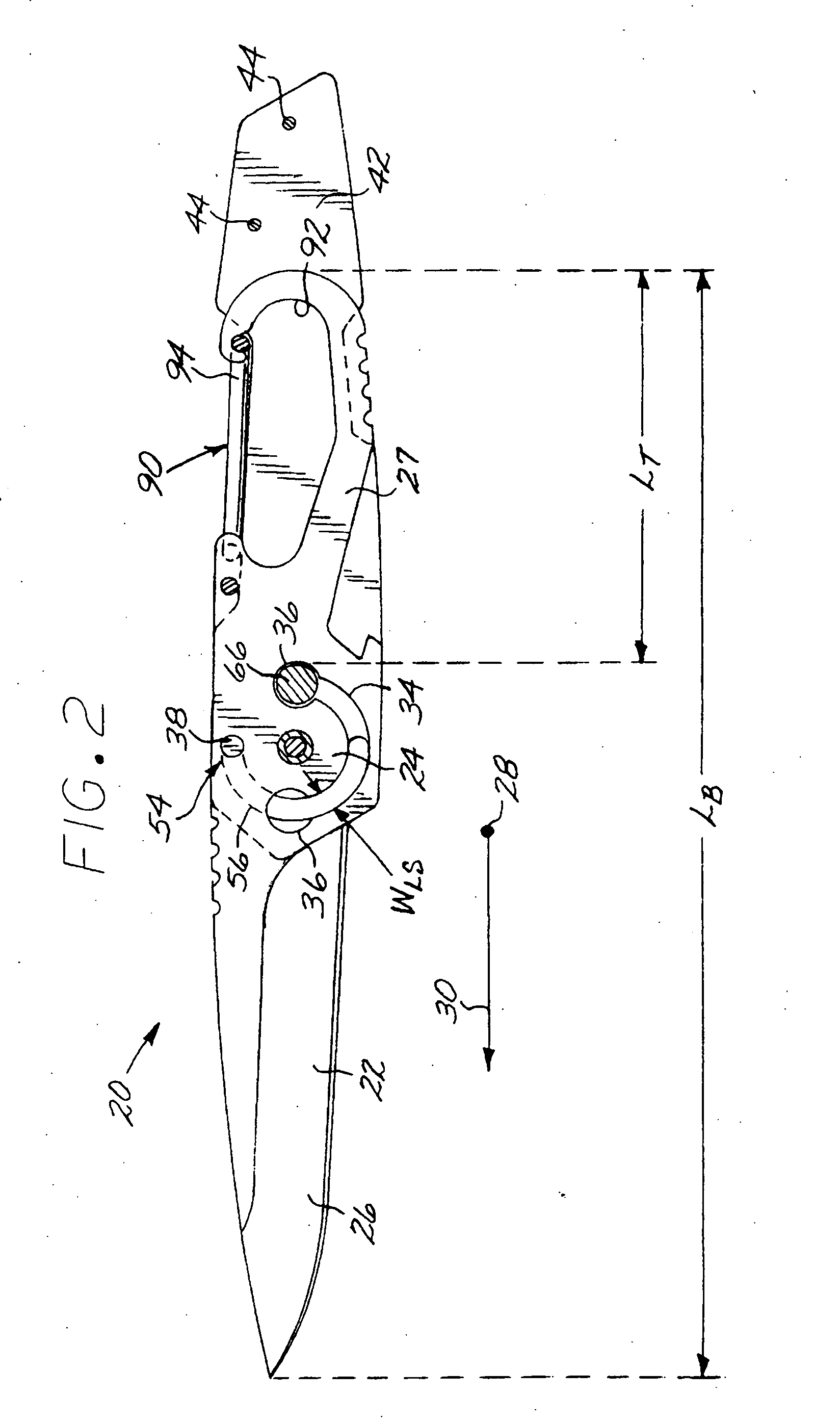

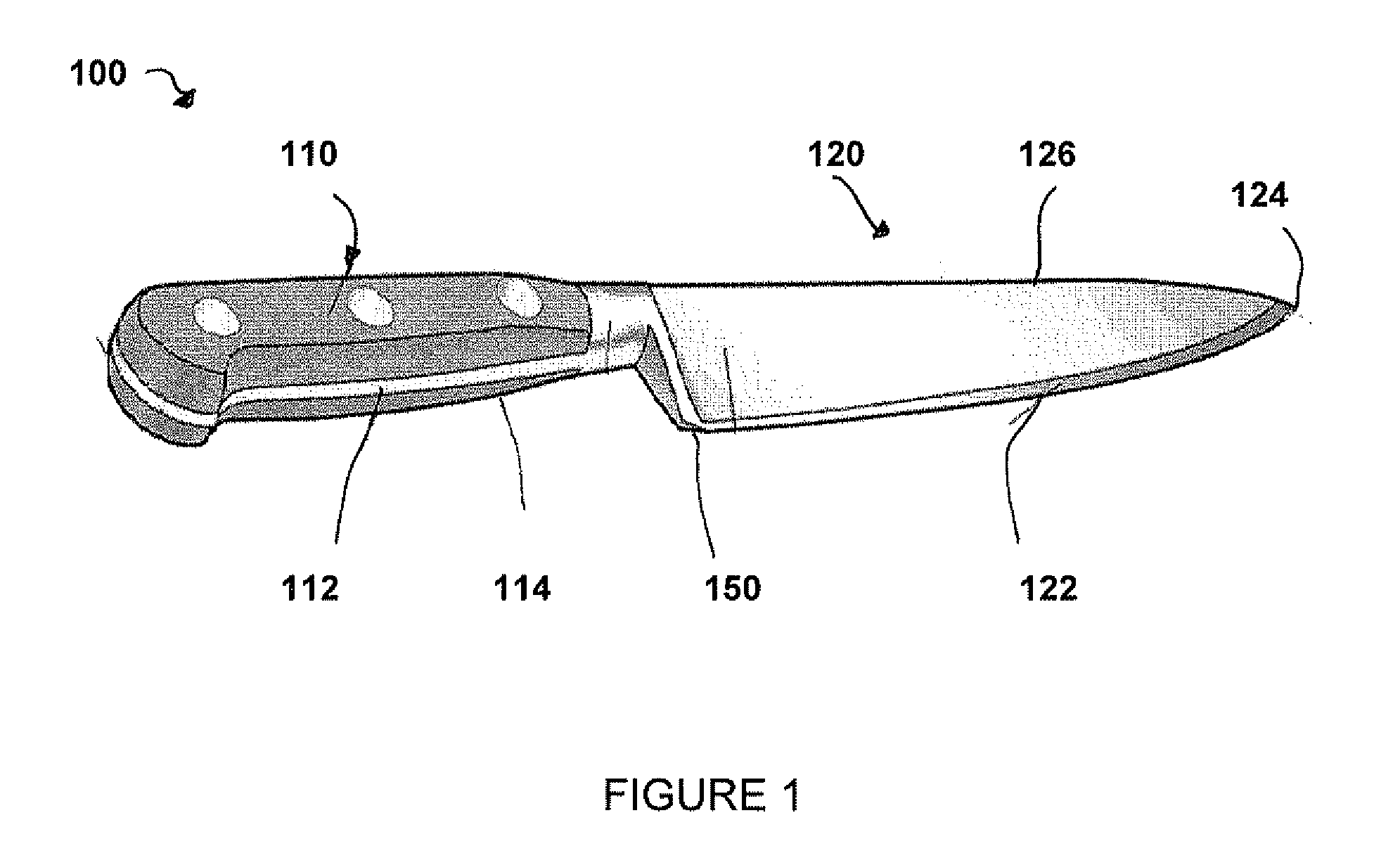

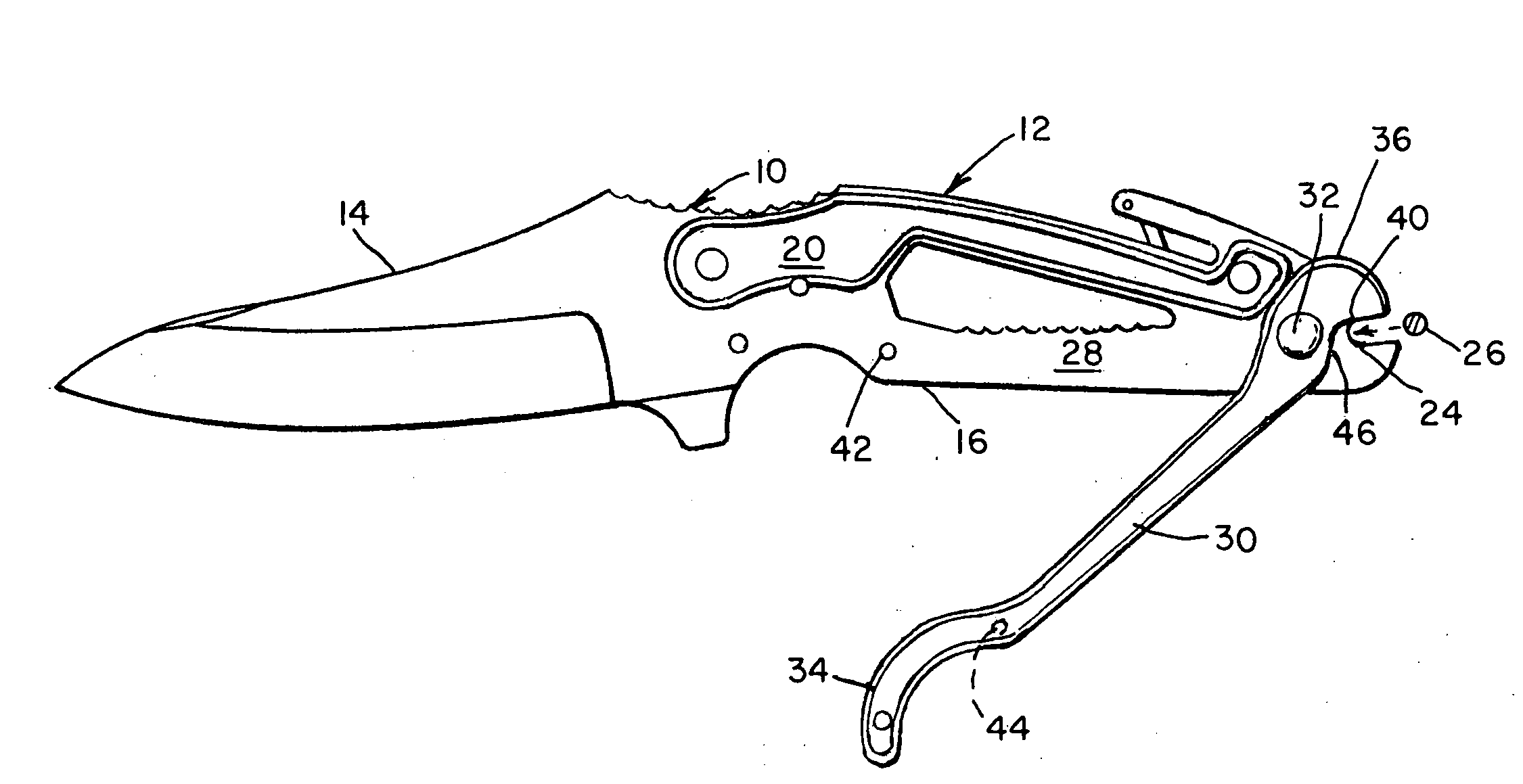

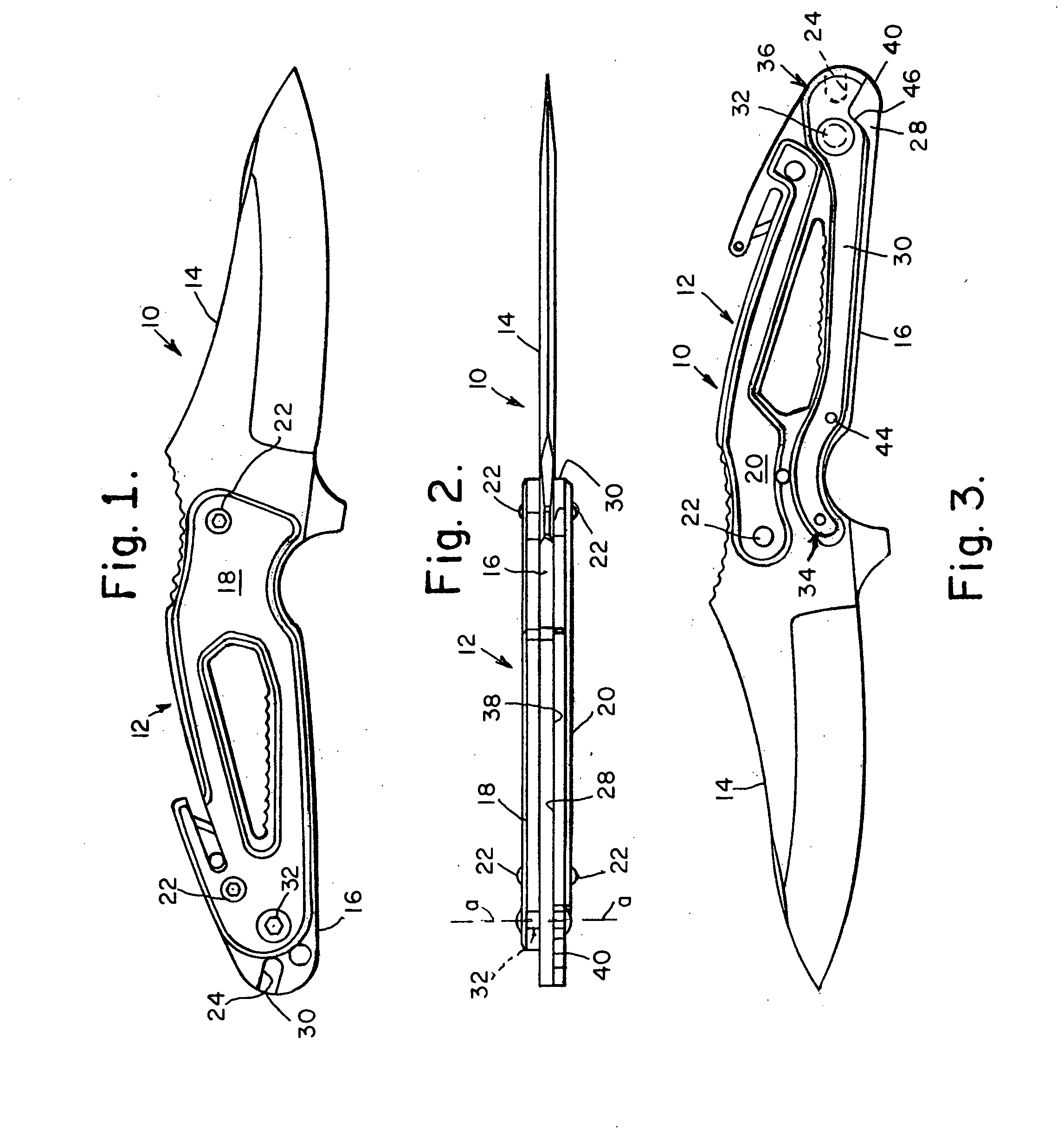

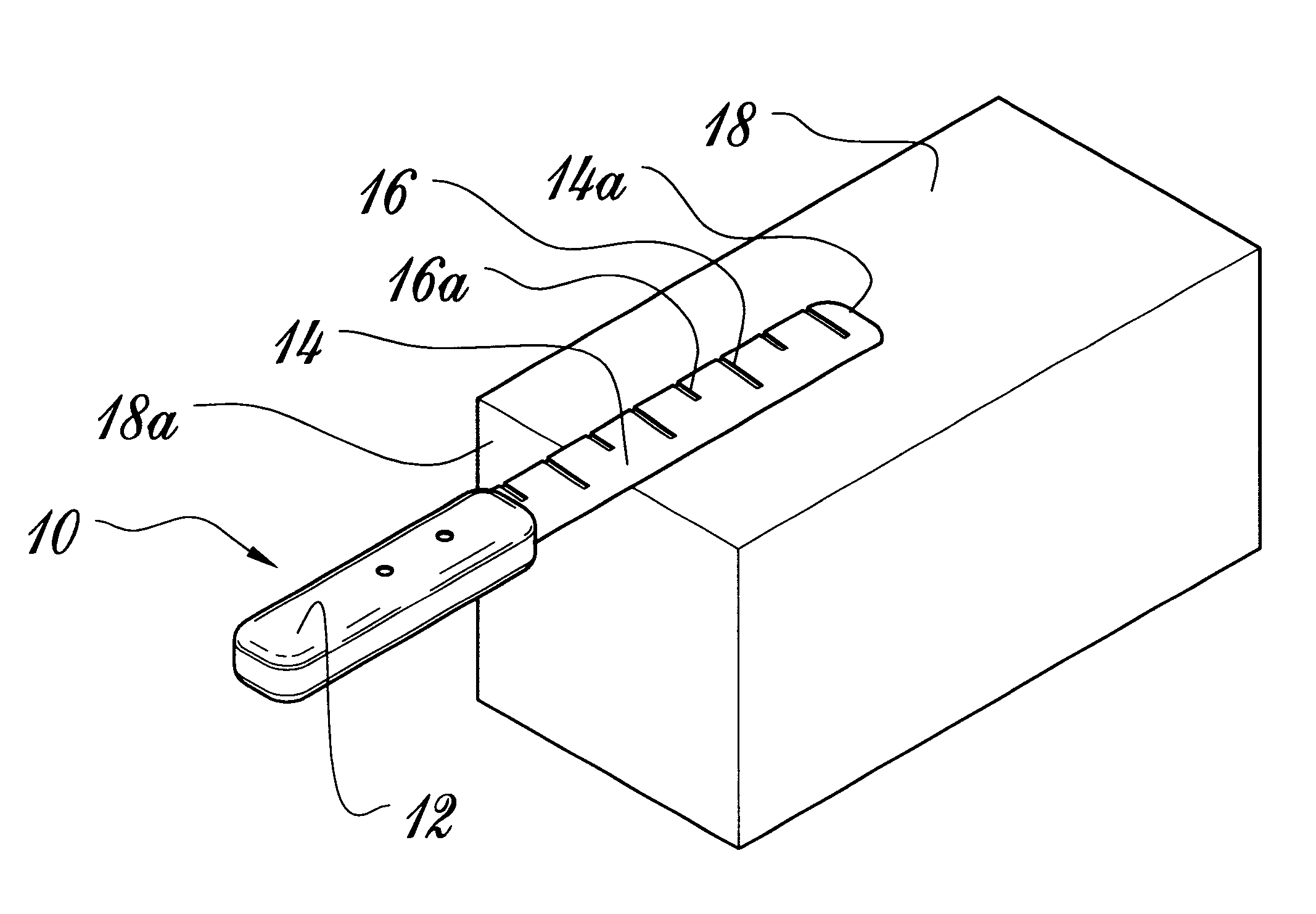

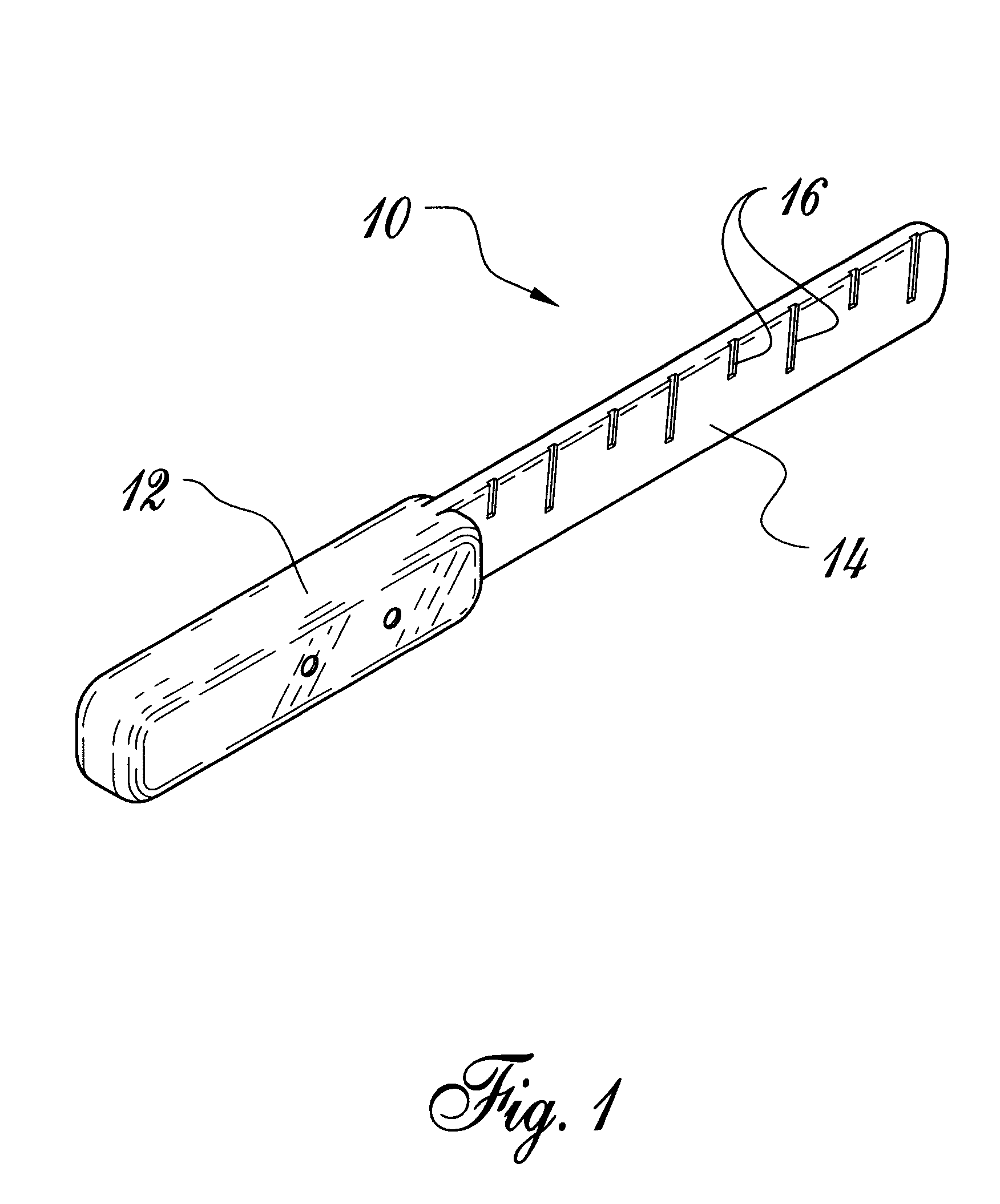

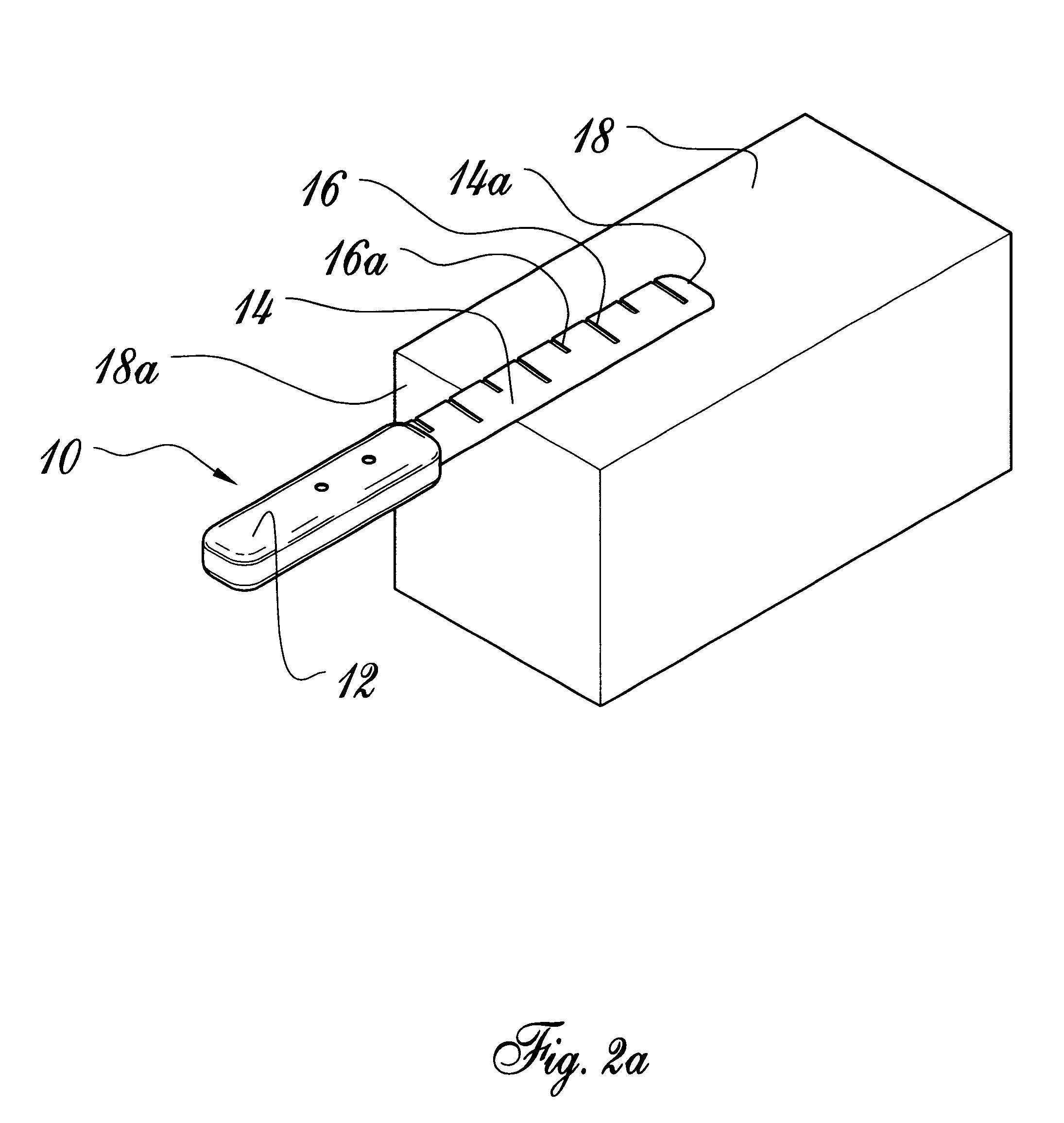

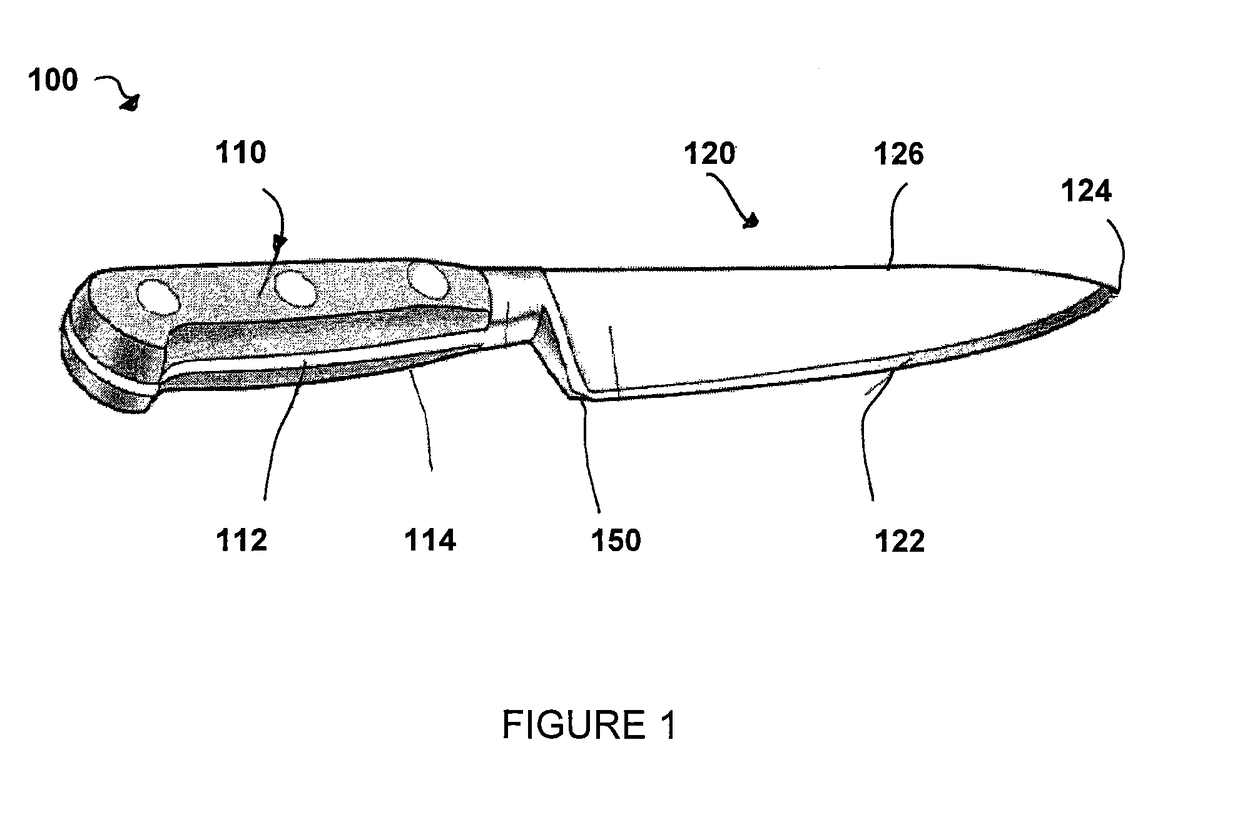

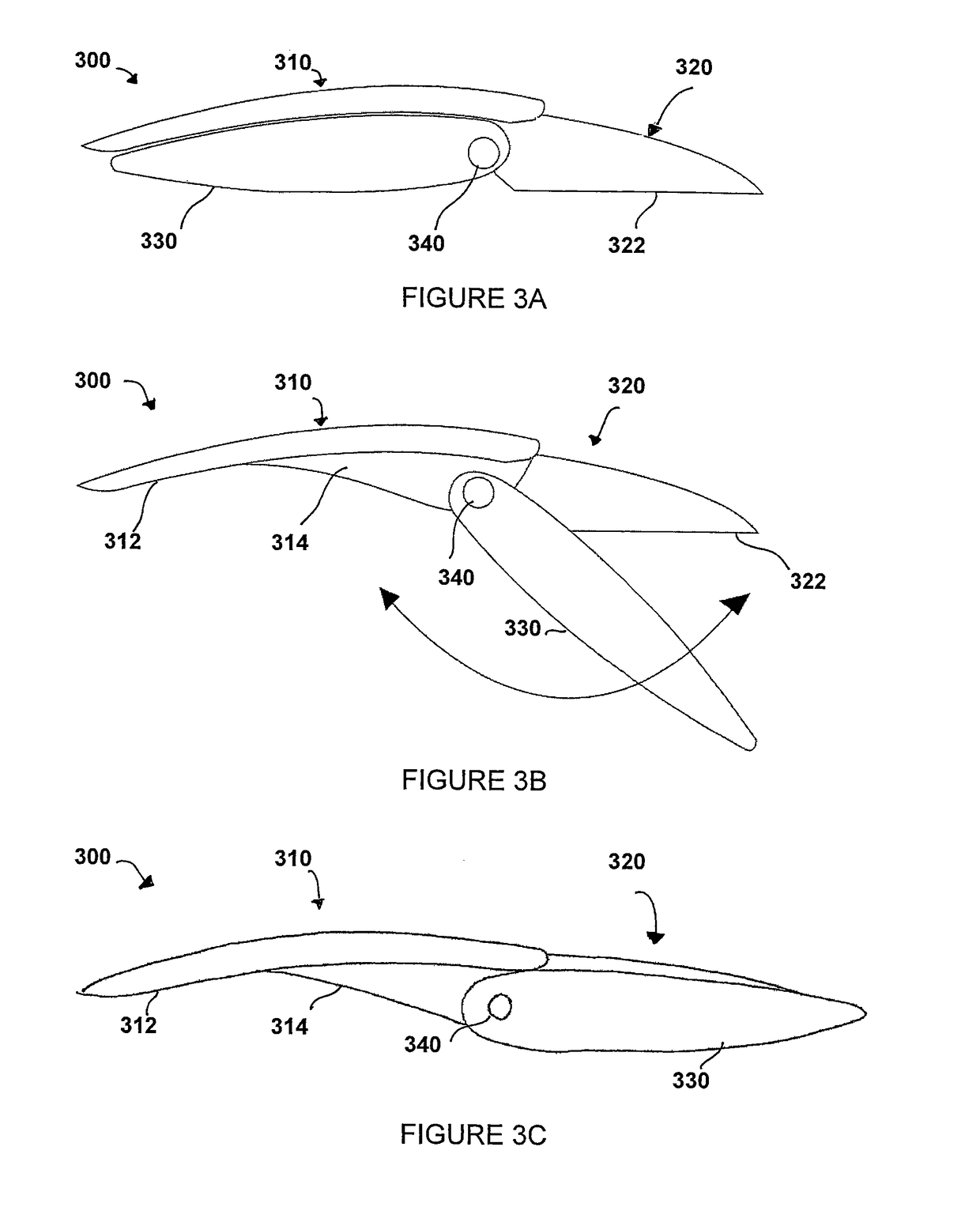

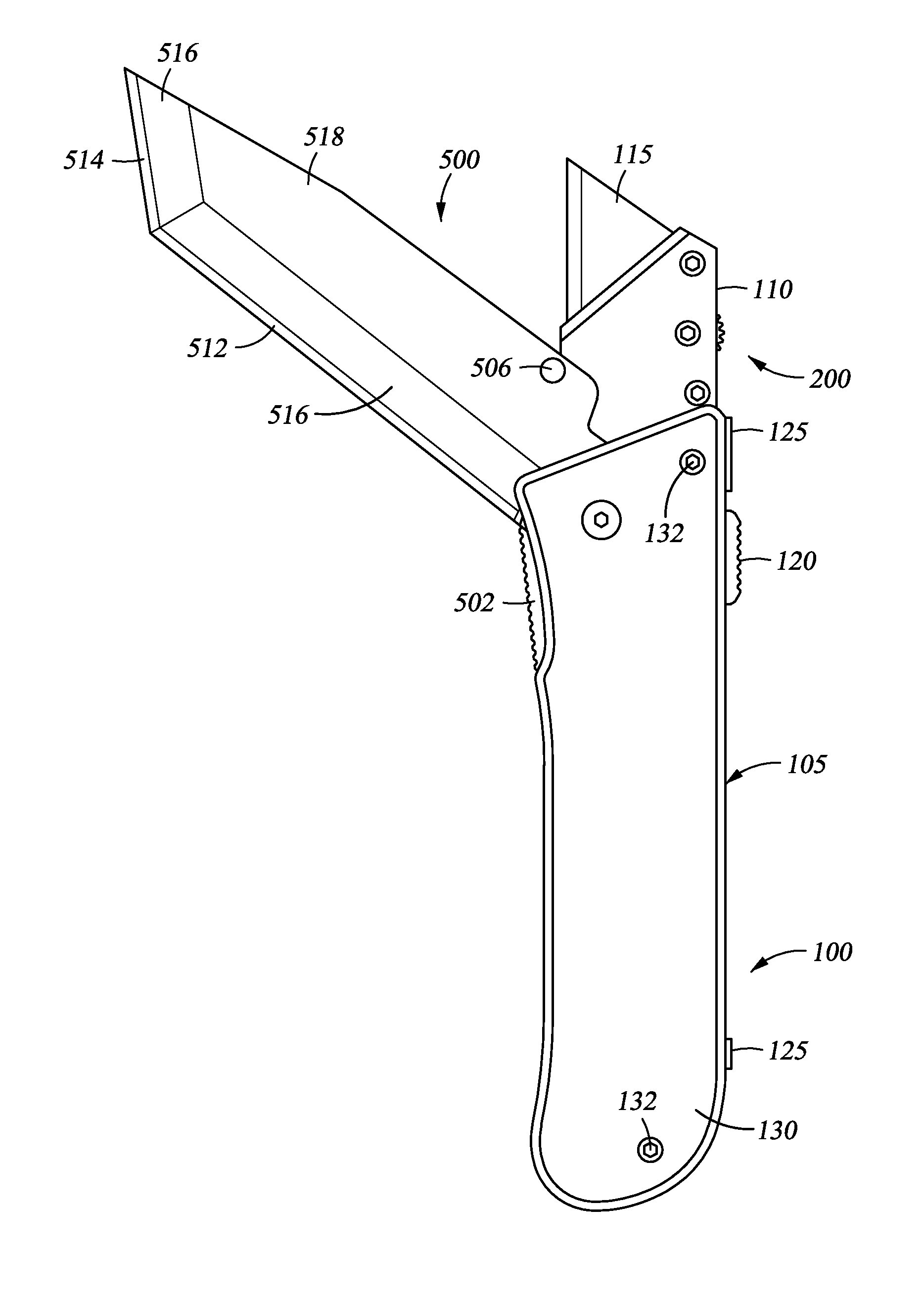

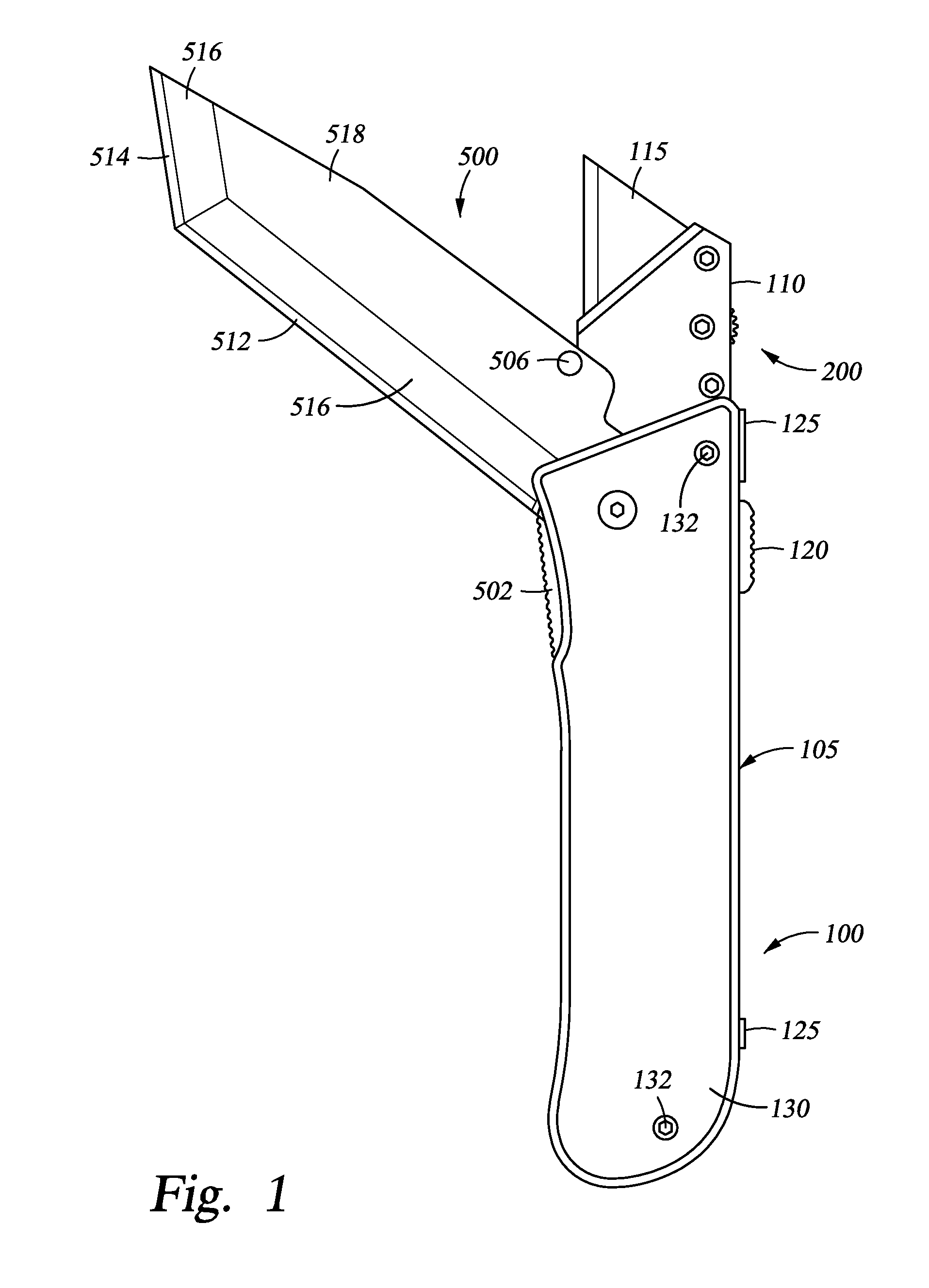

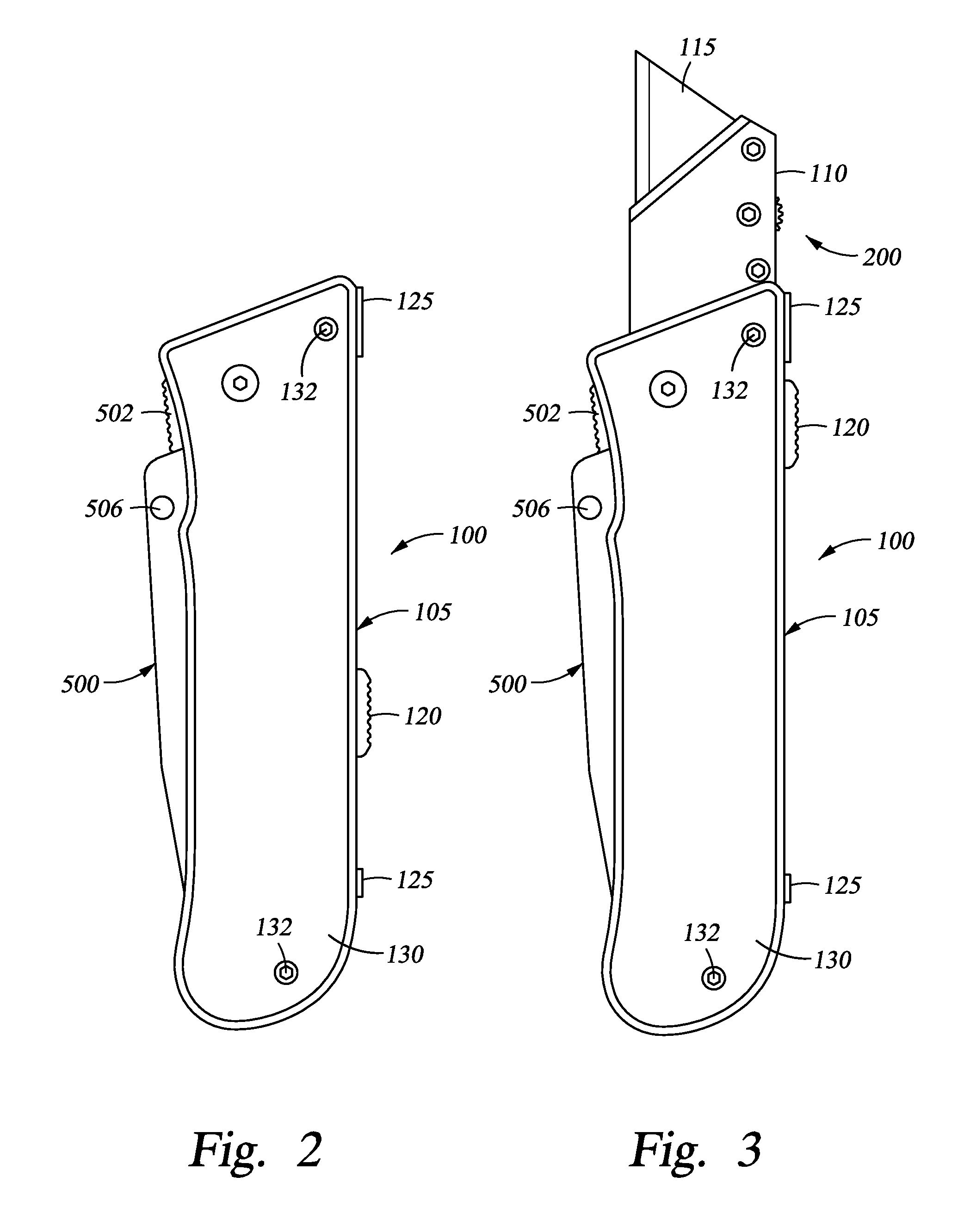

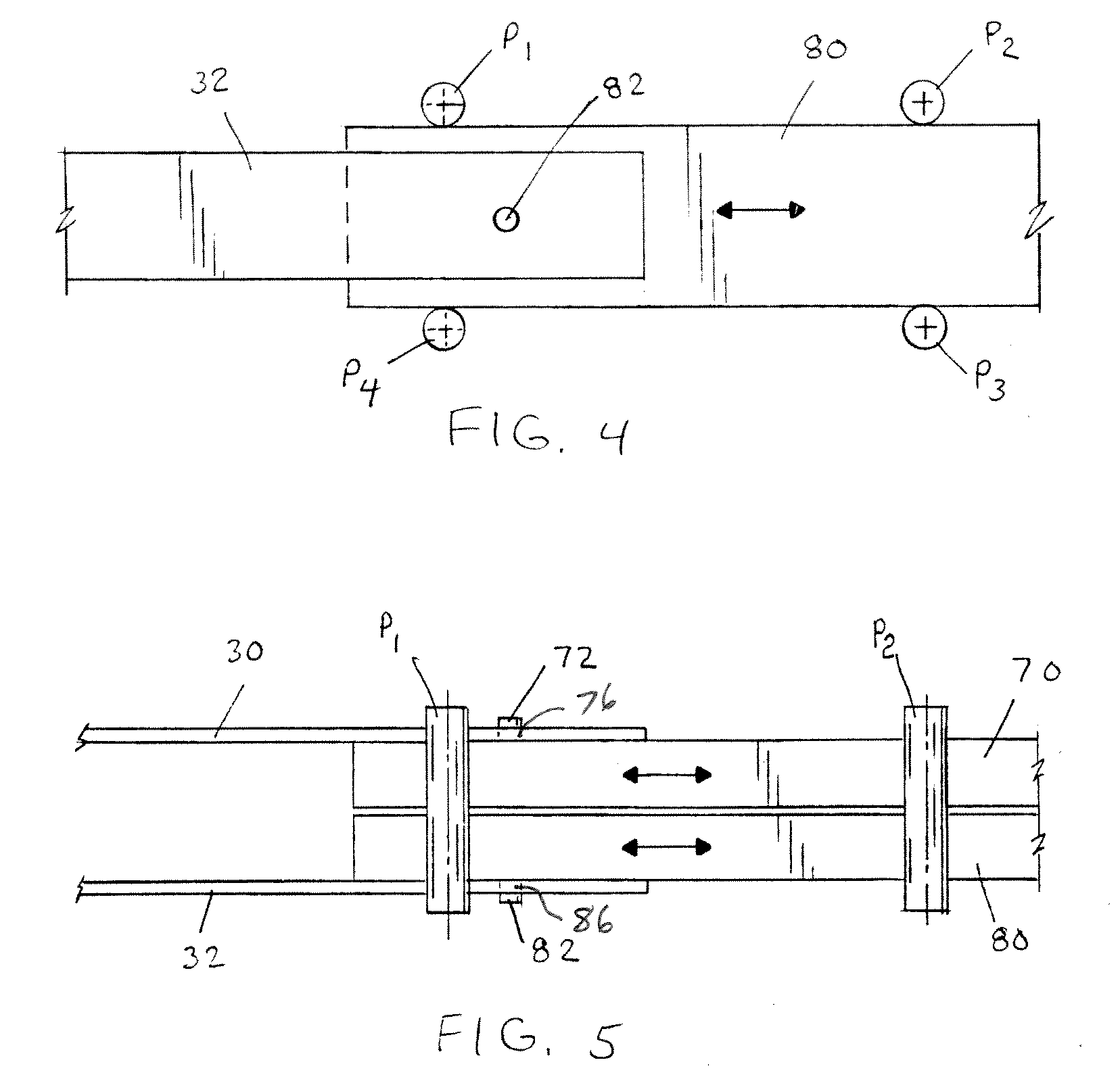

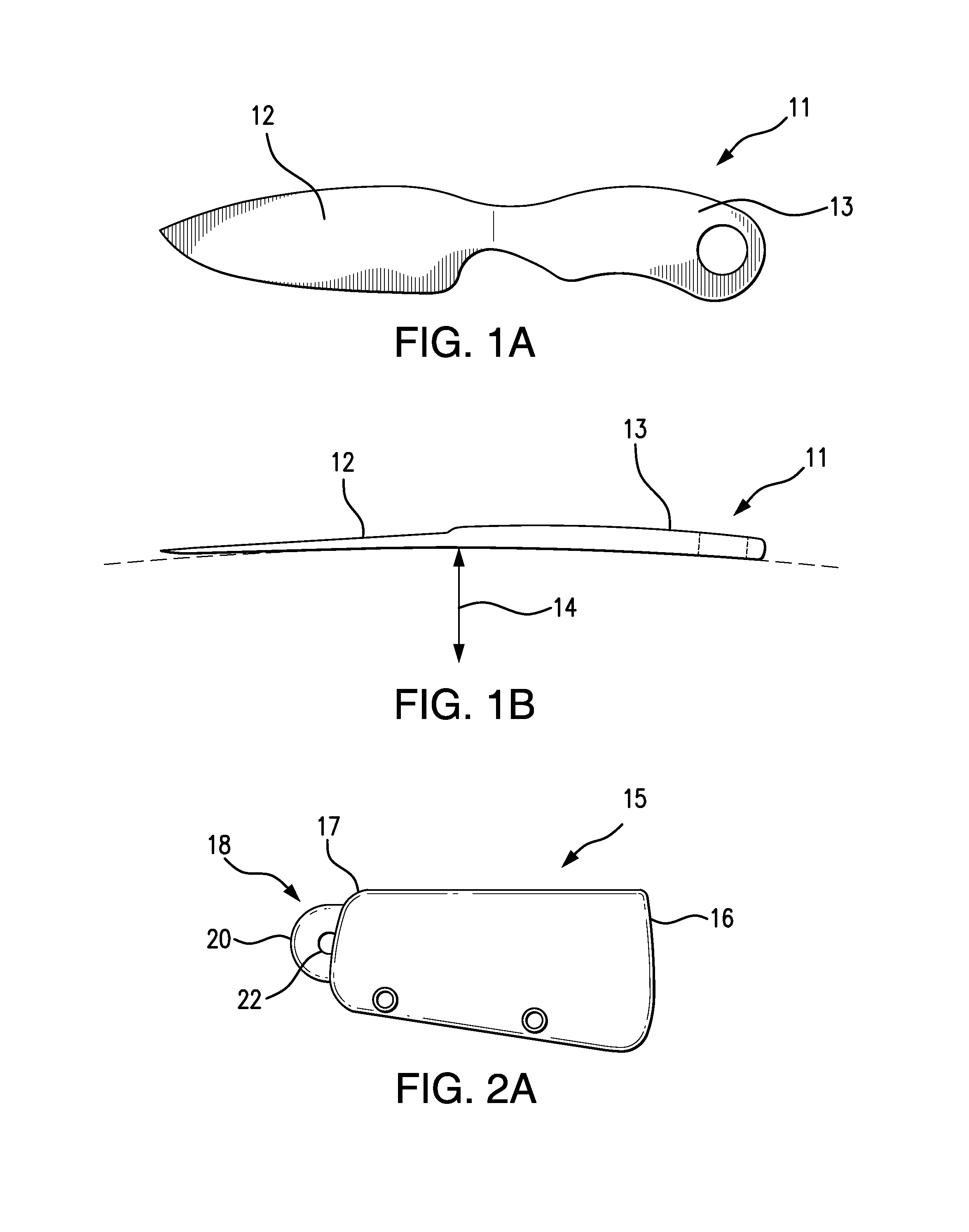

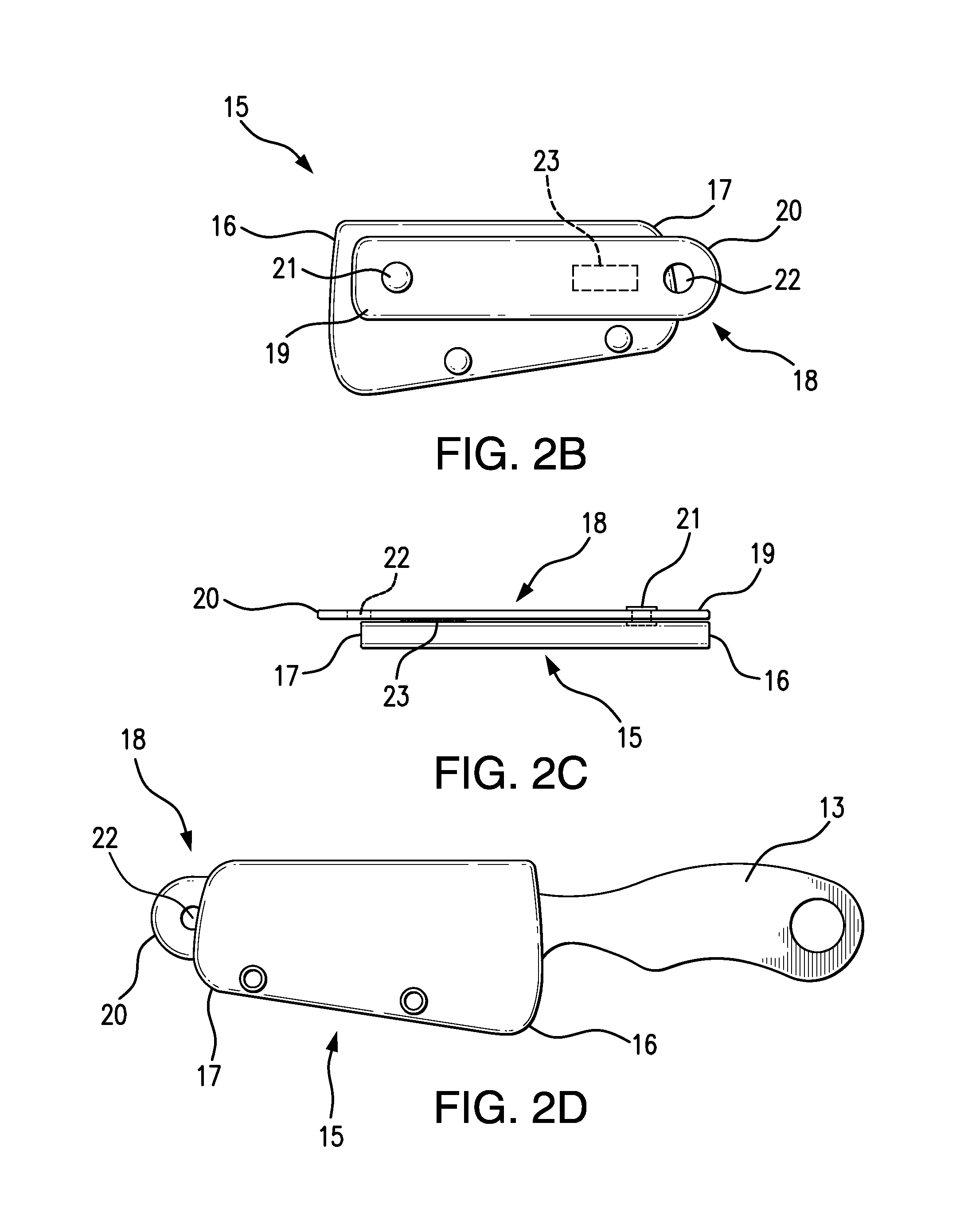

Fixed-blade knife with pivotable side pieces

InactiveUS7000323B1Precise positioningSmall sizeThrusting weaponsWeapon componentsEngineeringKnife blades

A fixed-blade knife includes a unitary blade having an implement, a tang, and a pivot region between the implement and the tang. The unitary blade is disposed between a pair of parallel and spaced-apart side pieces that pivot to cover or expose the implement. In the pivoted position wherein the implement is exposed, the side pieces form part of the handle that is used to grasp the knife. A locking structure locks the side pieces in a selectable position, and a limit structure prevents overrotation of the side pieces.

Owner:BUCK KNIVES

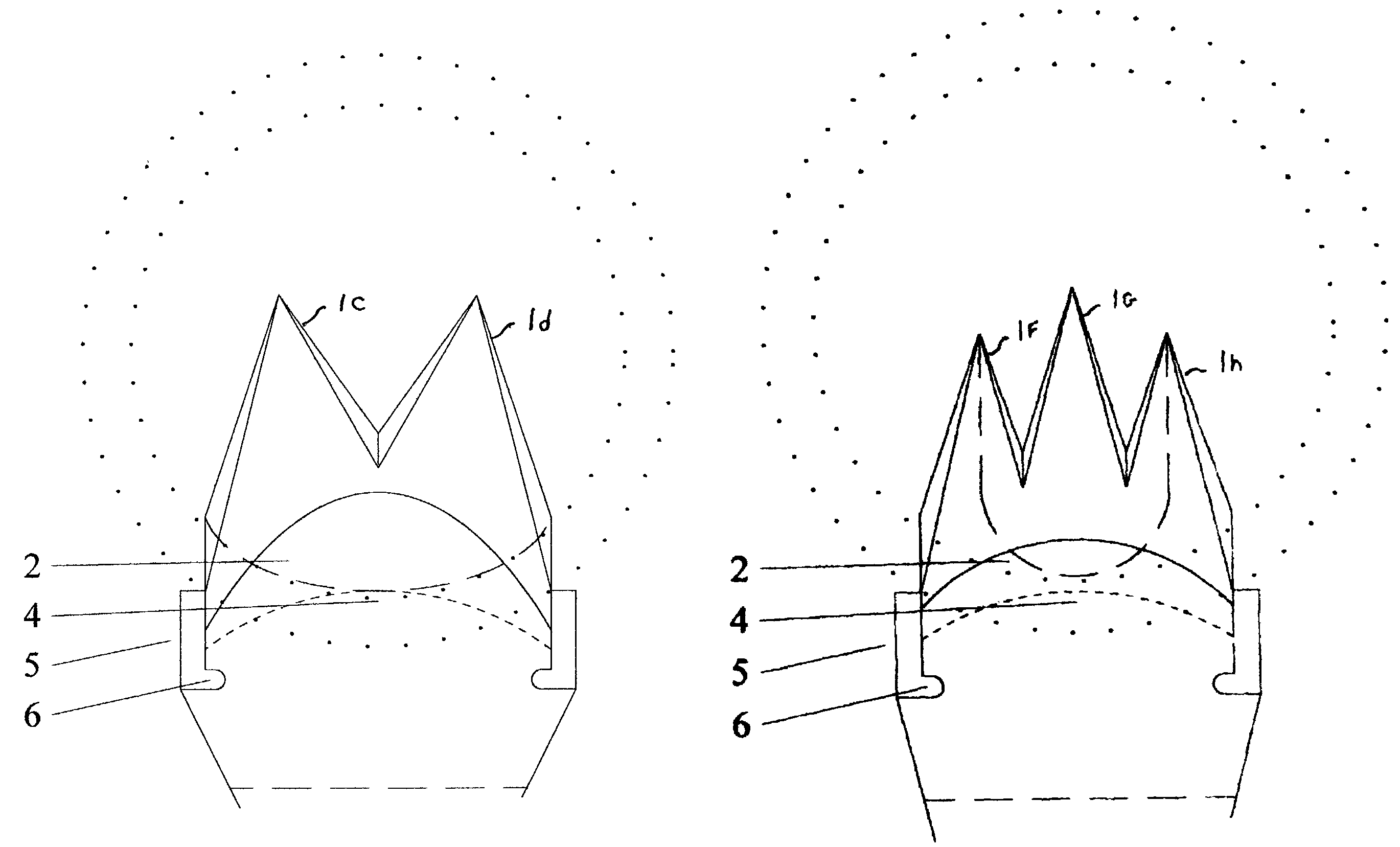

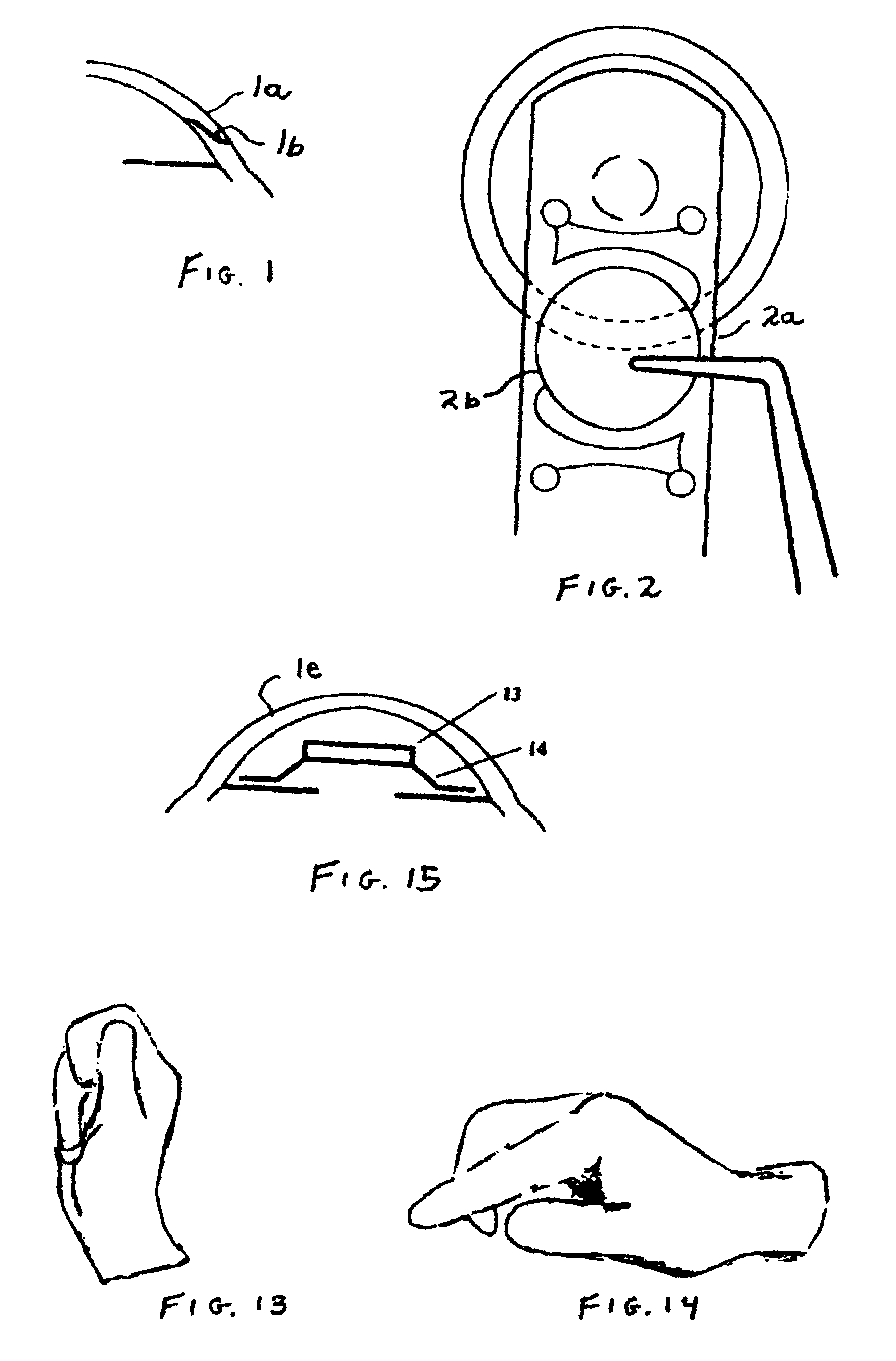

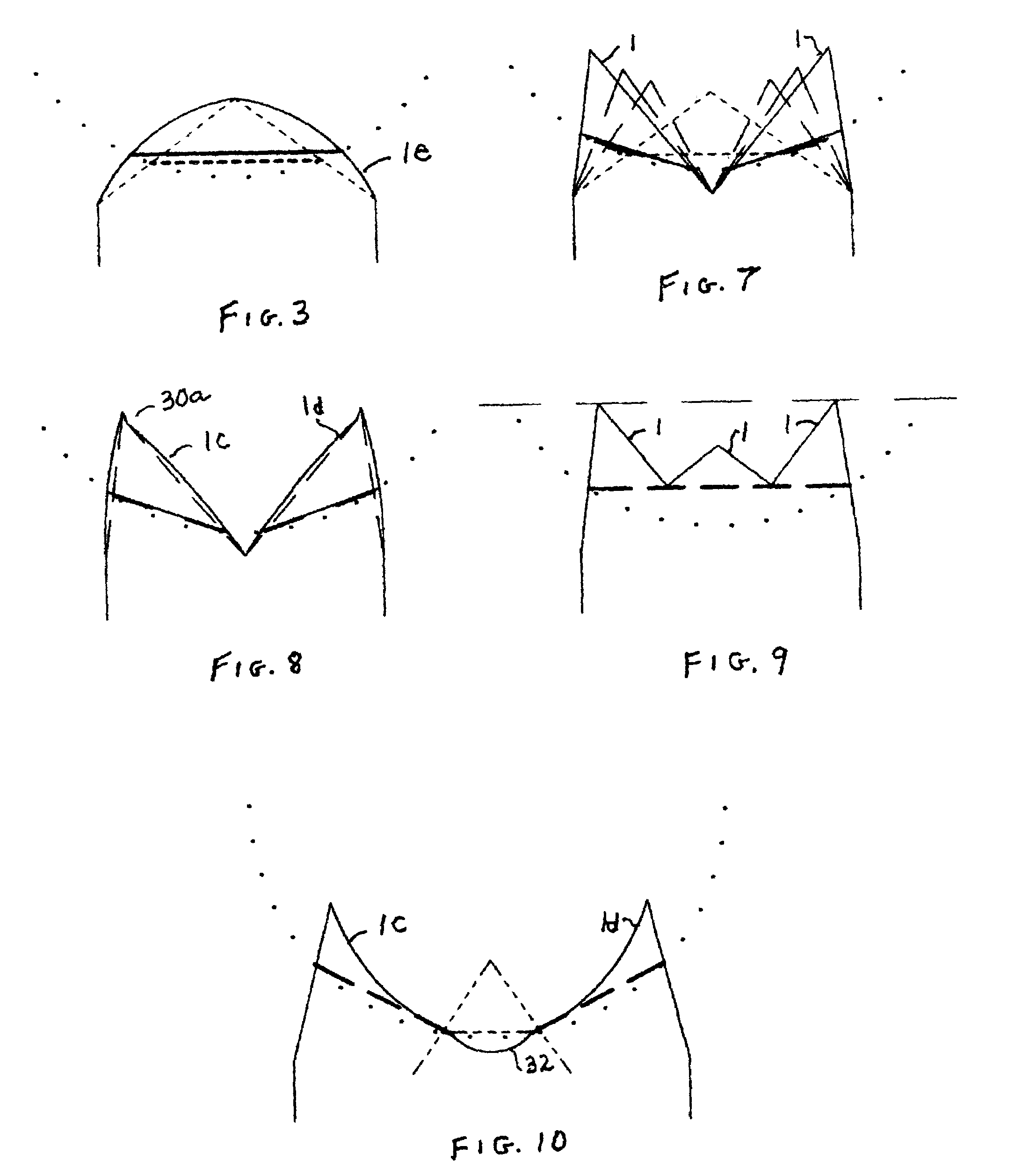

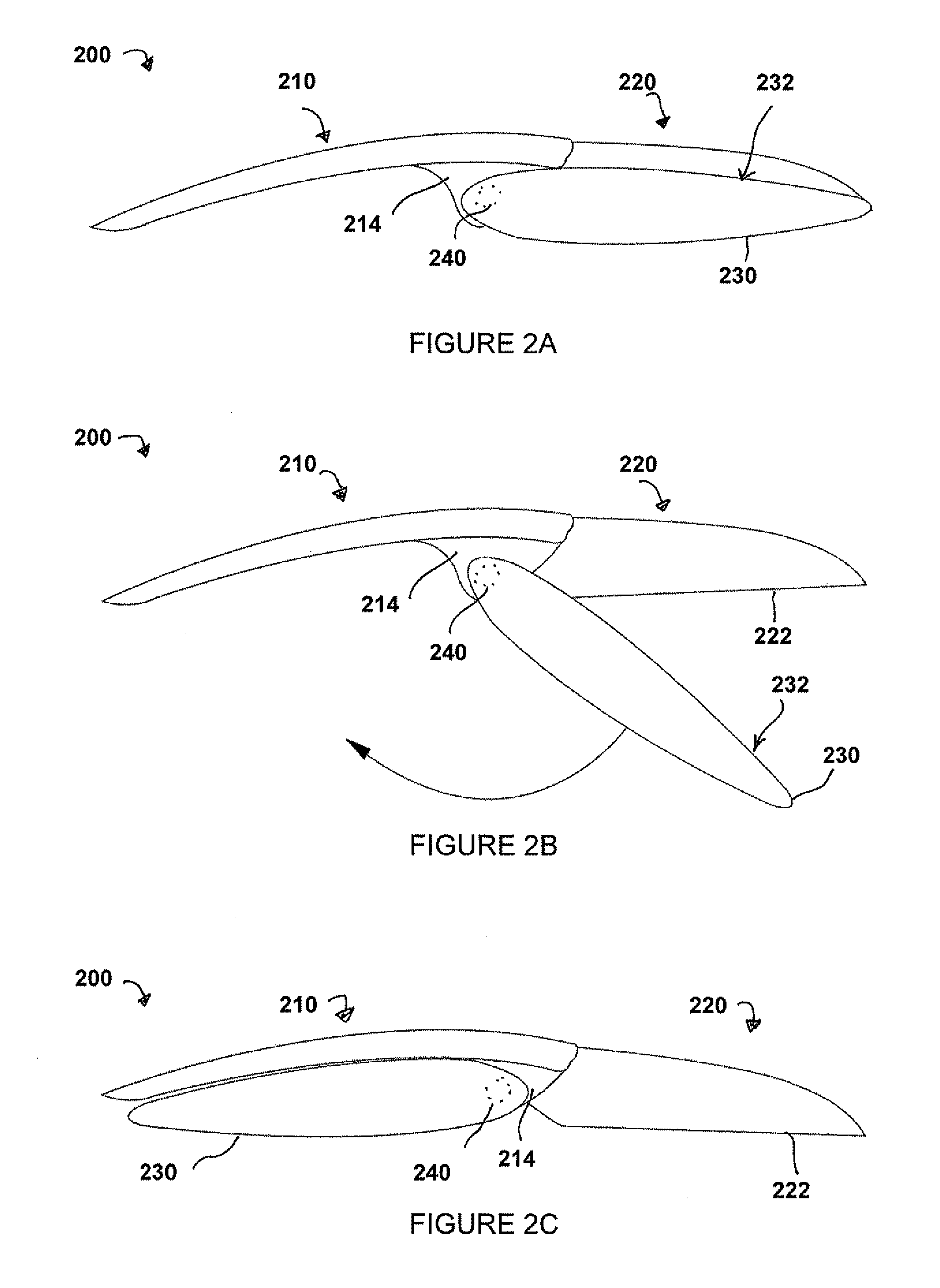

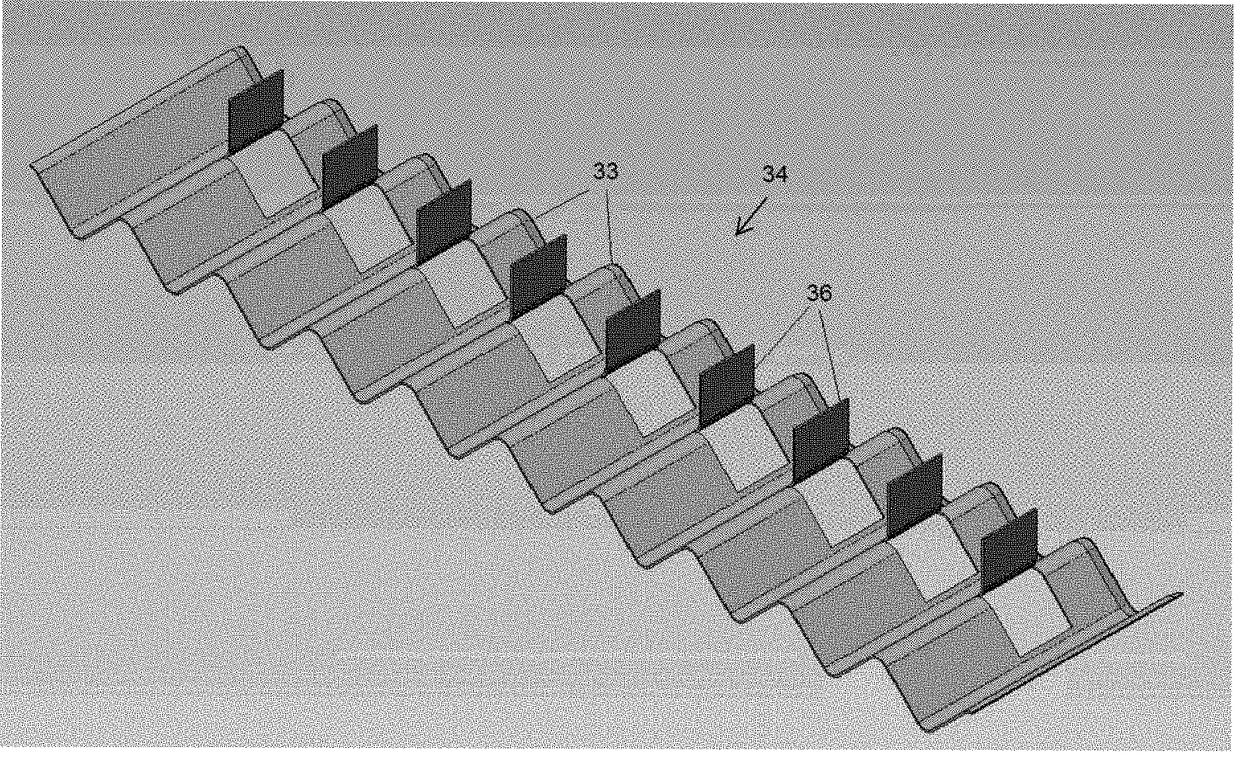

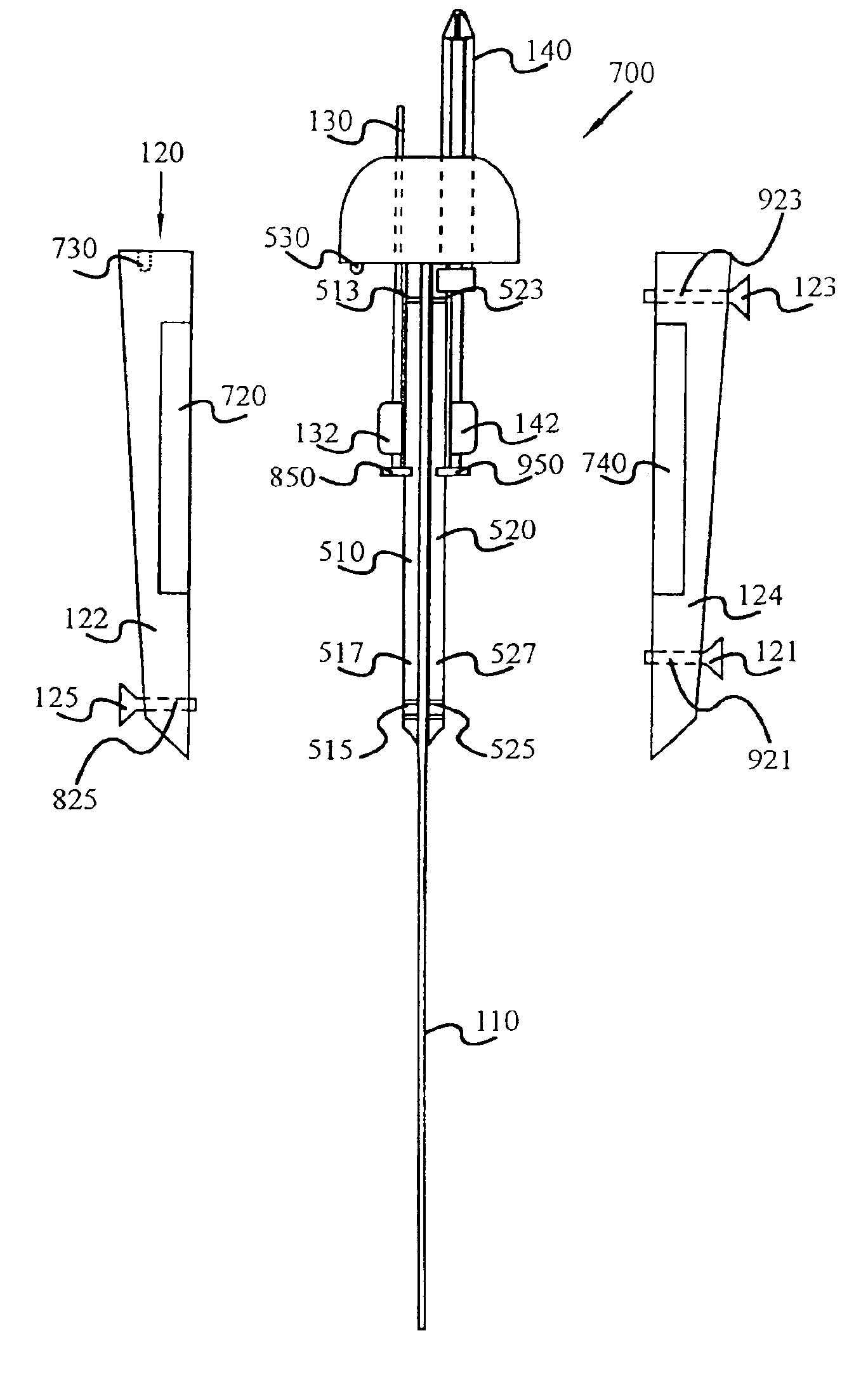

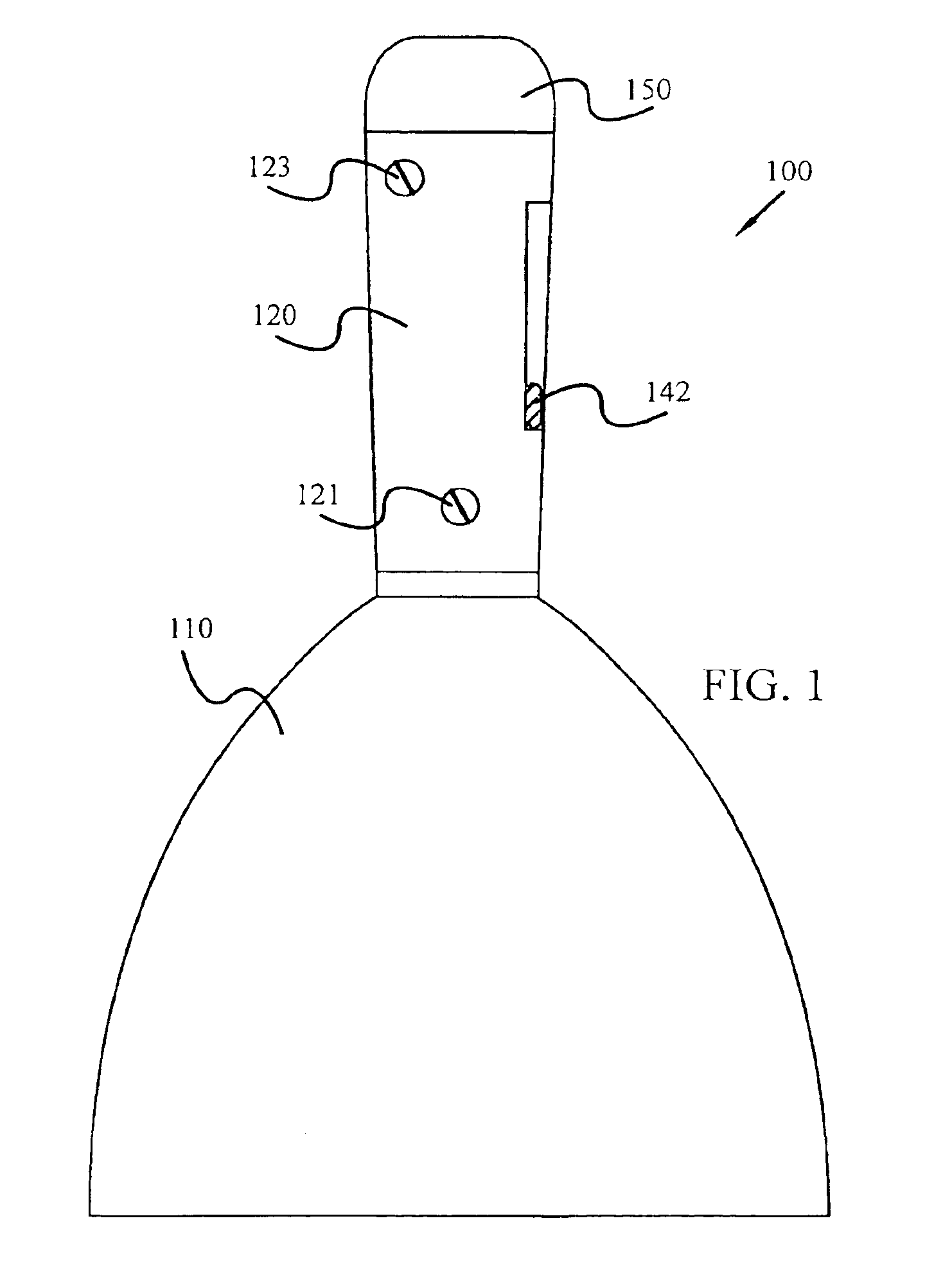

Surgical knives for large, self-sealing corneal incisions coupled to a universal intraocular lens (IOL) injector

A lens injector includes a thin sheet-like lens glide member, mounted upon a tapered knife, that maintains a wedge-shaped opening in the cornea upon withdrawal of the knife. The lens is thereafter advanced under the cornea by a plunger in the injector that maintains the lens in place as the injector device is removed. A multiple point blade knife may simultaneously make a set of several small, connected incisions. The fact that each blade has only a limited depth means that the resulting wide incision can be created without the need to penetrate deeply into the cornea, as would be necessary with a single-point blade of the desired width. This is especially beneficial for creating Z-shaped incisions, which become self-sealing when internal pressure pushes the inner layer against the outer layer. This shortens the process significantly, which then results in less trauma to the eye and streamlines the entire procedure.

Owner:SCHOSSAU TOM M

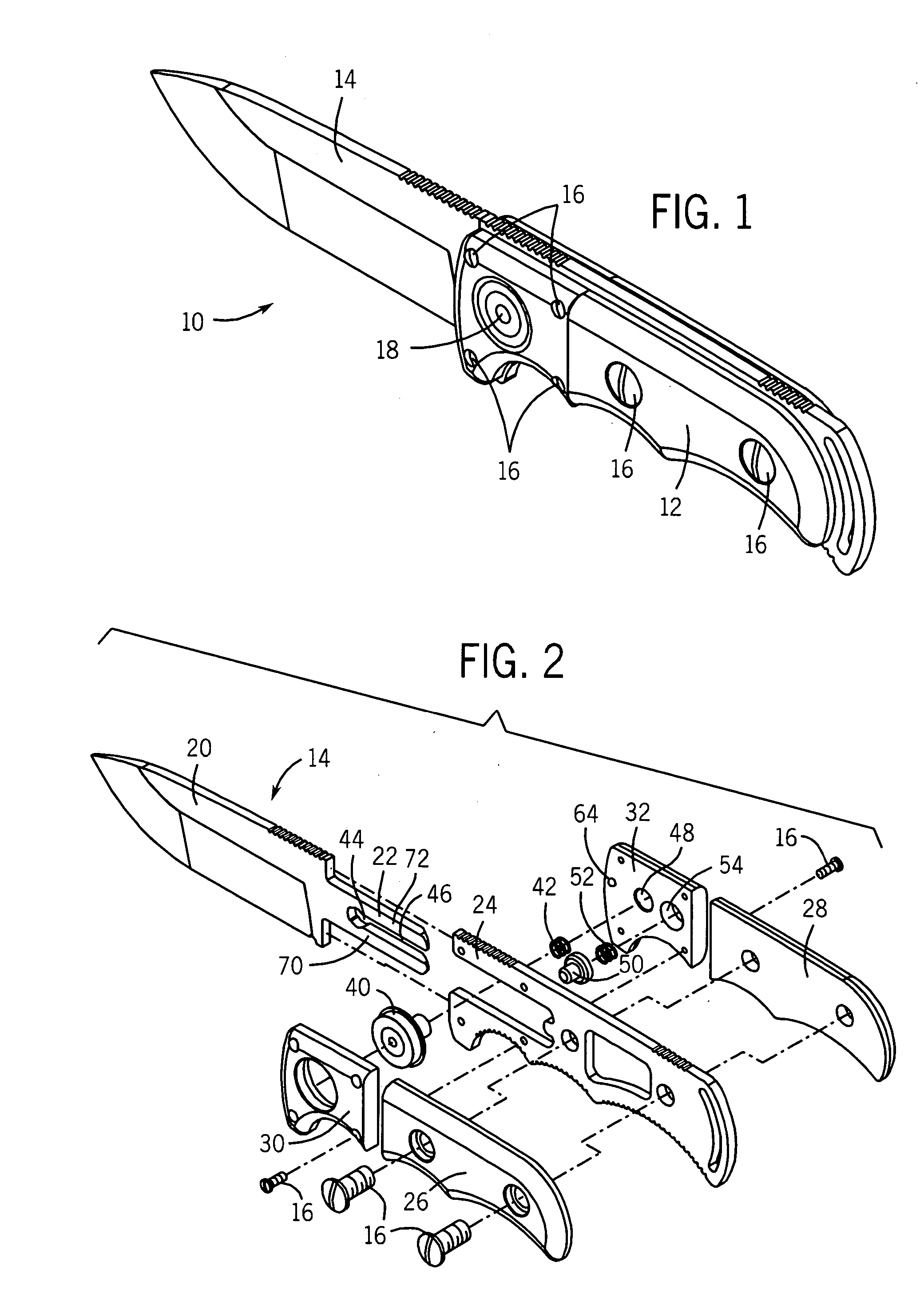

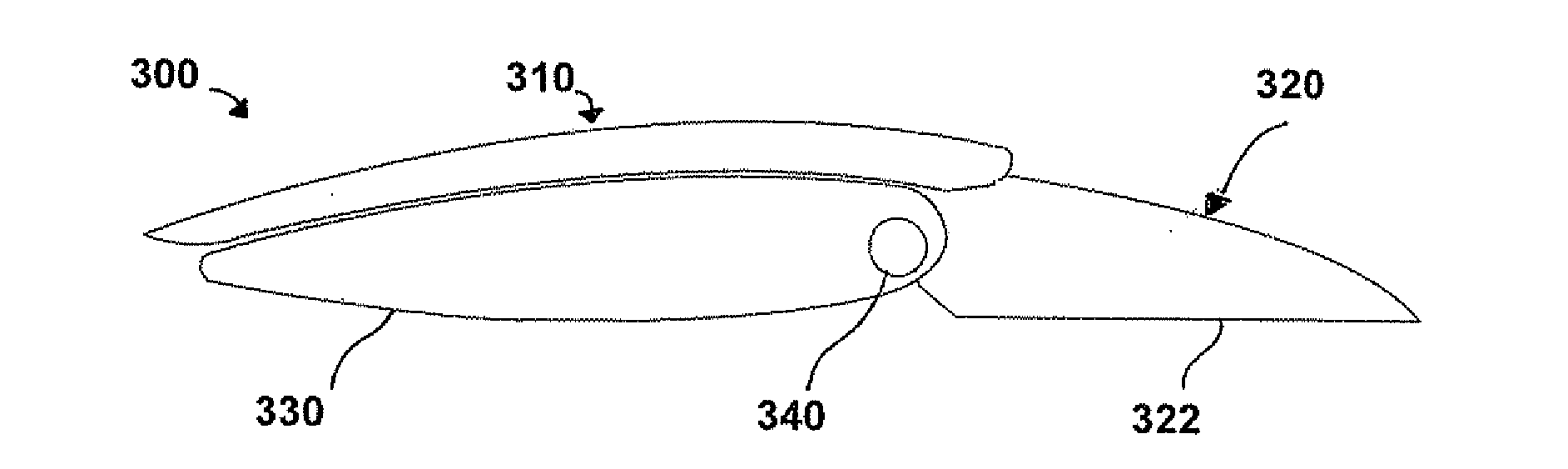

Fixed blade knife

InactiveUS20060080840A1Easy to disassembleThrusting weaponsWeapon componentsKnife sharpenerEngineering

A fixed blade knife, includes a handle, and a blade, coupled to the handle. The blade has a tang received within the handle. A plurality of lashing points defined by passages extending through both the handle and the tang are provided. The knife may be carried in a sheath with a knife sharpener removably coupled to the sheath.

Owner:OY FISKARS AB

Exchangeable blade knife

An exchangeable blade knife includes a handle and a blade adapted to be removably coupled to the handle. A bias mechanism is coupled to the handle, the bias mechanism applying a bias on the blade in a lateral direction to press the blade against the handle. The blade may be removed from the handle without also removing the bias mechanism from the handle.

Owner:OY FISKARS AB

Replaceable-blade knife

A replaceable-blade knife useful as a carpet knife or utility knife, and having a handle with a spare-blade holder movably mounted therein, and a blade-clamping bar for securing an active cutting blade at one end of the handle. A locking means is provided to lock the holder in a protective closed position, and alternatively to release the holder to an open position by movement of the bar, and to enable ready access to blades in the holder.

Owner:T&J

Exchange blade knife

An exchange blade knife includes a replaceable blade, a blade holder and a blade lock. The replaceable blade includes an opening adjacent to its base edge. The blade holder includes a blade recess for receiving the replaceable blade and a boss corresponding to the opening in the blade which projects from the surface of the blade recess. The boss has a low portion that is no thicker than the replaceable blade and a raised portion that extends above the surface of the replaceable blade. The blade lock pivots on the blade holder between an opened position for receiving the replaceable blade and a closed position for retaining the replaceable blade. The blade lock also includes an opening for receiving the boss of the blade holder.

Owner:WHITE JAMES DALE

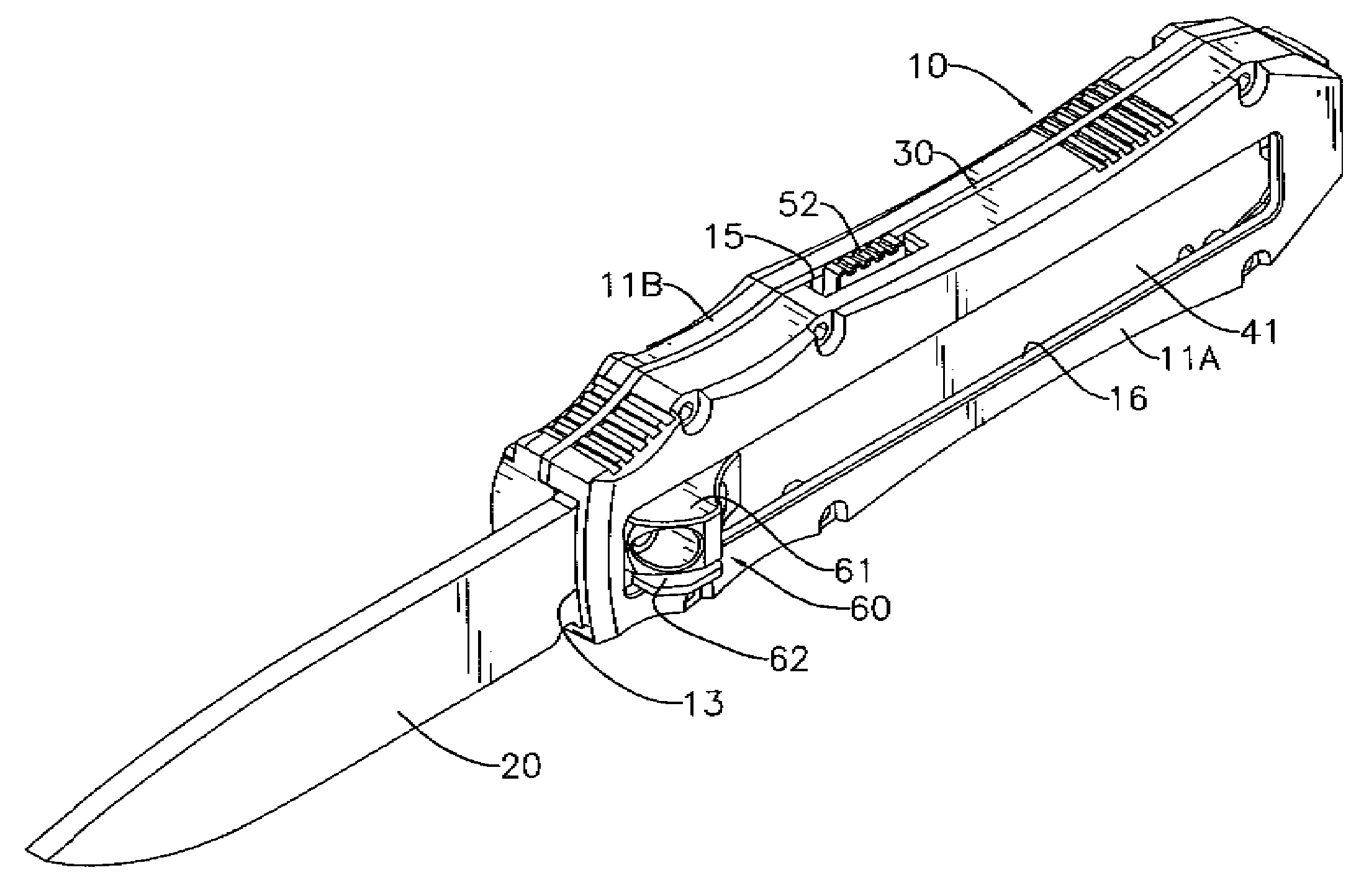

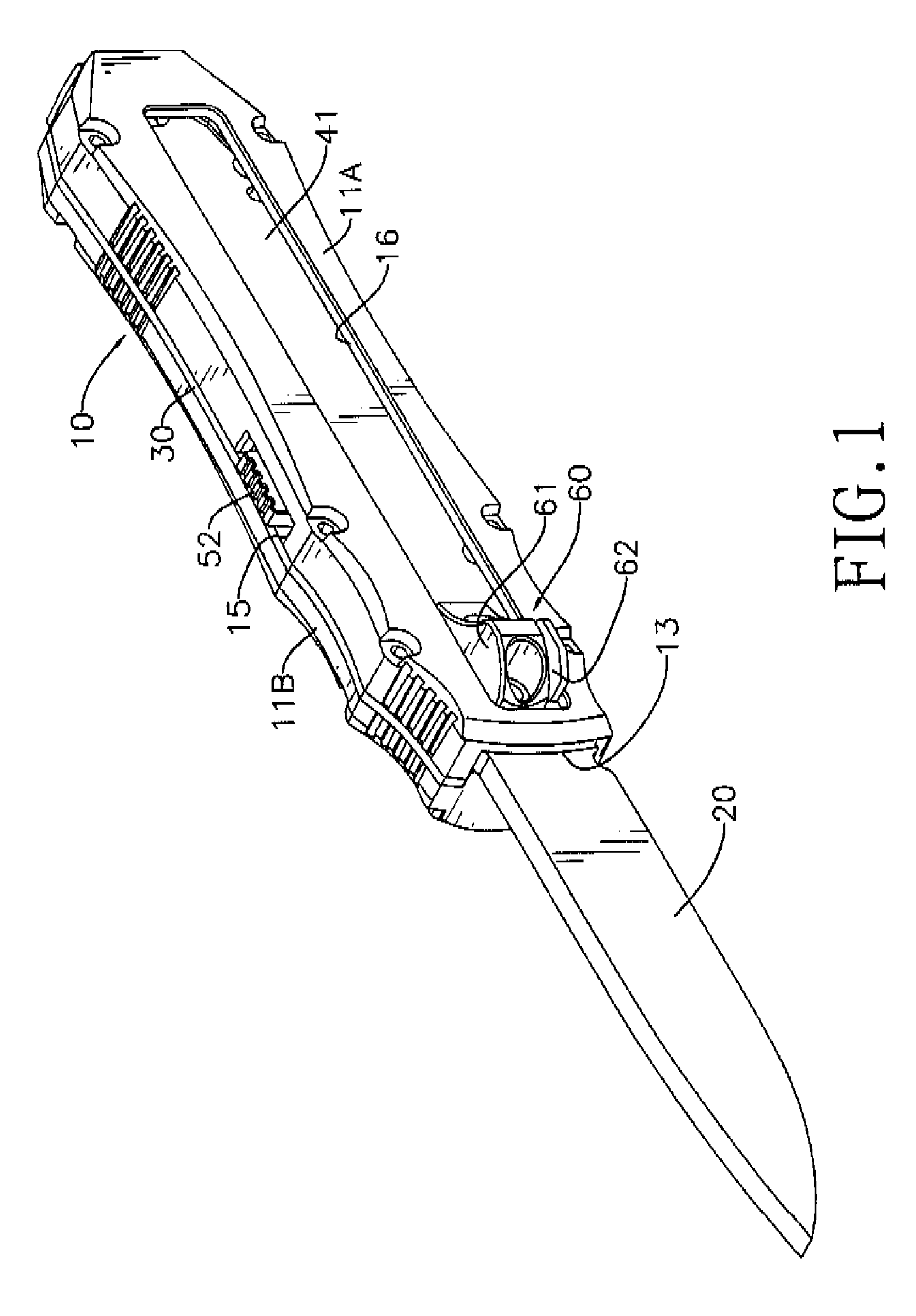

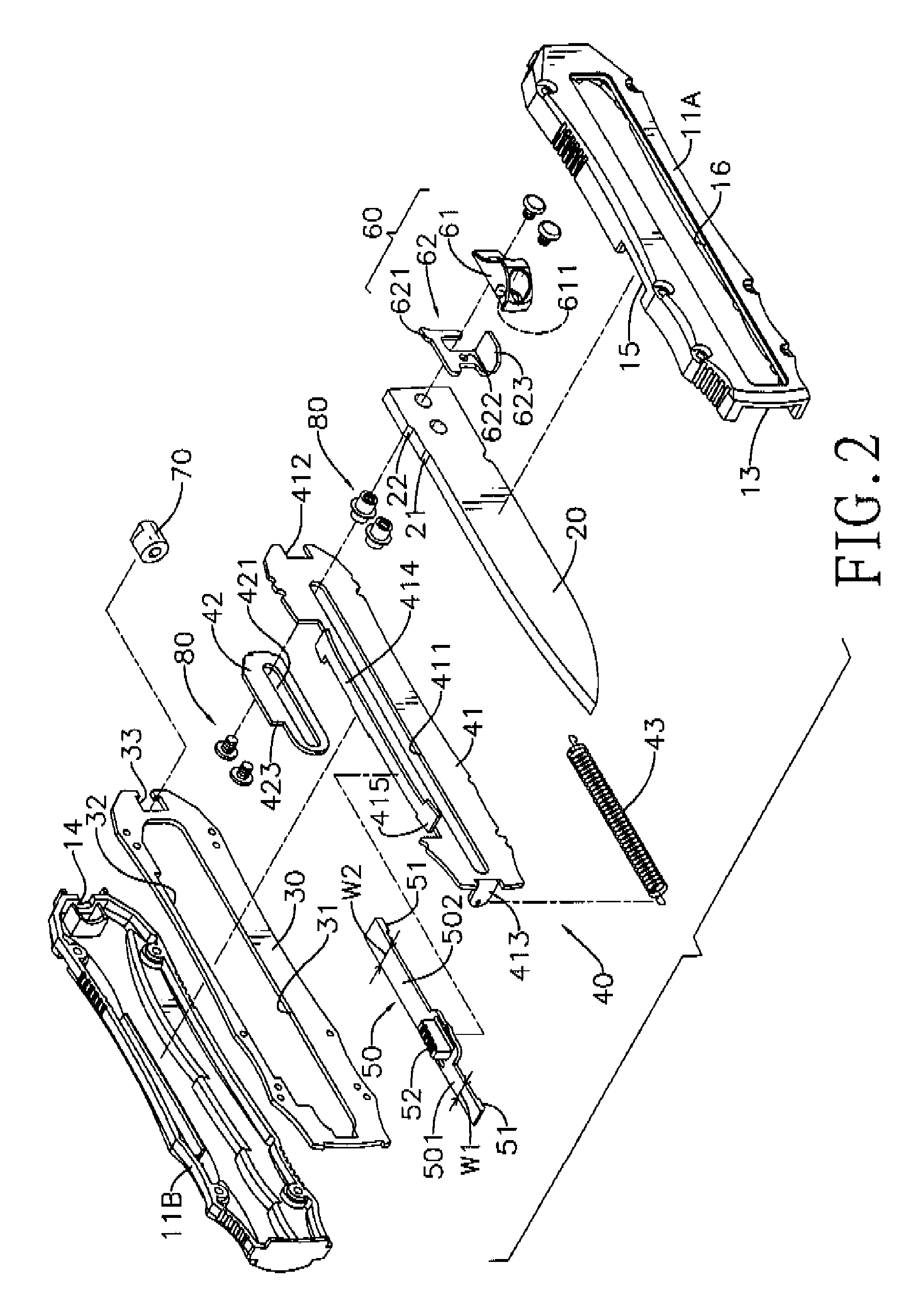

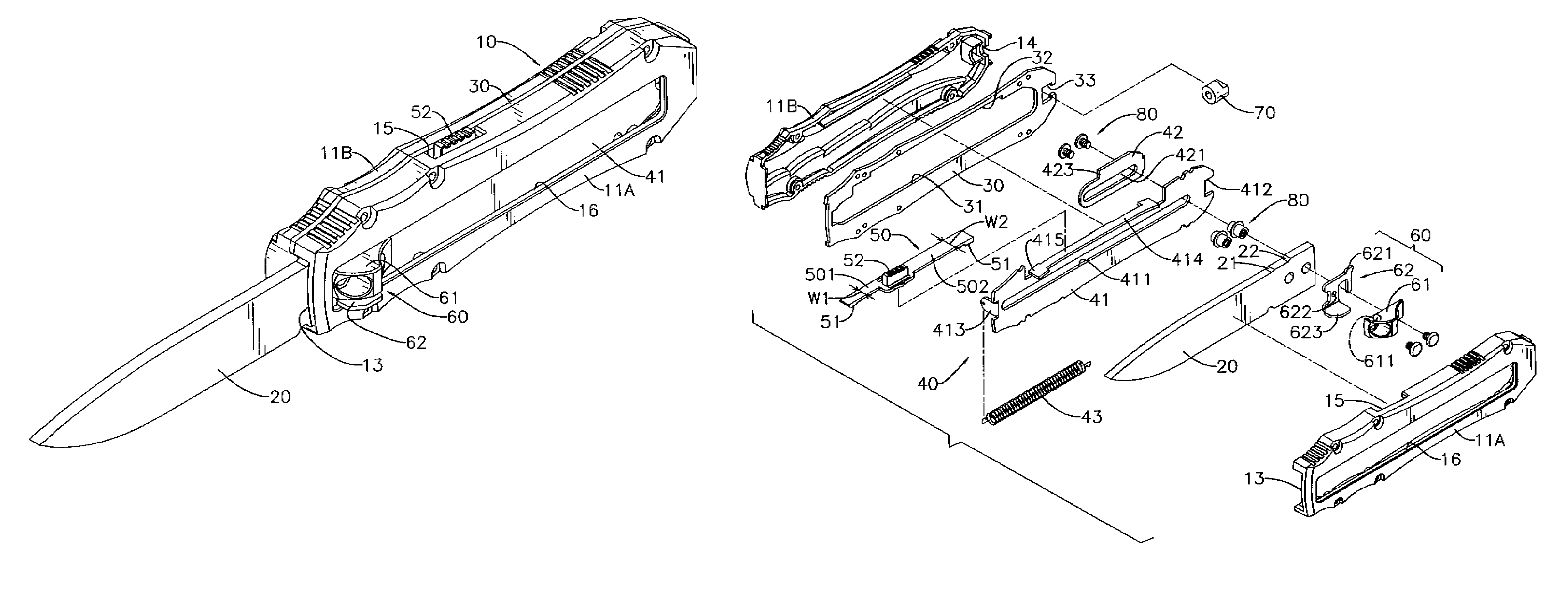

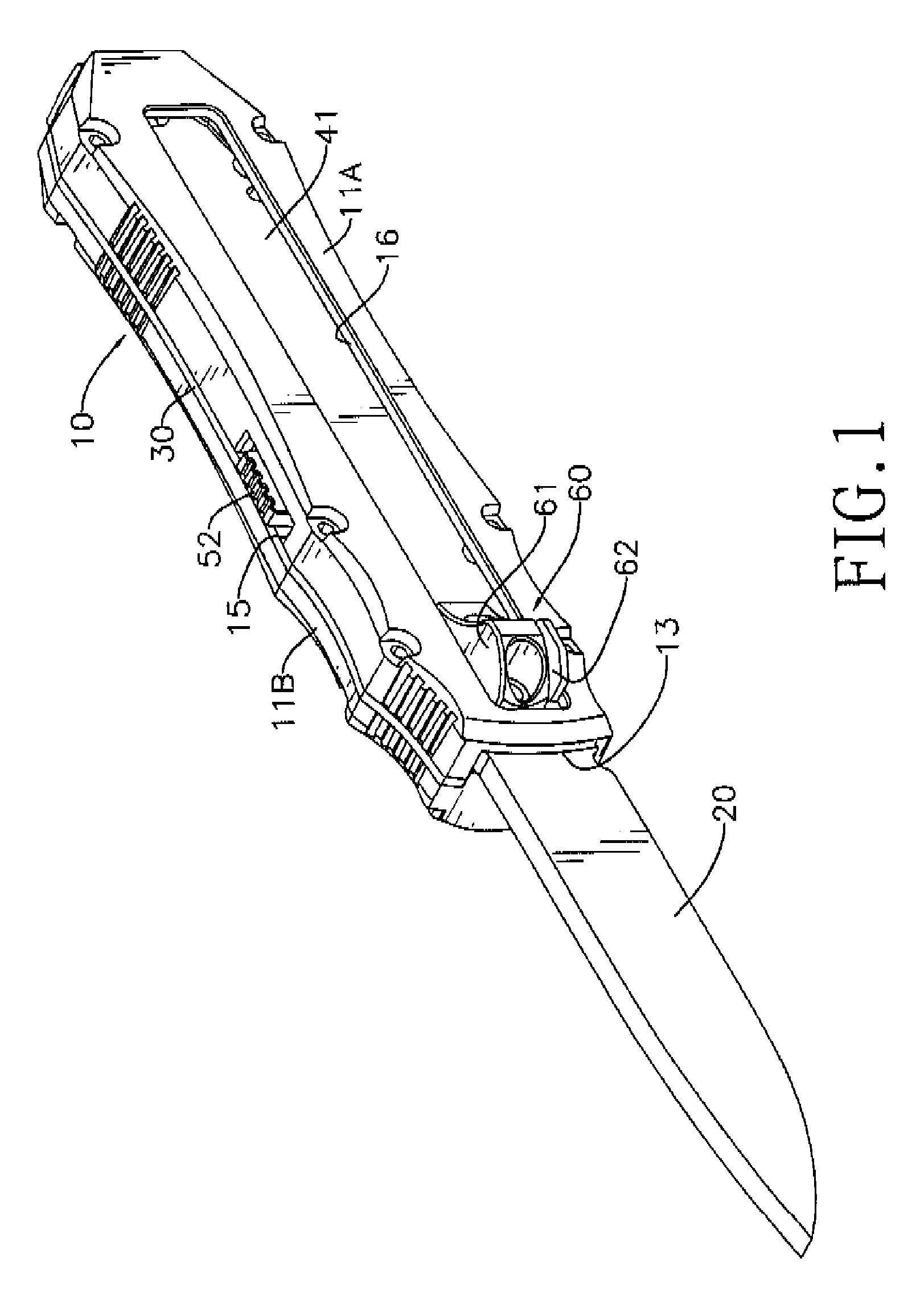

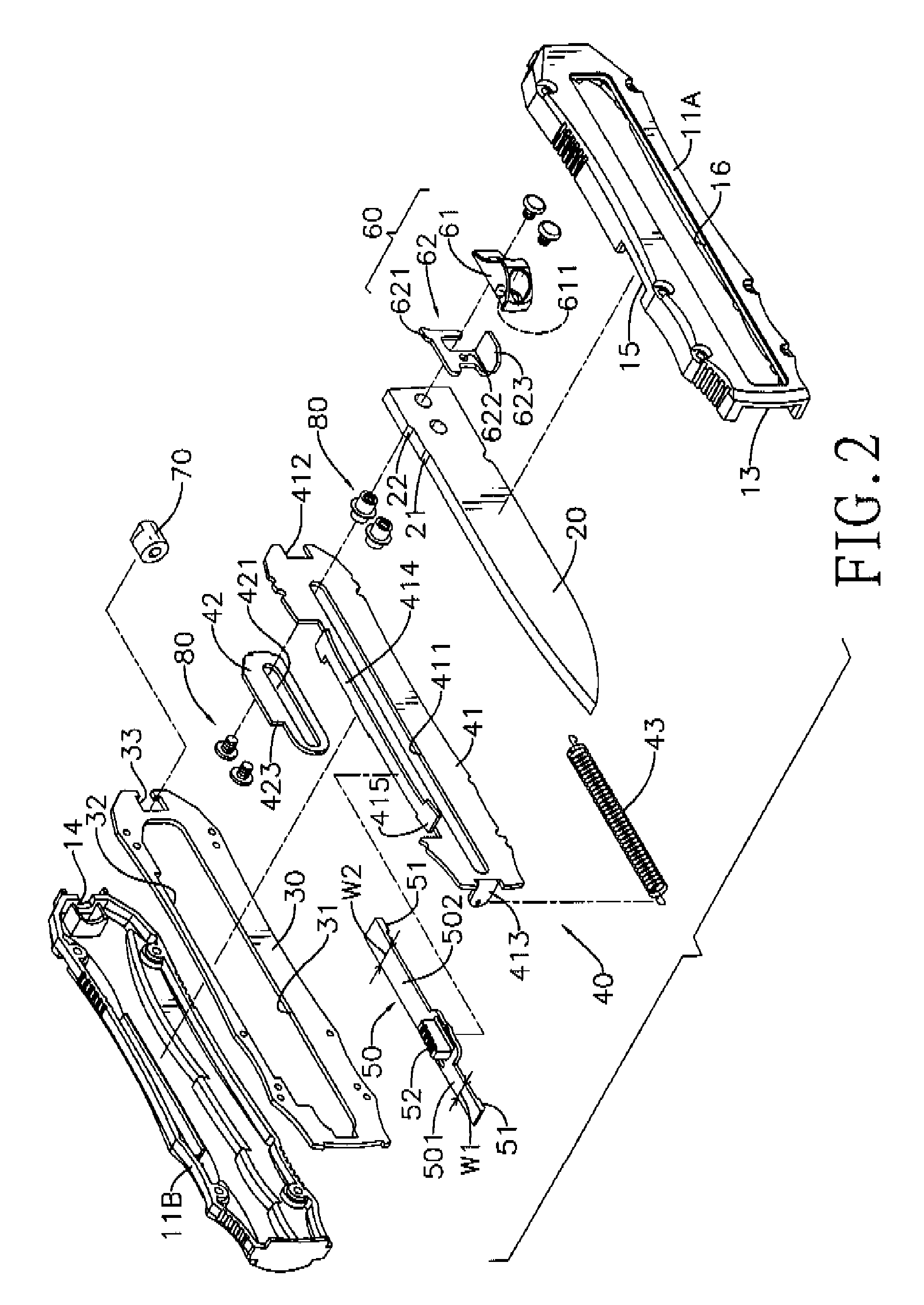

Retractable blade knife with opening assisted mechanism

A retractable blade knife with an opening assisted mechanism has a handle, a blade mounted in the handle, an extending assembly mounted between the blade and the handle. At least one detent formed at a spine edge of the blade. The extending assembly has a positioning frame, a slider mounted beside the positioning frame and attached to the blade and a spring attached to the positioning frame and the slider. The positioning frame has a resilient rod selectively abutting the spine edge and a proximal end of the blade. The blade should be pushed manually a certain distance to allow the spine edge of the blade to push a rear end of the resilient rod outwardly. When the detent of the blade and a lock protrusion of the slider both depart from the resilient rod of the positioning frame, the spring may further pull the slider to move together with the blade to stretch out the blade. Thus, the spring helps the blade to be extended quickly and the extending assembly also prevents the blade from being retracted or extended accidentally. Therefore, the retractable blade knife with an opening assisted mechanism is used safely and conveniently.

Owner:AOB PROD CO

Retractable blade knife with opening assisted mechanism

ActiveUS7797838B2Extended very quicklyEasy to useThrusting weaponsWeapon componentsDetentKnife blades

Owner:AOB PROD CO

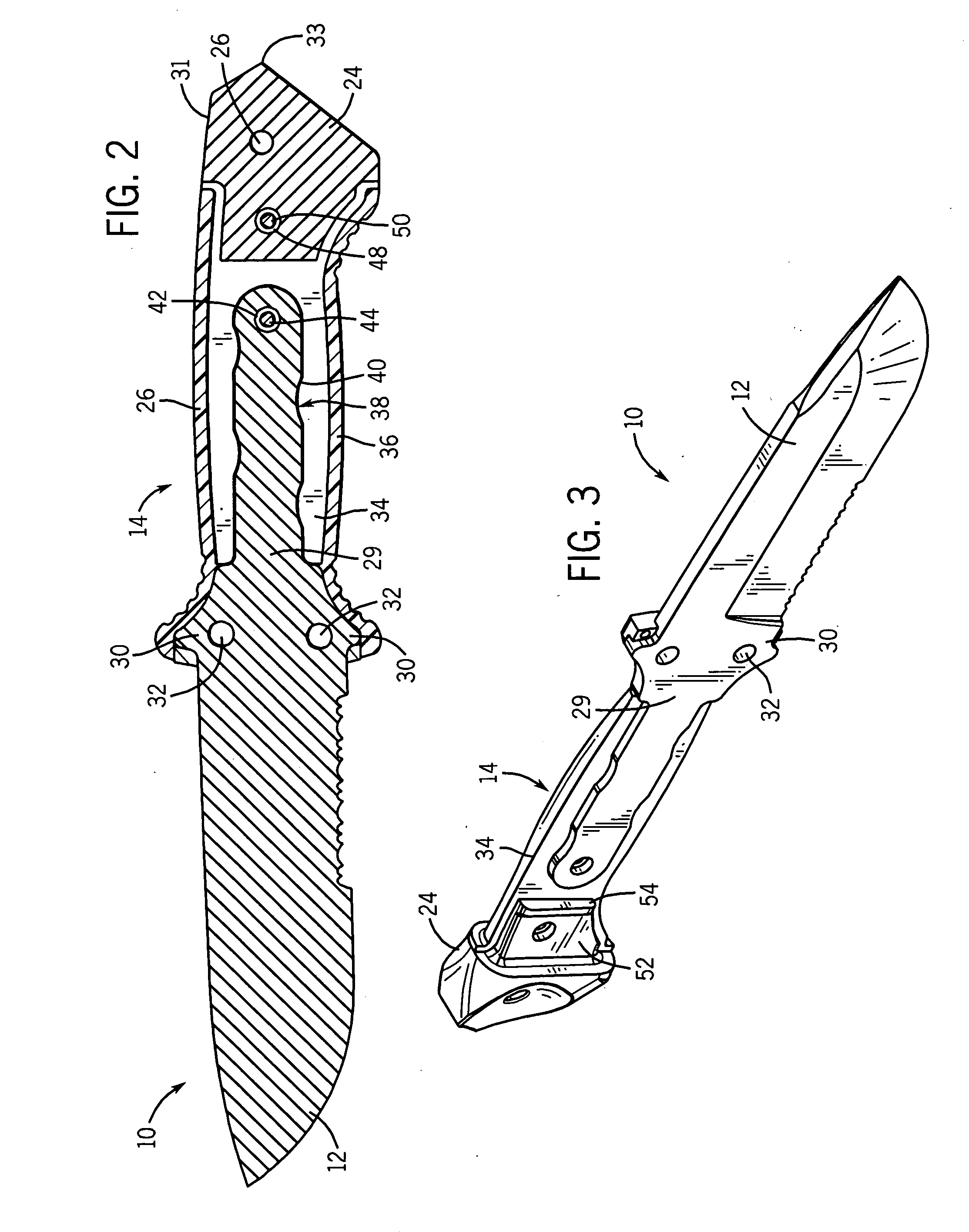

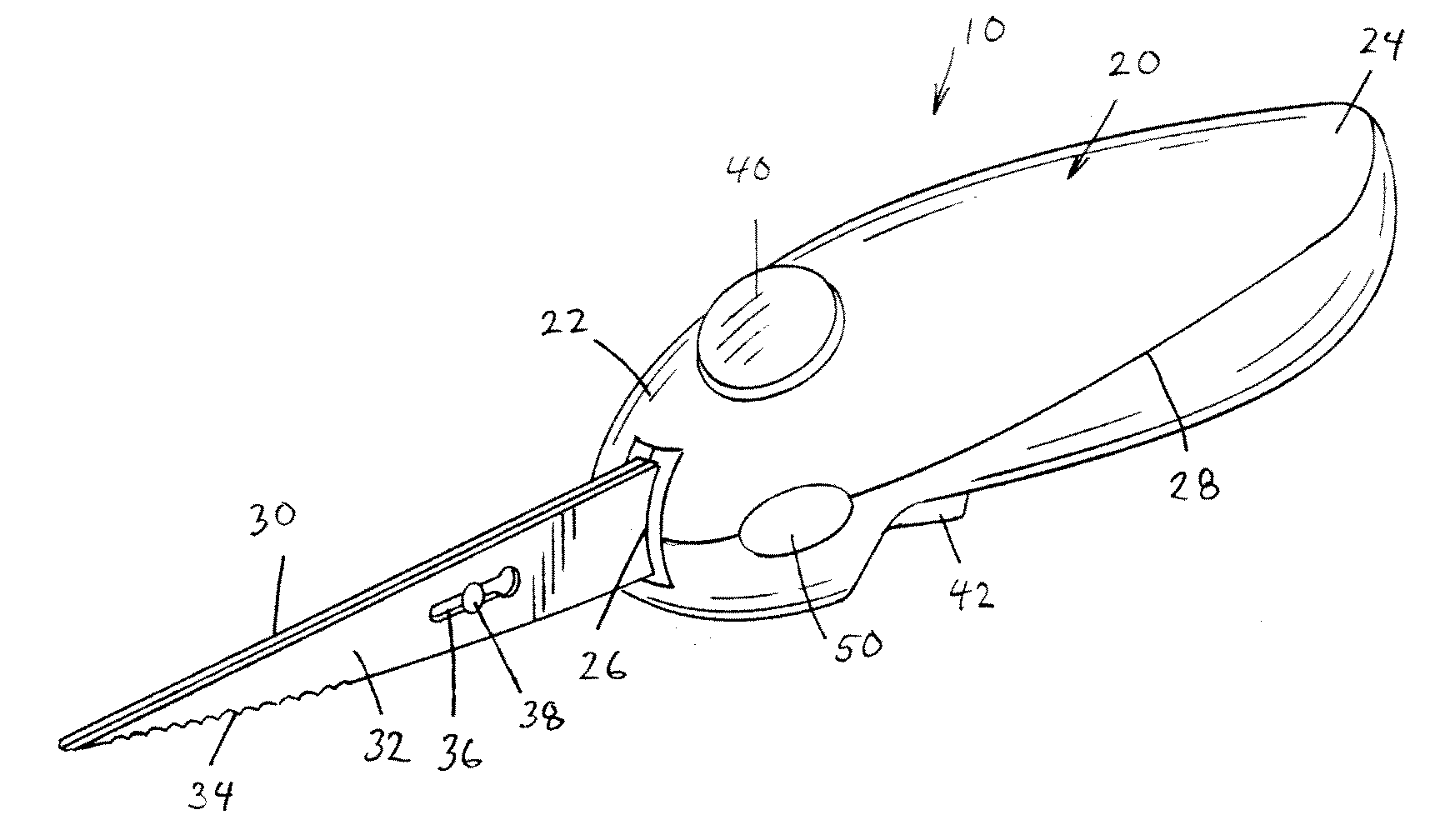

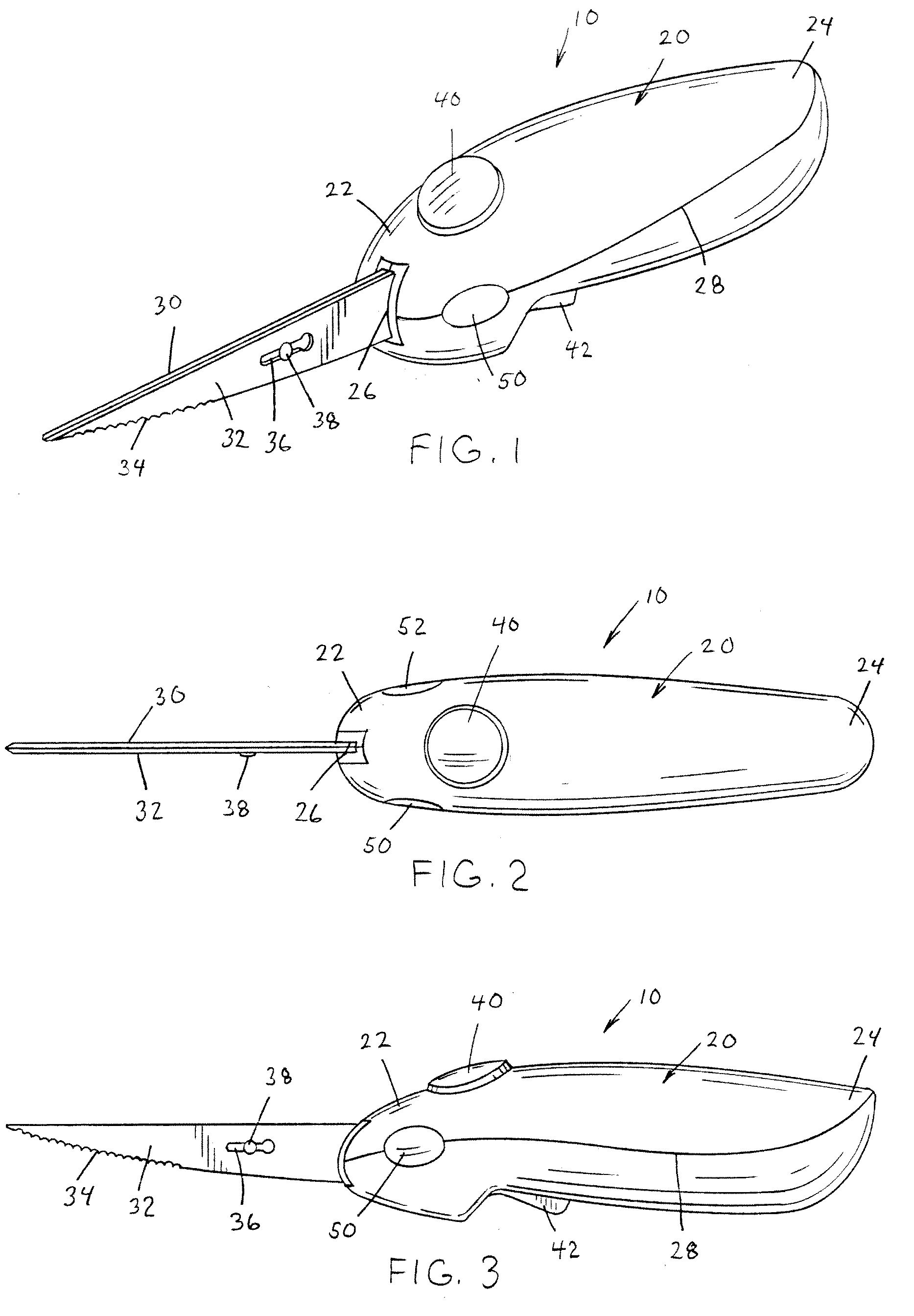

Fixed-blade knife with pivotable side pieces

InactiveUS20060080841A1Precise positioningSmall sizeThrusting weaponsWeapon componentsEngineeringKnife blades

A fixed-blade knife includes a unitary blade having an implement, a tang, and a pivot region between the implement and the tang. The unitary blade is disposed between a pair of parallel and spaced-apart side pieces that pivot to cover or expose the implement. In the pivoted position wherein the implement is exposed, the side pieces form part of the handle that is used to grasp the knife. A locking structure locks the side pieces in a selectable position, and a limit structure prevents overrotation of the side pieces.

Owner:BUCK KNIVES

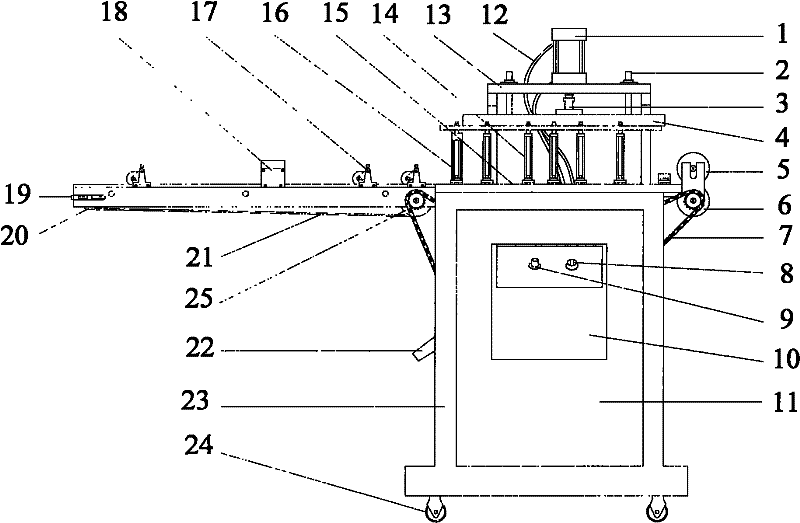

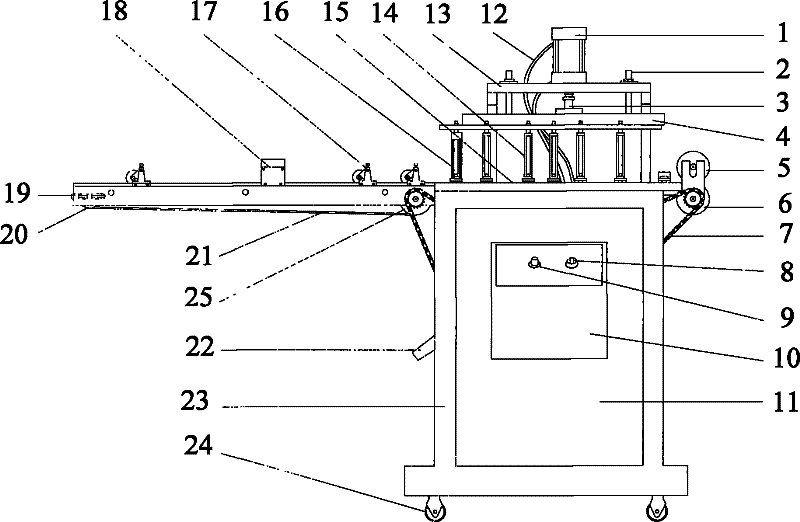

A non-woven fabric punching forming device

InactiveCN102284974AIncrease productivityEliminate the influence of human factorsMetal working apparatusPunchingEngineering

The invention relates to a non-woven fabric punching and forming device, which includes a pneumatic punching device, a knife die device, an electric transmission device and a motor box, the pneumatic punching device is arranged on the upper part of the device, and the knife die device is connected to the pneumatic punching device The lower part of the die cutter device is supported and connected on the top platform of the motor box, and the electric transmission device is arranged on the upper part of the motor box. Compared with the prior art, the present invention replaces the manual section cutting and manual ironing, and completes the punching at the same time as the section cutting, which improves the production efficiency and ensures the punching quality of the product. In addition, the punching knife edge is hidden in the In the positioning hole, it will not pose a safety hazard to the operator, ensuring production safety.

Owner:上海新必工贸有限公司

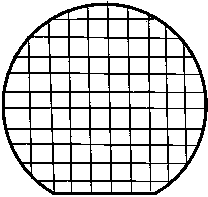

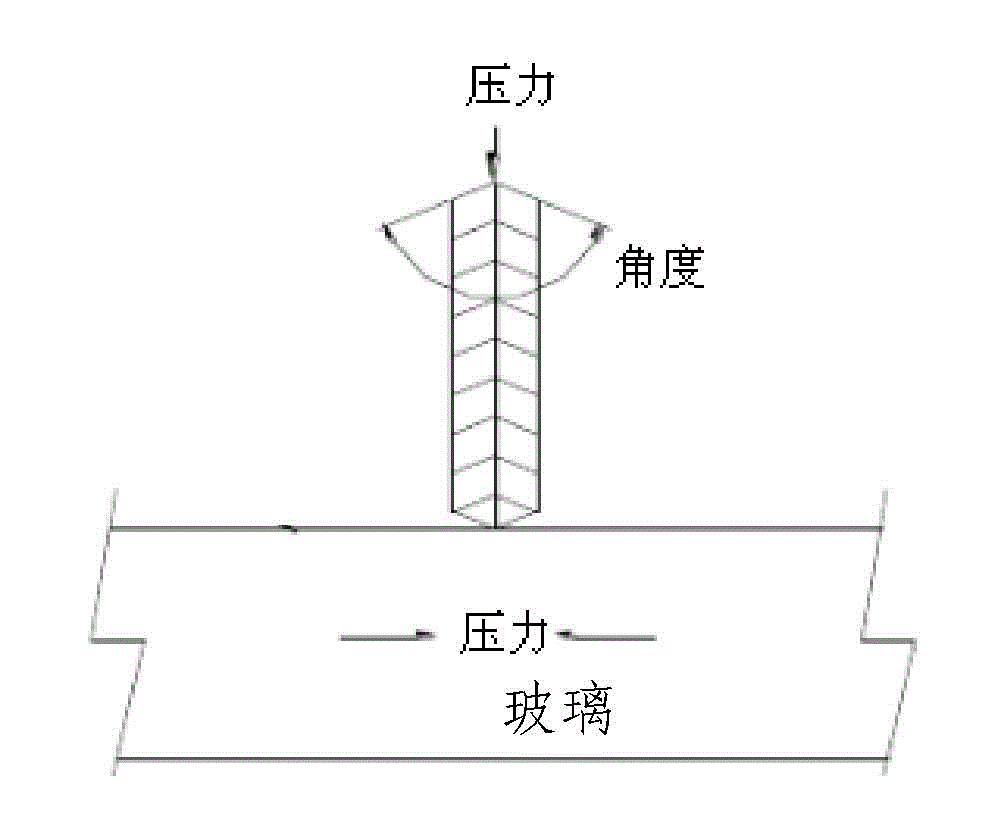

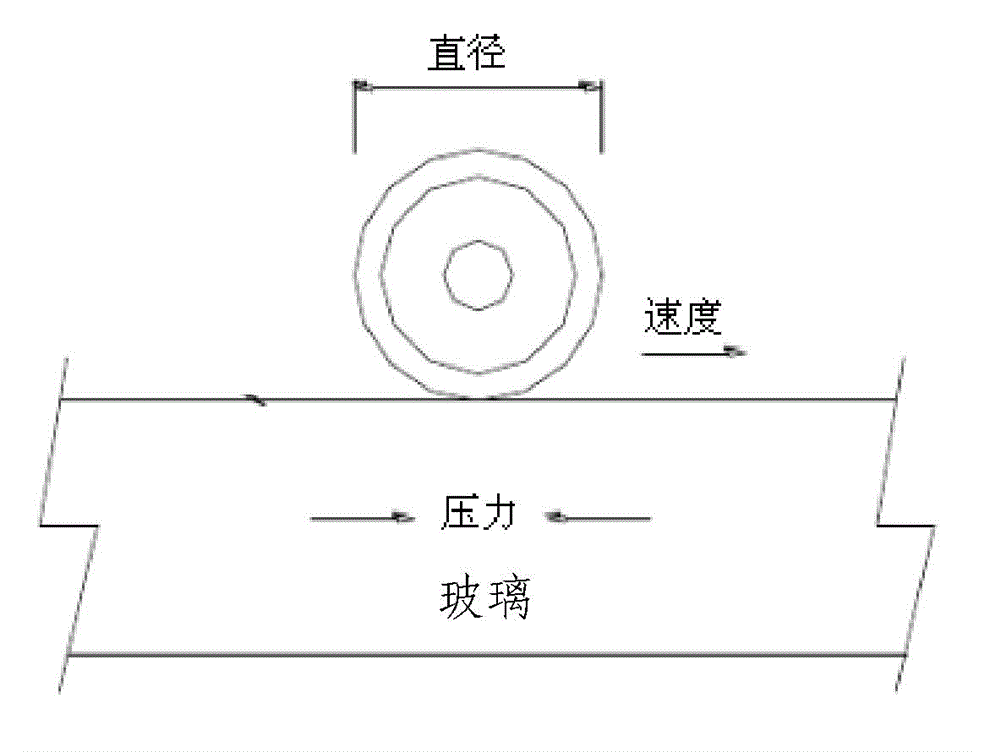

Cutting method of LED chip

InactiveCN104347760AAvoid ablationDoes not affect electrical characteristicsSemiconductor/solid-state device manufacturingFine working devicesEngineeringLaser cutting

The invention discloses a cutting method of an LED chip. The method comprises drawing scratches by use of laser on the back surface of the chip and performing saw cutting by use of a diamond saw blade knife, wherein the saw blade knife is an isosceles inverted triangle with a symmetrical left portion and right portion, and the included angle between a knife side surface and a horizontal line is 30 DEG to 60 DEG. The method further comprises performing overturning and film reversing on the back-cut chip and cutting the front surface of the chip along grooves to form crystal grains by use of a splinter knife. According to the invention, the problems of backside collapse, burr and the like by use of a conventional saw blade process are solved, the problem of ablation brought by laser cutting is avoided, and the method is simple to operate and easy to realize.

Owner:LATTICE POWER (JIANGXI) CORP

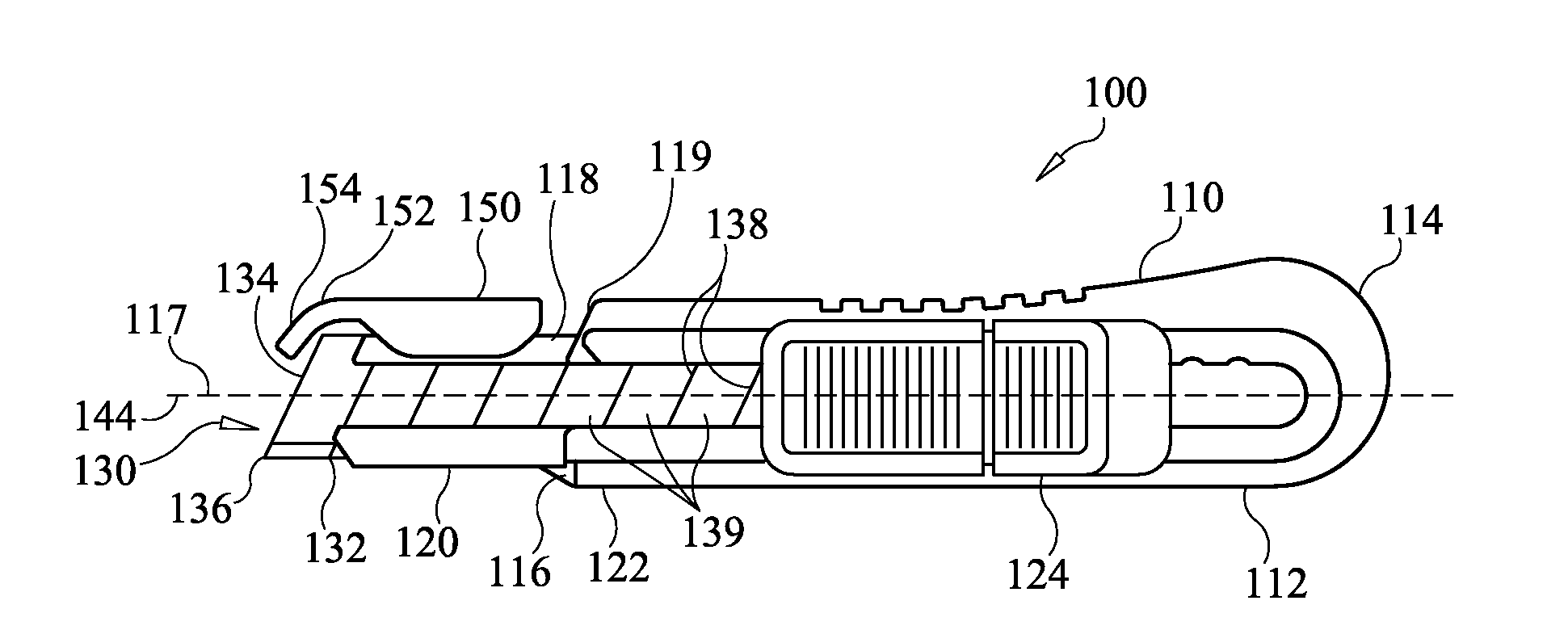

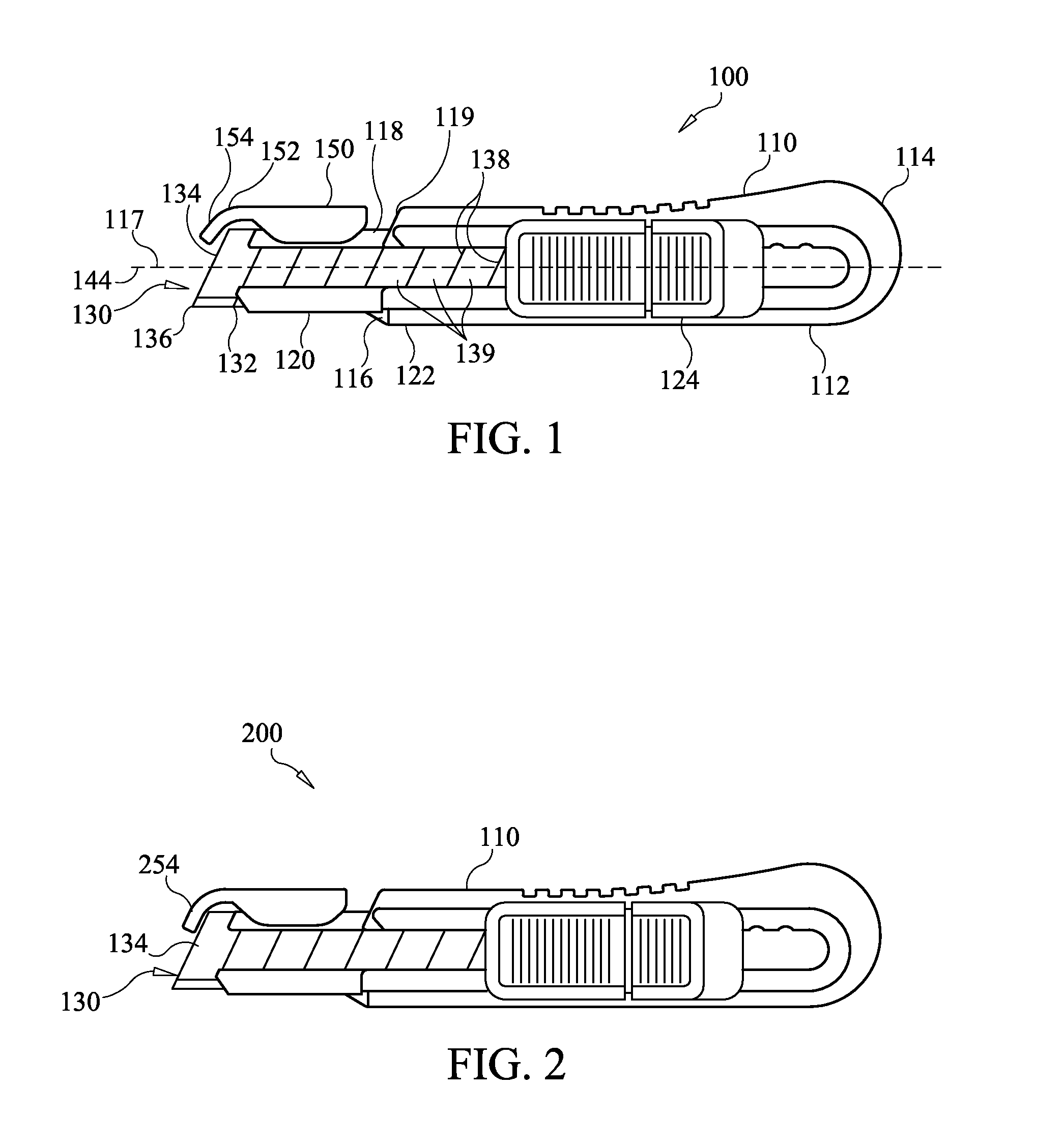

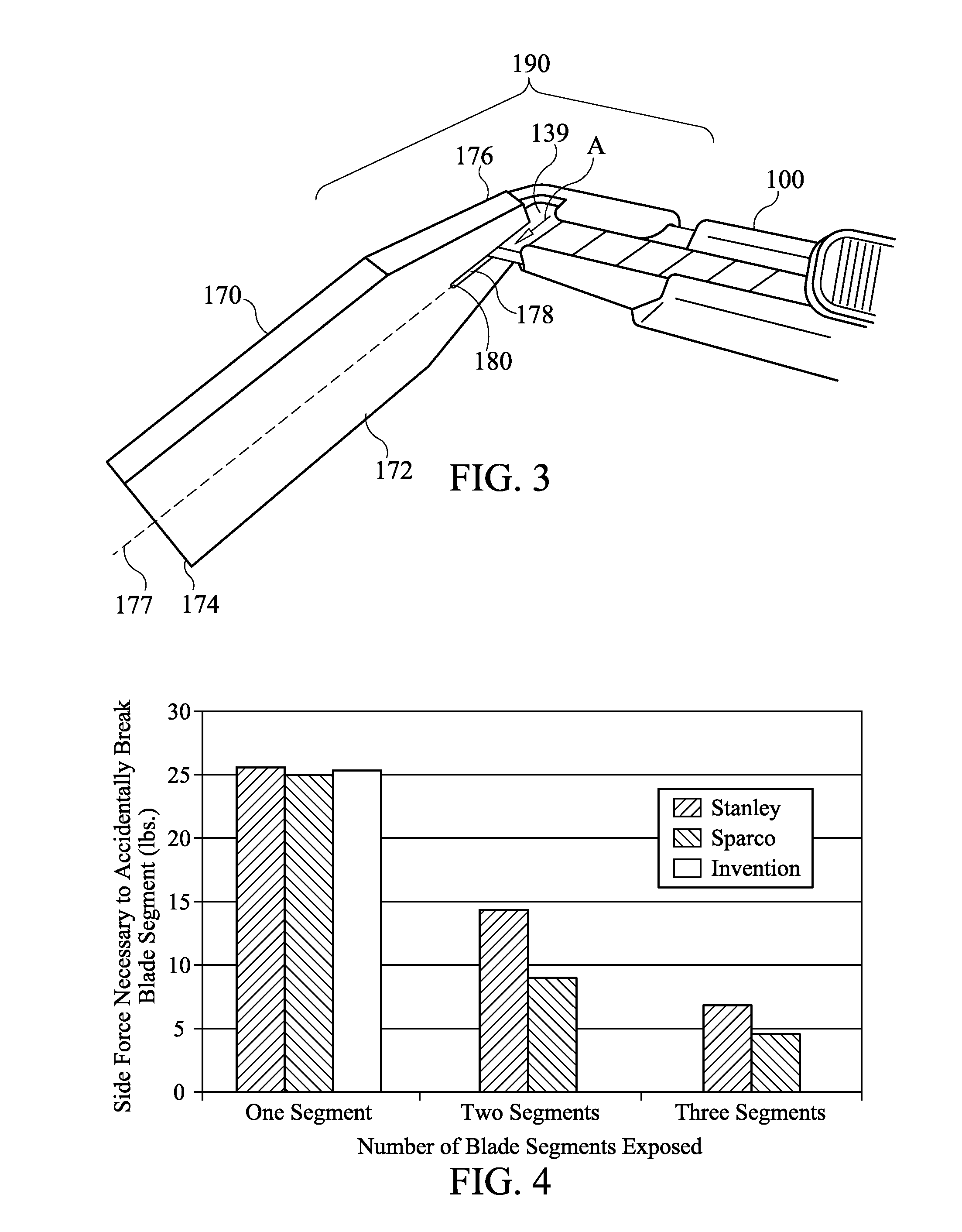

Snap-off blade knife with safety stop

A snap-off blade knife having a handle including a proximal portion, a distal portion, and a handle axis extending between the proximal portion and the distal portion is disclosed. The knife also includes a blade slidingly disposed within the handle along the handle axis. The blade comprises a plurality of scored segments. A blade stop fixedly extends from the distal portion of the handle. The blade stop includes a stop arm disposed to engage blade to limit extension of the blade from the handle. A kit comprising the snap-off knife and a blade segment snap-off tool is also disclosed.

Owner:UNIVERSITY OF DELAWARE

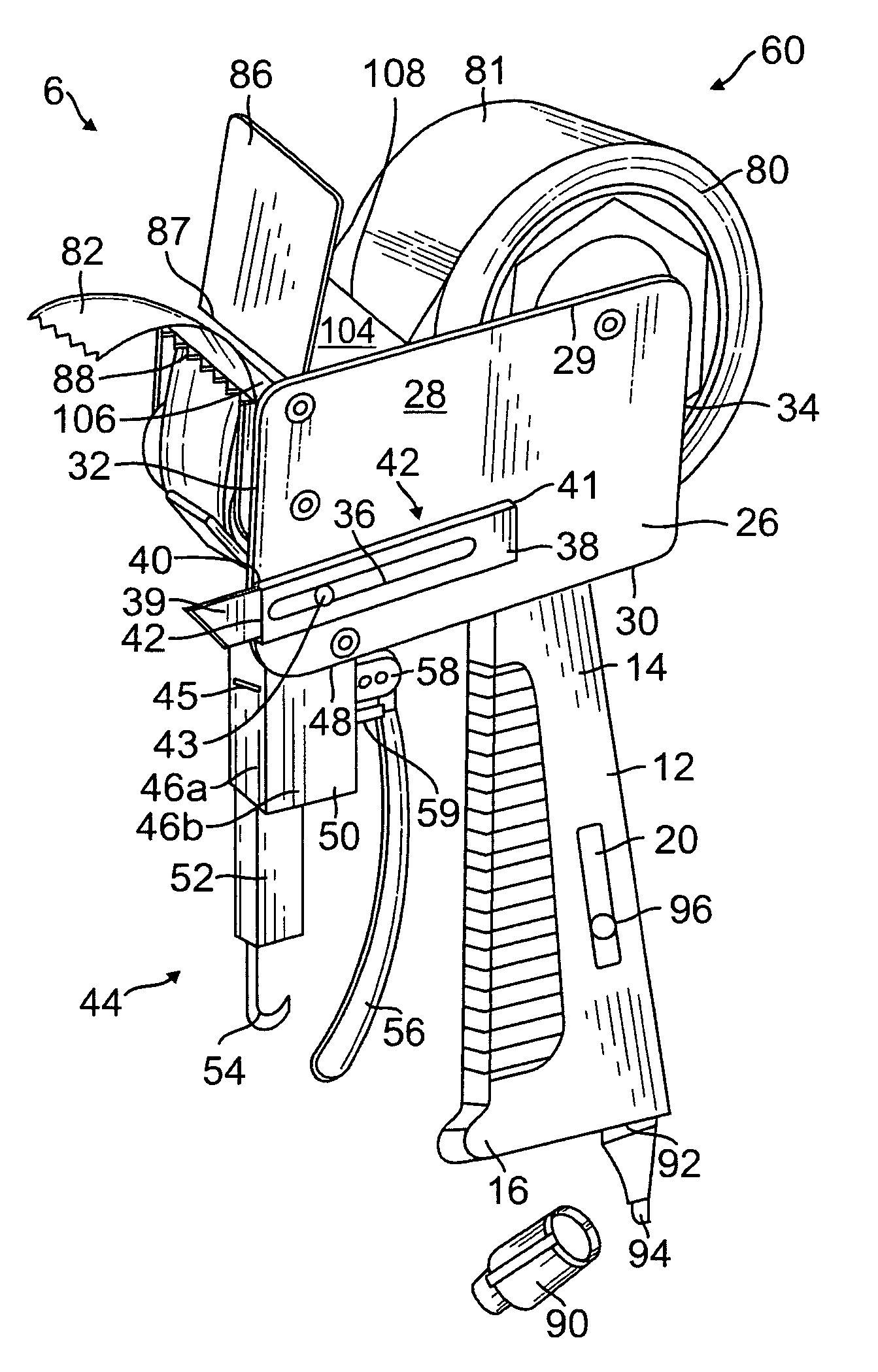

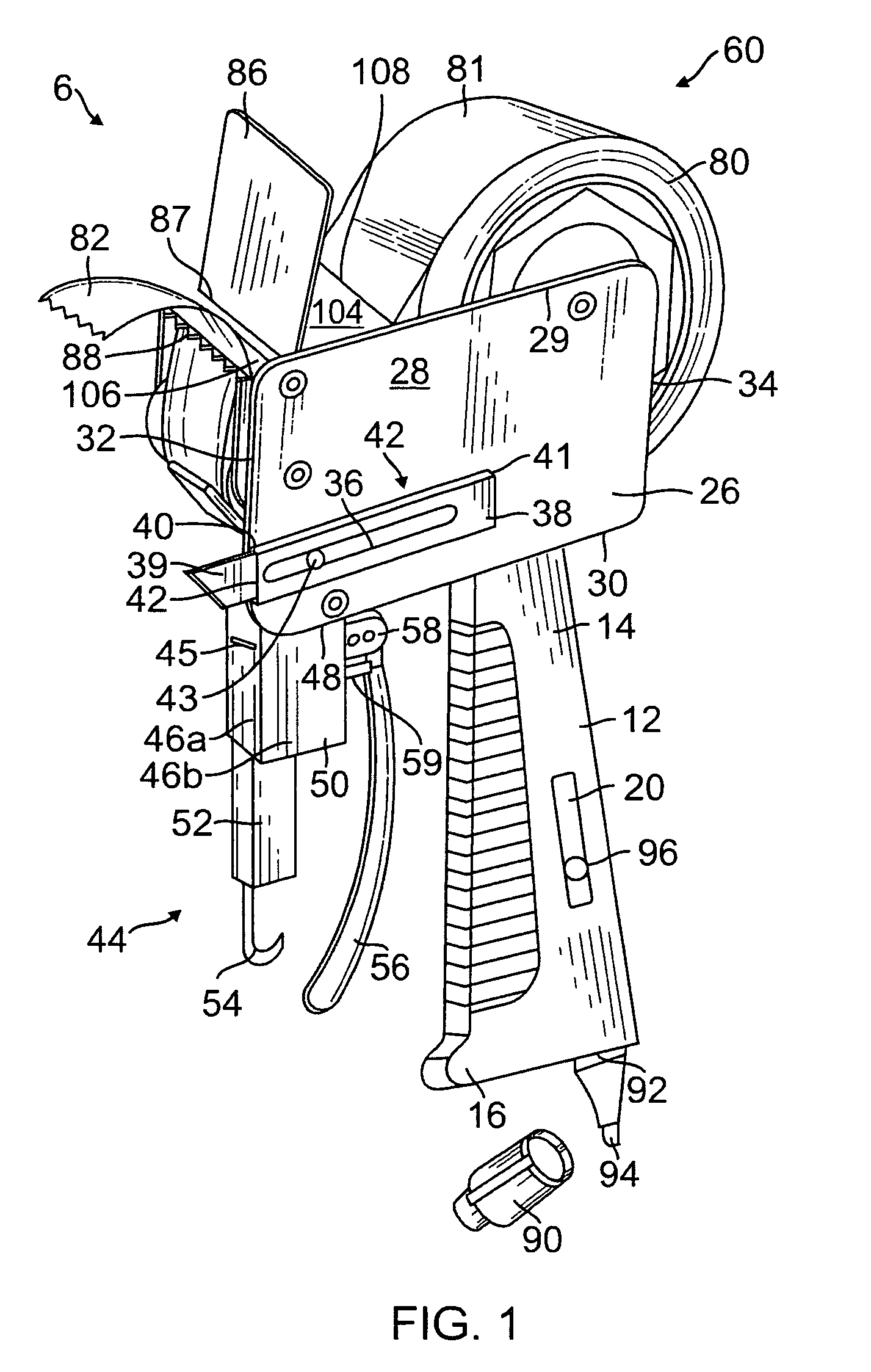

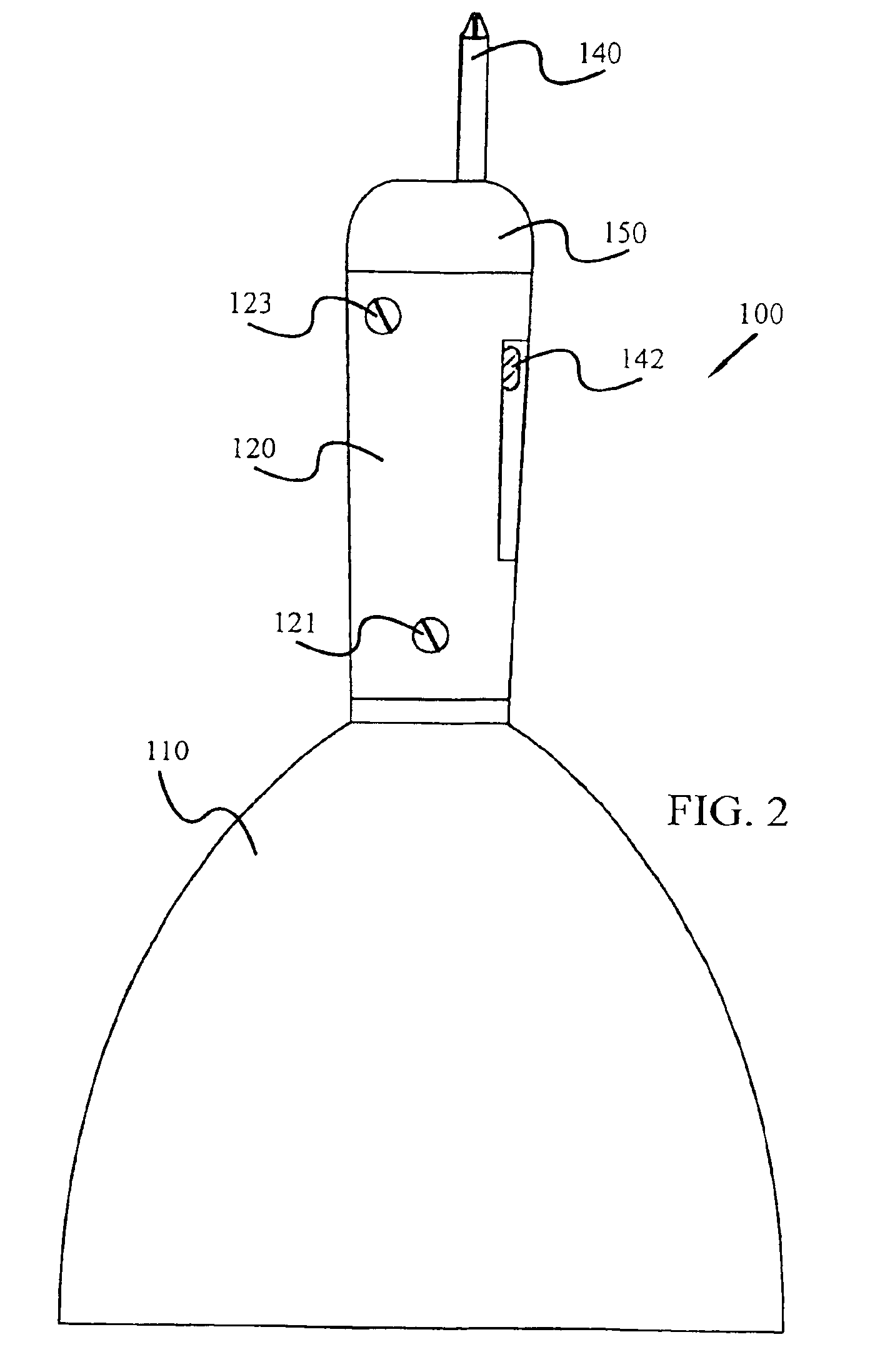

Four-in-one multi-component combination tool to facilitate forming and sealing cartons and boxes

InactiveUS7591037B1Easy to closeEffectively and conveniently assistOpening closed containersStapling toolsCartonEngineering

A four-in-one multi-component combination tool which has a combination of four features all combined into one tool to facilitate enclosing cartons and boxes such as parcel packages and also has the added features of a box cutter to cut up unused boxes and also a marker to mark the box or package after it is enclosed. The invention includes a tape roll assembly, a built-in extendable and retractable blade knife which functions as a box cutter, a stapler and an extendable and retractable marker, which are integrated to effectively and conveniently assist in packaging activities.

Owner:ALVARADO BISWELL CARMEN

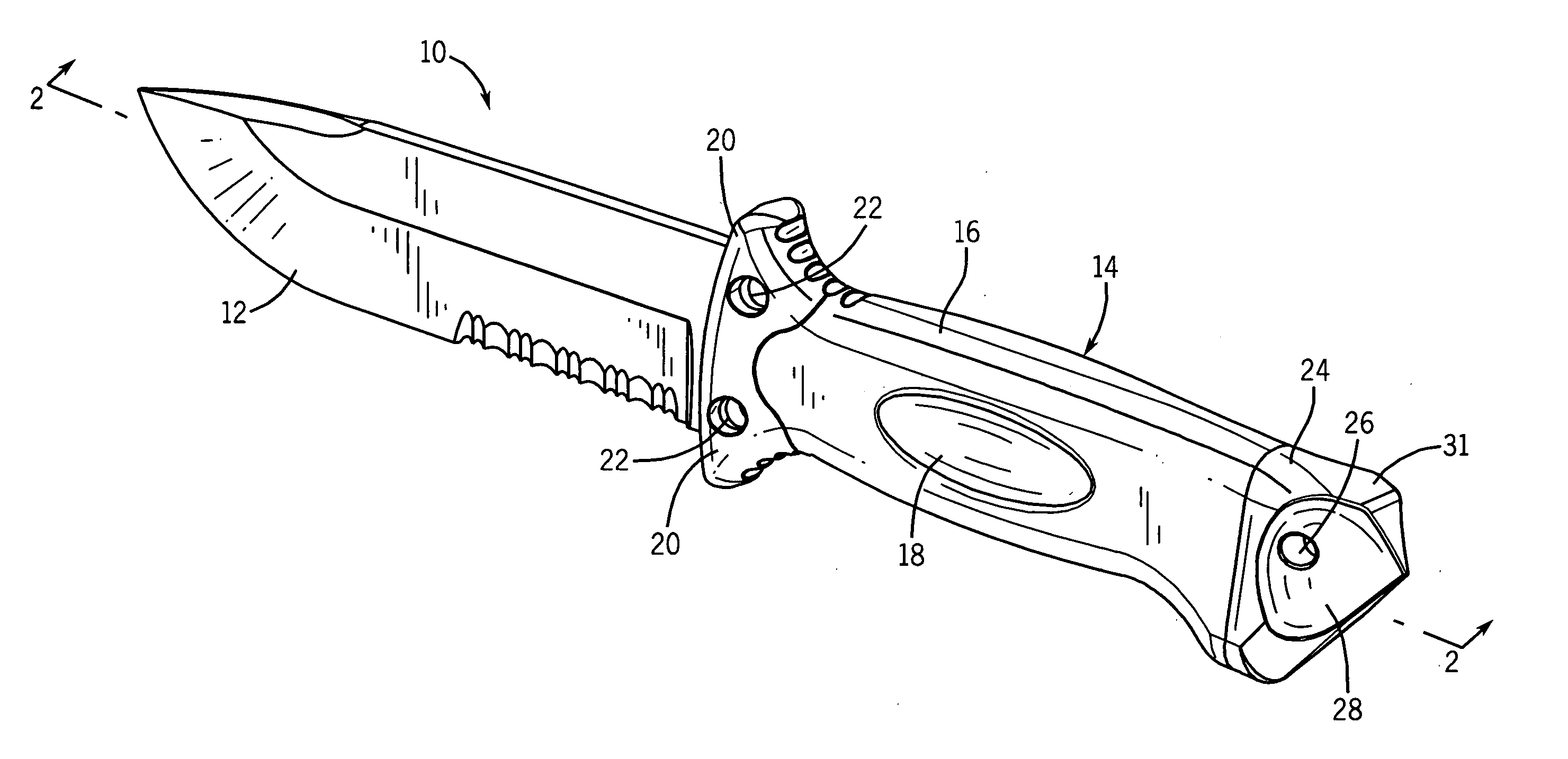

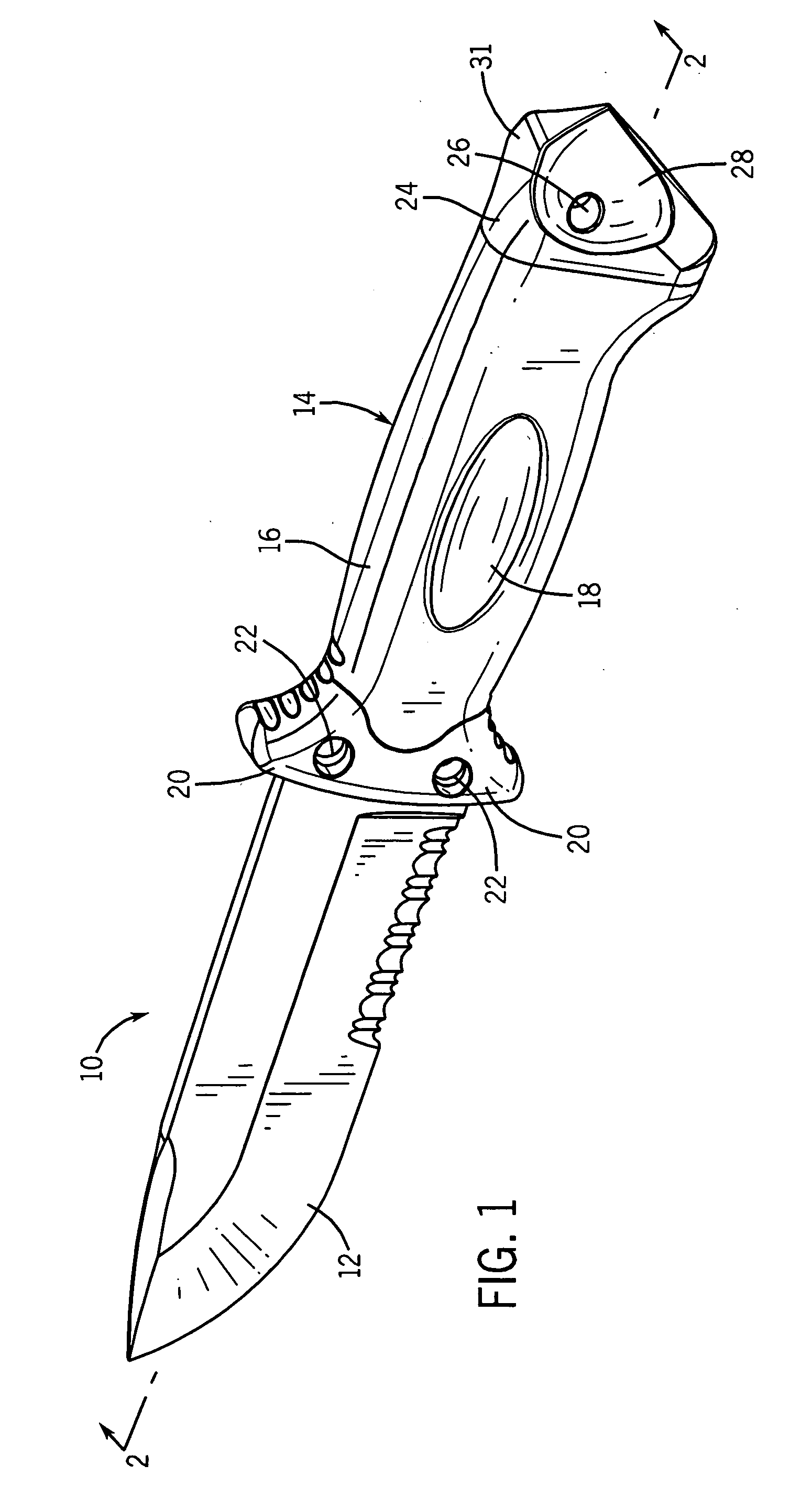

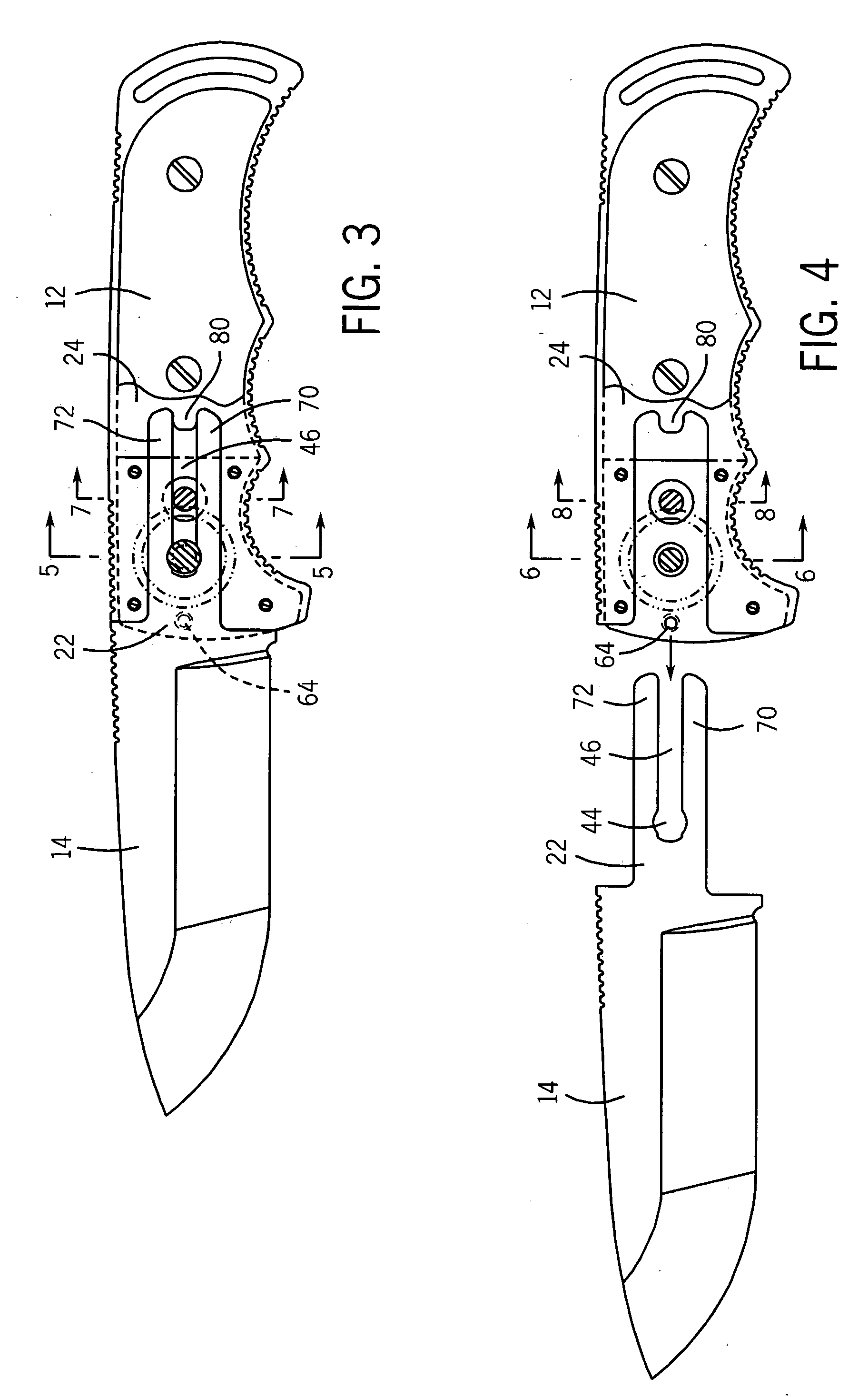

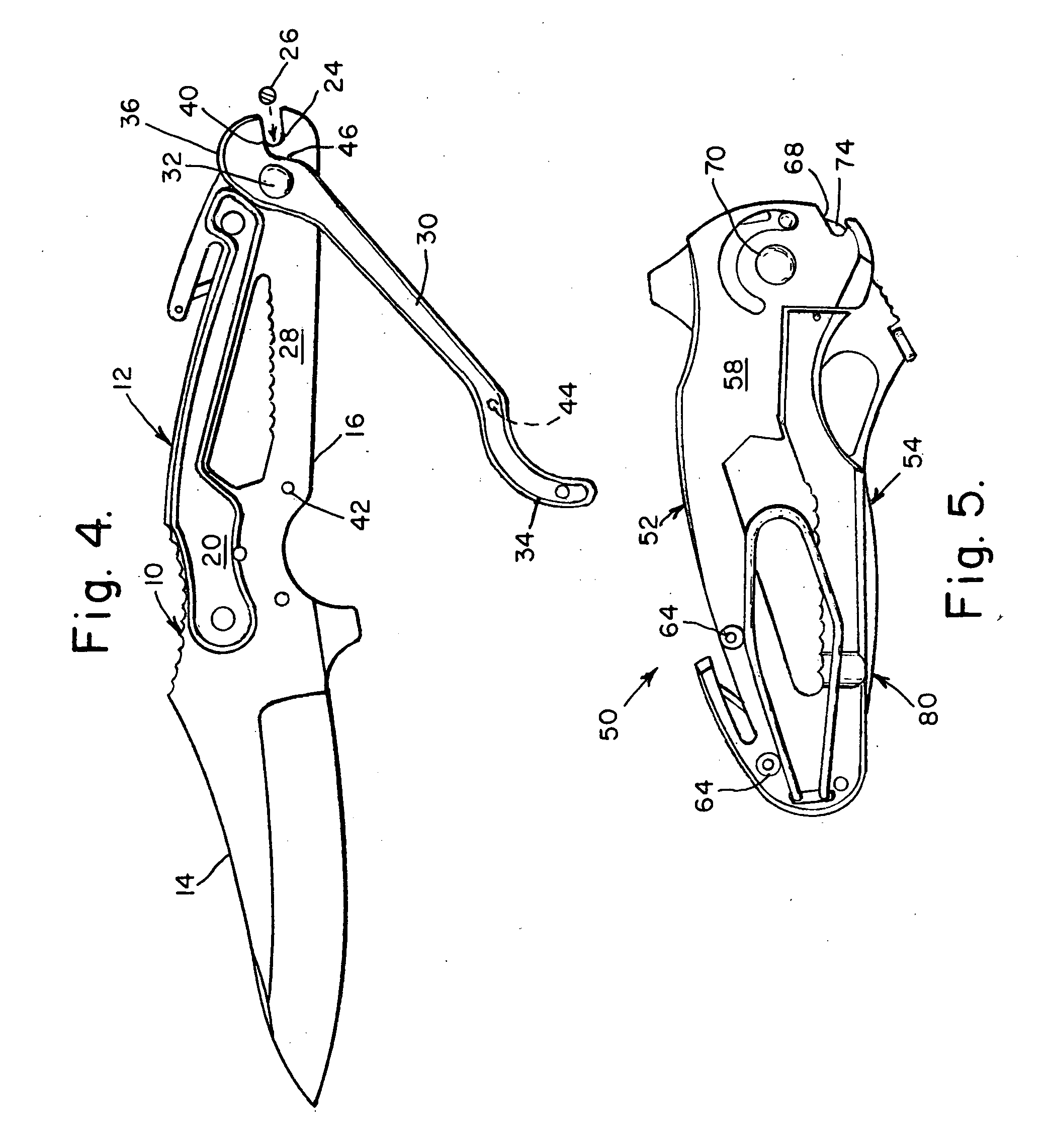

Fixed-blade knife having a multi-purpose guard

InactiveUS20090100683A1Stable knife handlingImprove gripThrusting weaponsWeapon componentsEngineeringKnife blades

A fixed-blade knife with a knife body comprising a blade having a cutting edge and an elongated handle exptending from the blade. A guard is pivotally coupled to the knife body and has a first and second position relative to the knife body. In other embodiments, the guard is slidably disposed along the knife body. In the first position, the guard is positioned adjacent the blade to at least partially cover the cutting edge. In the second position, the guard is positioned adjacent the handle to expose the cutting edge. A sharpening element may be disposed within the guard to hone and / or sharpen the cutting edge when the guard is pivoted relative to the cutting edge.

Owner:MASTRAD

Knives with wire cutter

InactiveUS20080110029A1Easily employable wire cuttingEasily employable wire cutting capabilityThrusting weaponsWeapon componentsEngineeringWire cutter

Combined knife and wire cutter apparatus including both fixed blade knife and folding knife embodiments. Both such embodiments comprise an elongate handle including at least one notch along an edge thereof for receiving a segment of a wire; and an elongate member pivotably secured to the handle and having a first end portion and a second end portion, the elongate member pivotable about a pivot axis in a first rotational direction with the first end portion moving away from the handle and in a second rotational direction with the first end portion moving toward the handle, the second end portion including a cutting edge situated for traversing the at least one notch when the elongate member is pivoted about the pivot axis.

Owner:SUREFIRE LLC

Graduated food-cutting knife and method of use thereof

A graduated blade knife, and a method of use thereof for cutting a selected quantity of solid soft-bodied foodstuff, the knife of the type comprising a handle, a blade integrally attached to and aligned with said handle, the blade defining an outer free tip, and graduated marks along said blade, said method comprising the steps of: a) flatly applying the knife blade against a flat surface of the soft foodstuff; b) sliding the knife along the soft-bodies foodstuff so as to align the blade graduated marks on the soft foodstuff according to the selected quantity of foodstuff to be cut; c) pivoting the knife around the blade tip so that the blade becomes transversely positioned relative to the soft foodstuff; d) transversely driving the knife blade into the soft foodstuff until the blade extends completely through the soft foodstuff; e) pivoting the knife around the knife blade tip so as to cut the soft foodstuff along a cutting line; and f) cutting the selected quantity out of the soft foodstuff according to the cutting line made in step (e).

Owner:GOSSELIN DENIS

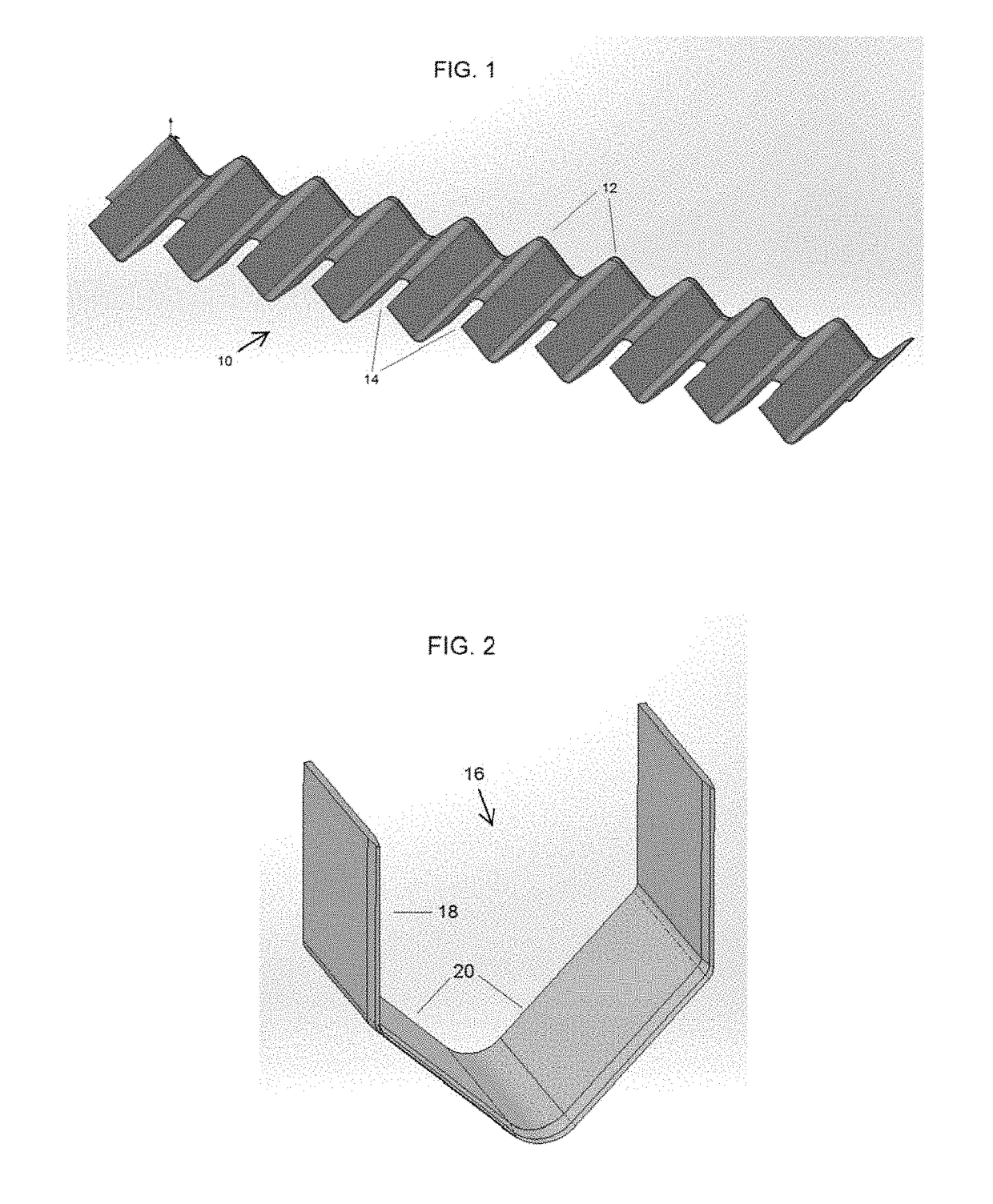

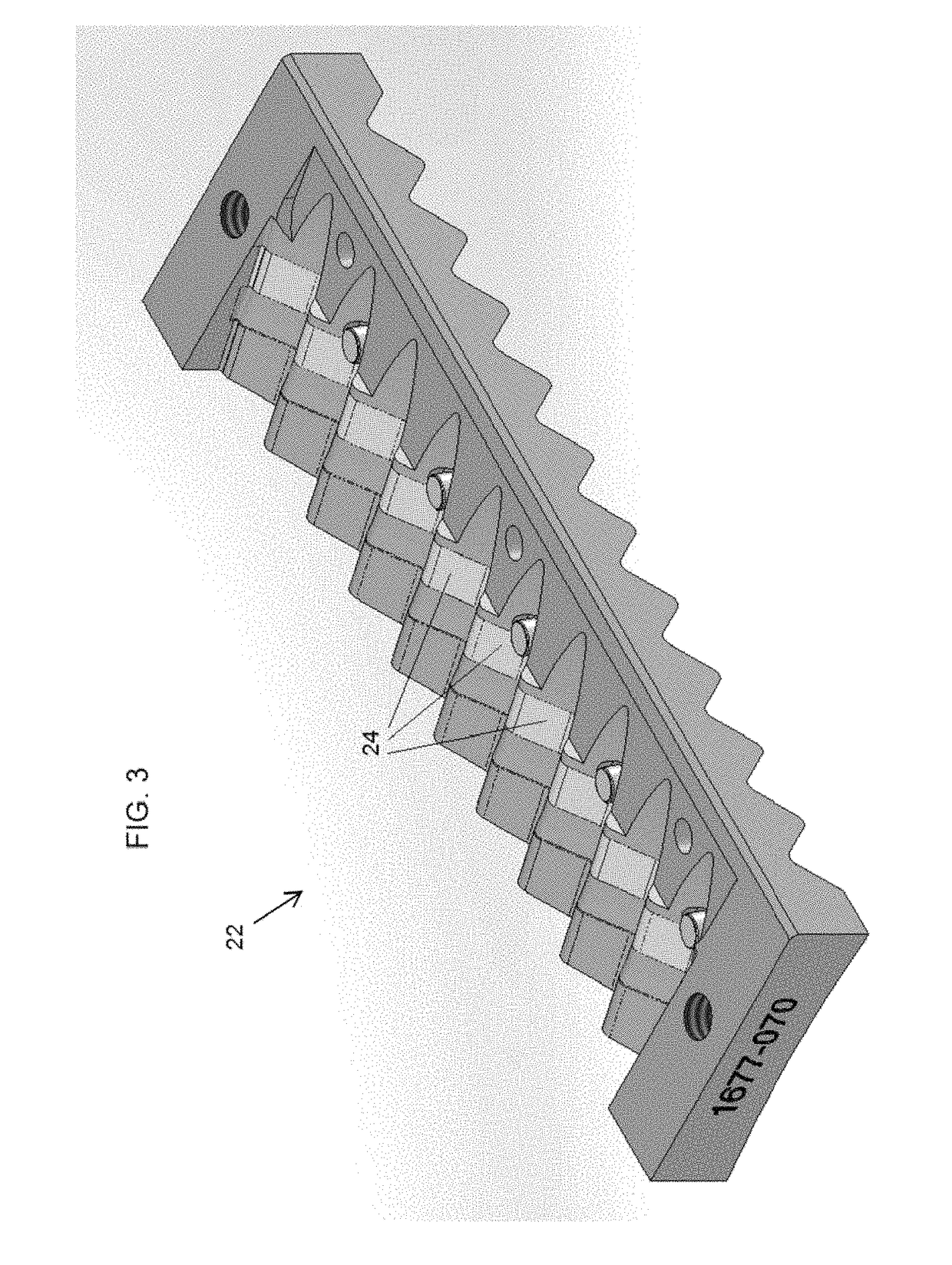

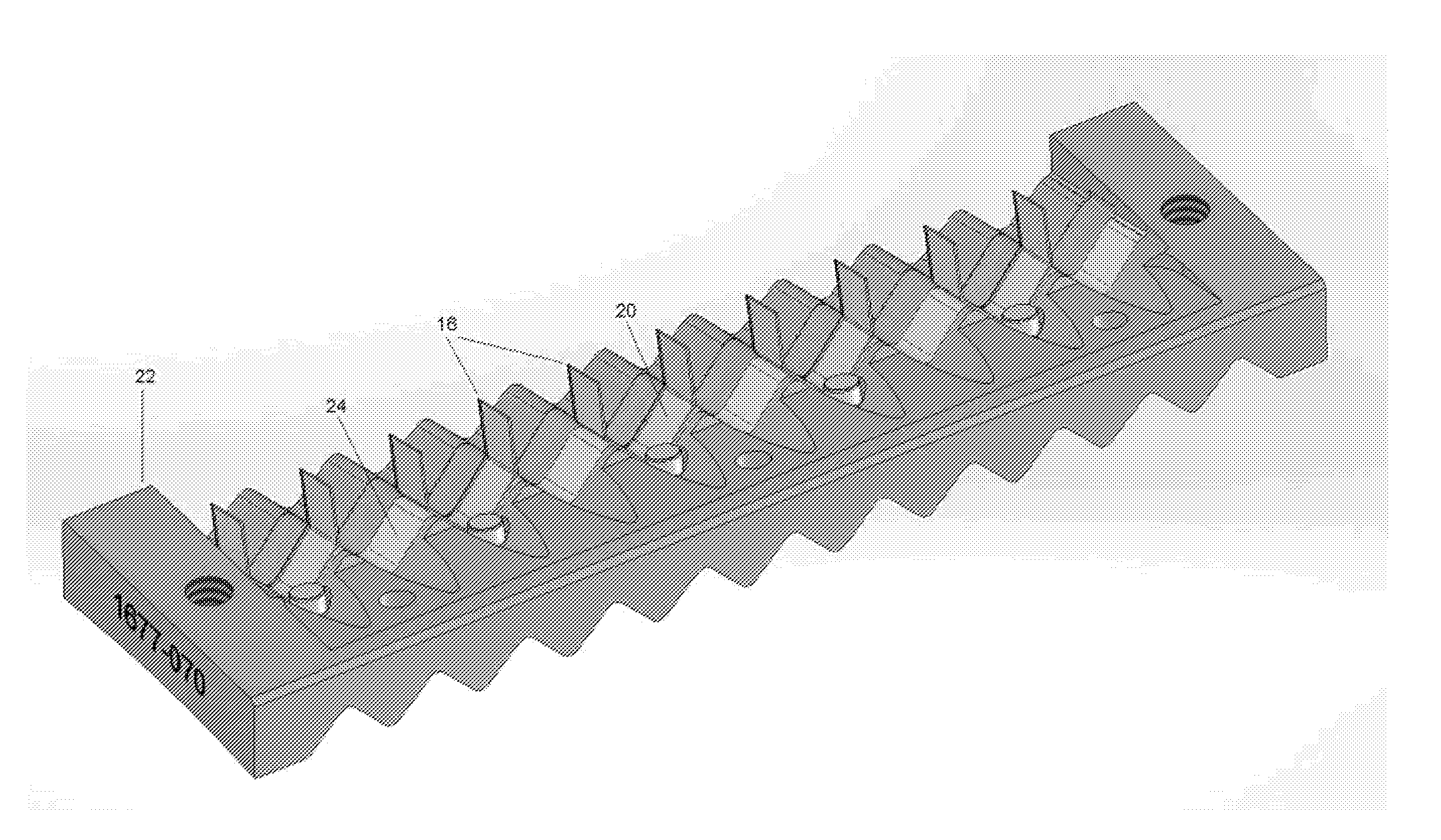

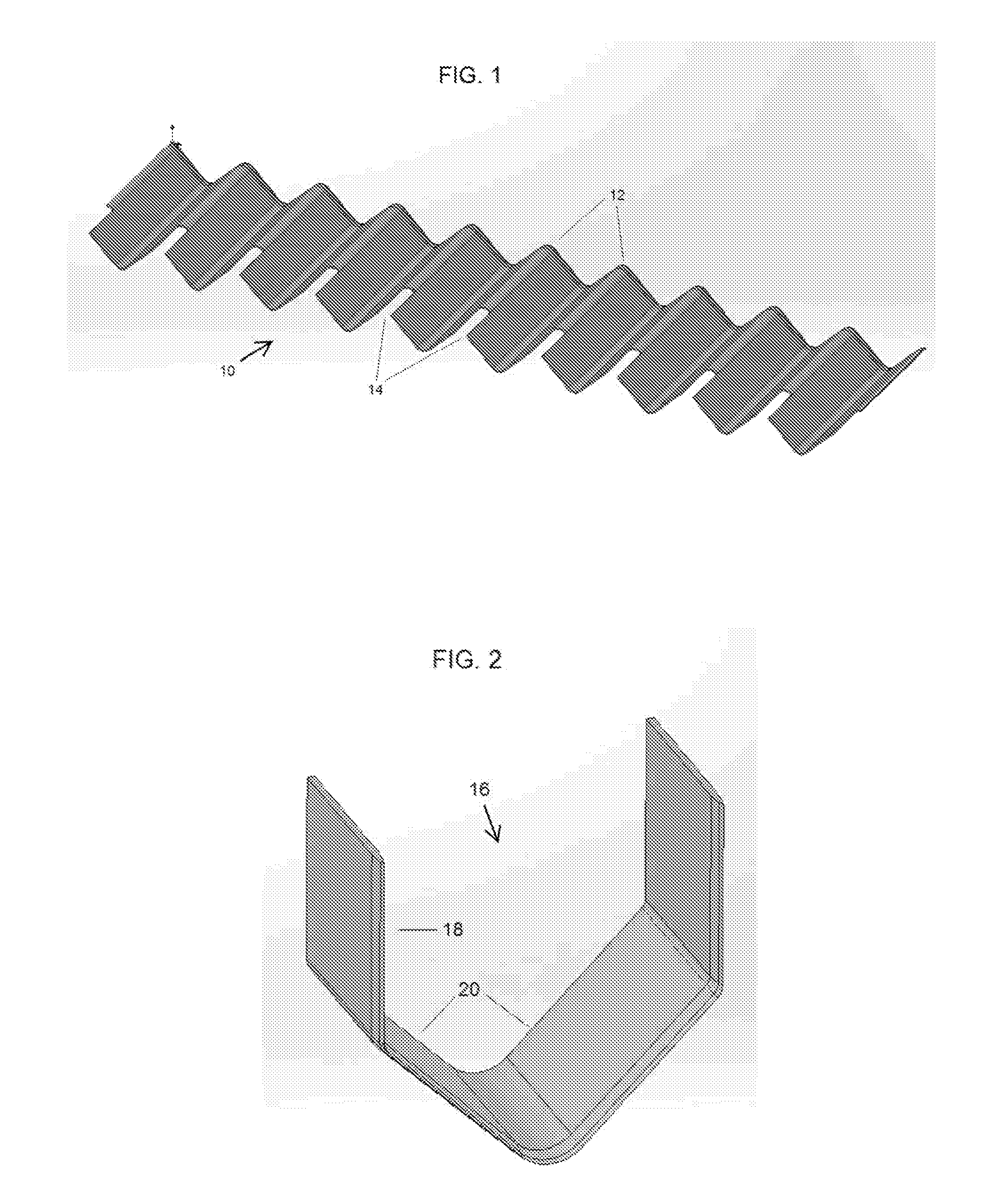

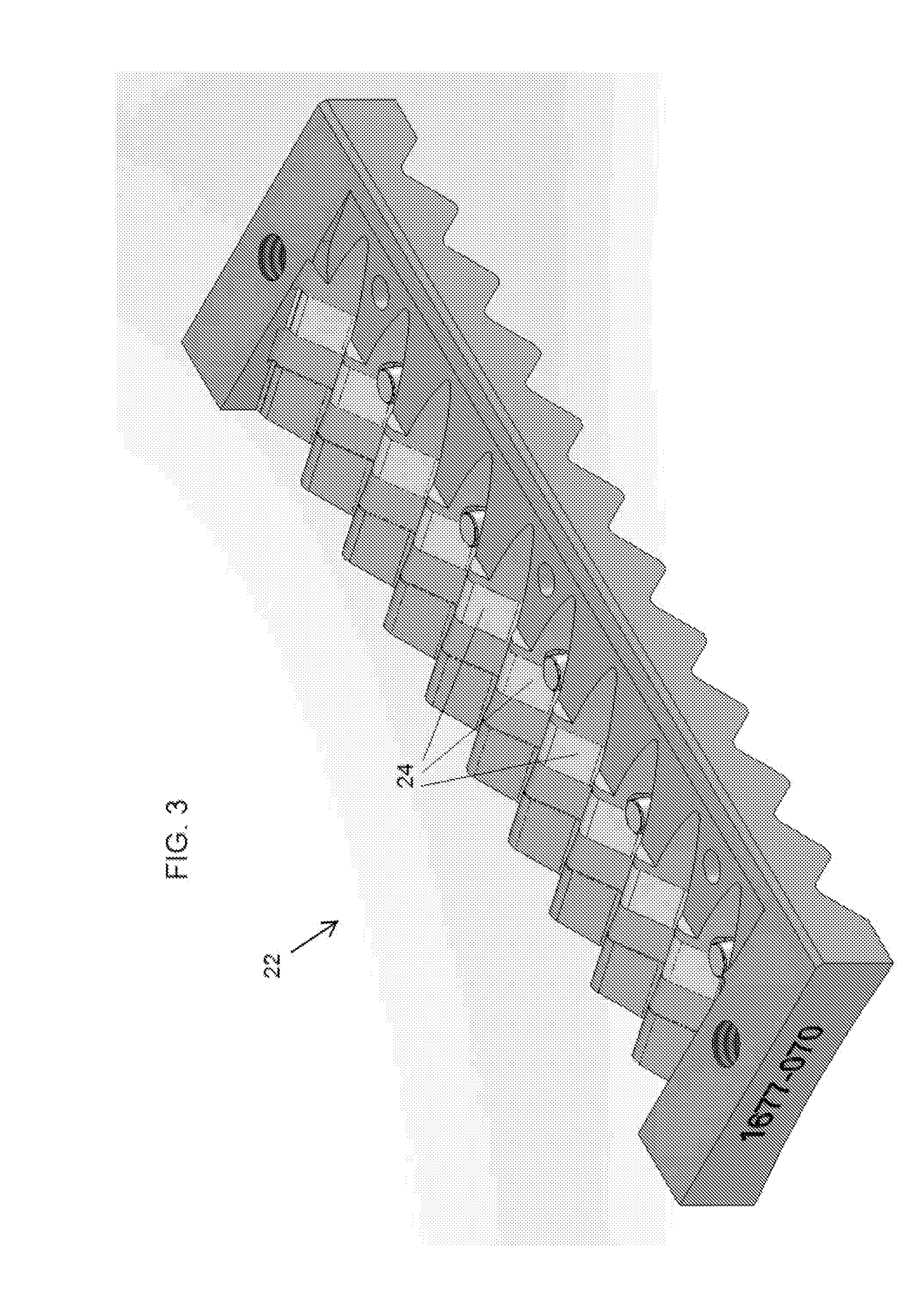

Knife assembly with tab blade

Knife assemblies and methods therefor that are adapted to be used with a cutting apparatus capable of producing a variety of shaped food products having large amplitudes, for example, sliced, shredded, and strip-cut food products. The knife assembly includes a primary blade having a corrugated shape to produce a large-amplitude food product slice having a periodic shape, and at least one tab blade assembled with or formed from the primary blade to cut a food product slice into strips.

Owner:URSCHEL LAB

Fixed-blade knife having a multi-purpose guard

InactiveUS8117754B2Improve gripPrevent slippingThrusting weaponsWeapon componentsEngineeringBlade knife

A fixed-blade knife having a knife body. The knife body has a blade with a cutting edge and an elongated handle extending from the blade. A guard is pivotally coupled to the knife body and adapted to be actuated between an open position and a closed position. The guard has an external surface that is ergonomically configured for handling the knife when the guard is in the open position. In the open position, the guard is positioned adjacent the handle to expose the cutting edge. In the closed position, the guard is positioned adjacent the blade to cover the cutting edge.

Owner:MASTRAD

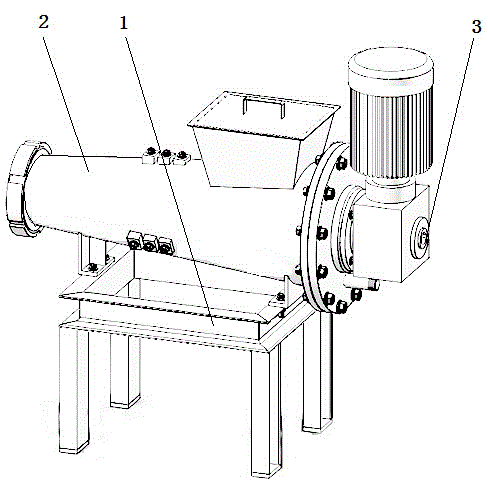

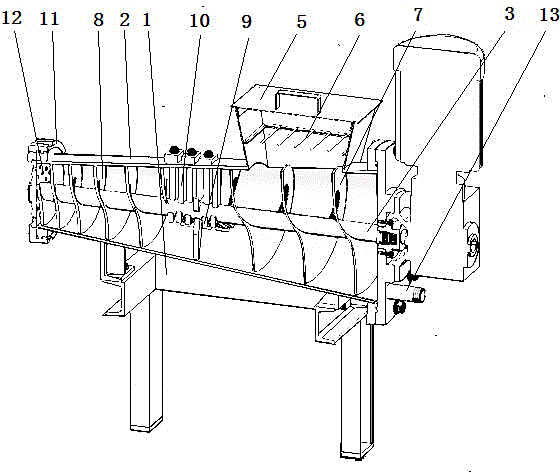

Crushing press used in kitchen

ActiveCN104437771ANovel structureEasy to useSolid waste disposalGrain treatmentsHelical bladeExpeller pressing

The invention discloses a crushing press used in a kitchen. The crushing press comprises a rack, a barrel, a transmission shaft and a power source, wherein a screw blade knife is arranged on the transmission shaft. The crushing press is characterized in that an intercepting grid is horizontally arranged on a feeding hopper at the upper end of the barrel; the barrel is in a conical shape; the diameter of the barrel is gradually reduced from the feeding end to the discharge end; a liquid outlet is formed in the bottom of the large-diameter end of the barrel, liquid of pressed and crushed materials flows to the liquid outlet through the gradient of the barrel, and is discharged through the liquid outlet, and thus the target of automatically discharging liquid is achieved; the screw blade knife on the transmission shaft is a screw blade with a conical gradual changing pitch; and the outer diameter conicity of the screw blade is the same as that of a taper clearance in the inner wall of the barrel, so that leftovers are crushed and pressed out under the variable pitch action of the screw blade knife. The crushing press has the advantages of being novel in structure, convenient to use, free of blockage, high in crushing and pressing efficiency, reliable in performance, fast to install and the like.

Owner:SHANDONG SHUANGLUN

Knife assembly with tab blade

Knife assemblies and methods therefor that are adapted to be used with a cutting apparatus capable of producing a variety of shaped food products having large amplitudes, for example, sliced, shredded, and strip-cut food products. The knife assembly includes a primary blade having a corrugated shape to produce a large-amplitude food product slice having a periodic shape, and at least one tab blade assembled with or formed from the primary blade to cut a food product slice into strips.

Owner:URSCHEL LAB

Multi-use broad bladed knife

In accordance with the present invention, a multi-use broad bladed knife is provided. The multi-use knife includes a broad blade, such as commonly used to apply spackle to a wall or other surface. The broad blade is attached to a handle, with a striking surface comprised of an appropriate hard material on the heel of the handle. Within the handle are slidably extendable and retractable implements, including a cutting edge and a screwdriver implement. The cutting edge and screwdriver implement may be extended through the heel of the handle through slits using buttons. The screwdriver implement and cutting edge may lock into place when extended for use and may also lock in place when retracted within the handle.

Owner:STUBBS SHAWN

Combination dual blade knife

A knife is provided. The knife comprises a handle and a utility blade mounted to a blade holder, the blade holder mounted to the handle and configured to move relative to the handle between a retracted position, in which the utility blade does not extend from the handle, and an extended position, in which the utility blade extends from the handle in an operative position. The knife further comprises a tanto-style blade mounted to the handle and configured to move relative to the handle between a closed position, in which a cutting edge of the tanto-style blade does not extend from the handle, and an open position, in which the tanto-style blade extends from the handle in an operative position.

Owner:JPJ INVESTMENT HLDG

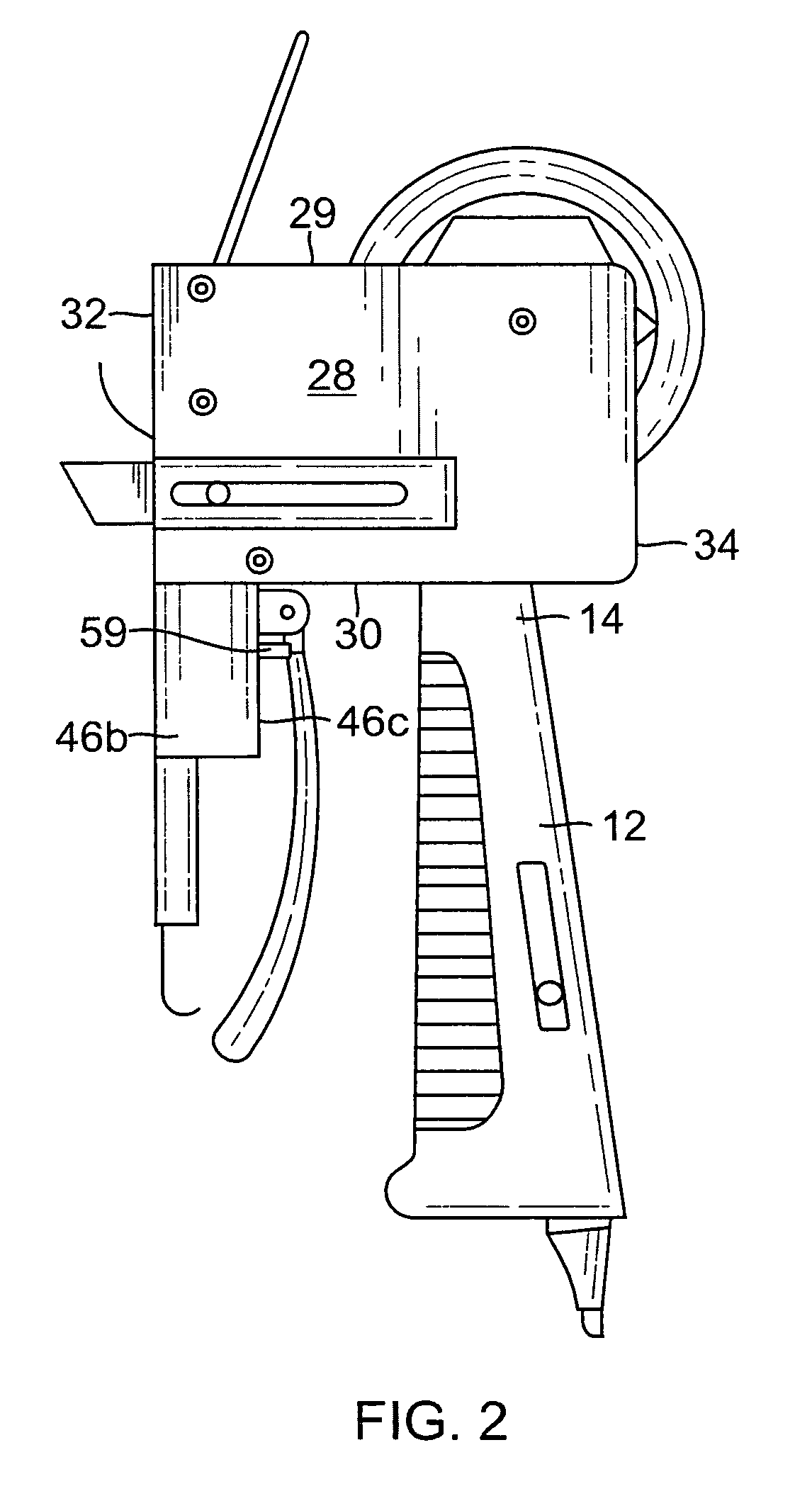

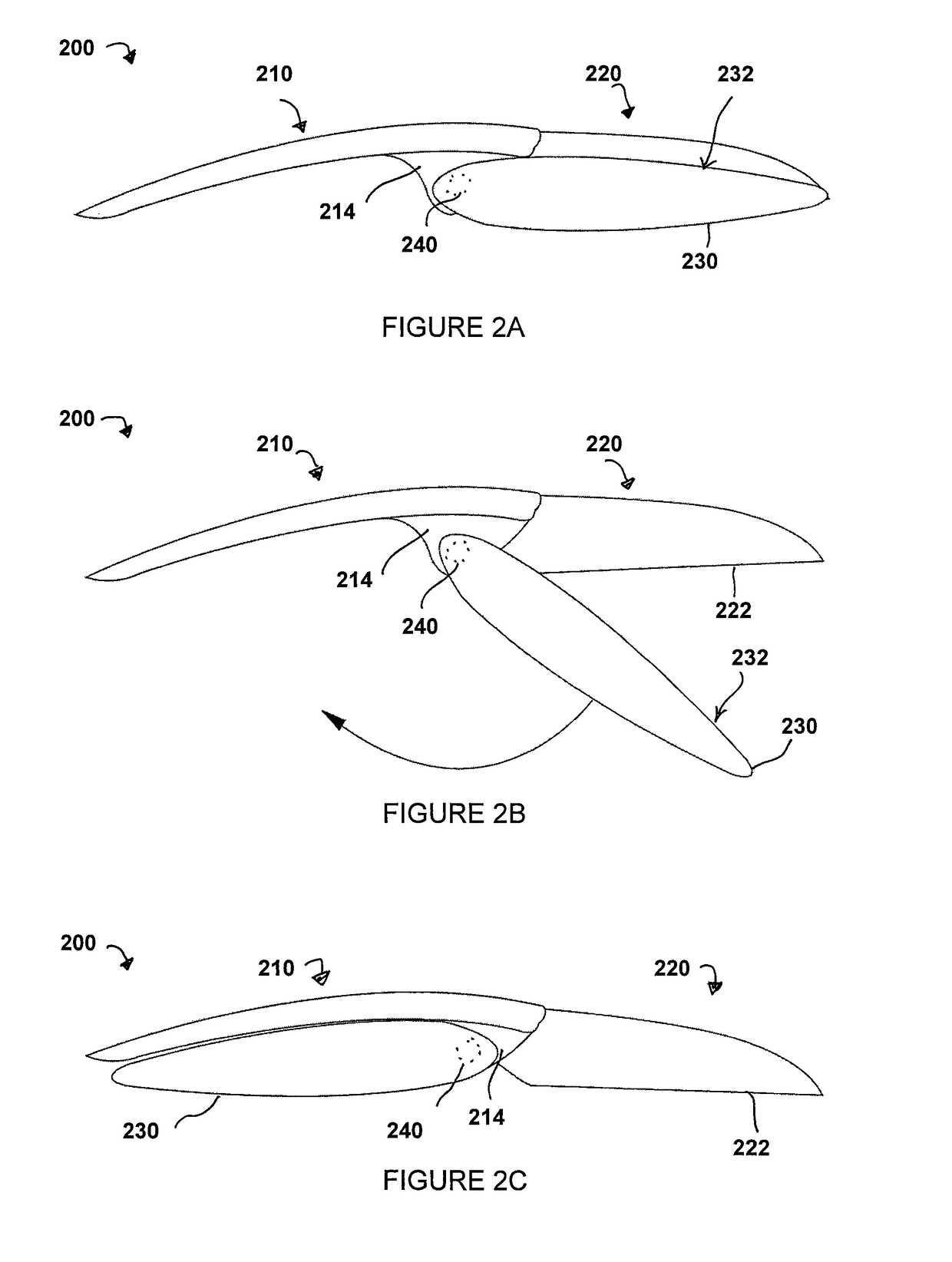

Easy opening of film wrapper

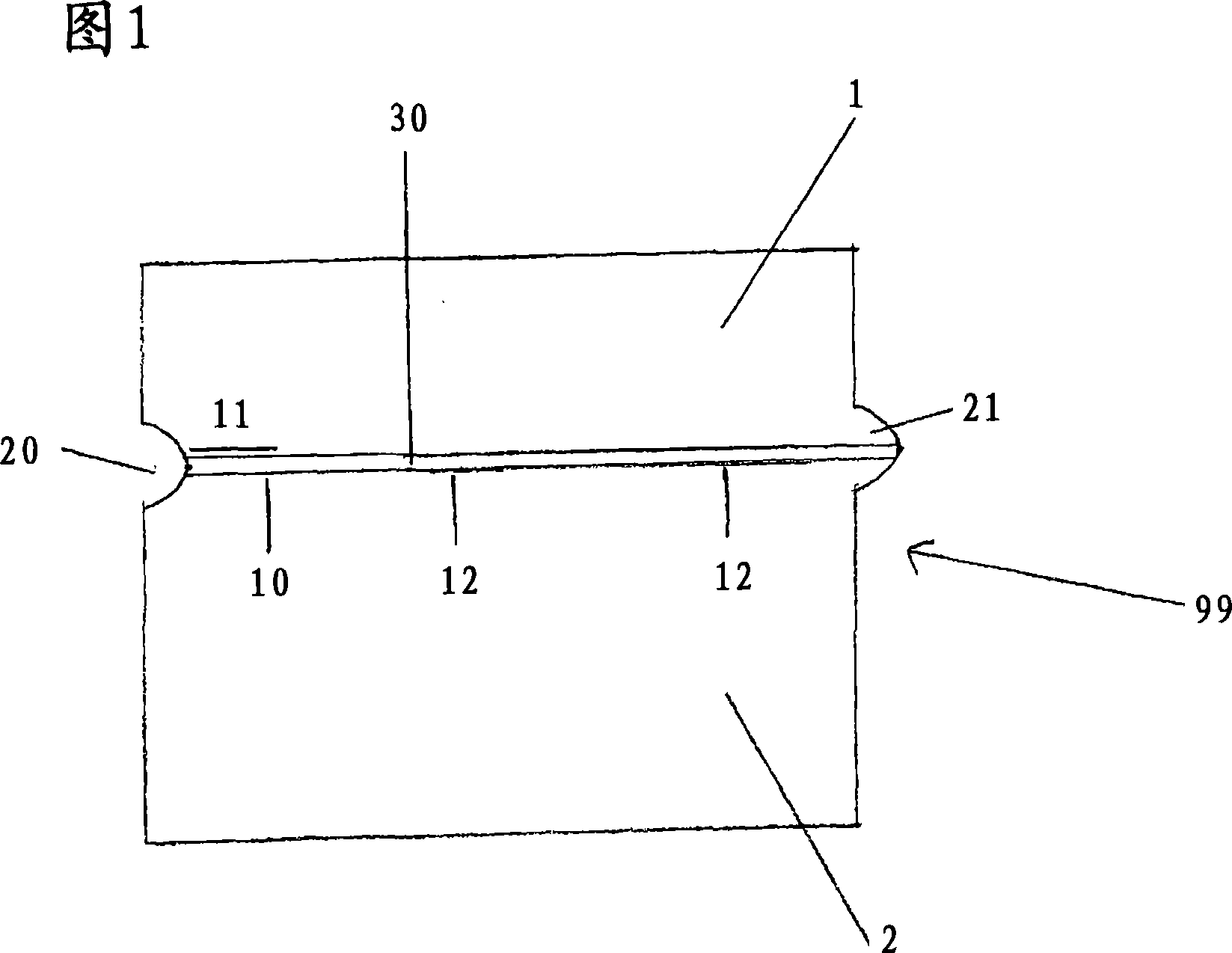

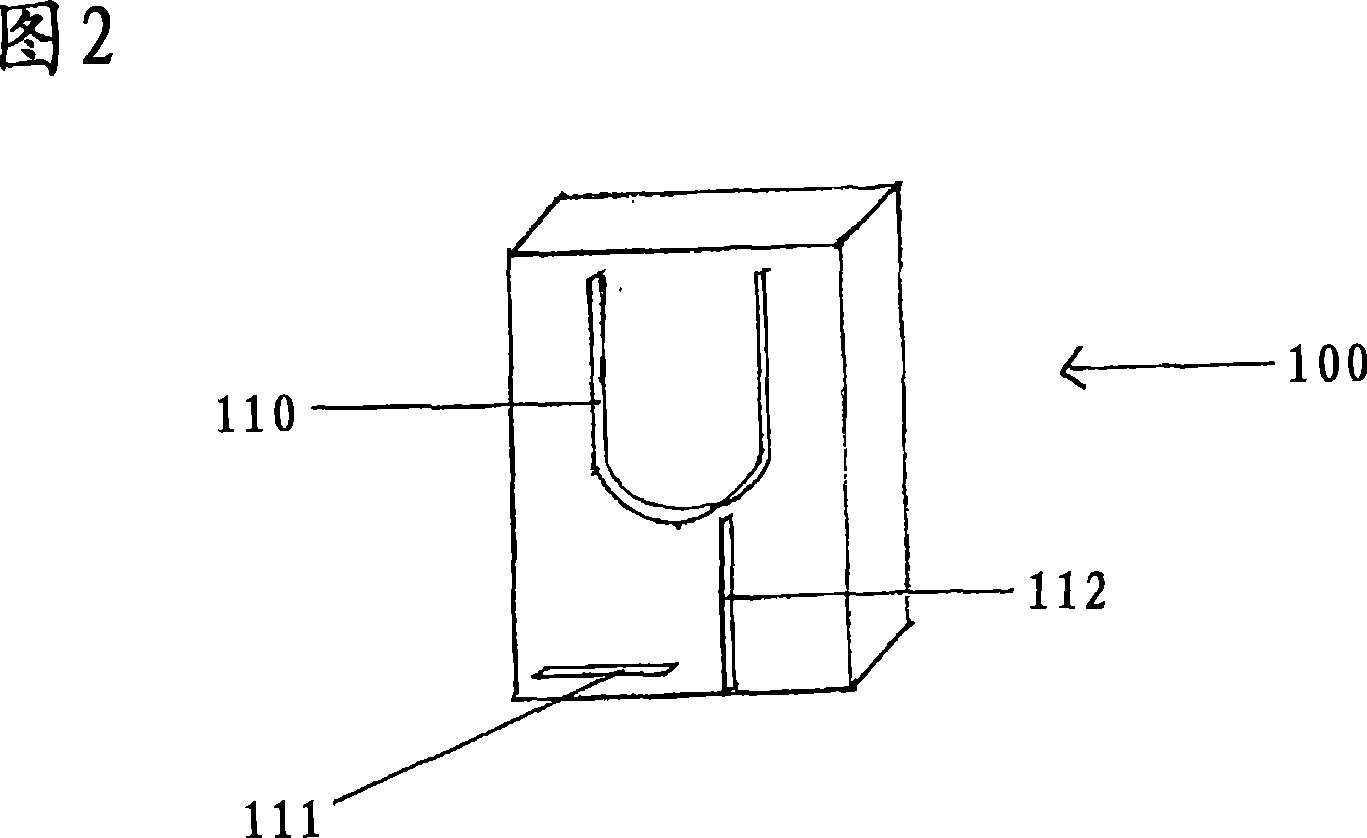

A film wrapper (99) comprises a tear tape (30) and at least one weakening line (10, 12) next to the tear tape (30) , the longitudinal axis of the at least one weakening line (10, 12) being substantially perpendicular to the tear tape (30) (perpendicular weakening lines (10, 12)) . An article is wrapped into the film wrapper. A multi- bladed knife (100) used for producing the film wrapper comprises a U-shaped or V-shaped first blade (110) and a second linear blade (112) parallel to the longitudinal axis of said first blade (110) and a third linear blade (111) perpendicular to the longitudinal axis of the first blade (110) .

Owner:PHILIP MORRIS PROD SA

Battery powered knife

InactiveUS20090038164A1Protection from damageImprove gripMetal working apparatusEngineeringKnife blades

A battery powered dual blade knife that includes a handle having an interior cavity for containing one or more batteries. The batteries can be removably positioned at the rear portion of the handle. The cavity of the handle includes an electric motor that is generally positioned in the front region of the handle. A pair of blades is connected to the front portion of the handle and is designed to be moved relative to one another by the electric motor. The handle can be designed to waterproof one or more internal components of the knife to protect the one or more internal components from water damage. The knife can include a blade stabilization arrangement for the knife blades and / or mounts for the knife blades to facilitate in the movement of the knife blades and / or mounts for the knife blades when the motor causes the knife blades and / or mounts for the knife blades to move relative to one another. The knife can include an enhanced motor configuration in improve the operation of the knife.

Owner:INNOVATION DIRECT

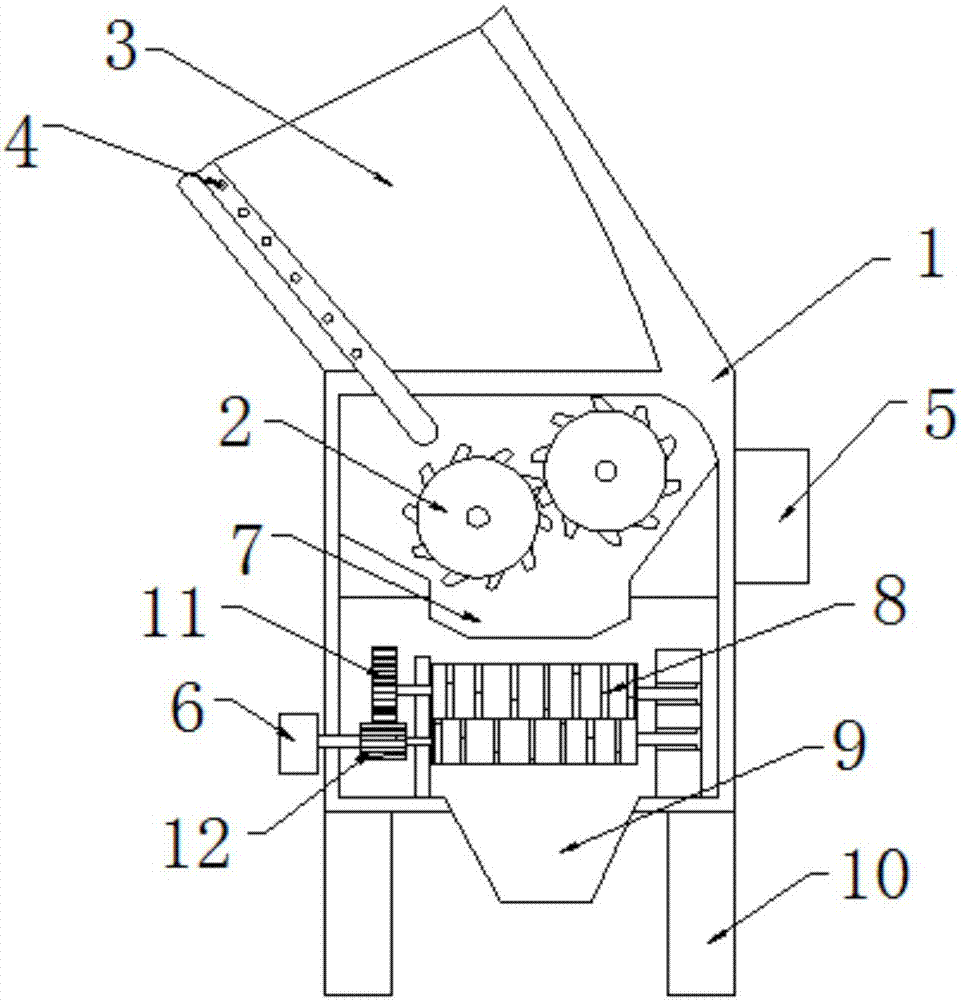

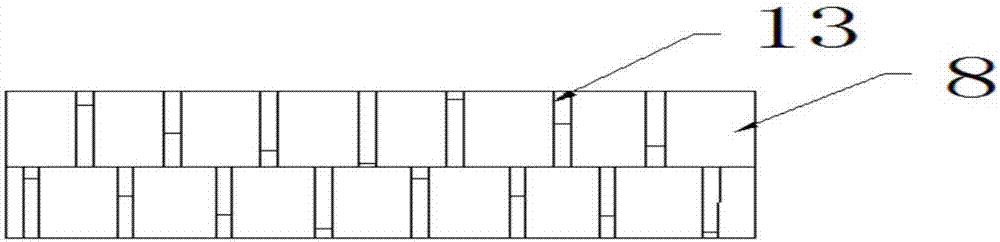

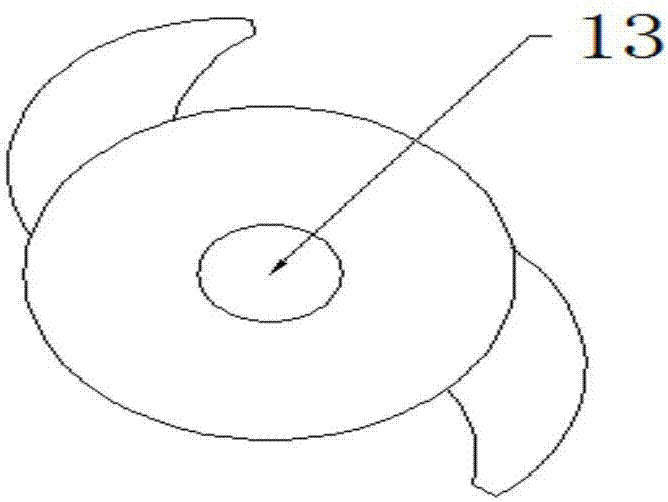

Scrap steel crushing device

The invention discloses a steel scrap crushing device, which comprises a main body, a first crushing knife roller set and a second crushing knife roller set, a feeding port is arranged directly above the main body, and the first crushing knife roller set is installed on the main body The upper end of the inner cavity, the front end of the feed port extends obliquely to directly above the first crushing knife roller set, the second crushing knife roller set is fixedly installed directly below the first crushing knife roller set, and the first crushing knife roller set A material guide channel is set between the crushing knife roller set and the second crushing knife roller set, and a first motor is fixedly suspended on the outer wall of the upper end of the main body, and the first motor rotates with the first crushing knife roller set through gear transmission. The second motor is fixedly installed on the outer wall of the lower end of the main body, and the second motor is connected with the second crushing knife roller group through a large gear and a pinion. The invention is simple in operation, and adopts a multi-stage cutting and crushing method to cut and crush scrap steel in all directions, and the crushing is sufficient and thorough.

Owner:LIANGXI HAOXING IND DESIGN OFFICE

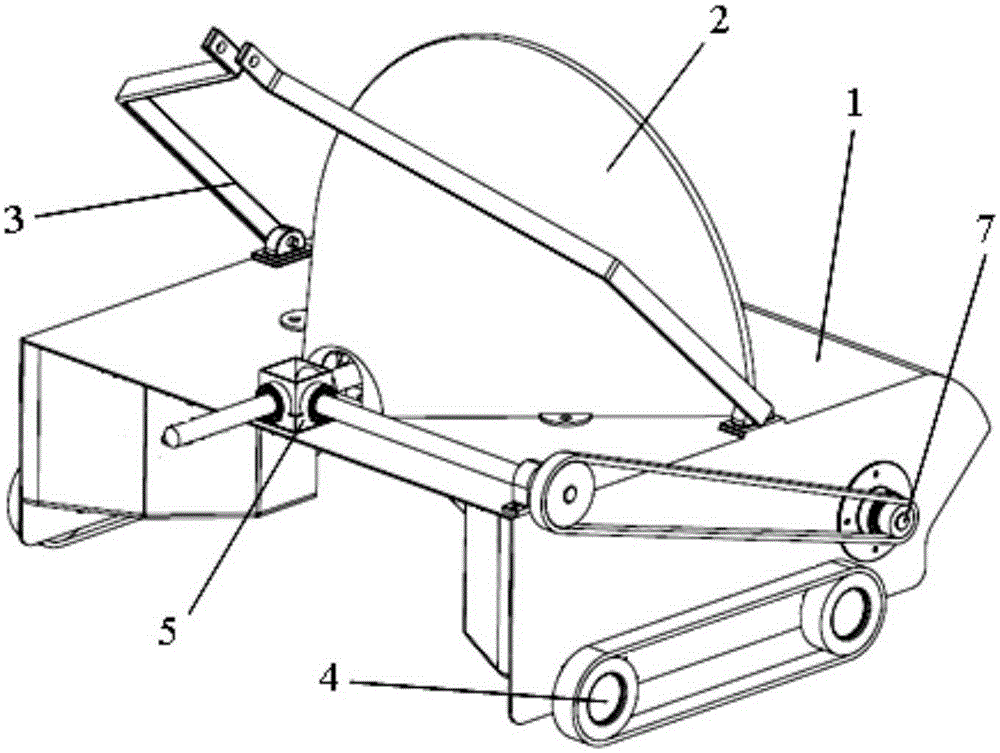

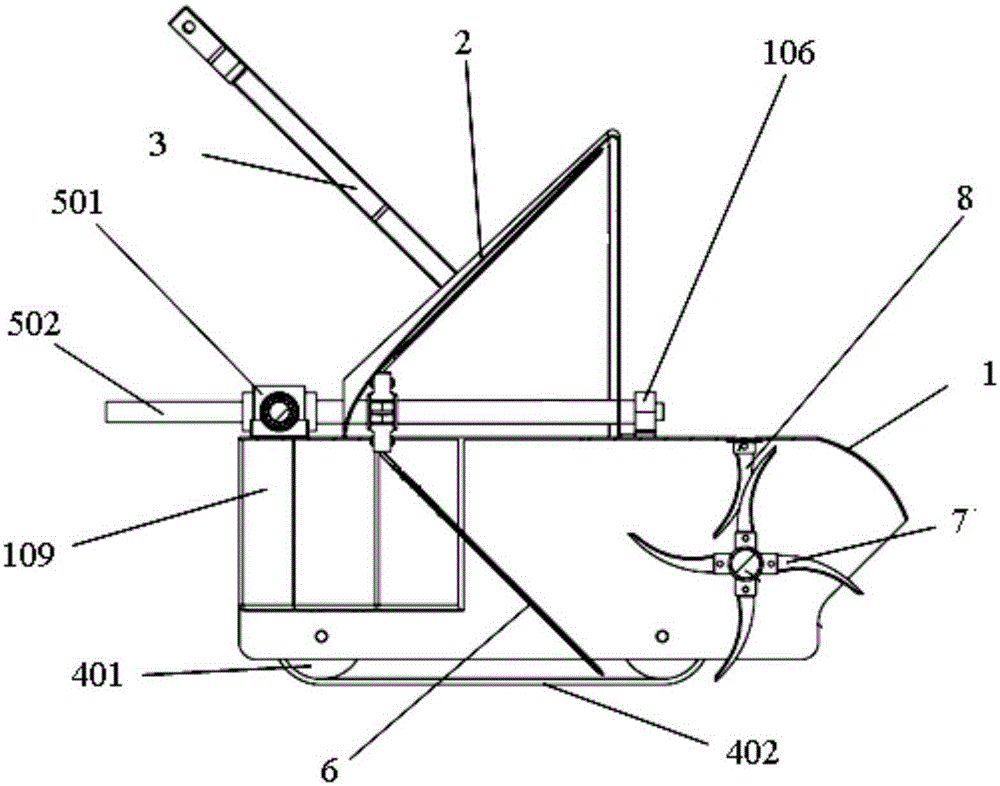

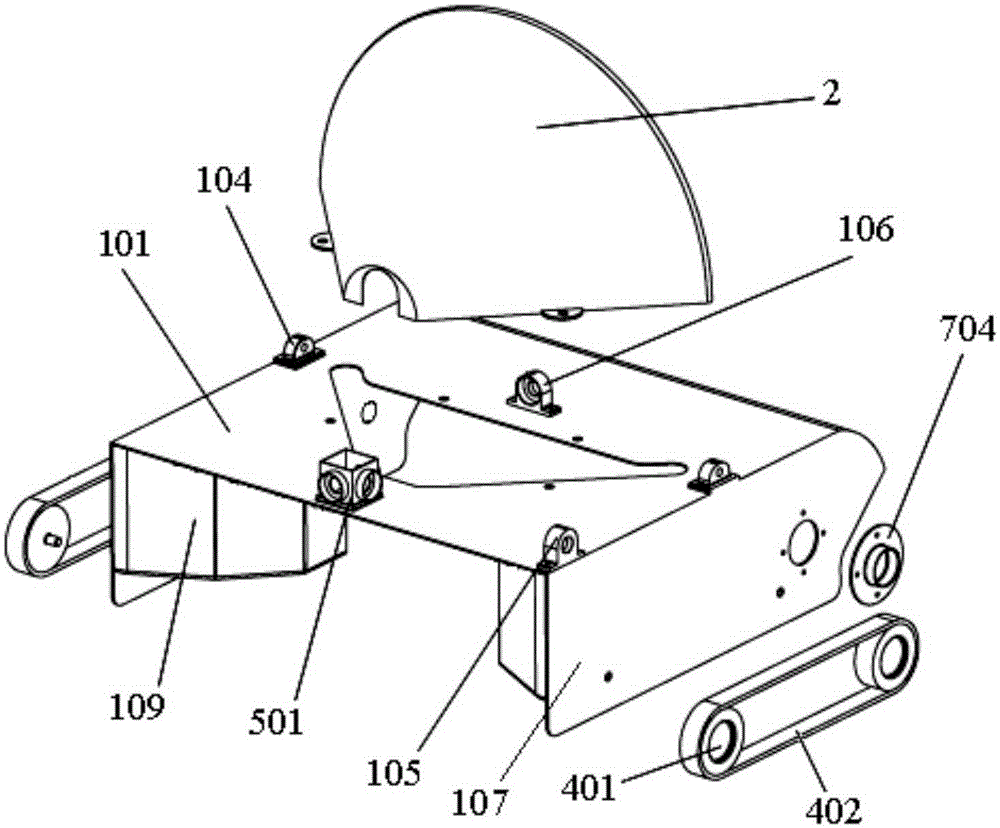

Blade knife pre-cutting type banana stem shattering and returning machine

InactiveCN105165266AReduce tanglingAvoid pollutionCrop conditionersMowersHobbingAgricultural engineering

The present invention belongs to the technical field of agricultural machinery, and relates to a blade knife pre-cutting type banana stem shattering and returning machine. The machine is composed of a hitching device, a blade knife pre-cutting device, a shattering device and a marching device, wherein the shattering device is composed of a hobbing cutter device and a fixed cutter device. Power of a tractor is transmitted through a transmission device individually to the blade knife pre-cutting device and the hobbing cutter device of the shattering device, precutting and segmenting of banana stems are completed by the blade knife pre-cutting device, and then shattering of the banana stems is completed through a bisection action of the hobbing cutter device and the fixed cutter device of the shattering device. With adoption of rotary cutting of blade knives of the blade knife pre-cutting device and the bisection action of the hobbing cutter device and the fixed cutter device, shattering of the banana stems is realized, filament winding is reduced, the shattering efficiency is high, shattering and returning of the banana stems can be completed in a high-efficiency and low-energy-consumption manner, pollution to the environment by the waste banana stems is prevented, and the machine is applicable to banana stem shattering and returning in banana main producing areas.

Owner:HAINAN UNIVERSITY

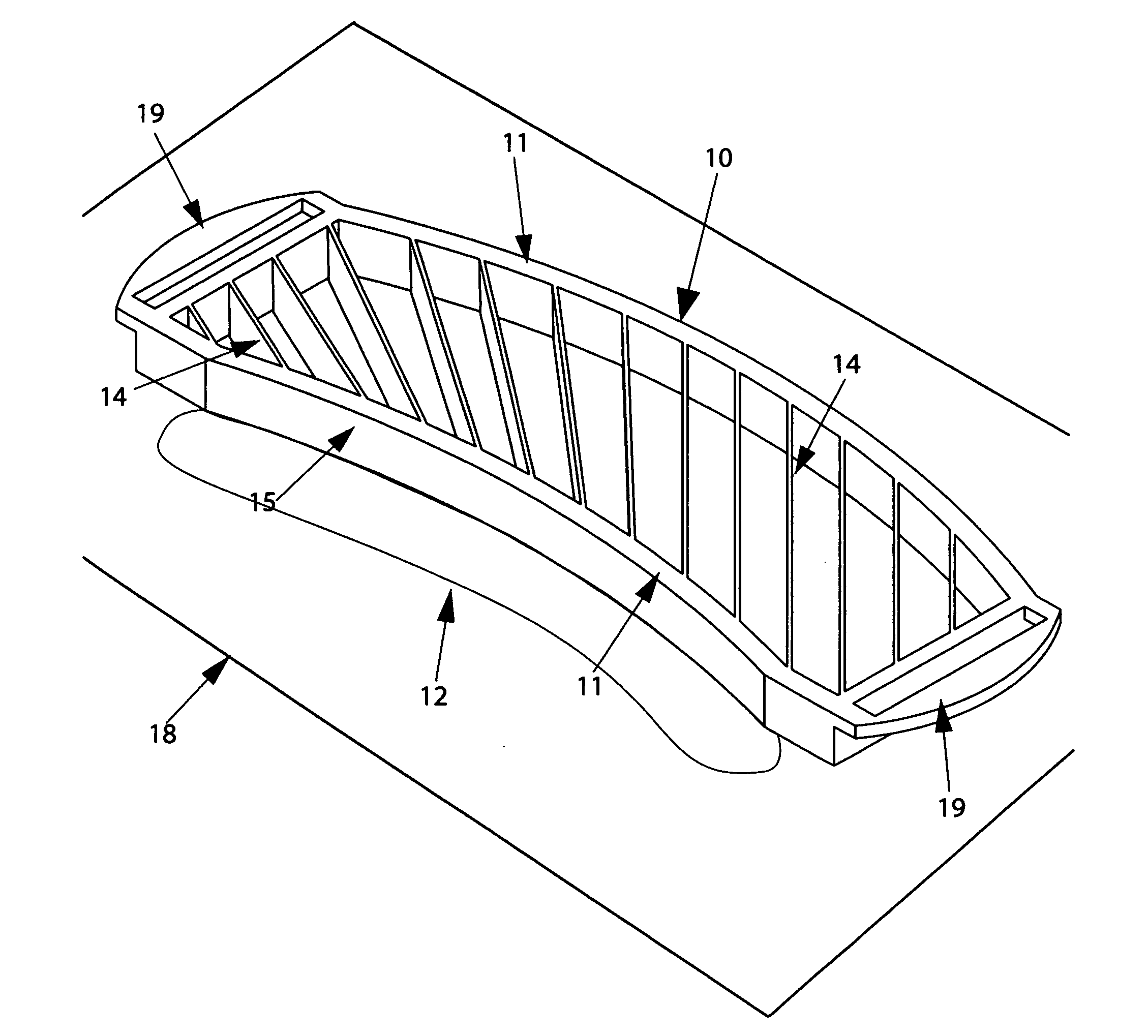

Plantain slicer

InactiveUS20100011973A1Easy to prepareSimple working processFruit stoningGrain treatmentsDiagonalEngineering

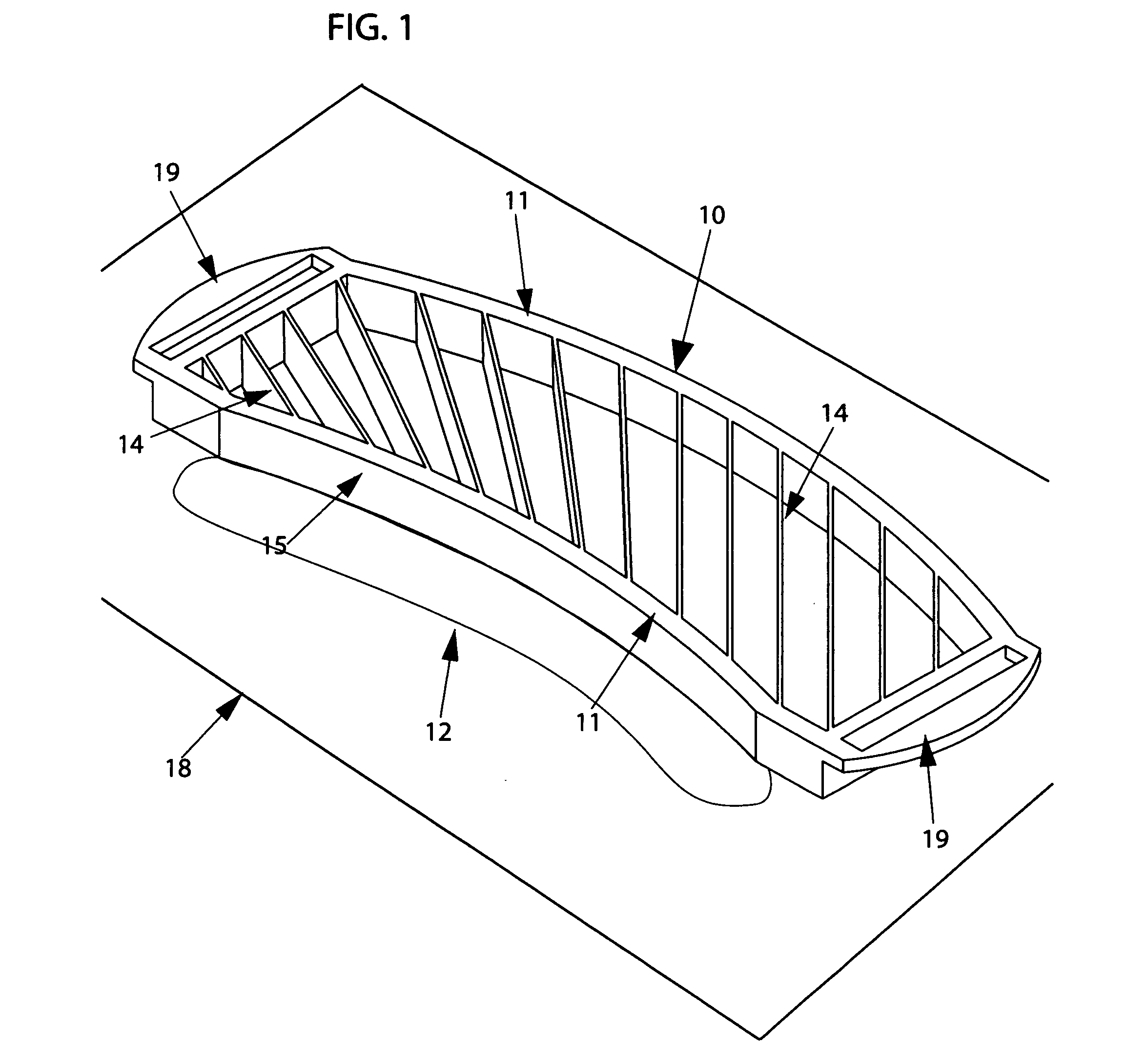

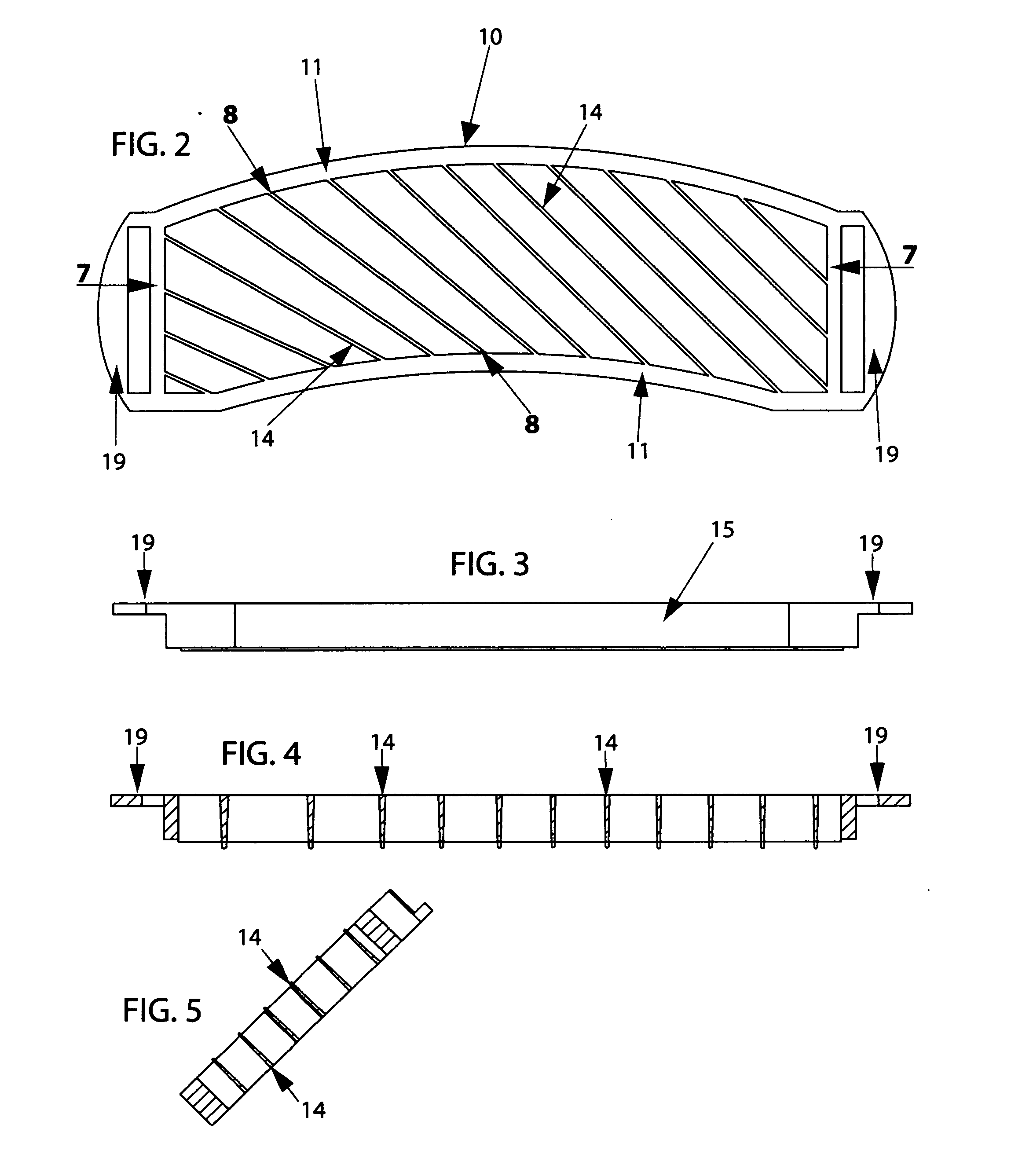

A utensil or tool specifically adapted for manually slicing ripened plantains, overcoming the previous method of a single blade knife, producing one slice at a time. The plantain slicer includes a frame which encompasses an area generally conforming to the shape and size of a typical plantain as well as other similar shaped vegetables and fruits. The frame has two opposing arched longitudinal sides which are interconnected with a multitude of spaced, substantially parallel arranged ribs, set at a diagonal. The ribs are sufficiently thin to cut diagonally through a pealed ripened plantain, vegetable and fruit. The user will have the ability to grasp the utensil by the handles which are located at each end of the frame and slice through the plantain by pushing down. The end result is uniform diagonal slices in one single action, allowing for even cooking. Openings in the handles permit the hanging of the utensil for storage.

Owner:KOVACS MARIANELA

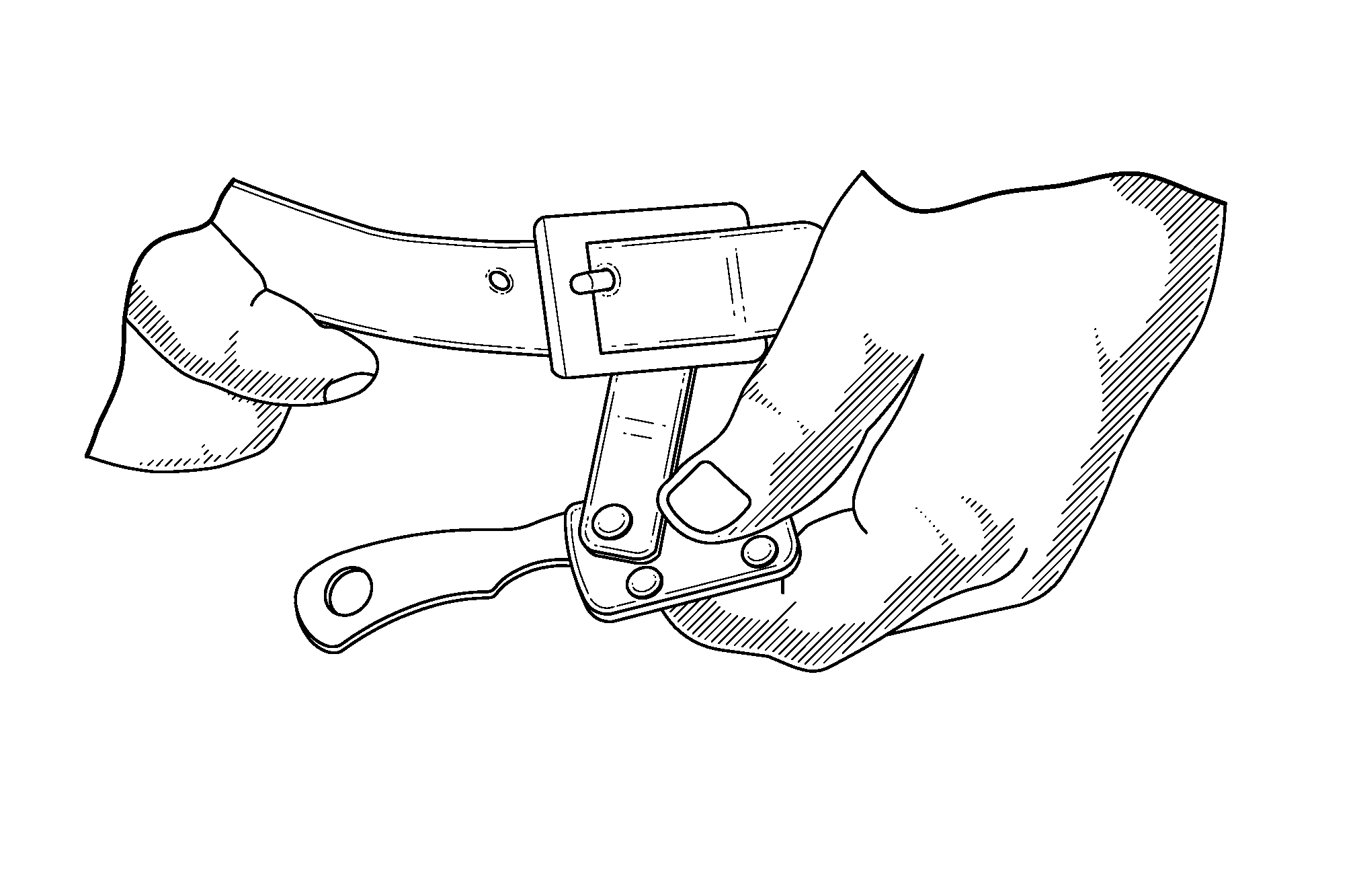

Concealed knife system

A method of concealing a fixed blade knife inconspicuously behind a trouser belt utilizes a rotating sheath connected by a strap to the tongue of the belt buckle. The sheath is concealed behind the belt by pushing it upward into alignment with the strap and is deployed by pushing it downward out of alignment with the strap. The knife is curved so as to conform to the contours of the wearer's waist.

Owner:VANHETEREN WILLIAM J

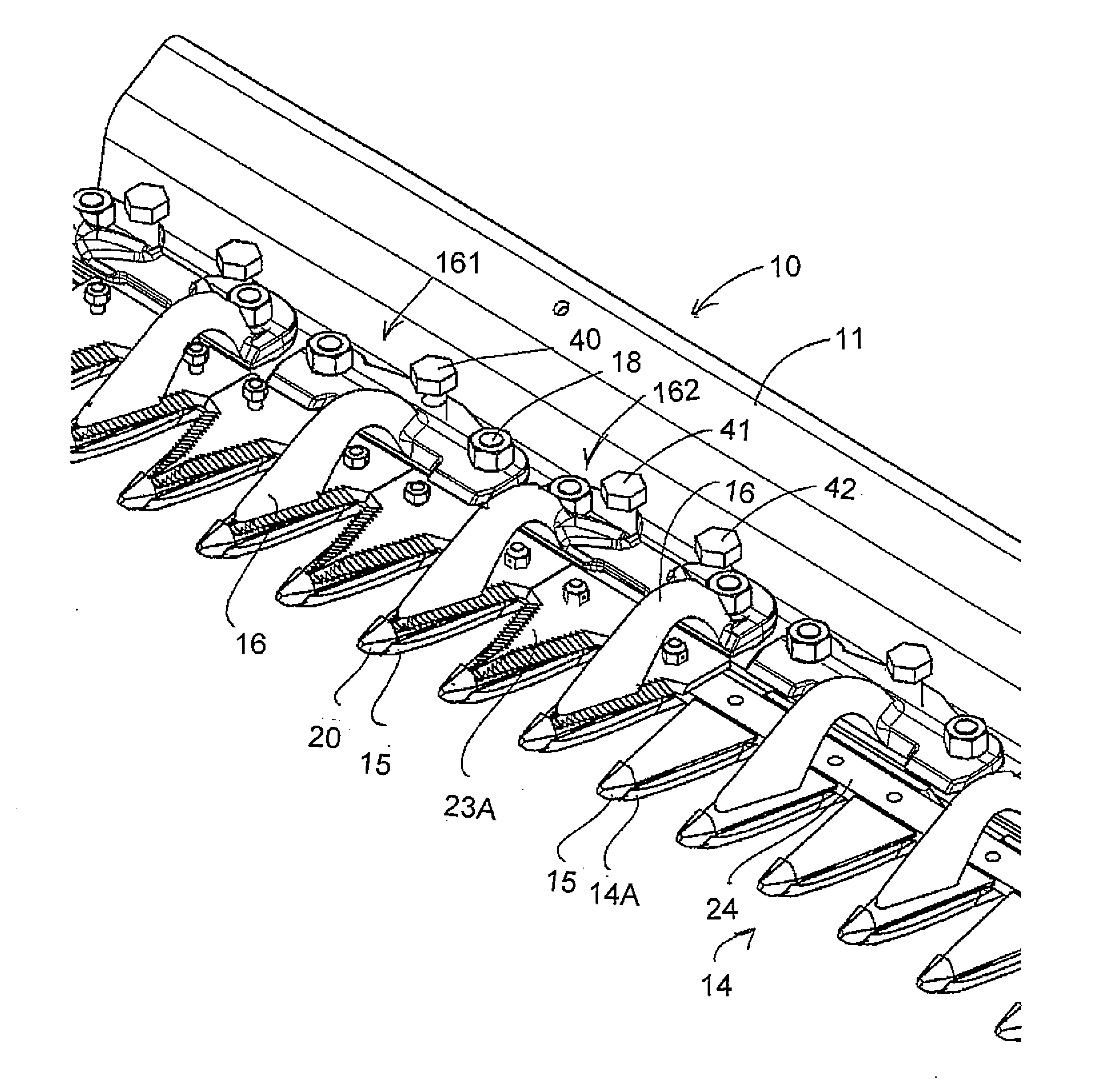

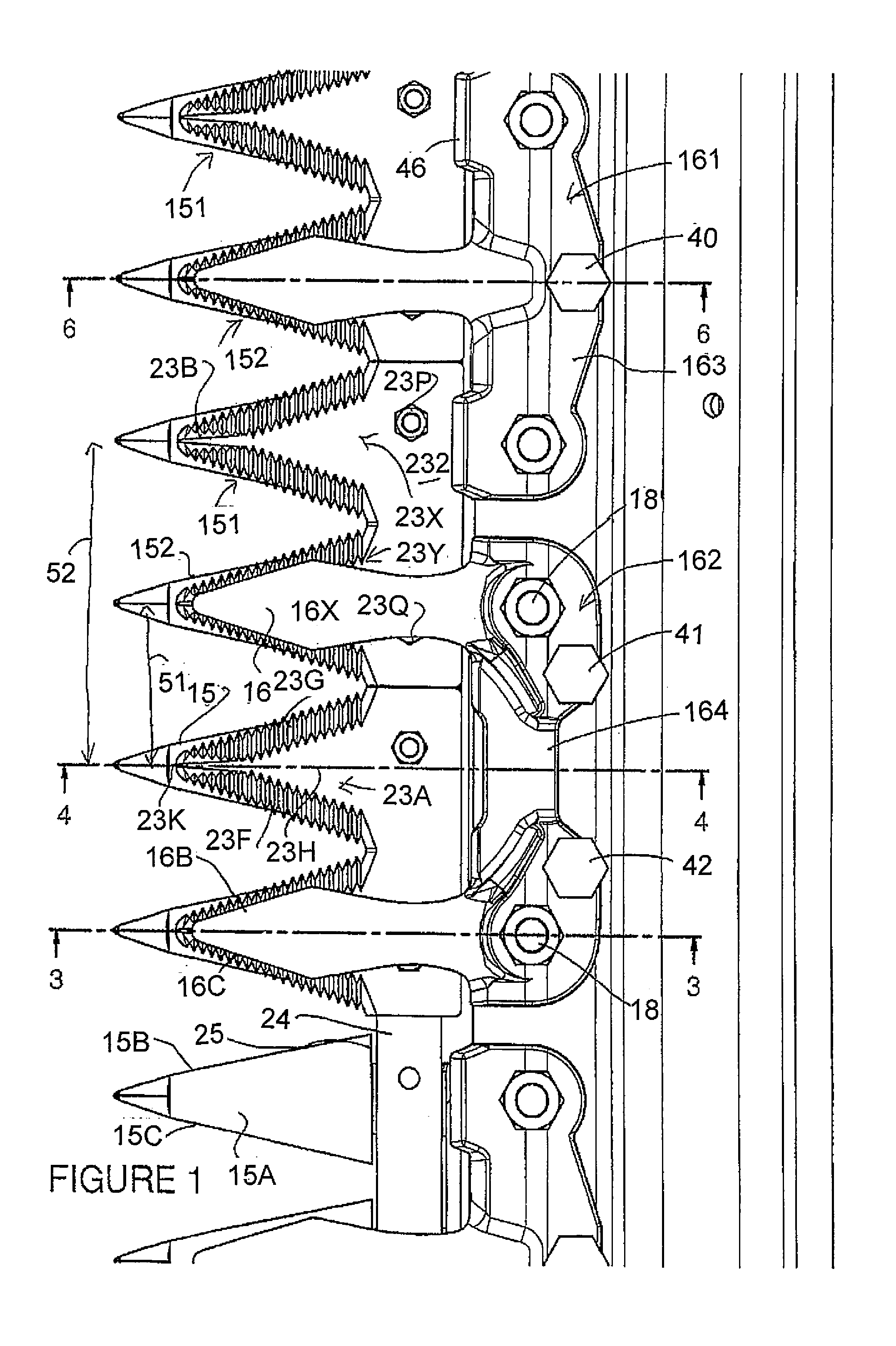

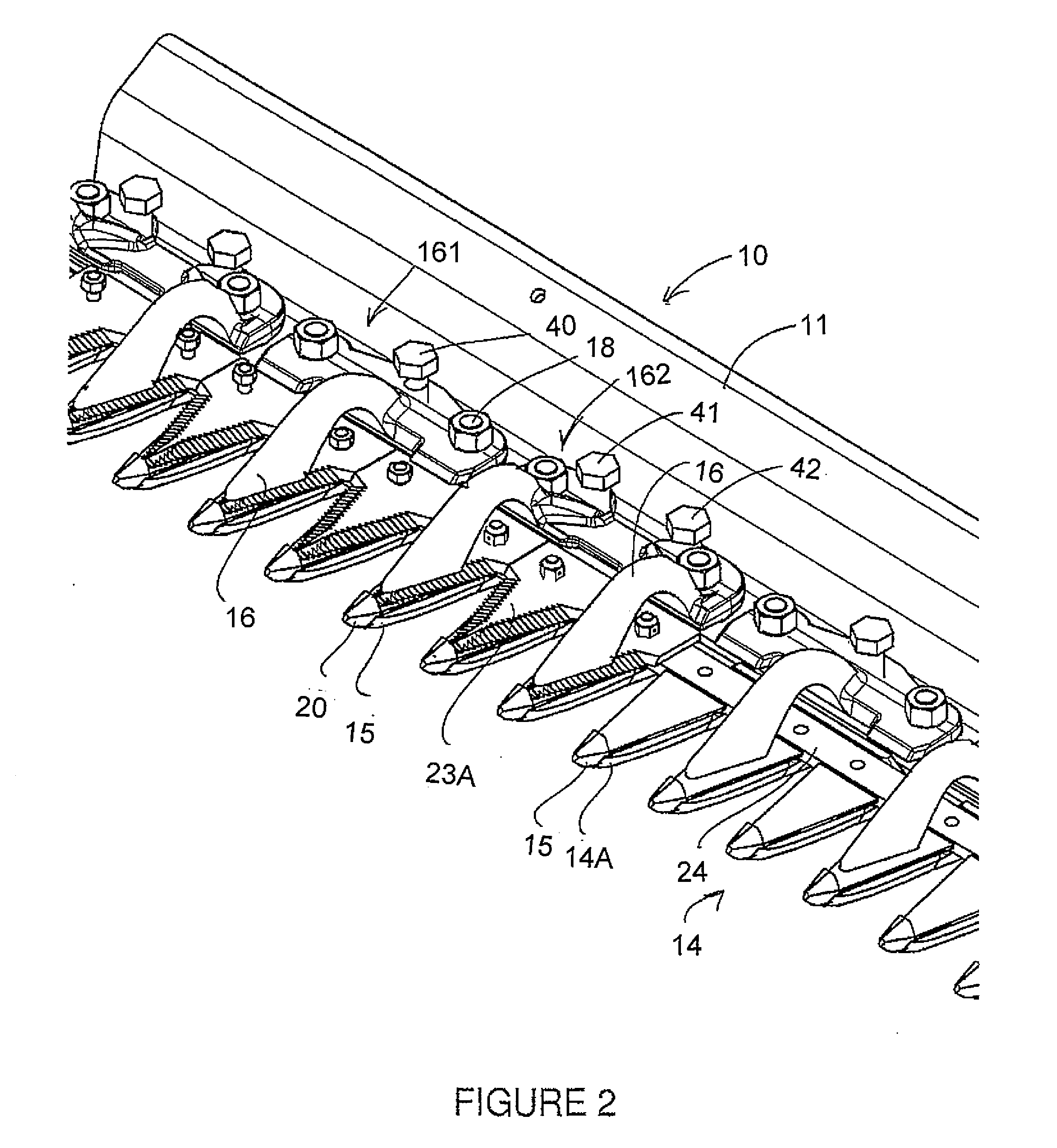

Sickle Cutter System with Blades Moving Across Wider Guard Fingers

A sickle cutting apparatus includes a plurality of triple finger knife guards which are arranged side by side along the cutter bar to cooperate with a reciprocating sickle bar carrying a row of double blade knife sections and a set of hold-down members carrying hold-down fingers. The hold-down members are arranged alternately as a single finger and double finger with each hold-down member being connected to the cutter bar in association with a respective triple guard. In this way the hold-down fingers are arranged at alternate guard fingers leaving the intervening guard fingers open. The system includes both pointed guards with no tang and stub guard so that the user can select either to be used with the hold-downs. The hold down fingers are all individually adjustable so that the double hold-down have two adjustment screws which can be individually operated causing flexing of the bridge between the double fingers.

Owner:MACDON INDS

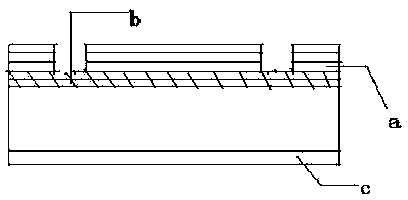

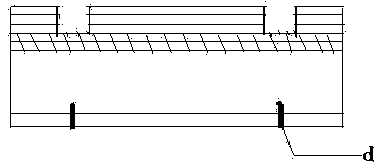

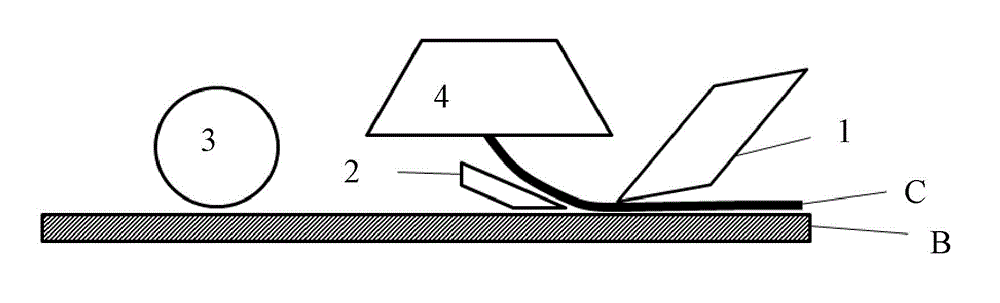

Cutting method and cutting tool of glass substrate of flexible organic light-emitting diode display

InactiveCN104591530AQuick cutSimple and fast operationGlass severing apparatusFlexible organic light-emitting diodeAcute angle

The invention discloses a cutting method and a cutting tool of a glass substrate of a flexible organic light-emitting diode display. The cutting tool comprises a pair of blade knives, a scraper knife and a cutter wheel. The scraper knife is positioned between the blade knives and the cutter wheel. The method comprises the following steps: the cutting tool is positioned above a flexible material; along a cutting direction, the pair of blade knives arranged side by side are positioned on the front, wherein the blades of the blade knives have acute angles; the cutting tools are started, and the two blade knives cut the flexible material along the cutting direction from one end of the flexible material; the scraper knife arranged behind the blade knives peels the cut flexible material between the two blade knives from the glass substrate; with the action of the scraper knife, a gap with width equal to the spacing between the two blade knives is cut on the flexible material; the cutter wheel behind the scraper knife performs a scoring process on the glass substrate exposed after the peeling of the flexible material; and a splitting process is carried out, such that the glass substrate is completely separated. According to the invention, the cutting of the flexible material and the glass substrate is completed in one step with the combined cutting tool and necessary accessories.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com