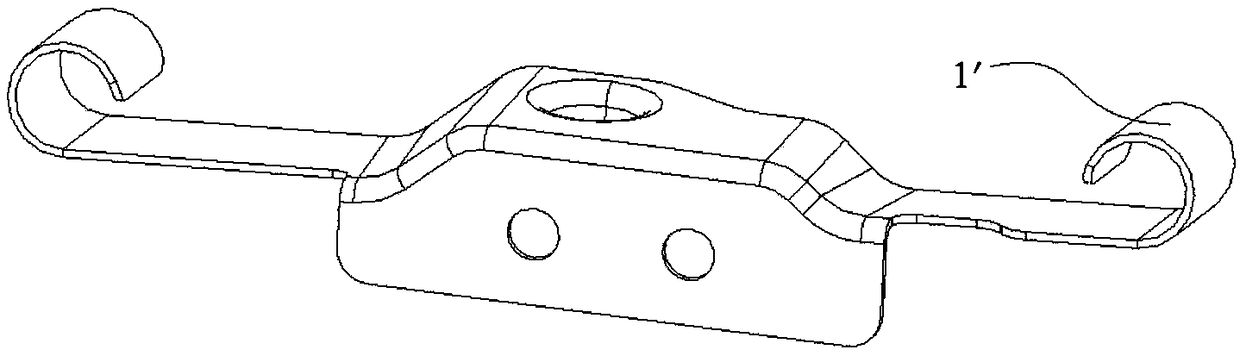

Edge curling method of stamping part and mold of edge curling method

A technology for stamping parts and hemming, which is applied in the field of stamping parts hemming methods and molds, can solve the problems of high difficulty and difficult to control precision, and achieves the effect of low manufacturing cost and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

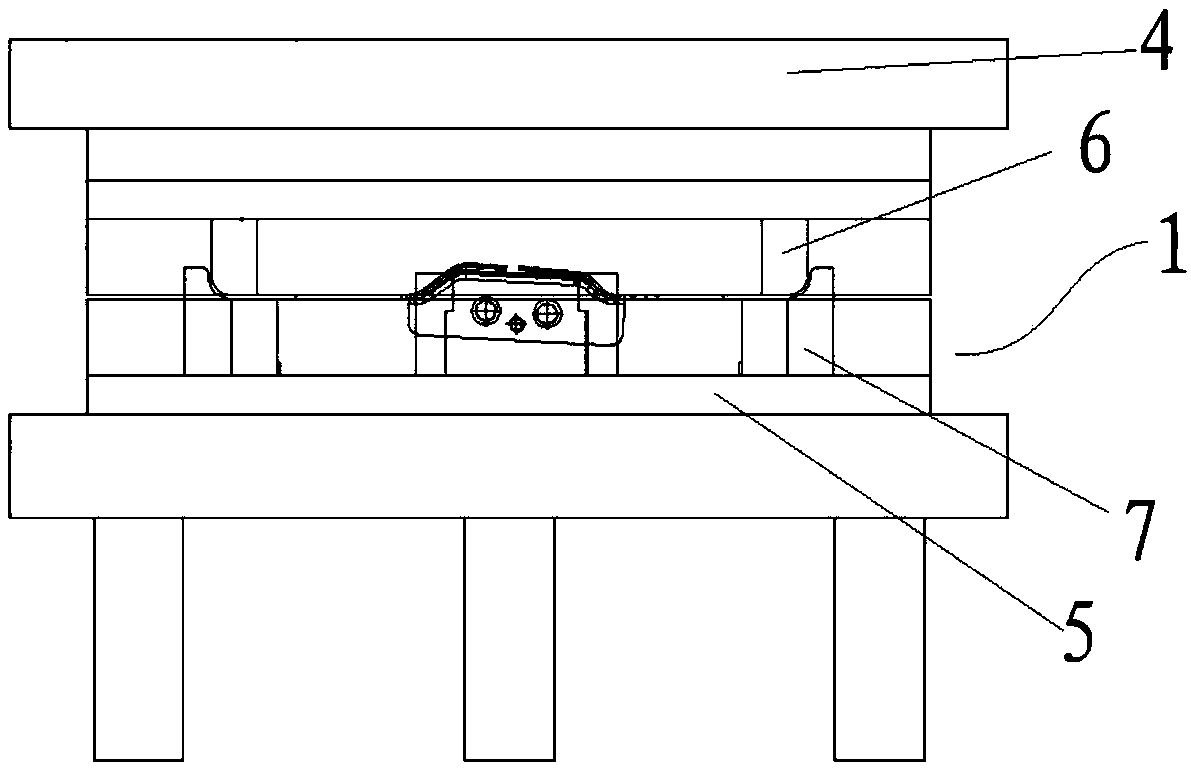

[0026] Such as Figure 2 to Figure 7 As shown, the embodiment of the present invention provides a stamping part curling method, including:

[0027] Step 1: Blanking, to obtain the sheet material of the size and shape required for the subsequent production of stamping parts.

[0028] Step 2: The main body is formed, and the non-curling part of the process part obtained in step 1 is formed to facilitate subsequent shape positioning.

[0029] Step 3: Hemming pre-bending, realize the pre-bending of the upper R angle of the hemming area of the process part obtained in Step 2, because of the strain strengthening effect of the metal sheet, the strength of the upper R angle will be higher, which is convenient for subsequent forming. The sequence can complete the processing of the hole position sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com