Silencer production curling machine and using method thereof

A technology of a muffler and a crimping machine is applied to machine tools suitable for grinding workpiece edges, parts of grinding machine tools, forming tools, etc. The effect of curling, improving quality and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

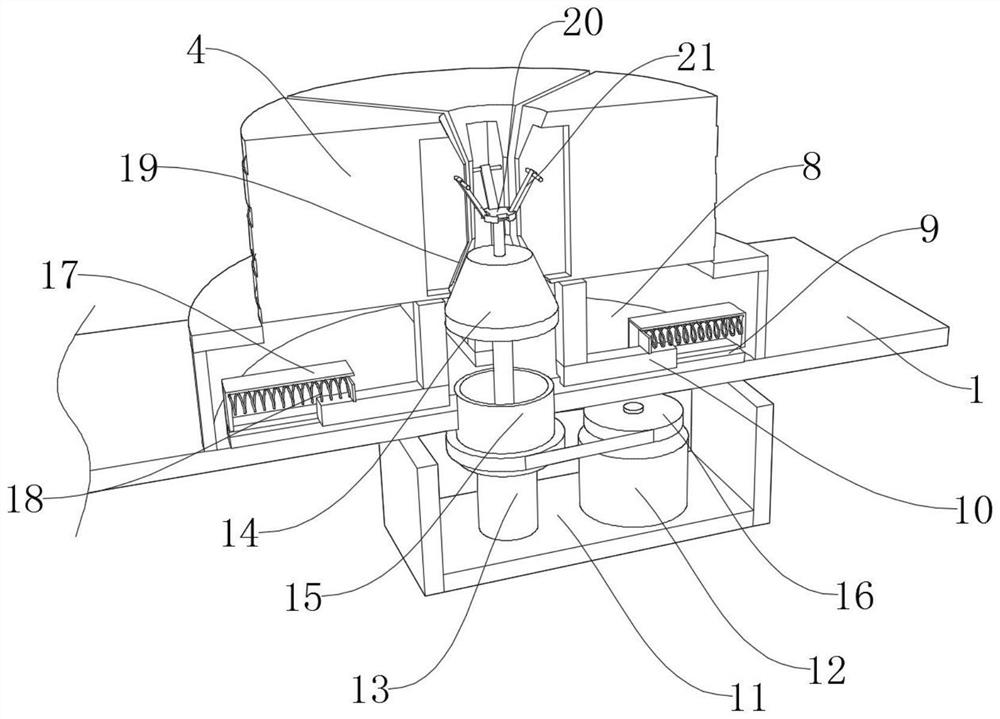

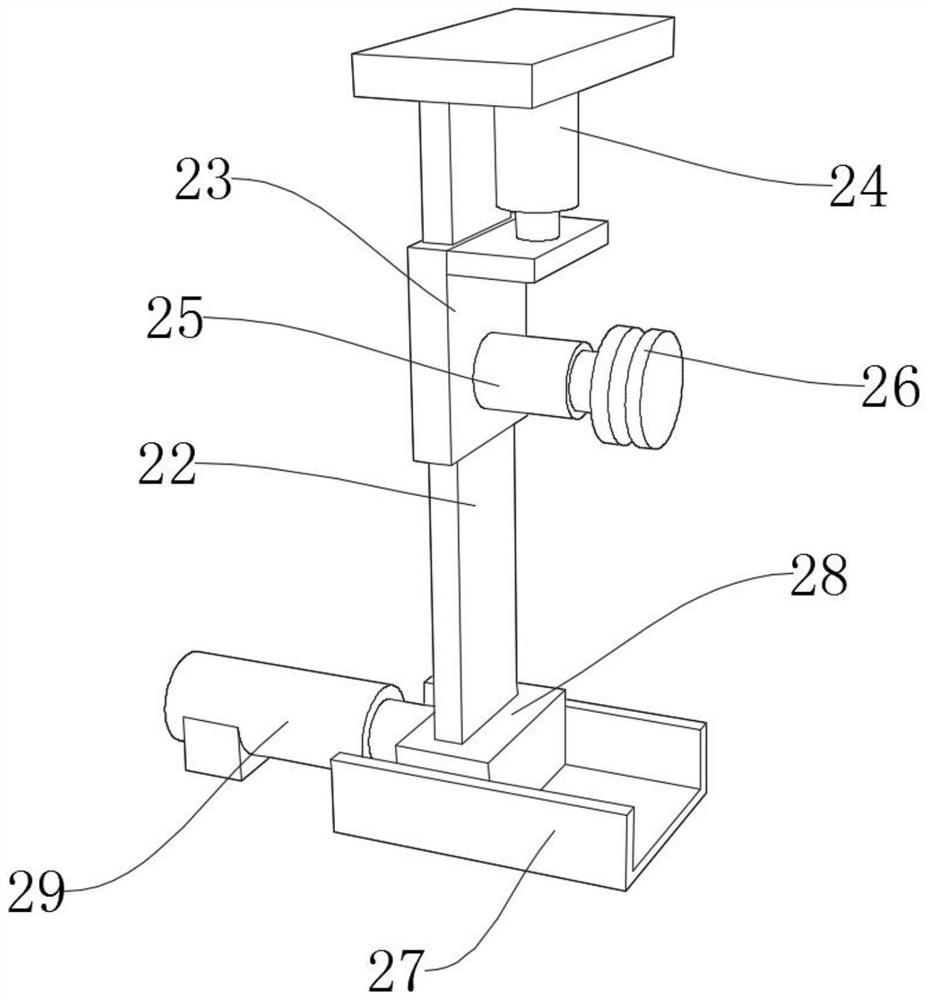

[0035] refer to Figure 1-Figure 6, a muffler production crimping machine, including a cabinet body 1, the top of the cabinet body 1 is provided with a through installation port, the installation port is rotatably connected with an installation cylinder 15, the top outer wall of the installation cylinder 15 is fixed with a turntable 8 by bolts, and the turntable 8 The upper surface of the cabinet is provided with a plurality of chutes 9, and the sliding grooves 9 are all slidably connected with the sliding frame 10, the top of the sliding frame 10 is fixed with a fan-shaped support block 4 by bolts, and the top inner wall of the cabinet 1 is fixed with a base 11 by bolts , the bottom surface of the base 11 is fixed with the first electric push rod 13 and the motor 12 by bolts, and one end of the output shaft of the motor 12 and the circumferential outer wall of the installation cylinder 15 are fixed with a pulley 16 by bolts, and the two pulleys 16 are connected by transmission...

Embodiment 2

[0037] refer to Figure 1-Figure 6 , the present invention provides a new technical solution: a muffler production crimping machine, including a cabinet 1, the top surface of the cabinet 1 is fixed with a control box 2 by bolts, and the product is conveniently controlled through the control box 2. The top of the cabinet 1 is provided with a penetrating installation port, and a mounting cylinder 15 is rotatably connected in the installation port. The top outer wall of the mounting cylinder 15 is fixed with a turntable 8 by bolts, and the top surface of the cabinet 1 is fixed with a protective box 3 by bolts. In the protective box 3, the internal components are conveniently protected by the protective box 3. The upper surface of the turntable 8 is provided with a plurality of chutes 9, and the sliding grooves 9 are all slidably connected with the sliding frame 10, and the top of the sliding frame 10 passes through. The fan-shaped support block 4 is fixed with bolts, and the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com