Curling device for processing packaging material

A packaging material and curling device technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems such as inconvenient use, achieve the effect of easy height adjustment, meeting different height curling requirements, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

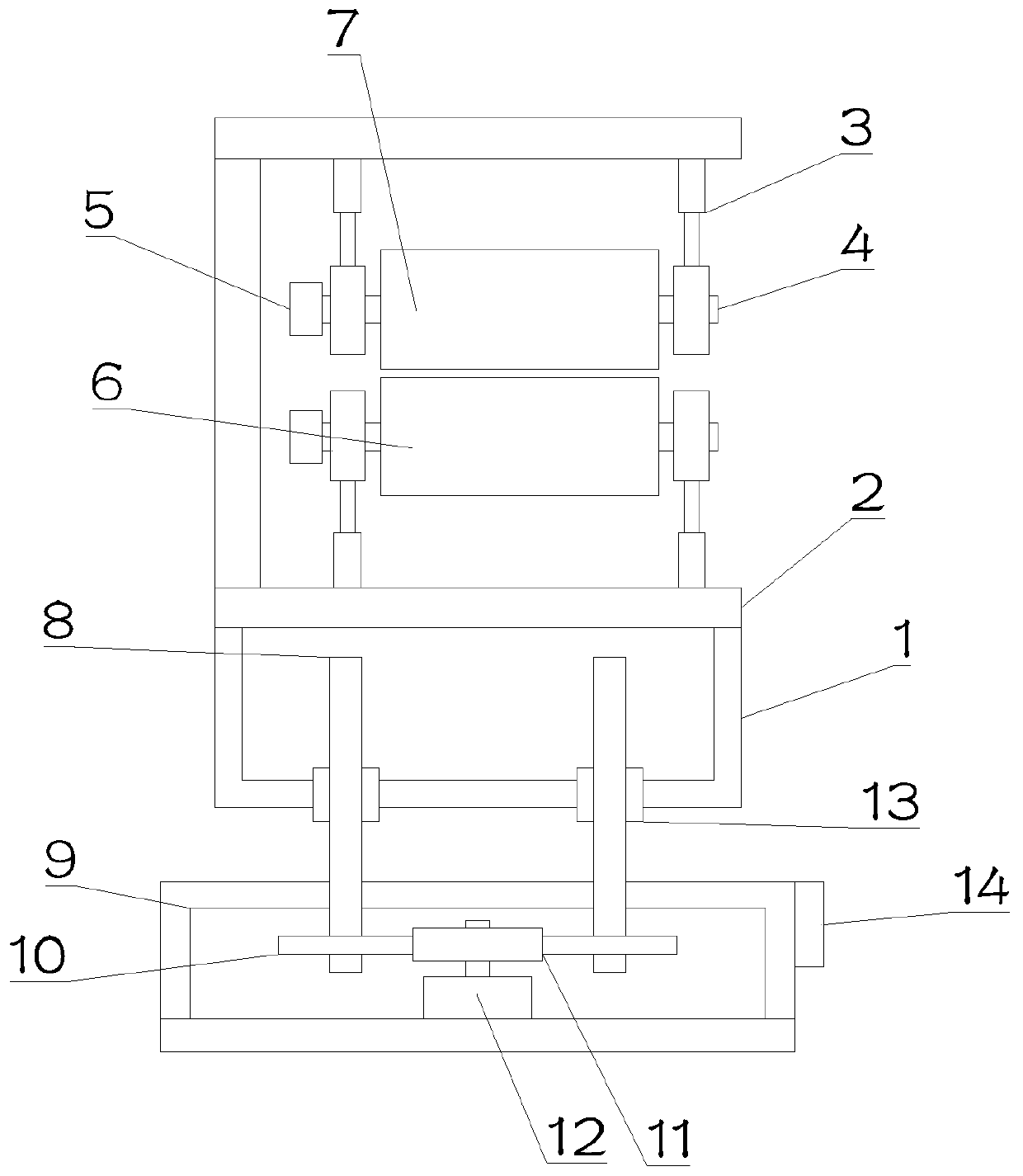

[0020] see Figure 1~3 , in Embodiment 1 of the present invention, a crimping device for packaging material processing includes a support 9 for supporting and installing, and a height adjustment assembly is arranged on the support 9 for adjusting the height of the entire device, and the height The adjustment assembly is provided with a frame 2 fixedly installed, and the frame 2 is provided with a curling assembly 1 6 and a curling assembly 2 7, which is convenient for two sets of curling at the same time, and the curling assembly 1 6 and the curling assembly 2 7 have In the same mechanism, the curling assembly one 6 and the curling assembly two 7 all include a curling wheel 4, an A motor 5 and a telescopic cylinder 3, and the upper end of the telescopic cylinder 3 is fixedly installed on the support member 1, and the two ends of the curling wheel 4 Rotate and install on the output ends of the two telescopic cylinders 3 respectively. This setting is convenient for adjusting the...

Embodiment 2

[0022] see Figure 1~3 , The main difference between Embodiment 2 and Embodiment 1 is that the height adjustment assembly includes a support member 1 , a rotating rod 8 , a support 9 , a second gear 11 , a B motor 12 and a mounting block 13 .

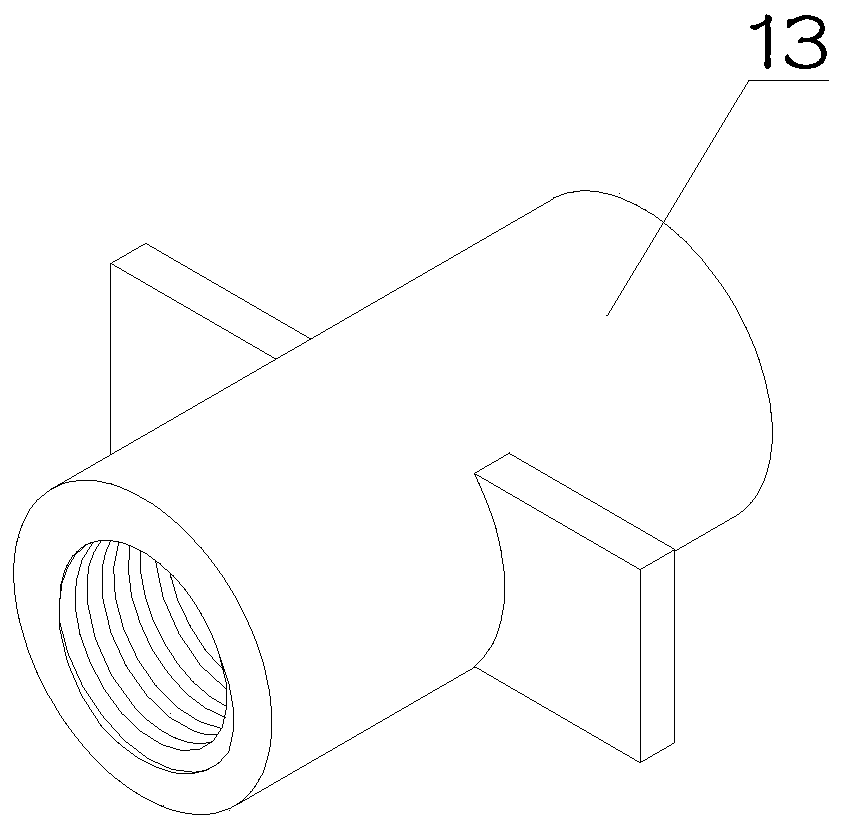

[0023] The support member 1 is fixedly installed on the bottom of the frame 2, and the bottom of the support member 1 is fixedly installed with two mounting blocks 13, and the mounting block 13 is provided with a threaded hole that is threaded with the outer side of the rotating rod 8, and the rotating rod 8 The bottom is set through the through hole on the support 9, and is rotatably mounted on the support 9. The bottom of the rotating rod 8 is sleeved with a first gear 10, and the first gear 10 is arranged inside the support 9. The seat 9 meshes with the second gear 11 at the output end of the B motor 12 , and the B motor 12 is fixedly mounted inside the support 9 . The B motor 12 rotates, drives the second gear 11 to rotate, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com