Manufacturing process of deformation-proof solid wood dismounting and mounting door

A manufacturing process and anti-deformation technology, applied in the direction of manufacturing tools, wood processing appliances, etc., can solve problems such as warping, expansion, cracking, etc., and achieve the effect of reducing expansion or shrinkage, reducing waste, and facilitating customers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

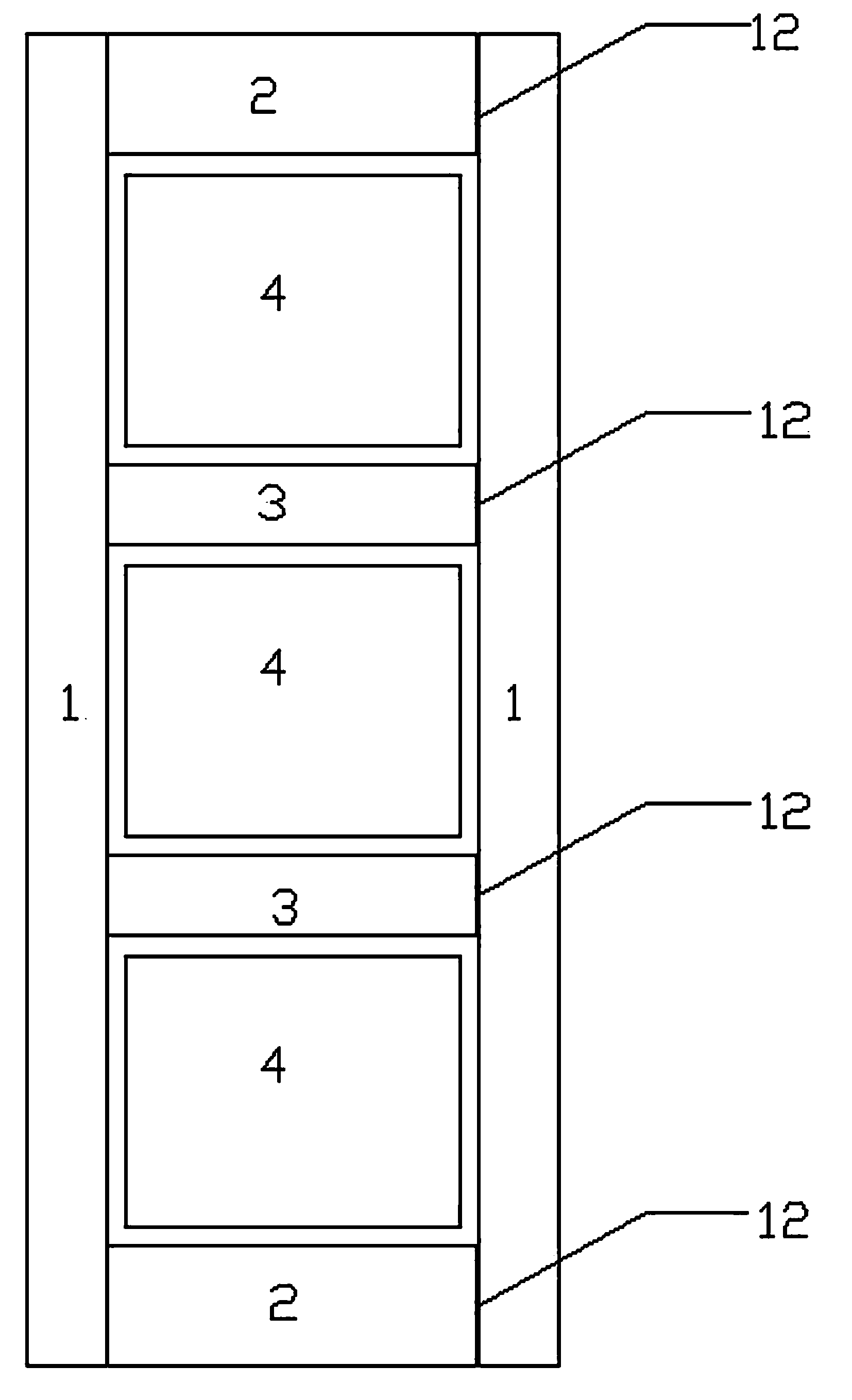

[0027] The invention relates to a manufacturing process of an anti-deformation solid wood door, which is characterized in that it includes a manufacturing process of an anti-deformation door edge and a head, a disassembly process, a natural seam treatment process, and a separate painting treatment process.

Embodiment 2

[0029] The manufacturing process of the anti-deformation door edge and the end head is as follows: Step 1: Cook the logs and then spin them into veneers, spin them into standard veneers, and dry the veneers to a moisture content of about 5-7%;

[0030] The second step: the surface of the veneer that needs to be bonded is coated with E0 or E1 grade environmental protection glue with a concentration of 75%, and is made into a type I multi-layer board under high temperature and high pressure;

[0031] Step 3: Store the multi-layer board for more than 15-20 days for health preservation, cut it to a certain length, and then sand it to determine the thickness;

[0032] Step 4: Cut the multi-layer board into multi-layer slats with a width of 10-50mm, and the width is the thickness of the anti-deformation multi-layer vertical panel; apply E0 grade water-based polymer isocyanate splicing glue to the natural texture surface of the multi-layer slats, The natural texture surface o...

Embodiment 3

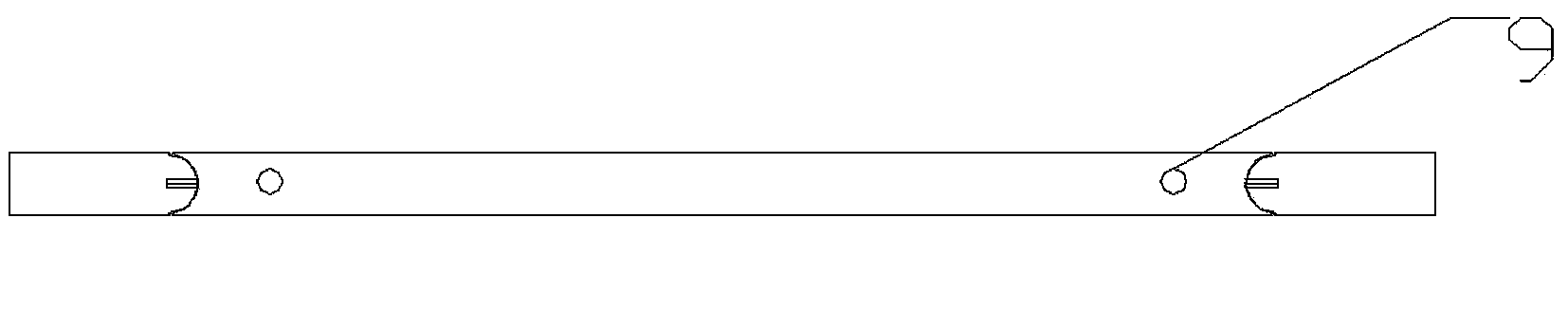

[0036] The disassembly and assembly process is as follows: the connection between the door side and the shank head is positioned with a round bar tenon, and the screw hole on the door side of the vertical head screw connection is drilled with a step drill. The holes are concentric holes, with small holes on the inside of the door side and large holes on the outside. , convenient for screw assembly and use; the hole of the hammer nut rod of the hammer head, this hole is a half hole without a through hole, and the depth is 2-3mm deeper than the hammer nut rod, and the core plate is connected with the door edge, the blade head, and the middle. Link, door edge and end milling groove, milling process line type; core board milling convex groove and process line type and inserting into the door edge and end head groove without glue or nailing, when the core board, door edge and end end The head shrinks or expands freely, so there will be no cracks in the core board and its surroundi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com