Cold end of low-temperature high-pressure plunger pump

A low-temperature high-pressure, plunger pump technology, applied in pumps, pump components, variable capacity pump components, etc., can solve the problem that ordinary materials do not have low-temperature use characteristics, cannot meet low-temperature high-pressure pumping of liquid nitrogen, and are unfavorable for low-temperature high-pressure pumping. and other problems, to achieve the effect of high output pressure, ensure reliability, and improve pumping capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

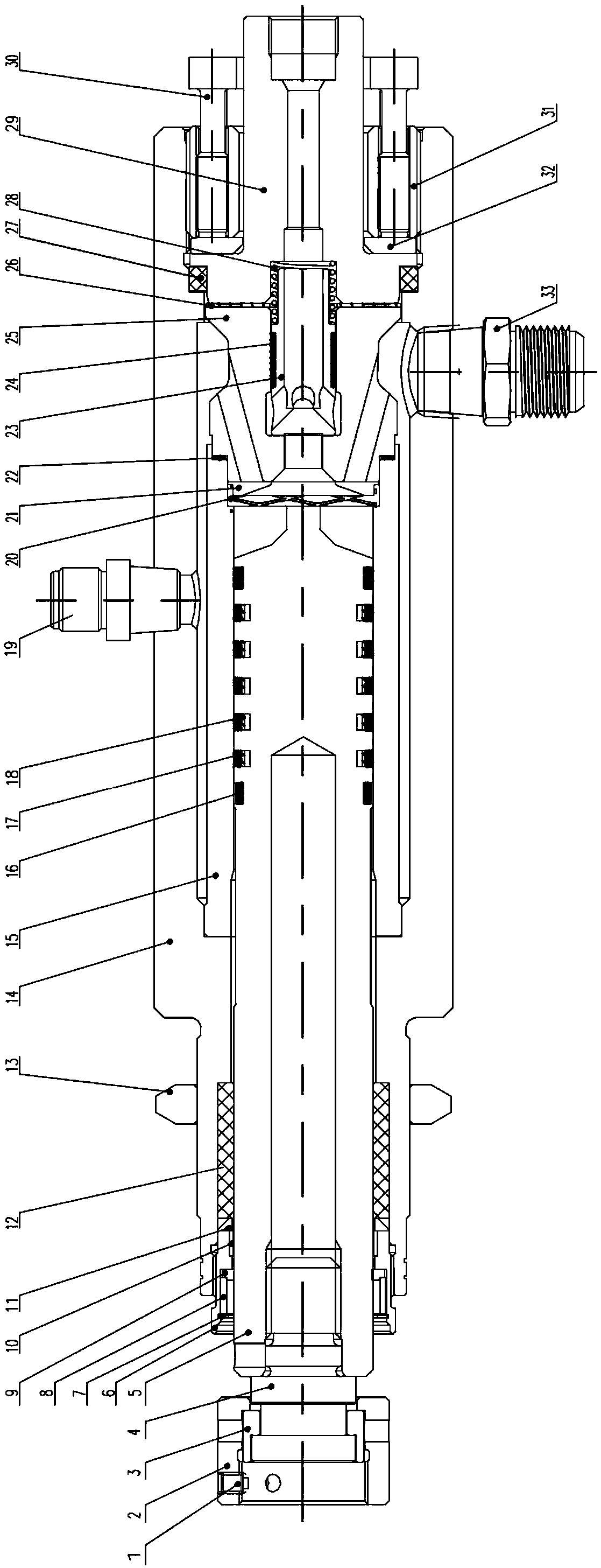

[0024] A cold end of a low-temperature high-pressure plunger pump includes a cold end housing 14, a plunger 5, and a cylinder liner 15. The plunger 5 is arranged inside the cylinder liner 15, and the cylinder liner 15 is located inside the cold end housing 14. The front end of the housing 14 is provided with a connecting and locking device. The cold end housing 14 includes two mutually connected cavities on the left and right. The right end of the plunger 5 is inserted into the cylinder liner 15, and the left end of the plunger 5 passes through the left The cavity body extends out of the cold end housing 14. The left cavity body is equipped with a seal around the plunger. The right cavity body includes a cylinder liner 15, a valve block and a discharge flange 29. The valve block includes a valve seat 25, The high-pressure valve 23 in the valve seat 25 and the low-pressure valve 21 installed between the cylinder liner 15 and the valve seat 25. The center of the valve seat 25 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com