Aid-base resistance anti-reflection coated glass

A coated glass, acid and alkali resistance technology, applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problem that the weather resistance of anti-reflection coated glass cannot meet higher requirements, and achieve good Anti-reflection effect and mechanical resistance, good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] The refractive index in the present invention refers to the refractive index when the wavelength of the transmitted light is 500-550 nm, and the film layer material is prepared by sputtering, preferably magnetron sputtering. The "layer" in the present invention should be understood as a single layer, or a stack of multiple layers, each layer has a given refractive index, and the sum of their geometric thickness also obeys the given value for the layer.

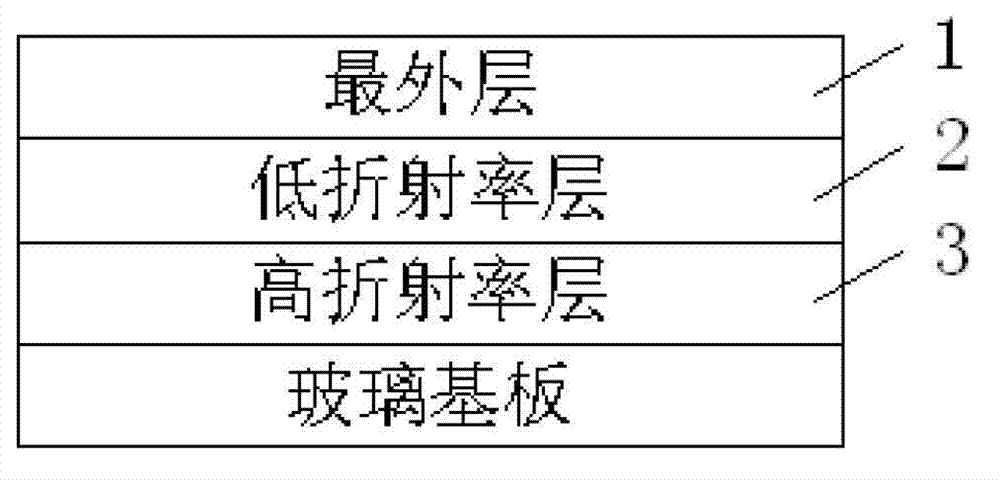

[0033] like figure 1 As shown, the acid and alkali resistant anti-reflection coated glass with a three-layer structure of the present invention includes a glass substrate and an anti-reflection film arranged on at least one surface of the glass substrate, and the anti-reflection film includes a glass substrate with a high refractive index A high-refractive-index layer made of high-refractive-inde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com