Double-layer passivating method for crystalline silicon solar battery

A technology of solar cells and crystalline silicon, applied in coatings, circuits, electrical components, etc., can solve the problems of difficult to obtain high-efficiency cells, high surface recombination speed, low front surface reflection, etc., achieve good anti-reflection performance, low cost, Enhance the effect of internal back reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A double-layer passivation method for crystalline silicon solar cells, the method comprising the following steps:

[0022] (1) Select 10pcs of P-type FZ monocrystalline silicon wafers (1W cm), clean with 1% HF solution, and polish with 20% NaOH solution;

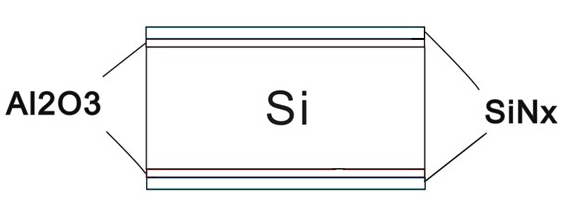

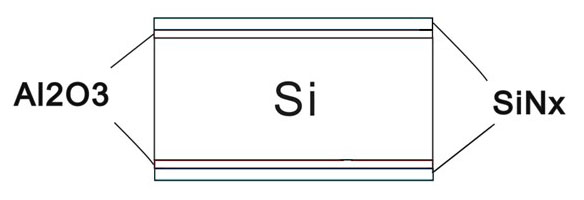

[0023] (2) Use the ALD method to grow Al2O3 on the silicon wafer obtained in step (1), with a refractive index of 1.6 and a thickness of 30nm;

[0024] (3) Use the PECVD method to grow SiNx on the silicon wafer obtained in step (2), with a refractive index of 2.05 and a thickness of 100nm;

[0025] (4) Anneal the sample obtained in step (3) at a temperature of 400° C. in an N2 atmosphere for 10 minutes to obtain a double-layer passivation dielectric film.

[0026] Implementation Effect:

[0027] The passivation effect of the double-layer passivation dielectric film manufactured by the method described in Example 1 is excellent, and the surface recombination speed reaches 3 cm / s, which is far superior to the current ...

Embodiment 2

[0029] A double-layer passivation method for crystalline silicon solar cells, the method comprising the following steps:

[0030] (1) Select 10pcs (1W cm) of N-type FZ single crystal silicon wafers, use 1% HF solution for cleaning, use 2.5% NaOH solution for texturing, and use BBr3 diffusion, the square resistance is 50W / sq;

[0031] (2) Use the ALD method to grow Al2O3 on the silicon wafer obtained in step (1), with a refractive index of 1.65 and a thickness of 15nm;

[0032] (3) Use the PECVD method to grow SiNx on the silicon wafer obtained in step (2), with a refractive index of 2.05 and a thickness of 70nm;

[0033] (4) Anneal the sample obtained in step (3) at a temperature of 400° C. in an N2 atmosphere for 10 minutes to obtain a double-layer passivation dielectric film.

[0034] Implementation Effect:

[0035] The double-layer passivation dielectric film manufactured by the method described in Example 2 has an excellent passivation effect, and the surface recombinati...

Embodiment 3

[0037] A double-layer passivation method for crystalline silicon solar cells, the method comprising the following steps:

[0038] (1) Select 10pcs of P-type FZ monocrystalline silicon wafers (1W cm), clean with 1% HF solution, and polish with 20% NaOH solution;

[0039] (2) Use the PECVD method to grow Al2O3 on the silicon wafer obtained in step (1), with a refractive index of 1.6 and a thickness of 15nm;

[0040] (3) Use the PVD method to grow SiNx on the silicon wafer obtained in step (2), with a refractive index of 2.15 and a thickness of 80nm;

[0041] (4) Annealing the sample obtained in step (3) at a temperature of 450° C. in an N2 atmosphere for 6 minutes to obtain a double-layer passivation dielectric film.

[0042] Implementation Effect:

[0043] The passivation effect of the double-layer passivation dielectric film manufactured by the method described in Example 3 is excellent, and the surface recombination speed reaches 5 cm / s, which is far superior to the current...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com