Method for preparing colorful film for protecting solar cell thin grid line metal electrode by adopting mask

A metal electrode, solar cell technology, applied in the field of solar cells, can solve problems such as restricting architects, unable to better meet people's aesthetic needs, monotonous color of solar cells, etc., to achieve good industrialization prospects, meet design diversity, Protects against oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

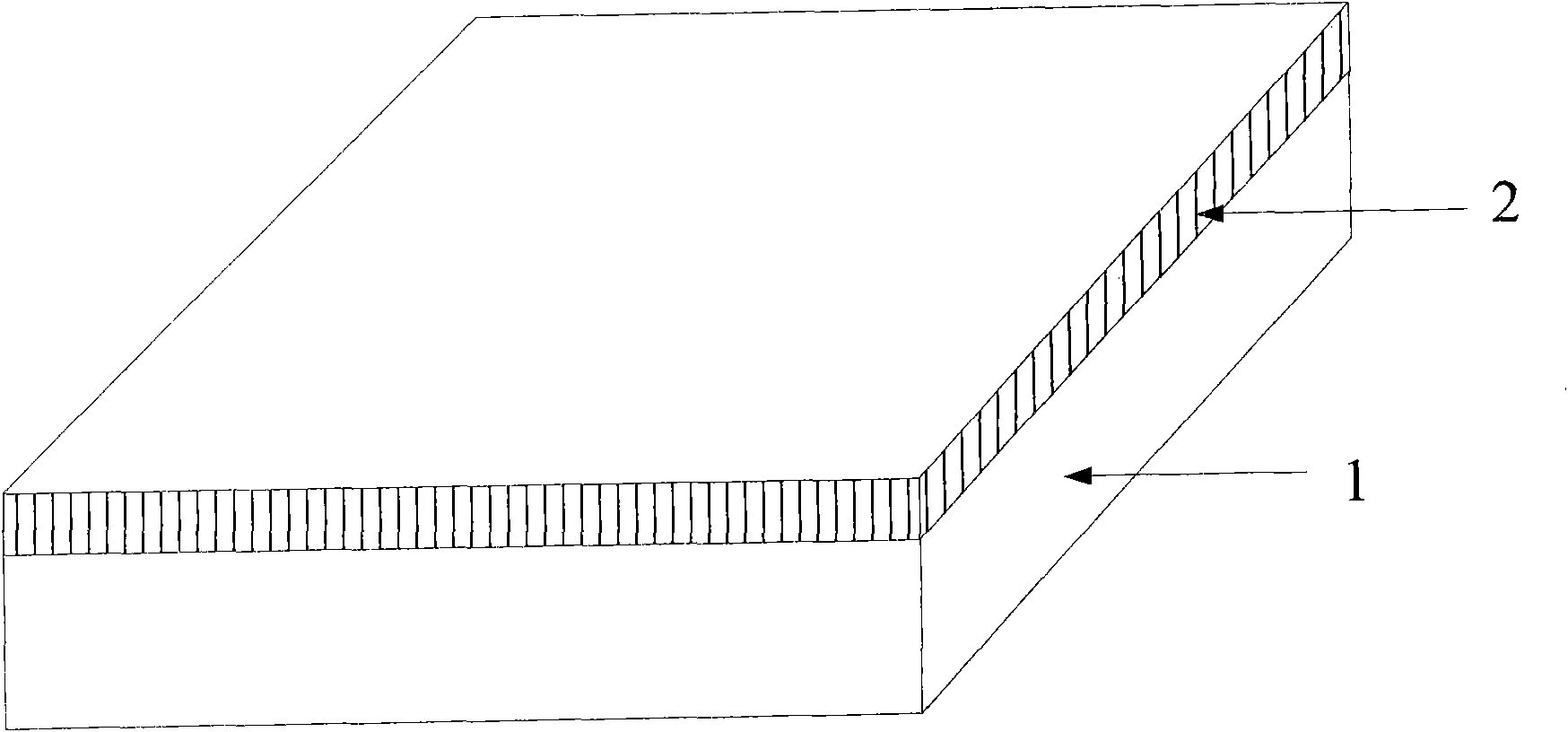

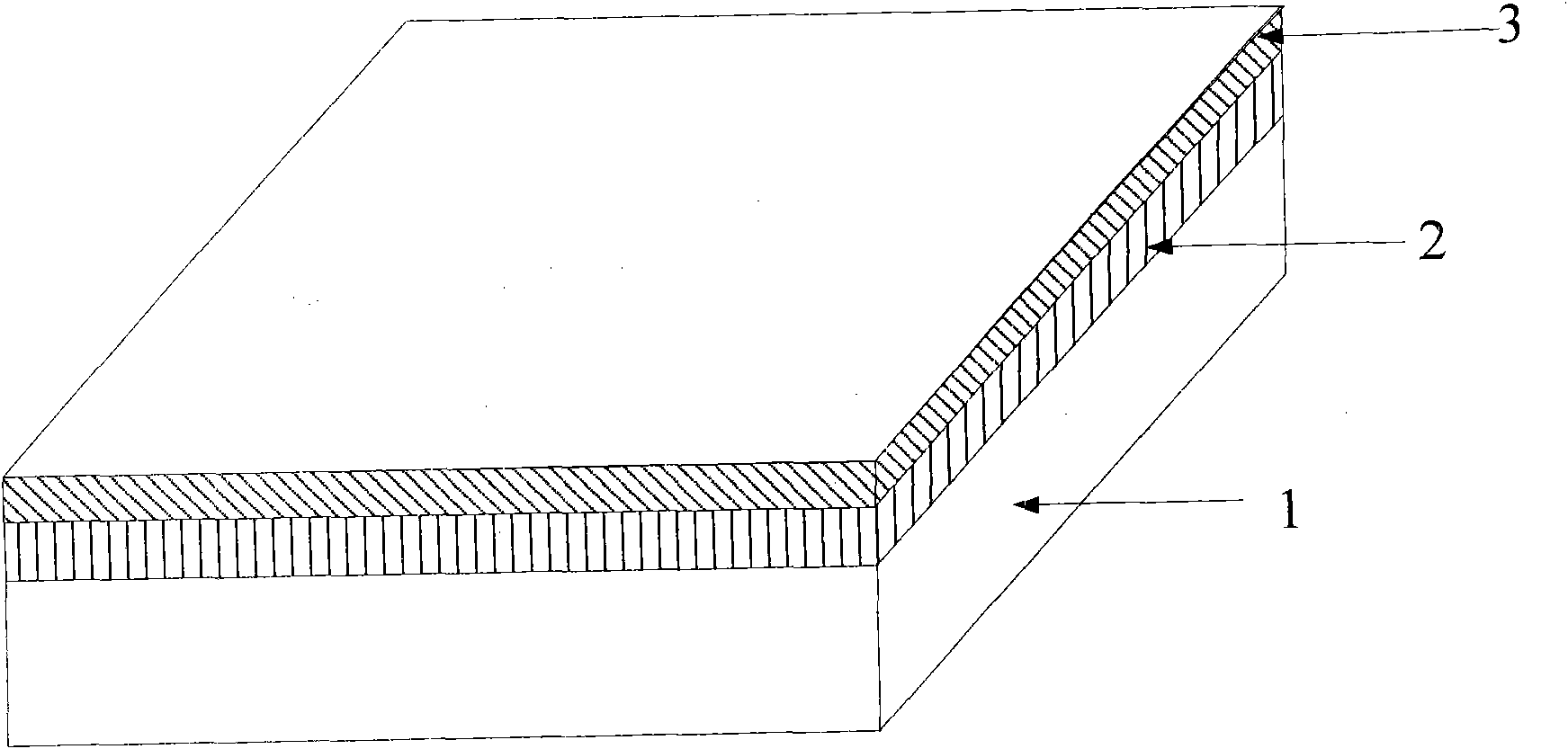

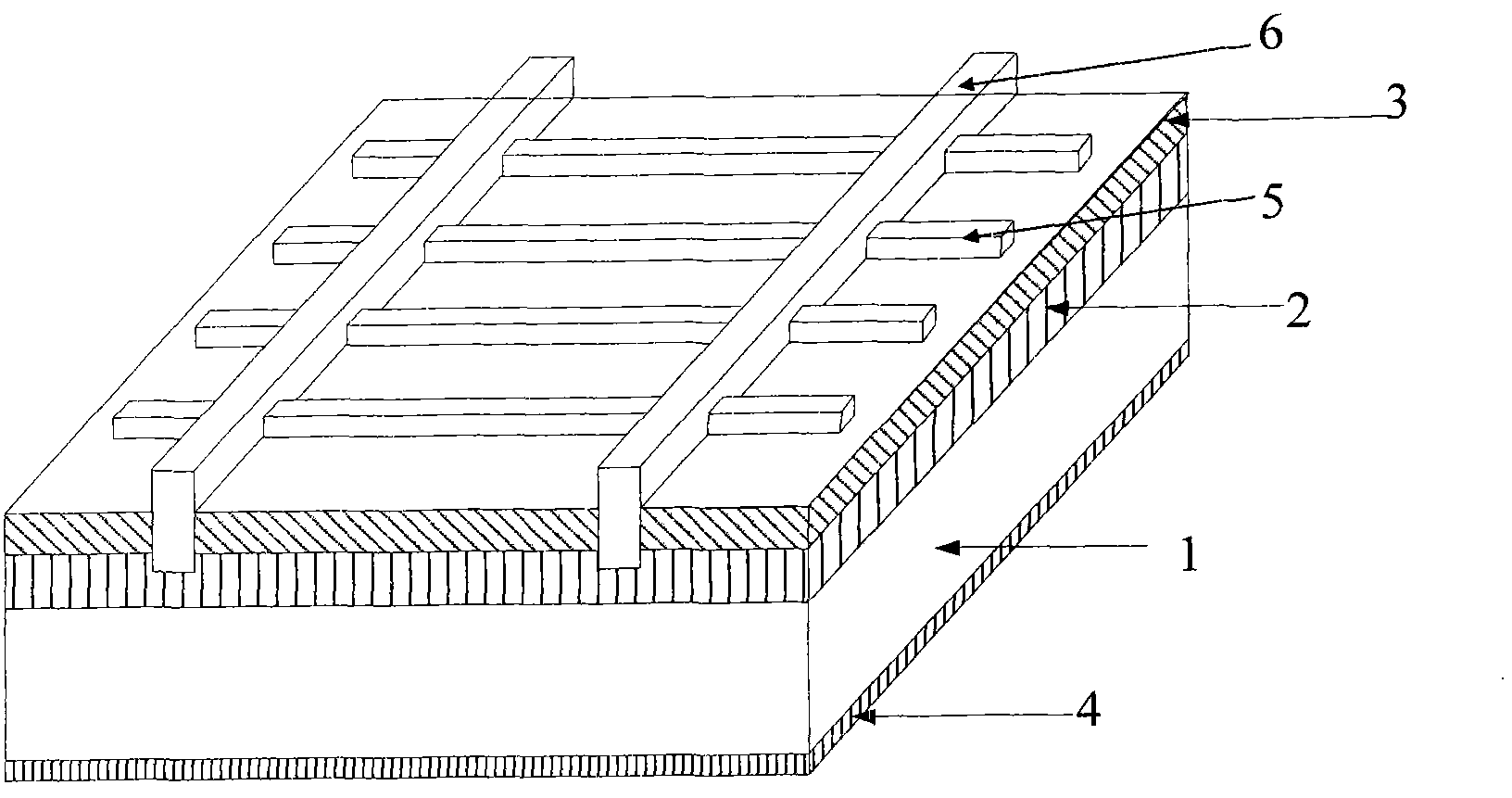

[0039] as attached Figure 1-3As shown, the p-type single crystal silicon wafer 1 is cleaned and acid-textured. Then, the phosphorous oxychloride gas is fed into the tubular diffusion furnace, and phosphorus is diffused at a high temperature of 800° C. to form a p-n junction 2 . Use 5% hydrofluoric acid aqueous solution to remove phosphosilicate glass, use plasma etching method to remove edges, and then use evaporation, sputtering, deposition, ion plating or CVD method, in this case, PECVD method is used , coating a layer of silicon nitride passivation film 3 with a thickness of 40nm and a refractive index of 2.1 above the n-type region. The passivation layer can also improve the passivation effect by increasing the hydrogen content, and at the same time reduce the thickness of the passivation layer to avoid Excessive absorption of light by a passivation layer. Use screen printing to print silver-aluminum paste on the back, dry it in a drying oven at a temperature zone of 18...

Embodiment 2

[0042] as attached Figure 1-3 As shown, the p-type silicon wafer 1 is cleaned and alkali-textured. Then, the phosphorous oxychloride gas is fed into the tubular diffusion furnace, and phosphorus is diffused at a high temperature of 800° C. to form a p-n junction 2 . Use 5% hydrofluoric acid aqueous solution to remove phosphosilicate glass, use plasma etching to remove edges, and then use PECVD to plate a composite passivation film 3 of silicon oxide and silicon nitride on the n-type region, wherein , the refractive index of silicon oxide is 1.46, and the thickness is 30nm; the refractive index of silicon nitride is 2.1, and the thickness is 20nm. Use screen printing to print silver-aluminum paste on the back, dry it in a drying oven at a temperature zone of 180-260°C, then print aluminum paste, and dry it again; The temperature zone is sintered to form the aluminum back field, the silver-aluminum electrode 4 and the front surface electrode, the fine-grid silver electrode 5 ...

Embodiment 3

[0045] as attached Figure 1-3 As shown, the n-type polysilicon wafer 1 is cleaned and acid-textured. Boron diffusion is then performed to form a p-n junction 2 . Wash with 5% hydrofluoric acid aqueous solution, then use plasma etching to remove edges, and use PECVD to coat an amorphous silicon passivation film with a thickness of 20nm and a refractive index of 2.0 on the n-type region 3. Use the screen printing method to print silver and aluminum paste on the back, dry it in a drying oven at a temperature zone of 180-260°C, then print aluminum paste, and dry it again; print silver paste on the front, and dry it at a temperature of 200-860°C The area is sintered to form aluminum back field, silver-aluminum electrode 4 and front surface electrode fine-grid silver electrode 5 and busbar silver electrode 6. The width of the formed busbar metal electrode is 3mm, and the width of the fine-grid metal electrode is 120 μm. as attached Figure 4-7 As shown, prepare a metal mask mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com