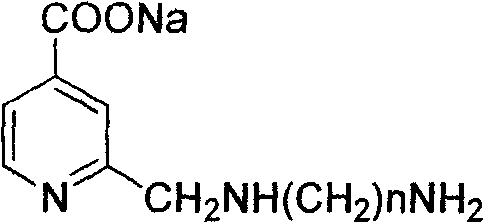

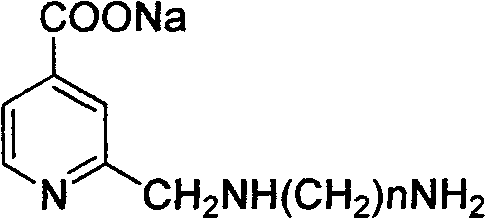

Preparation method of anionic aqueous polyurethane dispersoid for fabric coating and decoration

A water-based polyurethane, anionic technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of product yellowing, color deepening, yellowing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

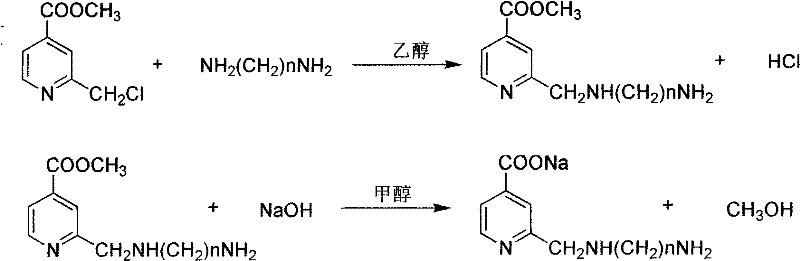

Method used

Image

Examples

Embodiment 1

[0033] Polytetrahydrofuran ether glycol 2000 (that is, the number average molecular weight is 2000, referred to as PTMEG2000, the same below) 42.9g, polytetrahydrofuran ether glycol 1000 (that is, the number average molecular weight is 1000, referred to as PTMEG1000, the same below) 21.5g, polycarbonate Ester diol 2000 (that is, the number average molecular weight is 2000, referred to as PCD2000, the same below) 14.4g, dicyclohexylmethane diisocyanate (abbreviated as H 12 MDI, hereinafter the same) 35.3g, catalyst stannous octoate (abbreviated as T-9, hereinafter the same) 0.05g, in a 500mL four-neck flask, heated to 70°C, reacted for 2.5h, cooled to 60°C, added 2-(( 3.3 g of sodium 2-aminoethylamino)methyl)pyridine-4-carboxylate and 80.0 g of acetone were reacted for 25 minutes to prepare a polyurethane prepolymer. Then cool down to 40°C, add ethylenediamine 2.2g, water 120.0g, emulsify under high-speed stirring for 0.5h, and finally, evaporate the solvent acetone under reduc...

Embodiment 2

[0035] PTMEG200087.5g, PCD200014.4g, H 12 MDI 28.2g, catalyst T-90.06g, in a 500mL four-necked flask, heated to 70°C, reacted for 3h, cooled to 60°C, added 2-((2-aminoethylamino)methyl)pyridine-4-sodium carboxylate 3.3 g and 70.0 g of acetone were reacted for 25 minutes to obtain a polyurethane prepolymer. Then lower the temperature to 40°C, add 0.9g of ethylenediamine and 120.0g of water, emulsify for 0.5h under high-speed stirring, and finally, evaporate the solvent acetone under reduced pressure to obtain the pyridinecarboxylic acid type anionic waterborne polyurethane dispersion WPU2.

Embodiment 3

[0037] PTMEG2000 80.0g, PCD2000 20.0g, H 12 MDI 35.3g, catalyst T-90.13g, in a 500mL four-necked flask, heated to 75°C, reacted for 2h, cooled to 60°C, added 2-((2-aminopropylamino)methyl)pyridine-4-sodium carboxylate 3.7 g and 80.0 g of acetone were reacted for 25 minutes to obtain a polyurethane prepolymer. Then lower the temperature to 35°C, add ethylenediamine 2.2g, water 120.0g, emulsify under high speed stirring for 0.5h, finally, distill off the solvent acetone under reduced pressure to obtain pyridine carboxylic acid type anionic waterborne polyurethane dispersion WPU3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com