High-power laser diode heat sink

A laser diode and high-power technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve problems affecting the output light performance and quality of laser diodes, increase the difficulty of heat sink design, and limit machining processes, etc., to achieve Get rid of the use of glue, avoid uneven lighting, and ensure cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. But it should not limit the protection scope of the present invention.

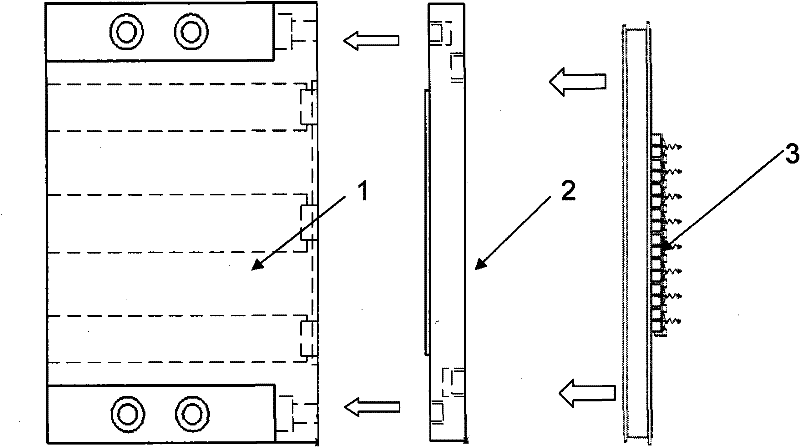

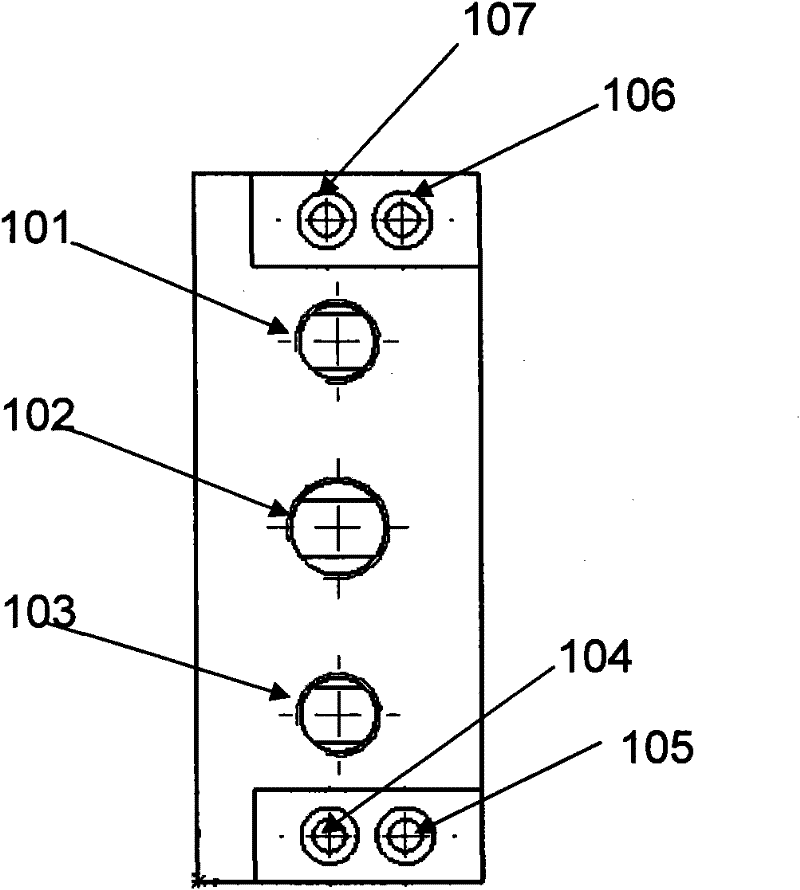

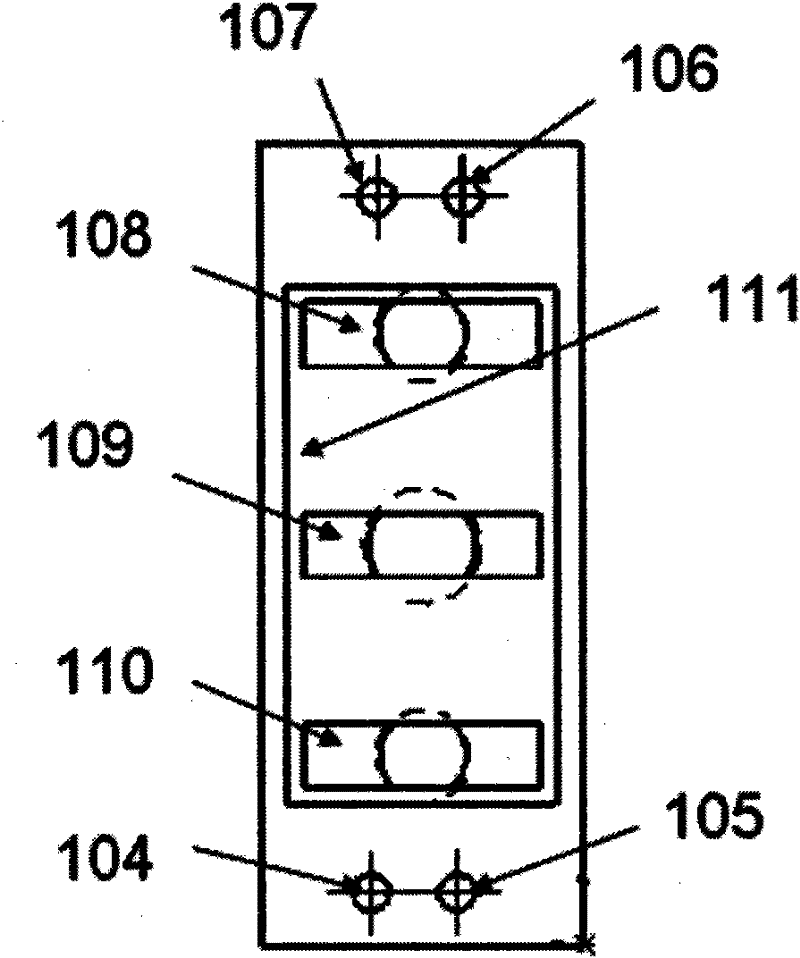

[0027] see first figure 1 , figure 1 It is an exploded view of the connection structure of the high-power laser diode heat sink and the laser diode module of the present invention, figure 2 It is the left view of the first module of the high-power laser diode heat sink of the present invention, image 3 It is the right view of the first module of the high-power laser diode heat sink of the present invention, Figure 4 It is a cross-sectional view of the module of the high-power laser diode heat sink of the present invention. Figure 5 It is the left view of the second module of the high-power laser diode heat sink of the present invention. Image 6 It is the right view of the second module of the high-power laser diode heat sink of the present invention. Figure 2 to Figure 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com