A compressor suction pipe and its manufacturing method and application

A compressor and suction pipe technology, applied in the field of compressors, can solve the problems of secondary melting of solder, vibration, poor quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

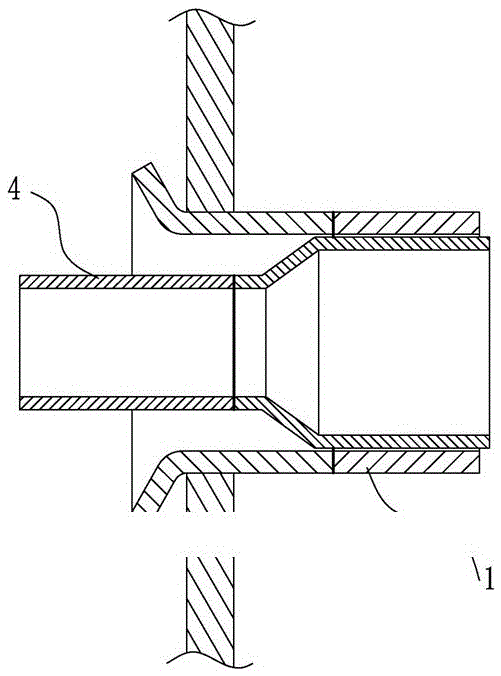

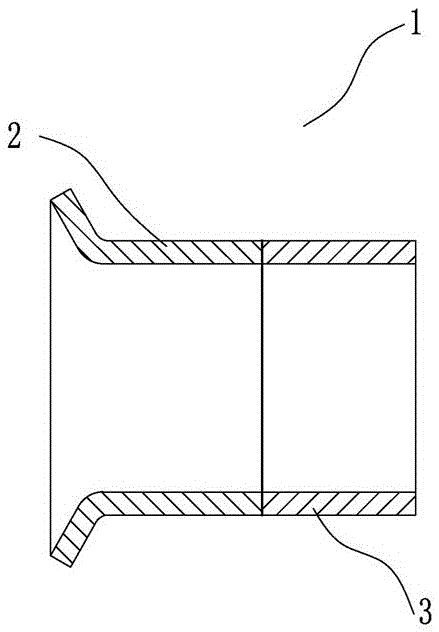

[0036] One of the specific implementations of a compressor suction pipe of the present invention, such as figure 1 , figure 2 and image 3 As shown, the compressed suction pipe includes an inner suction pipe 4 and an outer suction pipe 1, the inner suction pipe 4 includes a first inner pipe 5 and a second inner pipe 6, and the inner suction pipe 4 is a stepped pipe , wherein the small end is the first inner tube 5, the large end is the second inner tube 6, and among the butt ends of the first inner tube 5 and the butt ends of the second inner tube 6, the inner diameter of one of the butt ends is smaller than that of the other butt end Outer diameter, the first inner tube 5 is a copper-plated tube or iron tube, the second inner tube 6 is any one of copper-plated tube, copper tube and iron tube, preferably, the first inner tube 5 and the second inner tube 6 are all copper-plated tubes; the suction outer tube 1 includes a first outer tube 2 and a second outer tube 3, and among...

Embodiment 2

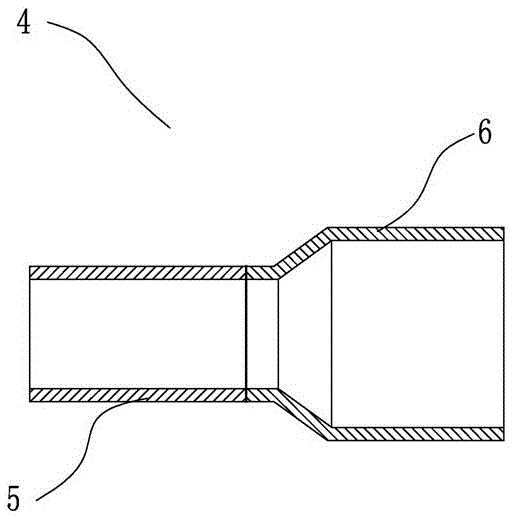

[0046] The second specific embodiment of a compressor suction pipe of the present invention, as Figure 4 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the suction inner tube 4 is a conical tube, wherein the small end is the first inner tube 5 and the big end is the second inner tube 6 .

Embodiment 3

[0048] The third specific embodiment of a compressor suction pipe of the present invention, as Figure 5 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the suction inner tube 4 is a cylindrical tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com