Preparation method of nano silicon dioxide/polyacrylate modified epoxy resin adhesive

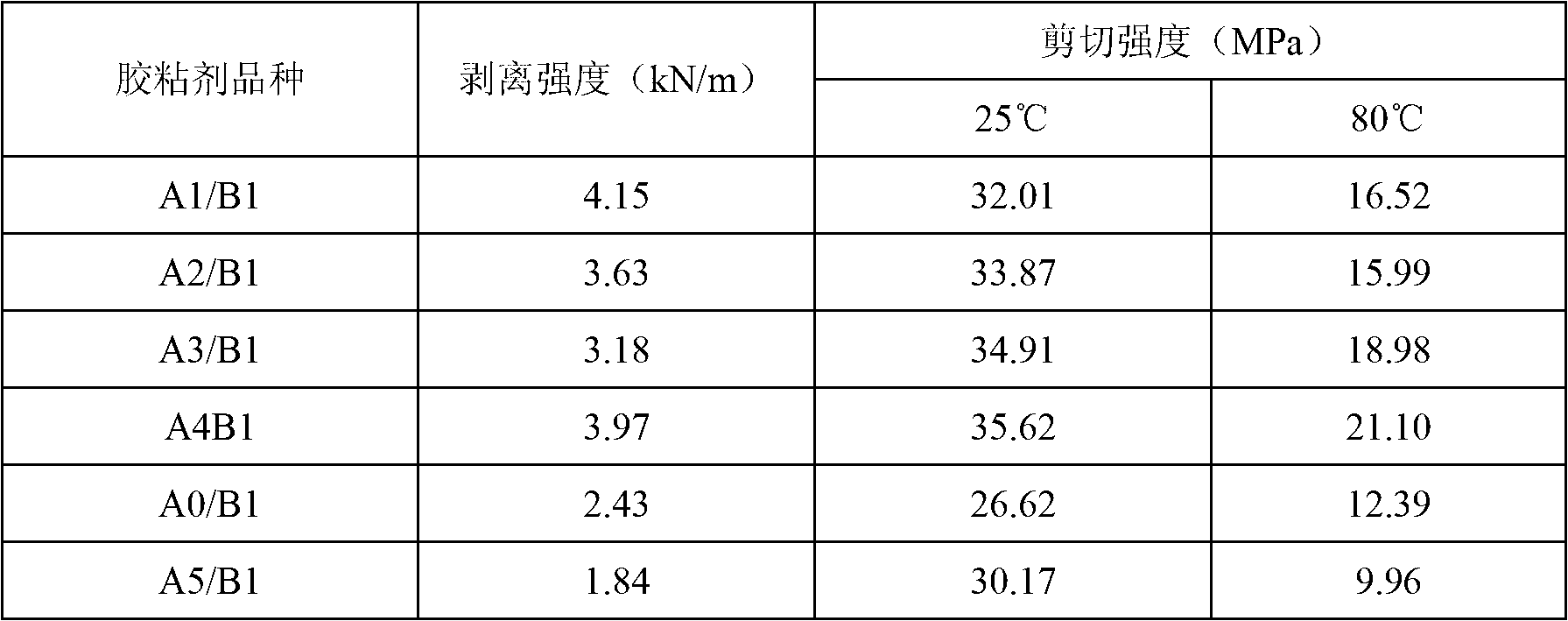

A technology of nano-silica and polyacrylate, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of high temperature performance and unsatisfactory peel strength, and achieve obvious toughening effect and excellent bonding performance Excellent effect of improving shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

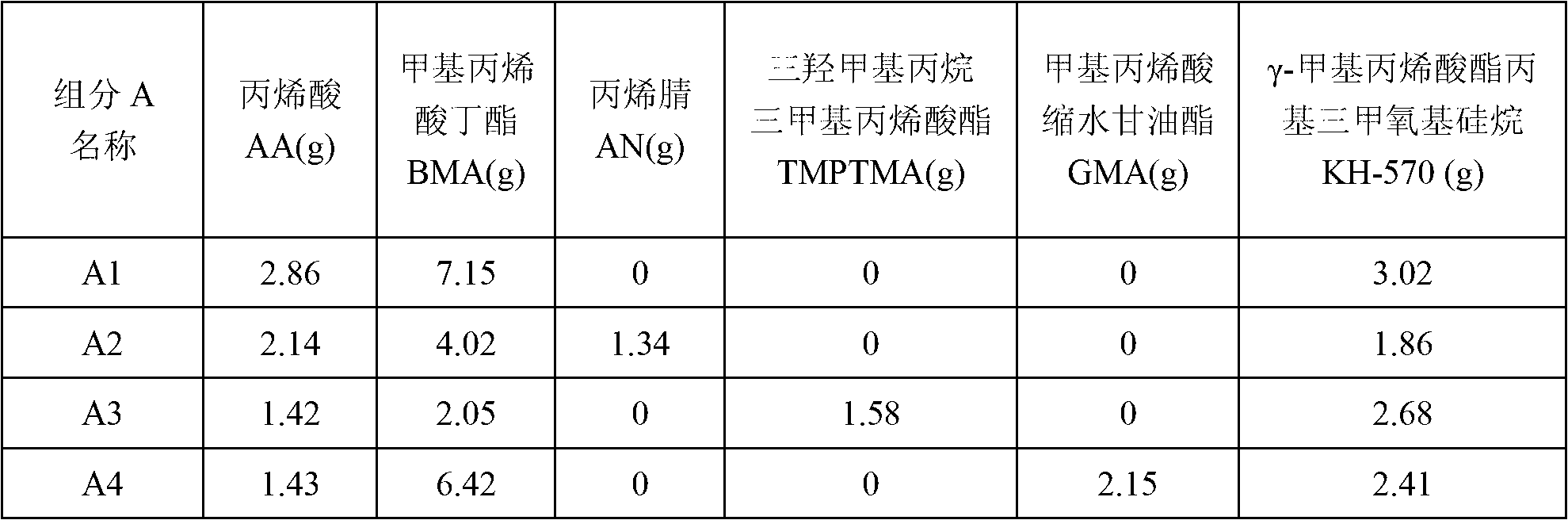

[0017] Specific embodiment one: the preparation method of nano silica / polyacrylate modified epoxy resin adhesive of this embodiment, carry out according to the following steps: one, 3~30g silica sol is mixed with 20~80g solvent, at 1200~2400r Stir at a shear rate of 0.5-1.5 hours, then adjust the shear rate to 120-600r / min, raise the temperature to 65-85°C, and under nitrogen protection, dissolve the initiator-dissolved acrylate comonomer Add the coupling agent dropwise to the reaction system at a constant speed, and react for 3 to 6 hours to obtain polyacrylate-modified nano-silica composite particles;

[0018] 2. Mix the polyacrylate-modified nano-silica composite particles obtained in step 1 with 30-100g of epoxy resin, react at 90-120°C for 1-2h, then add hydroquinone, and then vacuum Remove the solvent, unreacted acrylate comonomer and coupling agent by degassing method to prepare nano-silica / polyacrylate modified epoxy resin;

[0019] 3. Take 100 parts by weight of nano...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that step one mixes 15g of silica sol with 50g of solvent, stirs for 1h at a shear rate of 2000r / min, and then adjusts the shear rate to 400r / min, The temperature was raised to 80°C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the amount of initiator in step one is 0.1-1.5g, the amount of acrylate comonomer is 3-30g, and the amount of coupling agent is 1.5~15g. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com