Bi-component epoxide-resin adhesive and preparation method thereof

A technology of epoxy resin and novolac epoxy resin, which is applied in the direction of epoxy resin glue, novolak epoxy resin adhesive, adhesive, etc., can solve the problem of unsatisfactory tensile shear strength, not many adhesives, and curing Complicated process and other issues to achieve the effects of improved tensile shear strength, improved flexibility, and high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Calculated by the weight of novolac epoxy resin in units of 100

[0020] A component B component

[0021] Novolak epoxy resin 100 1,4-bis(2,4-diaminophenoxy)benzene 20

[0022] CTBN 12

[0023] Cycloaliphatic epoxy resin 24

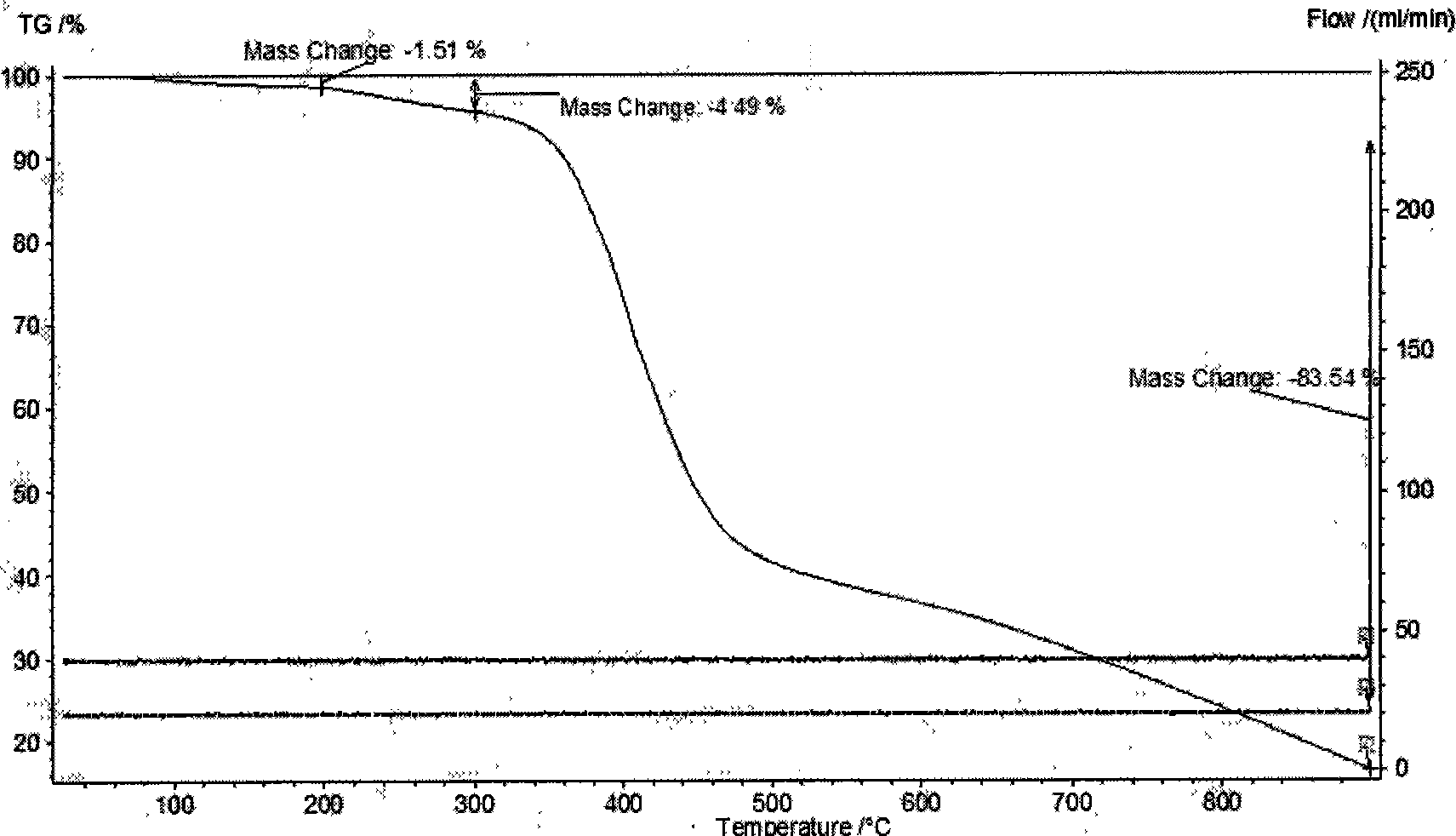

[0024] When ready to use, just mix the two components evenly, and its performance test is shown in Table 1. Through thermogravimetric analysis, it is found that the cured product of this adhesive has a thermogravimetric loss of only 1.51% at 200°C.

[0025] from figure 1 It can be seen from the figure that the cured product of Example 1 has good heat resistance, the thermal weight loss at 200°C is only 1.51%, and the thermal weight loss at 300°C is only 4.49%.

Embodiment 2

[0037] Calculated by the weight of novolac epoxy resin in units of 100

[0038] A component B component

[0039] Novolak epoxy resin 100 1,4-bis(2,4-diaminophenoxy)benzene 20

[0040] CTBN 12

[0041] Cycloaliphatic epoxy resin 30

[0042] When ready to use, mix the two components evenly.

Embodiment 3

[0044] Calculated by the weight of novolac epoxy resin in units of 100

[0045] A component B component

[0046] Novolak epoxy resin 100 1,4-bis(2,4-diaminophenoxy)benzene 20

[0047] CTBN 12

[0048] Cycloaliphatic epoxy resin 35

[0049] When ready to use, mix the two components evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com