A kind of thermoplastic starch capable of repeated heat processing and preparation method thereof

A thermoplastic starch, repeated thermal processing technology, applied in the field of starch deep processing, can solve the problems of starch no longer having thermoplasticity, poor thermal stability of thermoplastic starch, reduced molecular weight of starch, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

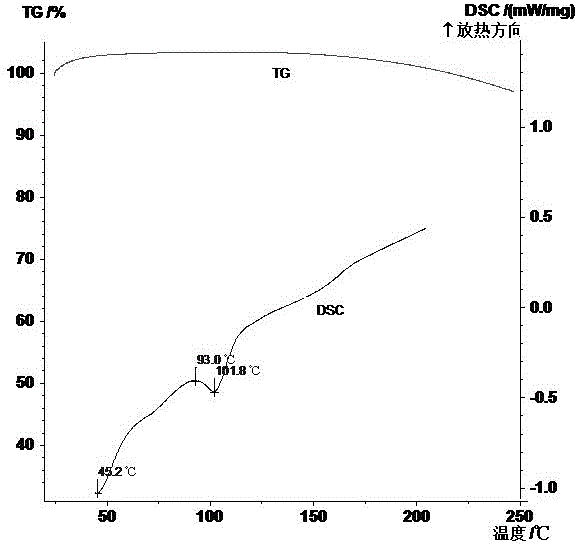

Image

Examples

Embodiment 1

[0037] (1) 40 parts by weight of tapioca starch, 40 parts by weight of pea starch and 2 parts by weight of hydroxylamine sulfate are refined by a ball mill until the particle size of the powder is ≤ 5 microns to obtain aminated starch;

[0038] (2) The C 18 The dimer acid of hydrogenated fatty acid is added to the high-speed mixer, the temperature of the high-speed mixer is raised to 100°C, the stirring speed is controlled at 200-300rpm, and glacial acetic acid is added while stirring, and the pre-condensation is carried out in the high-speed mixer for 30 minutes. The amount of glacial acetic acid added is controlled 2% of the mass of hydrogenated aliphatic dimer acid;

[0039] (3) Add the precondensed polymer obtained in step (2) into a two-stage twin-screw reaction extruder, set the temperature of the first-stage screw reactor to 80-120°C, and mix through the gap between the screw flight and the barrel to make the amination The crystals of starch relax to form amorphous ge...

Embodiment 2

[0042] (1) Thining 40 parts by weight of sweet potato starch, 45 parts by weight of acorn starch and 3 parts by weight of hexamethylenediamine through a vortex airflow refiner to obtain aminated starch;

[0043] (2) The C 18 The dimer acid of hydrogenated fatty acid is added to the high-speed mixer, the temperature of the high-speed mixer is raised to 100°C, the stirring speed is controlled at 250rpm, and glacial acetic acid is added while stirring, and the pre-condensation is carried out in the high-speed mixer for 45min. 3% of the mass of aliphatic dimer acid;

[0044] (3) Add the precondensed polymer obtained in step (2) into a two-stage twin-screw reaction extruder, set the temperature of the first-stage screw reactor to 80-120°C, and mix through the gap between the screw flight and the barrel to make the amination The crystals of starch relax to form amorphous gel powder, which is polycondensed with hydrogenated aliphatic dimer acid; through the second-stage screw react...

Embodiment 3

[0047] (1) Grinding 80 parts by weight of sago starch and 3 parts by weight of decanediamine through a grinder until the particle size of the powder is ≤5 microns to obtain aminated starch;

[0048] (2) C obtained by derivatizing the aminated starch obtained in step (1) with 10 parts by weight of dimer linolenic acid and dimer oleic acid 18 Add the dimer acid of hydrogenated fatty acid into the high-speed mixer, the temperature of the high-speed mixer is raised to 110°C, the stirring speed is controlled at 300rpm, and glacial acetic acid is added while stirring, and the pre-condensation is carried out in the high-speed mixer for 35min. The amount of glacial acetic acid added is controlled at 2% of hydrogenated aliphatic dimer acid quality;

[0049] (3) Add the precondensed polymer obtained in step (2) into a two-stage twin-screw reaction extruder, set the temperature of the first-stage screw reactor to 80-120°C, and mix through the gap between the screw flight and the barrel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com