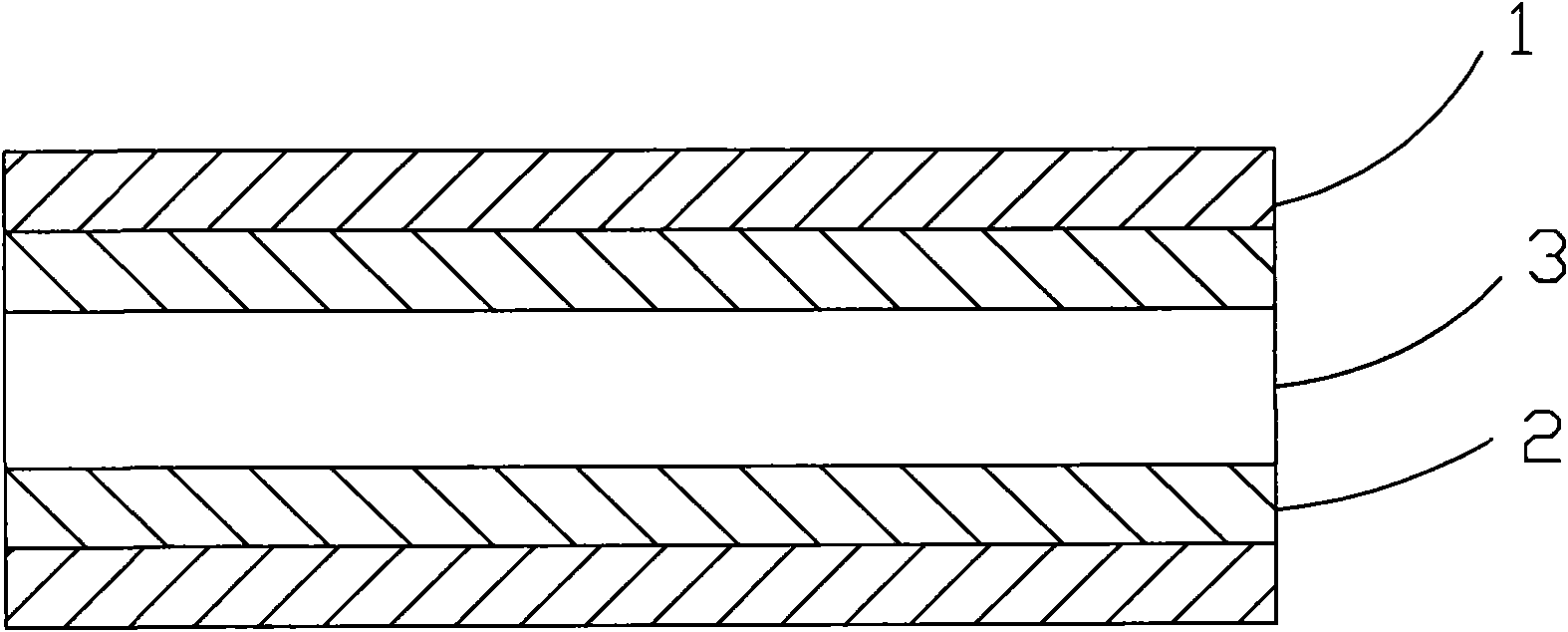

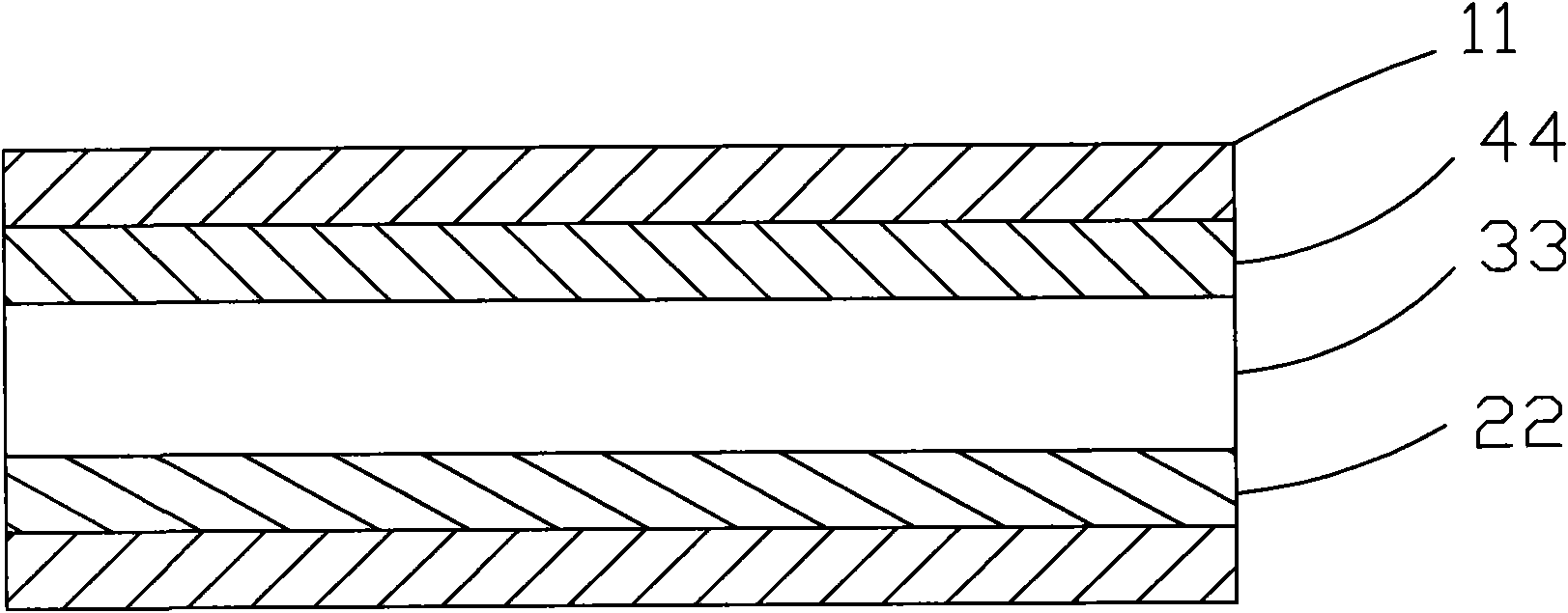

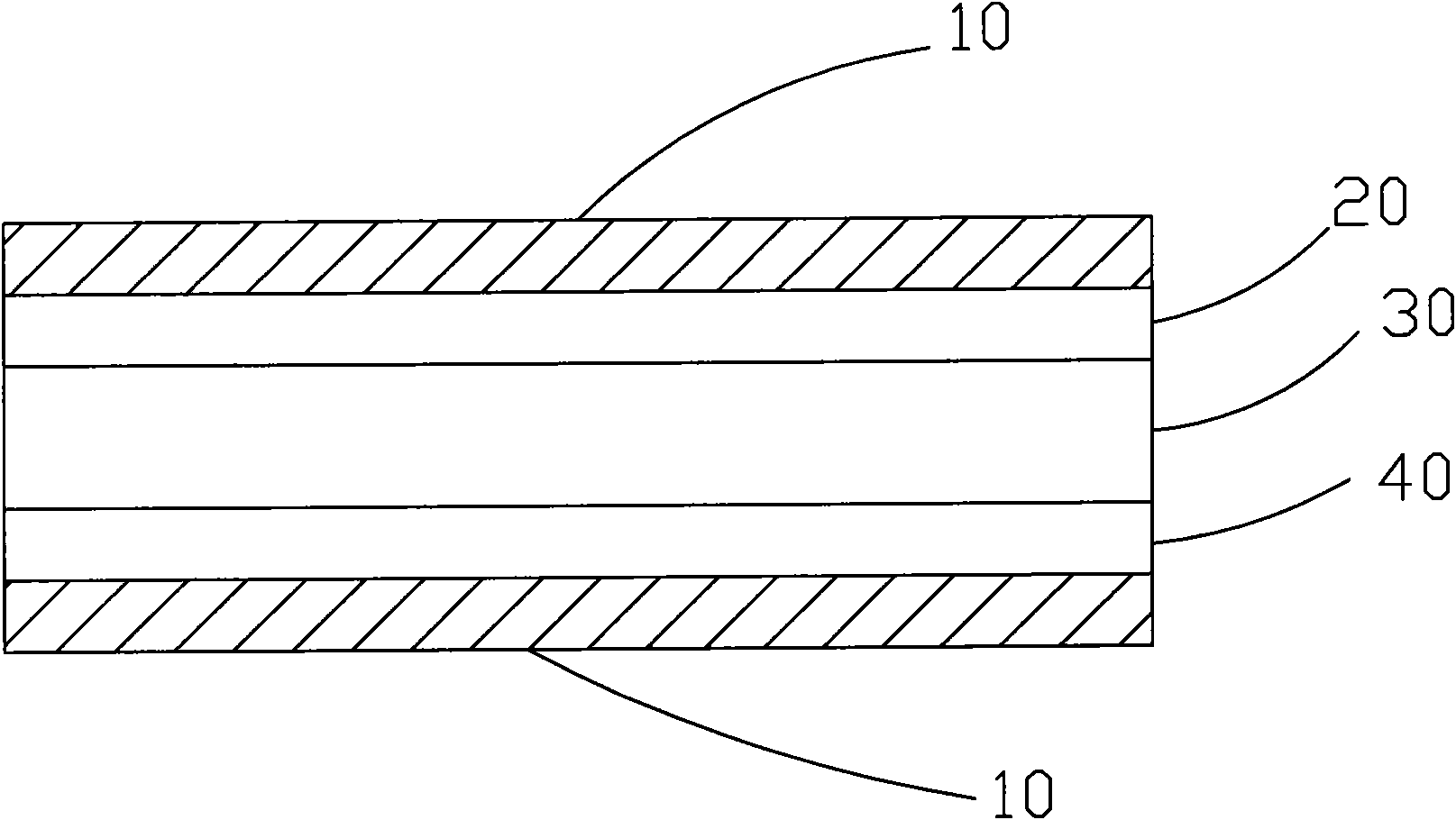

Two-layer-process double-sided flexible copper-clad laminate (CCL) and manufacture method thereof

A technology of flexible copper-clad laminates and manufacturing methods, which is applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of reduced dimensional stability, peeling strength and dimensional stability of copper-clad laminates, etc., to achieve Improved dimensional stability, good industrialization prospects, high heat resistance and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Synthesis of high thermal expansion coefficient thermosetting polyimide resin:

Synthetic example 1

[0052] Synthesis example 1: weigh the p-PDA of 10.2g, dissolve in NMP340g while stirring in a 500ml there-necked flask, then weigh the ODA of 12.6g, dissolve in the solution, and cool the solution in a water bath. 45.7 g of BPDA was added under nitrogen flow, and then the solution was returned to room temperature, and the stirring was continued for 3 hours to carry out a polymerization reaction to prepare a viscous acid solution of a thermosetting polyimide resin with a high thermal expansion coefficient.

[0053] Synthesis of low thermal expansion coefficient thermosetting polyimide resin:

Synthetic example 2

[0054] Synthetic example 2: weigh the p-PDA of 14.7g, dissolve in the NMP340g while stirring in the there-necked flask of 500ml, then weigh the ODA of 6.8g, dissolve in the solution, the solution is cooled in a water bath, in 39.6 BPDA and 7.3 g of PMDA were added successively under nitrogen flow, and then the solution was returned to room temperature, and the stirring was continued for 3 hours to carry out polymerization reaction to prepare a viscous acid solution of low thermal expansion coefficient thermosetting polyimide resin.

[0055] Synthesis of thermoplastic polyimide resin:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com