Preparation method of lithium ion battery diaphragm

A technology for lithium ion batteries and separators, which is applied in the field of preparation of lithium ion battery separators, can solve the problem of uneven pore size and distribution of micropores of separators, widened molecular weight distribution, poor performance of separators such as air permeability, thermal shrinkage and membrane breaking temperature. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

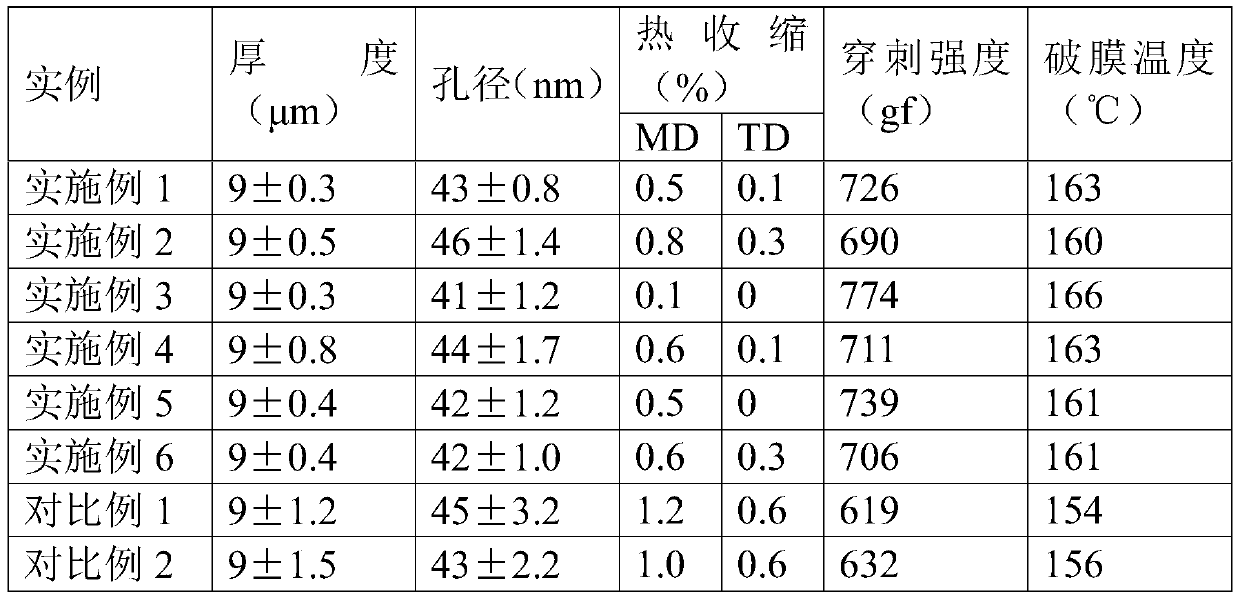

Examples

preparation example Construction

[0021] A preparation method of a lithium-ion battery diaphragm, comprising the following steps:

[0022] (a) mixing ultra-high molecular weight polyethylene and a solvent, heating and stirring for the first time to obtain a pre-swelling mixed solution;

[0023] (b) Grinding the pre-swelling mixture, then adding a fluoropolymer, heating and stirring for the second time to obtain a dispersion;

[0024] (c) melting and extruding the dispersion to obtain a plasticized melt film;

[0025] (d) post-processing the plasticized melt film.

[0026] Preferably, the weight average molecular weight of the ultra-high molecular weight polyethylene is 1.0×10 6 ~8.0×10 6 g / mol; further preferably, the weight average molecular weight of the ultra-high molecular weight polyethylene is 1.5×10 6 ~3.0×10 6 g / mol.

[0027] It can be understood that in the pre-swelling mixed solution of the present invention, the solid content of ultra-high molecular weight polyethylene can be relatively high. ...

Embodiment 1

[0060] (a) 120kg weight average molecular weight is 1.5×10 6 g / mol ultra-high molecular weight polyethylene and 280kg 40 ℃ kinematic viscosity is 40mm 2 / s Add liquid paraffin into the stirring tank, start heating to 110°C at a stirring rate of 150r / min, and keep it warm for 5 hours to obtain a pre-swelling mixture.

[0061] (b) Adding pure zirconium beads with a particle size of 1.2 mm into the sand mill, transporting the pre-swelled mixed solution into the sand mill, and circulating it 6 times at a grinding rate of 800 r / min to obtain a uniformly dispersed mixed solution;

[0062] In the homogeneously dispersed mixed solution, add fluoropolymer (FX5922 of 3M Company), the concentration of the fluoropolymer in the uniformly dispersed mixed solution is 1000ppm, at 80°C with a stirring rate of 200r / min Stir for 3 hours, and stir evenly to obtain a dispersion.

[0063] (c) The dispersion liquid is heated and continuously extruded by a twin-screw extruder, the heating temperatu...

Embodiment 2

[0066] This example is the same as Example 1 except that the amounts of ultra-high molecular weight polyethylene and liquid paraffin are changed to 80kg and 320kg respectively in step (a). The specific technical solutions are:

[0067] (a) 80kg weight average molecular weight is 1.5×10 6 g / mol ultra-high molecular weight polyethylene and 320kg 40 ℃ kinematic viscosity is 40mm 2 / s Add liquid paraffin into the stirring tank, start heating to 110°C at a stirring rate of 150r / min, and keep it warm for 5 hours to obtain a pre-swelling mixture.

[0068] (b) Adding pure zirconium beads with a particle size of 1.2 mm into the sand mill, transporting the pre-swelled mixed solution into the sand mill, and circulating it 6 times at a grinding rate of 800 r / min to obtain a uniformly dispersed mixed solution;

[0069] In the homogeneously dispersed mixed solution, add fluoropolymer (FX5922 of 3M Company), the concentration of the fluoropolymer in the uniformly dispersed mixed solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com