Extinction type self-adhesive surface protection film and manufacturing method thereof

A surface protective film, self-adhesive technology, applied in the field of matte self-adhesive surface protective film and its manufacturing, can solve the problems of poor matting effect, residual glue or shadow on the protected surface, and many crystal points, etc. Good extinction performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

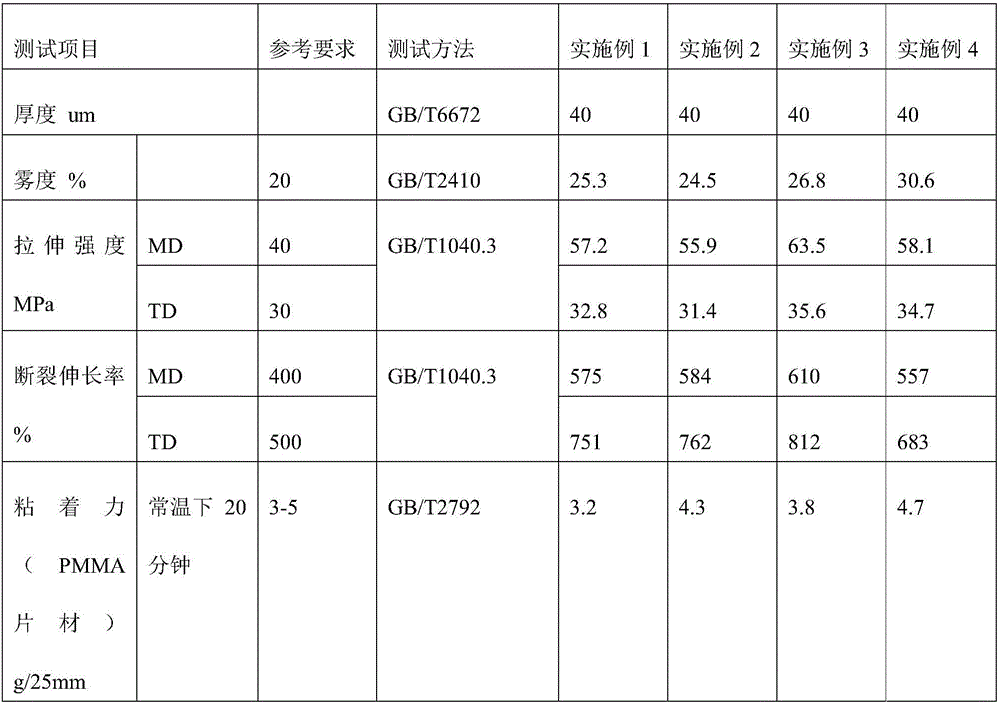

Embodiment 1

[0024] A matting type self-adhesive surface protection film, including a self-adhesive layer, an intermediate layer and an anti-adhesive layer, the self-adhesive layer is made of ultra-low density polyethylene, and the intermediate layer is composed of a mixture of ethylene-propylene copolymer and polyethylene with a low crystal point , the mass percent of ethylene-propylene copolymer and polyethylene with low crystal point is 80 / 20, the anti-adhesive layer is formed by mixing polypropylene and high-density polyethylene, and the mass percent of polypropylene and high-density polyethylene is 90 / 10.

[0025] The thickness of the self-adhesive layer is 10% of the total thickness, the thickness of the middle layer is 75% of the total thickness, and the thickness of the release layer is 15% of the total thickness.

Embodiment 2

[0027]A matting self-adhesive surface protection film comprising a self-adhesive layer, an intermediate layer and a release layer. The self-adhesive layer is composed of a mixture of ultra-low density polyethylene and ethylene methacrylic acid, and the mass percentage of ultra-low density polyethylene and ethylene methacrylic acid is 80 / 20; the middle layer is made of low crystal point ethylene-propylene copolymer Composition; the anti-adhesive layer is formed by mixing polypropylene and high-density polyethylene, wherein the mass percentage of polypropylene and high-density polyethylene is 80 / 20.

[0028] The thickness of the self-adhesive layer is 15% of the total thickness, the thickness of the middle layer is 70% of the total thickness, and the thickness of the release layer is 15% of the total thickness.

Embodiment 3

[0030] A matting self-adhesive surface protection film comprising a self-adhesive layer, an intermediate layer and a release layer. The self-adhesive layer is composed of ultra-low density polyethylene, ethylene methacrylic acid and soft polypropylene, and the mass percentage of ultra-low density polyethylene, ethylene methacrylic acid and soft polypropylene is 80 / 10 / 10. The middle layer is composed of ethylene-propylene copolymer with low crystallization point and polyethylene mixed, the mass percentage of ethylene-propylene copolymer with low crystallization point and polyethylene is 70 / 30, and the anti-adhesive layer is made of polypropylene and high-density polyethylene Mixed composition, the mass percentage of polypropylene and high-density polyethylene is 95 / 5.

[0031] The thickness of the self-adhesive layer is 10% of the total thickness, the thickness of the middle layer is 75% of the total thickness, and the thickness of the release layer is 15% of the total thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com