Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Easy to form holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing compound core low-segregation large-sized hollow steel ingot

InactiveCN101279359AGuaranteed sequential solidificationIncrease profitFoundry mouldsFoundry coresTemperature differenceIngot

The invention relates to a casting process of all levels of large-scale hollow ingots below 250-ton level, in particular to a manufacturing method of composite core low-segregation large-scale hollow ingots. The manufacturing method is applicable to the preparation process of all large-scale hollow ingots which adopt the composite core pouring, comprising the casting of the hollow ingots with various shapes, specifications and materials. In addition to the usage of the computer simulation means to reasonably design an ingot mold and a pouring system, the invention mainly adopts the composite core hole forming technology, the large temperature difference cooling technology, the narrow gap molding sand technology, the bottom pouring dispersible gate drainage technology, the thick and large chassis mandatory cooling technology and a liquid nitrogen ejector device etc., and the invention further designs the corresponding mold and the equipment, pours the steel water with the different materials and prepares the low-segregation hollow ingots. The invention can ensure the serial solidification of the hollow ingots, reduce the defects of shrinkage, loose and inclusion, control the segregation position, lead the segregation band of the hollow ingots to be positioned at the middle position and improve the utilization rate and the using range of the hollow ingots.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

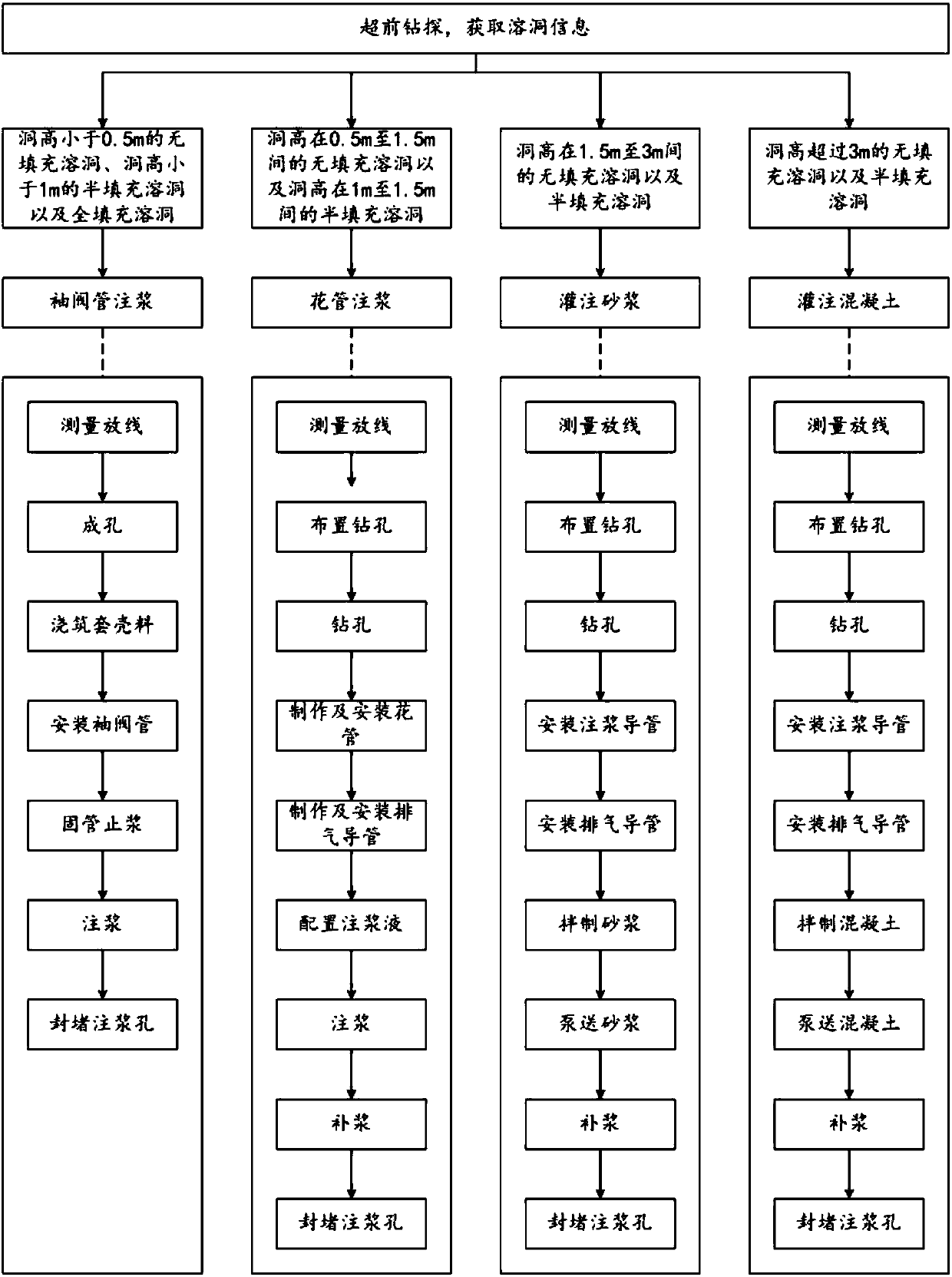

Karst cave treatment method applied to karst area cast-in-situ bored pile construction

The invention relates to a treatment method of karst caves with different sizes and types applied to karst area cast-in-situ bored pile construction. Firstly, the depths and the heights of the karst caves at pile positions are obtained by adopting an advance drilling technology; treatment is conducted on non-filled karst caves and semi-filled karst caves with the cave heights being higher than 3 mby adopting a concrete pouring method; treatment is conducted on non-filled karst caves and semi-filled karst caves with the cave heights being between 1.5 m and 3 m by adopting a mortar pouring method; treatment is conducted on non-filled karst caves with the cave heights being between 0.5 m and 1.5 m and semi-filled karst caves with the cave heights being between 1 m and 1.5 m by adopting a screen pipe grouting method; and treatment is conducted on non-filled karst caves with the cave heights being lower than 0.5 m and semi-filled karst caves and full-filled karst caves with the cave heights being lower than 1 m by adopting a sleeve valve pipe grouting method. The karst cave treatment method can conduct treatment on the different types of karst caves well.

Owner:CHINA FIRST METALLURGICAL GROUP

Polyolefin microporous diaphragm and preparation method thereof

ActiveCN102148346AEasy to form holesUniform hole formationCell component detailsPorosityPower battery

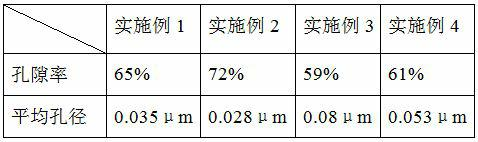

The invention belongs to the technical field of preparation of lithium batteries and in particular relates to a polyolefin microporous diaphragm for a lithium ion power battery and a preparation method thereof. The polyolefin microporous diaphragm is formed by adding a beta crystal type nucleating agent and an antioxidant into polyolefin resin, wherein the weight percent of the content of the beta crystal type nucleating agent to the polyolefin resin is 0.001-5.0%, and the weight percent of the antioxidant to the polyolefin resin is 0.001-1%. By adopting the polyolefin resin after modification for preparing the porous diaphragm, the diaphragm is easy to form holes; furthermore, the formed holes are uniform, the aperture is small (the average aperture is 0.01-0.1 mu m), the porosity is high (35%-80%), the air permeability is good, and the strength of the diaphragm is high.

Owner:河南天工膜材新能源科技有限公司

Water-based aramid fiber coating liquid, preparation method thereof, lithium ion battery and diaphragm of lithium ion battery

ActiveCN110845957AImprove wettabilityImprove thermal stabilitySecondary cellsCell component detailsActive agentLithium-ion battery

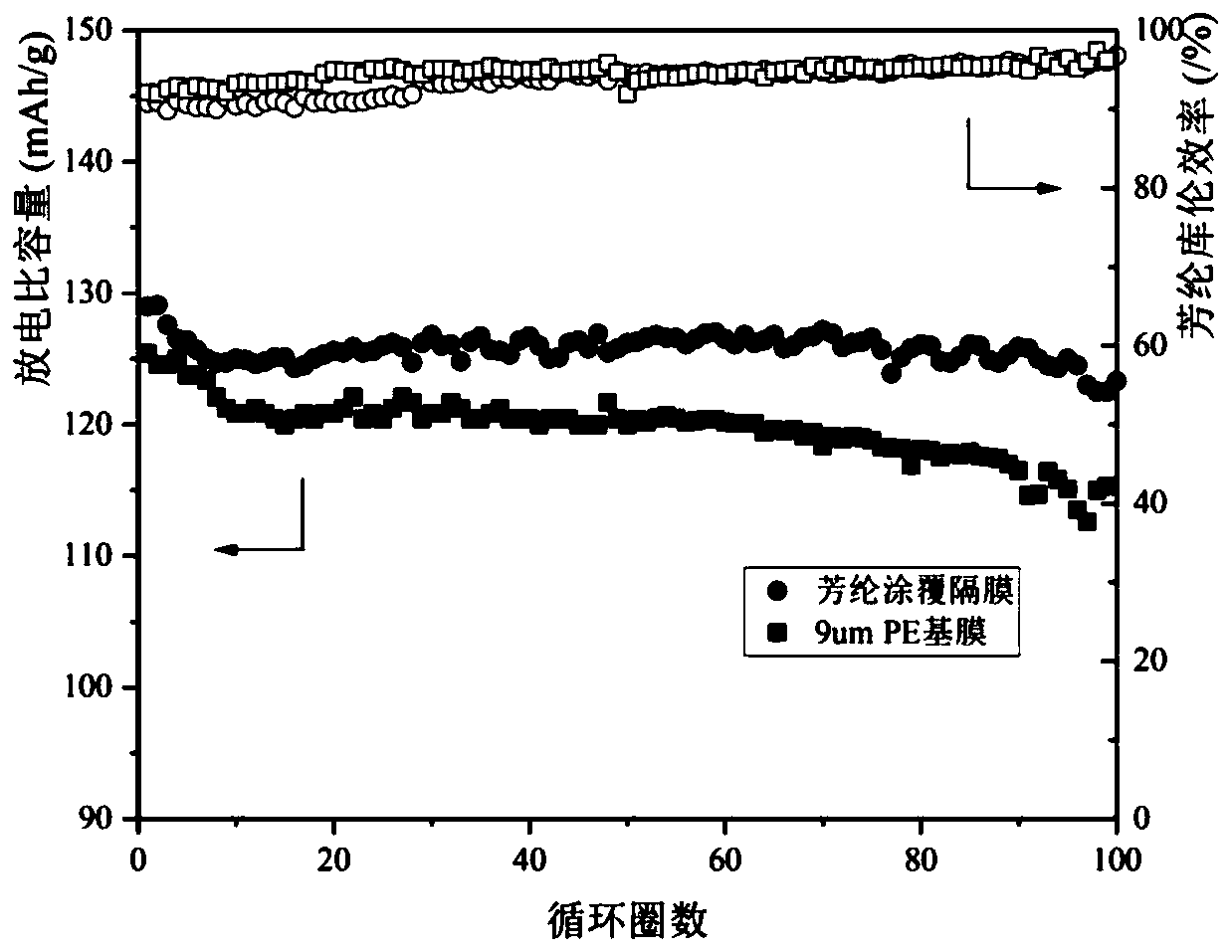

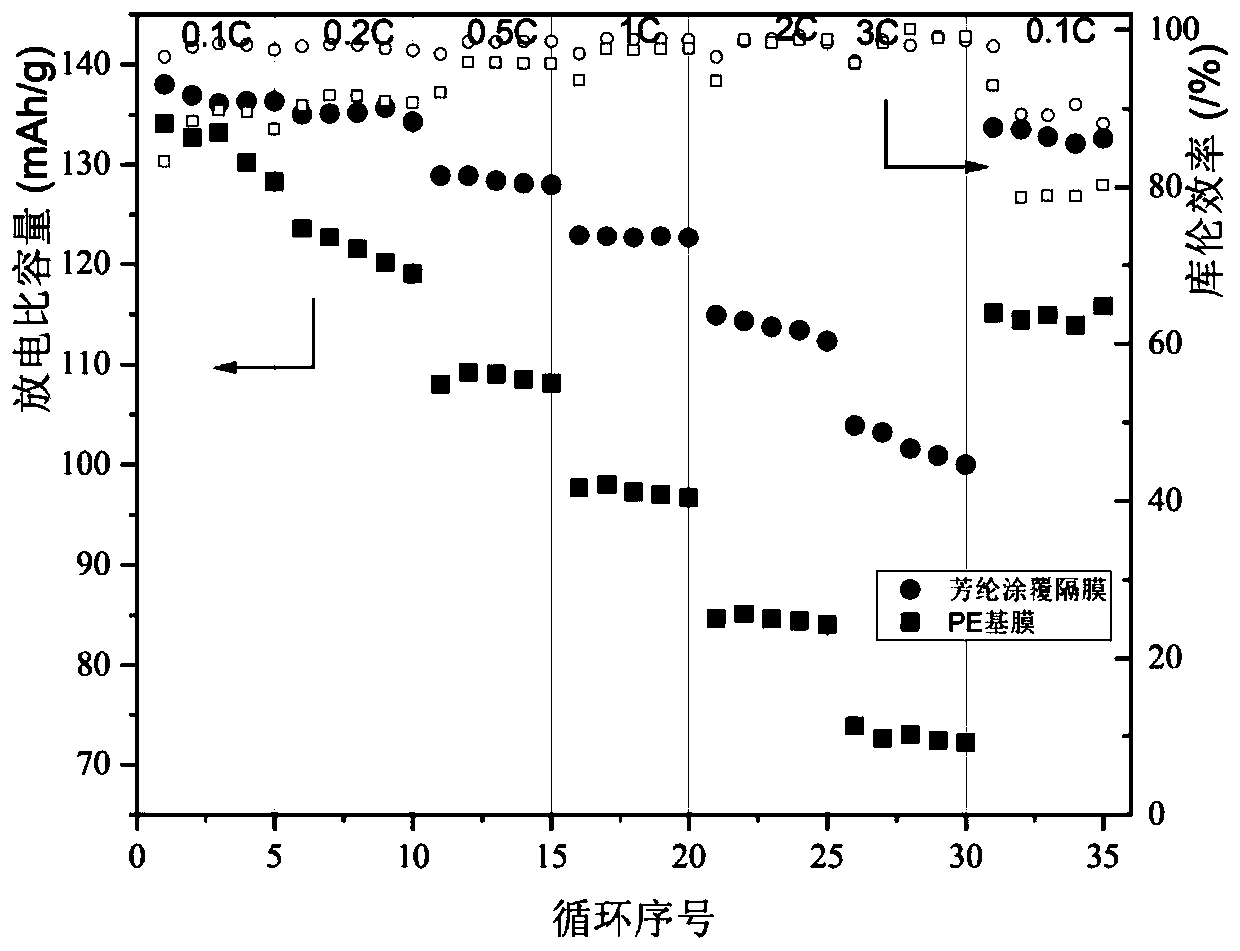

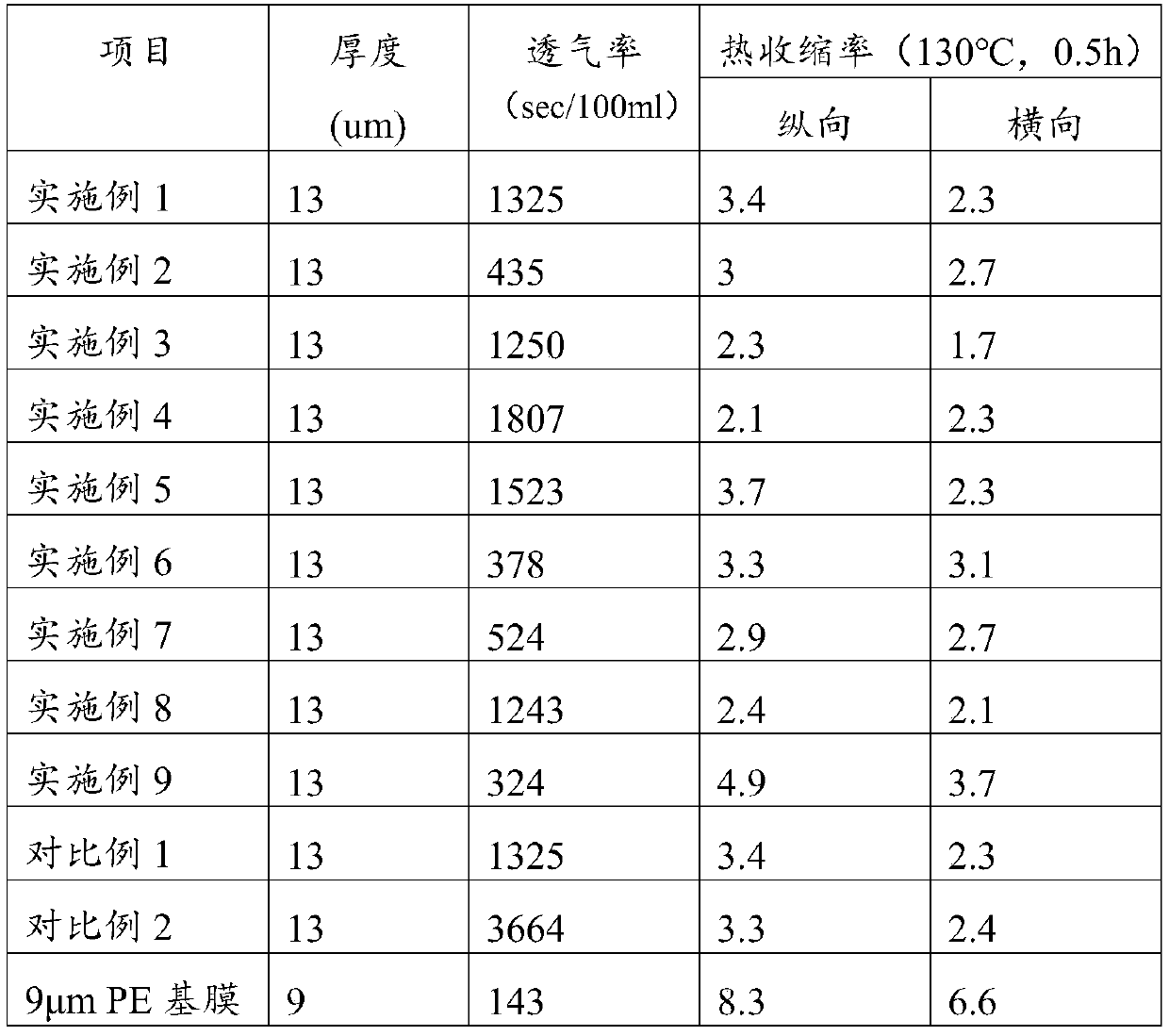

The invention discloses a water-based aramid fiber coating liquid, and belongs to the technical field of lithium ion battery. The water-based aramid fiber coating liquid comprises the following components in parts by mass: 100 parts of an aramid nano-fiber water-based dispersion solution, 0.25-3 parts of an adhesive, 0.2-3 parts of a wetting agent, 0.1-3 parts of an active agent and 0.3-5 parts ofa pore-forming agent, wherein the mass solid content of the aramid nano-fiber water-based dispersion solution is 0.2%-15%; the adhesive comprises at least one of the following components: an acrylicacid component, a polyurethane component, a polyimide polymer and carboxymethyl cellulose. The lithium ion battery diaphragm prepared by coating the water-based aramid fiber coating liquid has the characteristics of uniform coating, and good pore-forming uniformity; bonding treatment of a coating layer and a base membrane is excellent, the diaphragm possesses good wettability and good thermal stability, so that the excellent battery performance of the lithium ion battery is ensured.

Owner:SHANGHAI UNIV +1

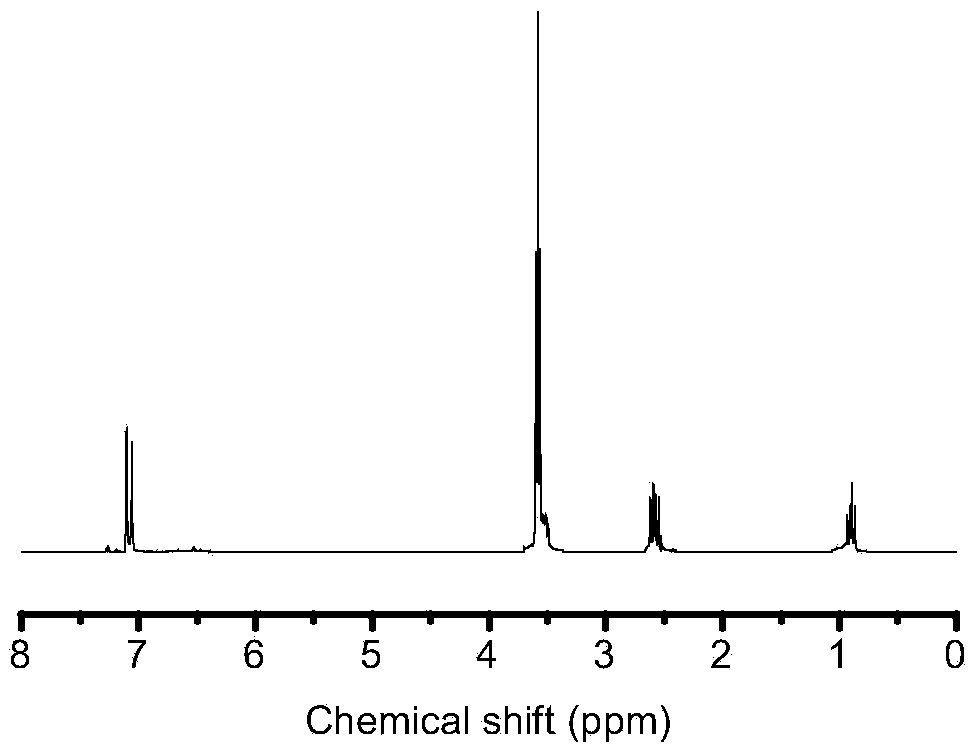

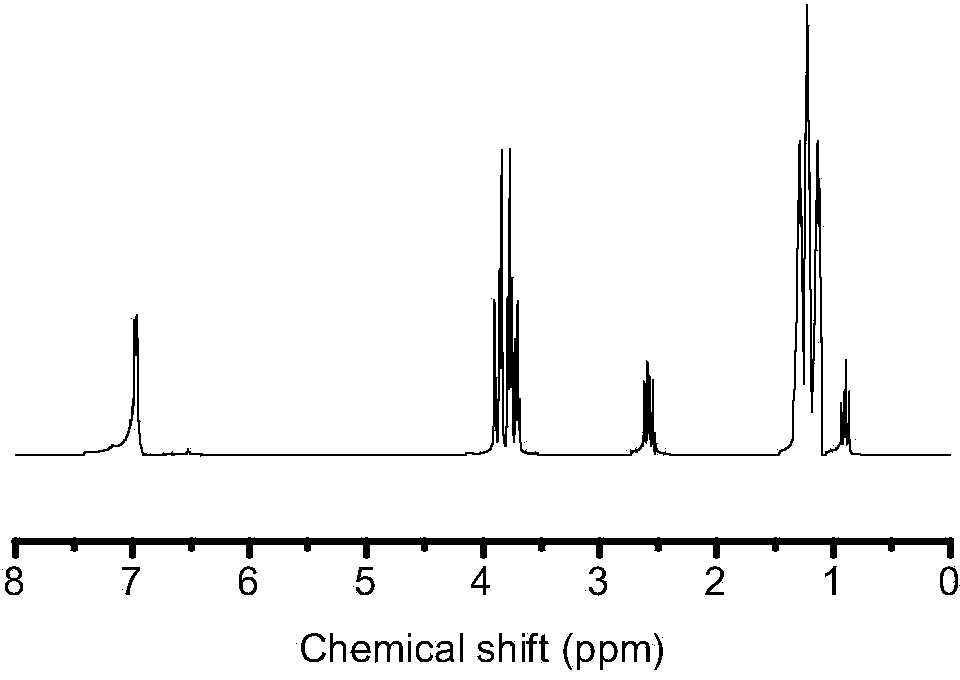

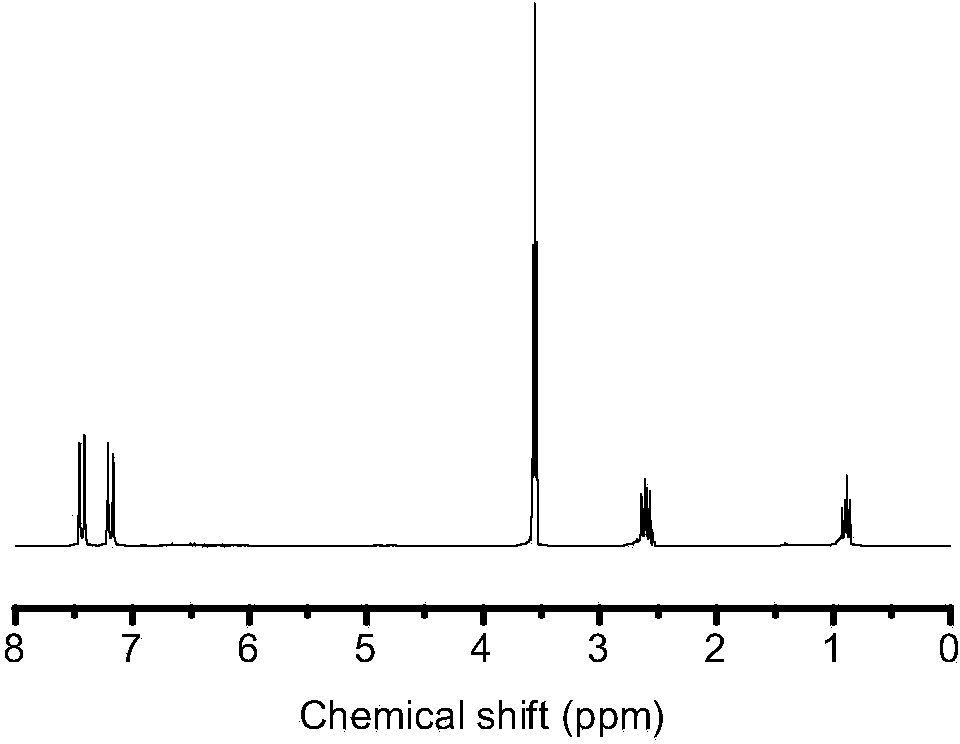

Preparation method of aromatic ring-containing bridged silsesquioxane monomer

The invention discloses a preparation method of an aromatic ring-containing bridged silsesquioxane monomer. The preparation method is characterized in that divinyl aromatic hydrocarbon and trialkoxyl silane are used as raw materials, tetrahydrofuran or diozane is used as a solvent, dicyclopentadiene platinum is used as a catalyst, and C=C double bonds of the divinyl aromatic hydrocarbon and Si-H bond of the trialkoxyl silane are subjected to hydrosilylation to synthesize the aromatic ring-containing bridged silsesquioxane monomer under the water-free and oxygen-free condition. The method has the advantages of simple process flow, high reaction specificity, no byproducts and high product yield.

Owner:HEFEI UNIV

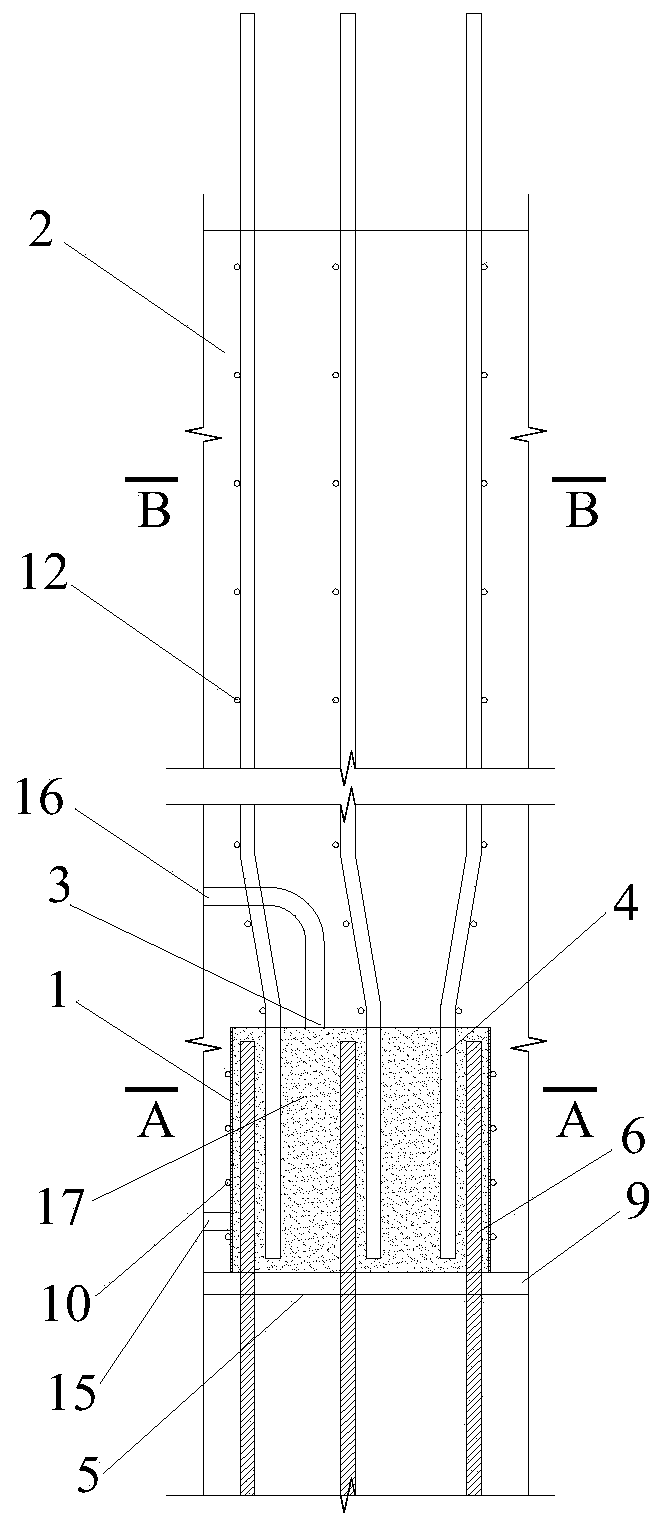

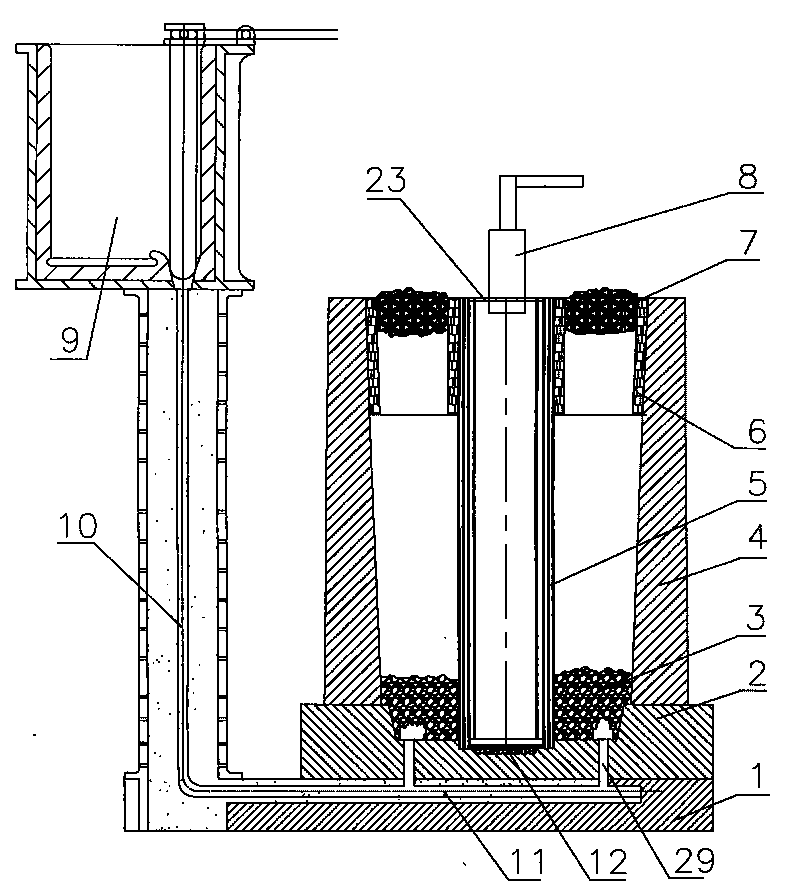

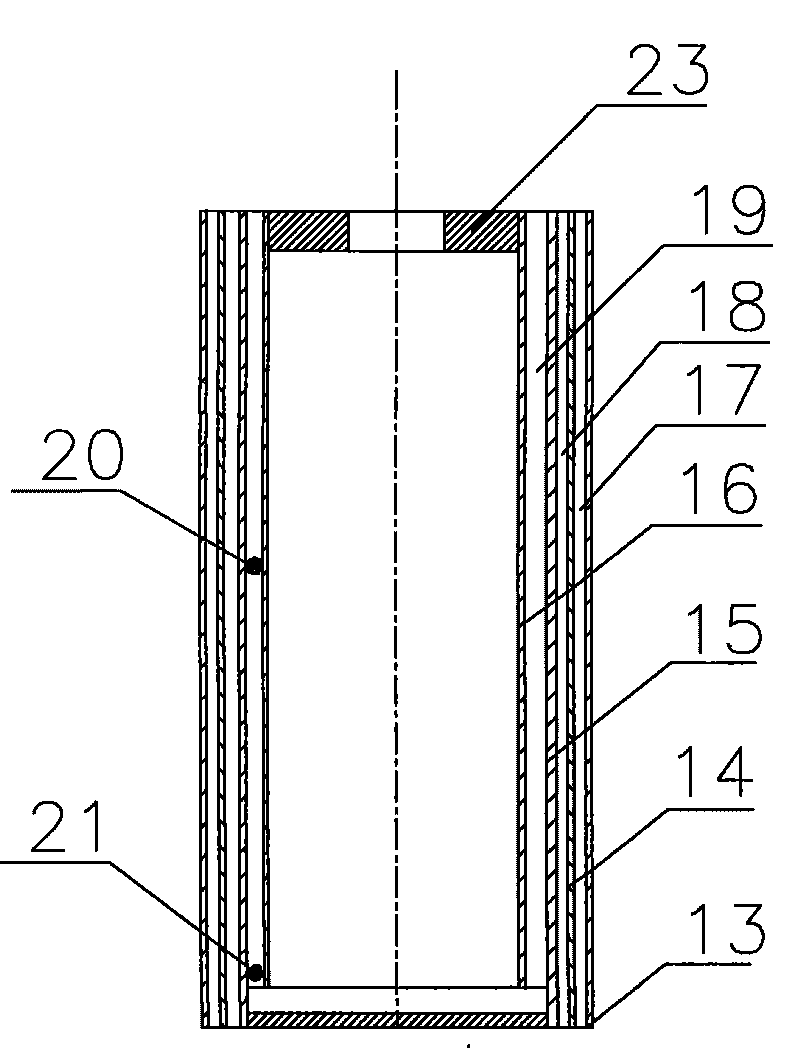

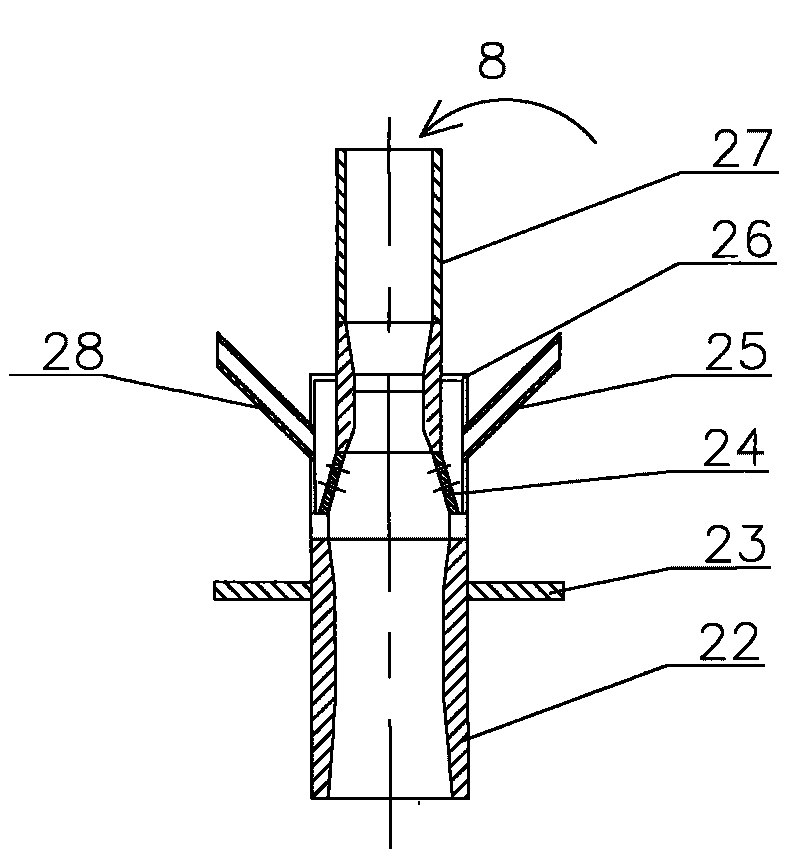

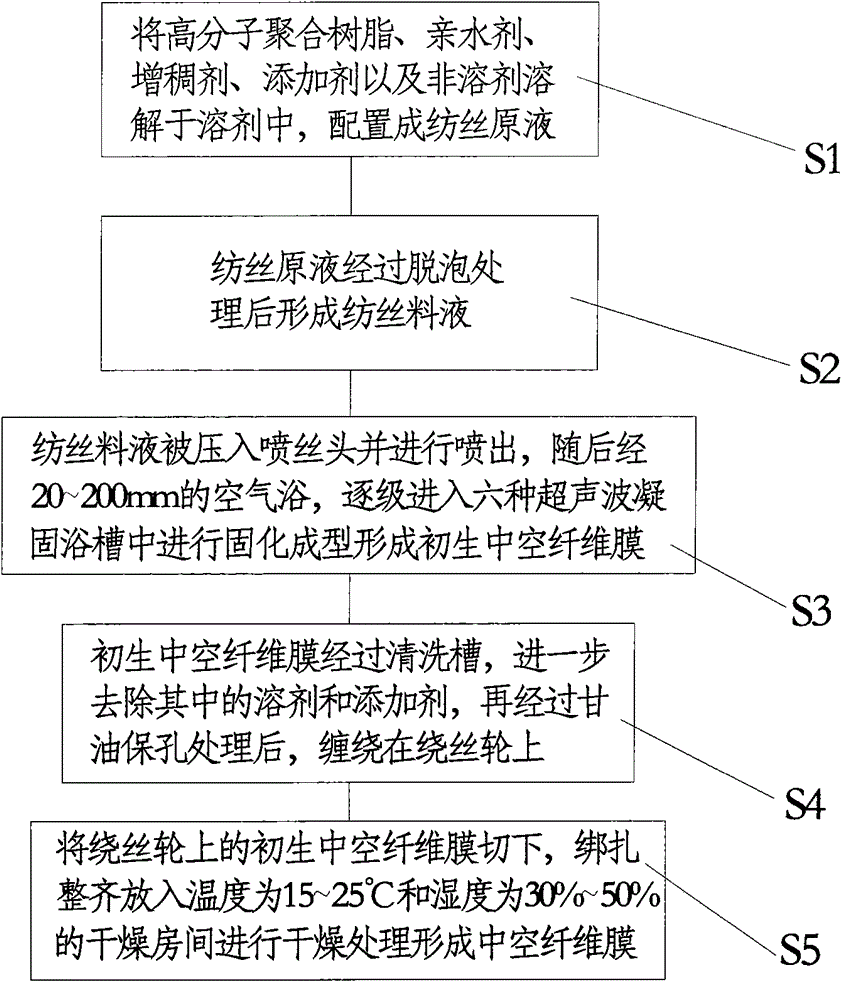

Supersonic wave technology-based hollow fiber film preparation method

The invention relates to a supersonic wave technology-based hollow fiber film preparation method. The preparation method comprises the following steps of S1, dissolving a polymer resin, a hydrophilc agent, a thickener, an additive and a nonsolvent in a solvent to obtain a spinning stoste, S2, carrying out deaeration treatment on the spinning stoste to obtain a spinning material liquid, S3, pressing the spinning material liquid into a spinning jet, carrying out spraying, carrying out 20-200mm air bath treatment, and stepwise feeding the sprayed materials into all levels of ultrasonic coagulation bathes for curing molding of a primary hollow fiber film, S4, treating the primary hollow fiber film by a washing tank, carrying out glycerin hole-retaining treatment, and winding the primary hollow fiber film on a wire winding wheel, and S5, cutting off the primary hollow fiber film on the wire winding wheel, tidily binding the primary hollow fiber film, putting it into a drying room and carrying out drying. The invention provides the supersonic wave technology-based hollow fiber film preparation method. The supersonic wave technology-based hollow fiber film preparation method improves hollow fiber film pore-forming efficiency, shortens spinning time and improves generation efficiency.

Owner:BEIJING E & E TECH

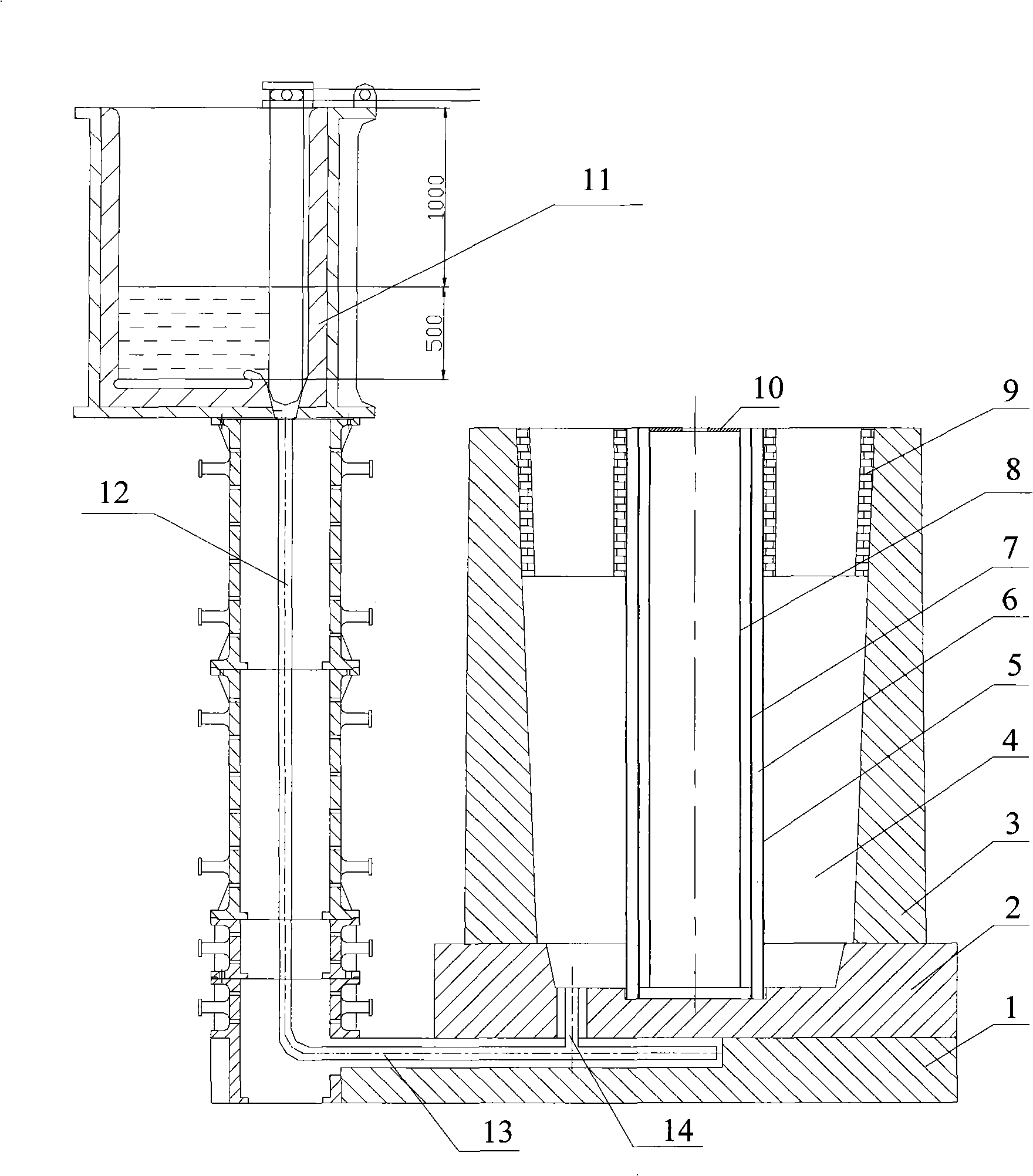

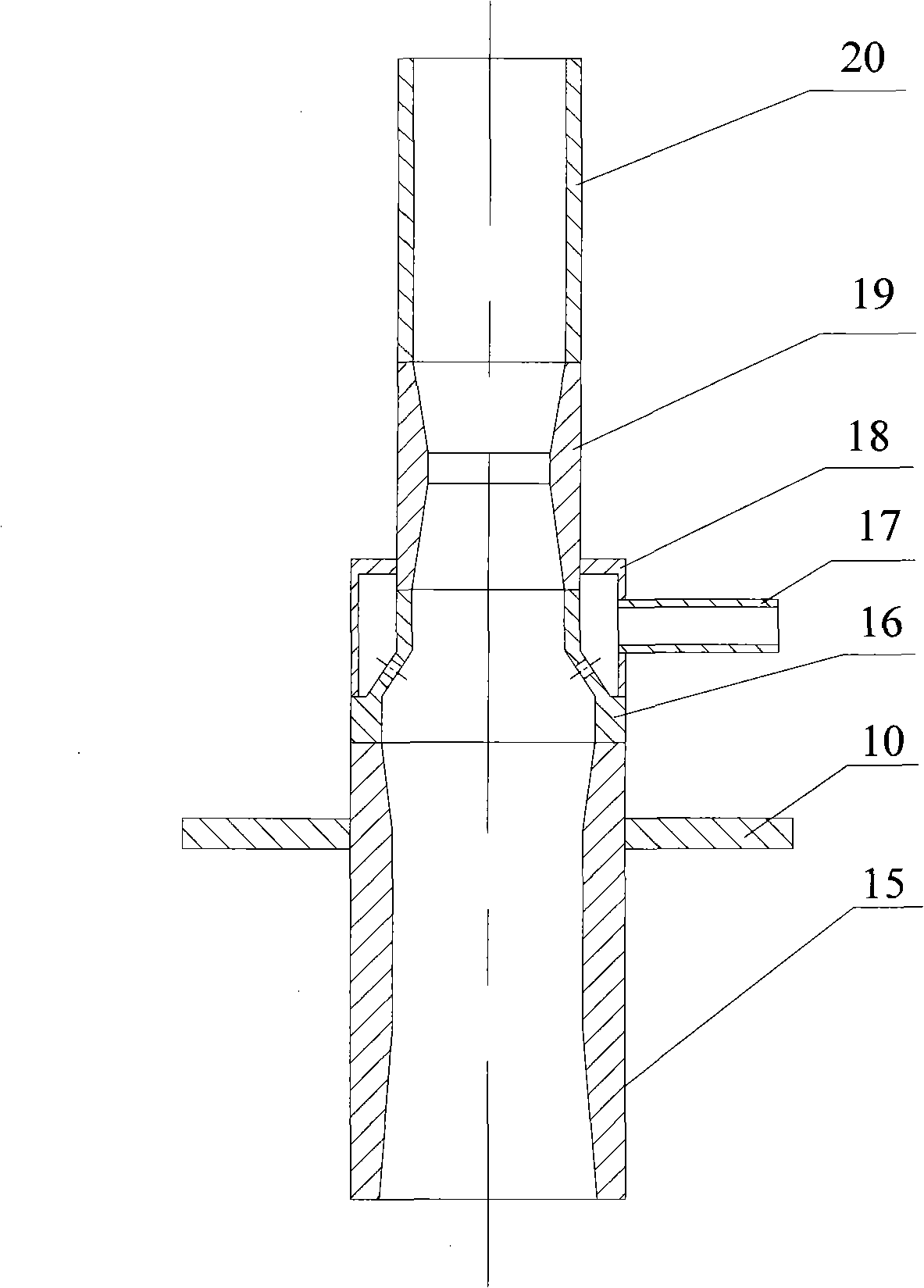

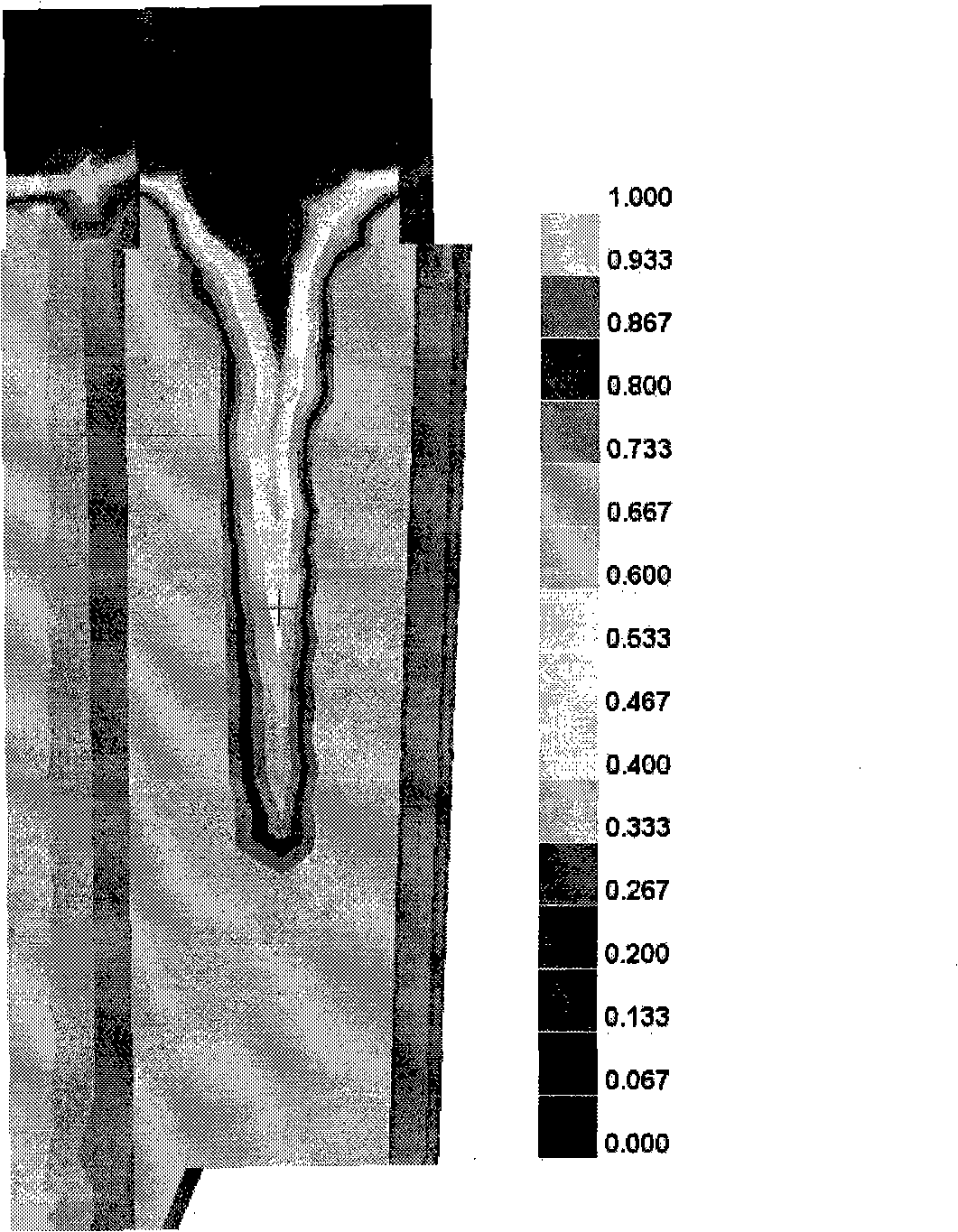

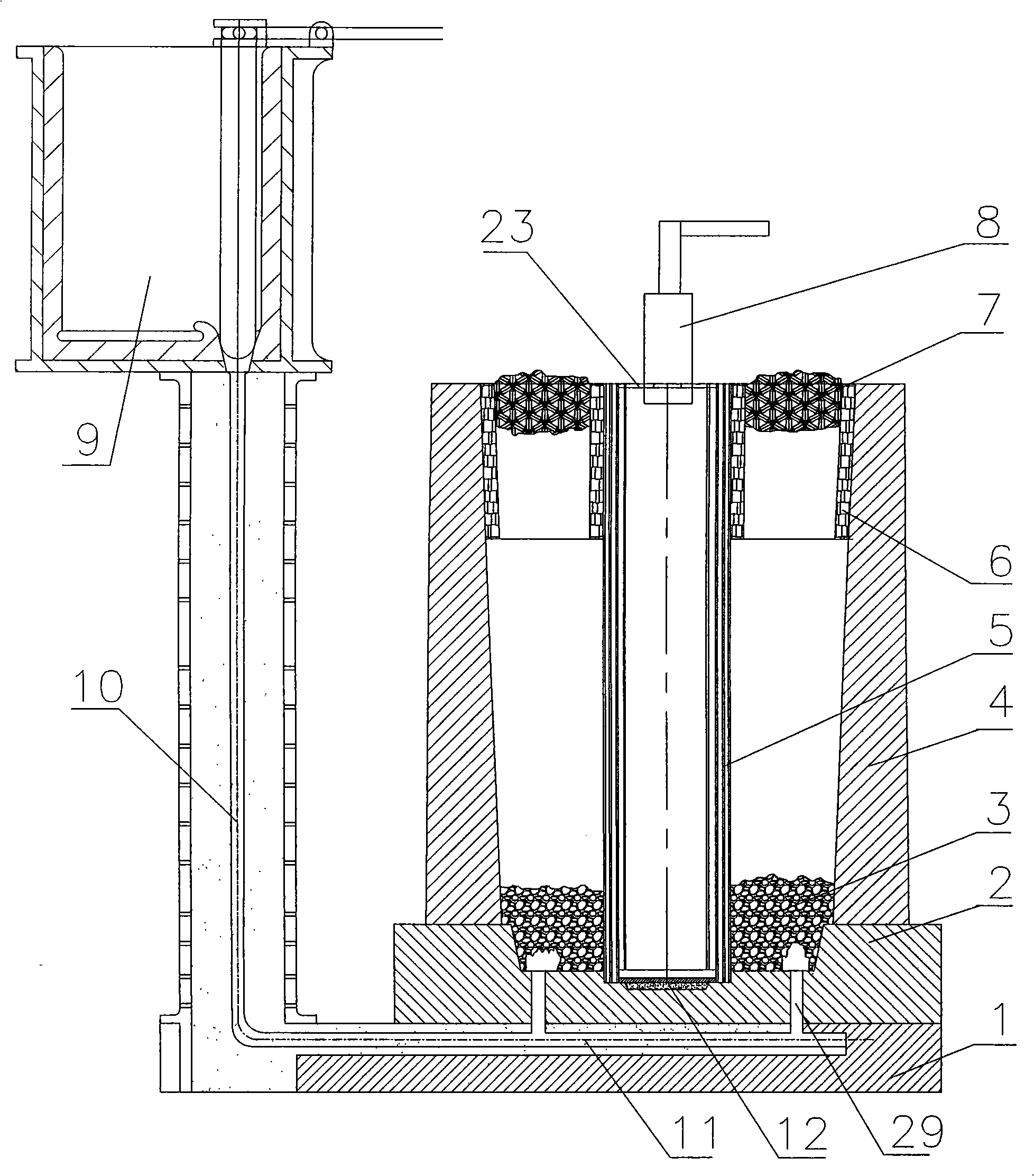

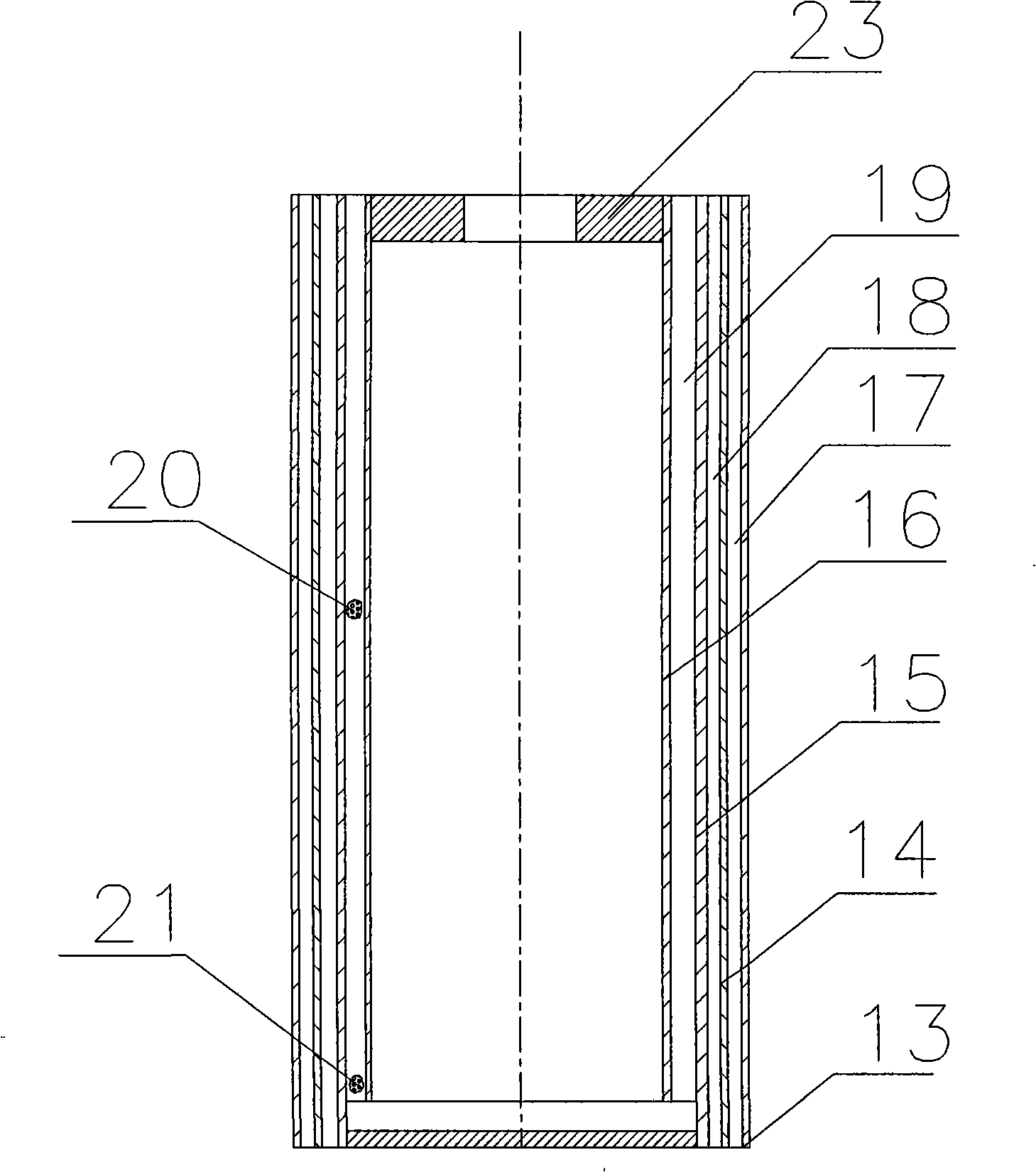

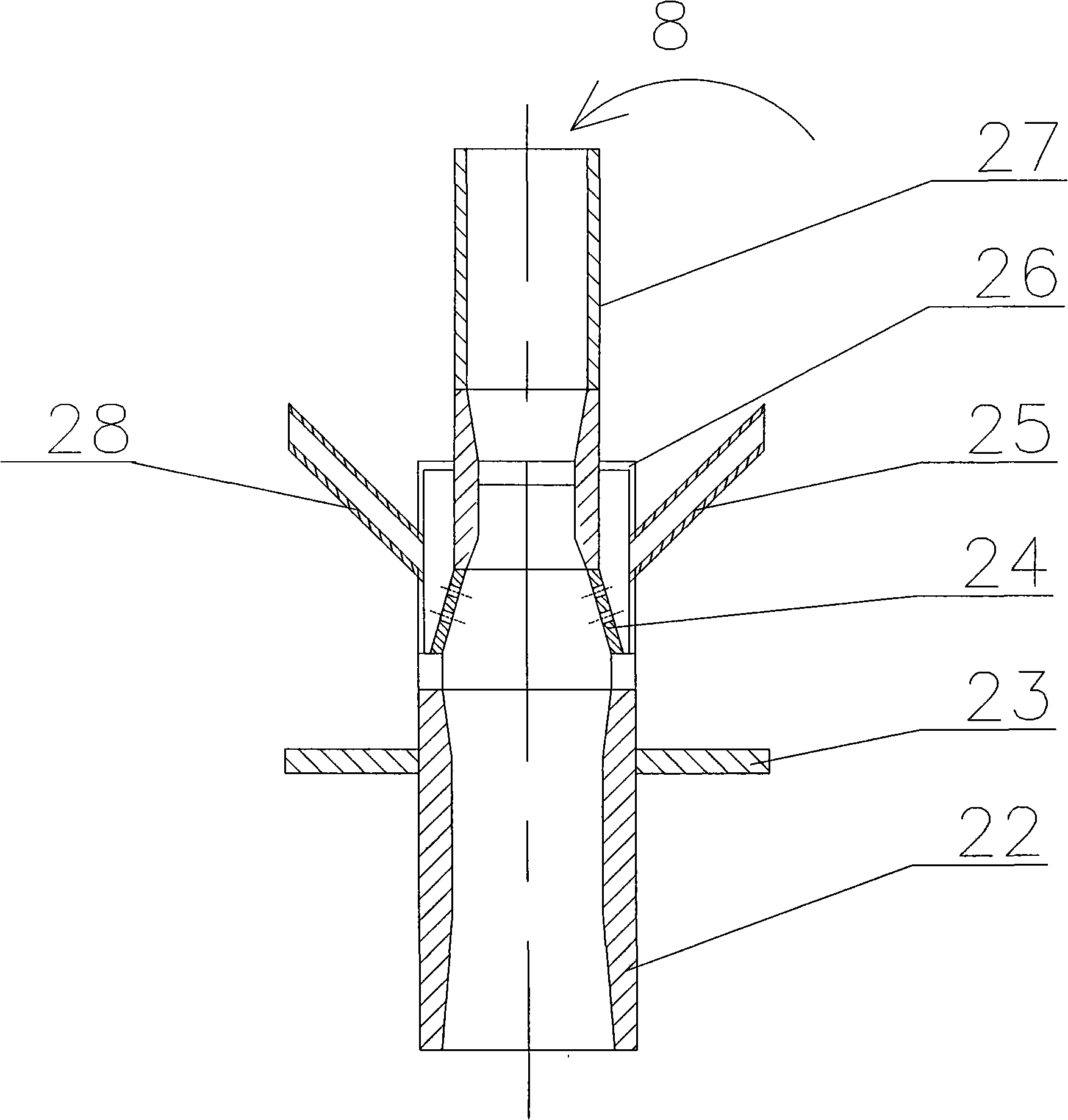

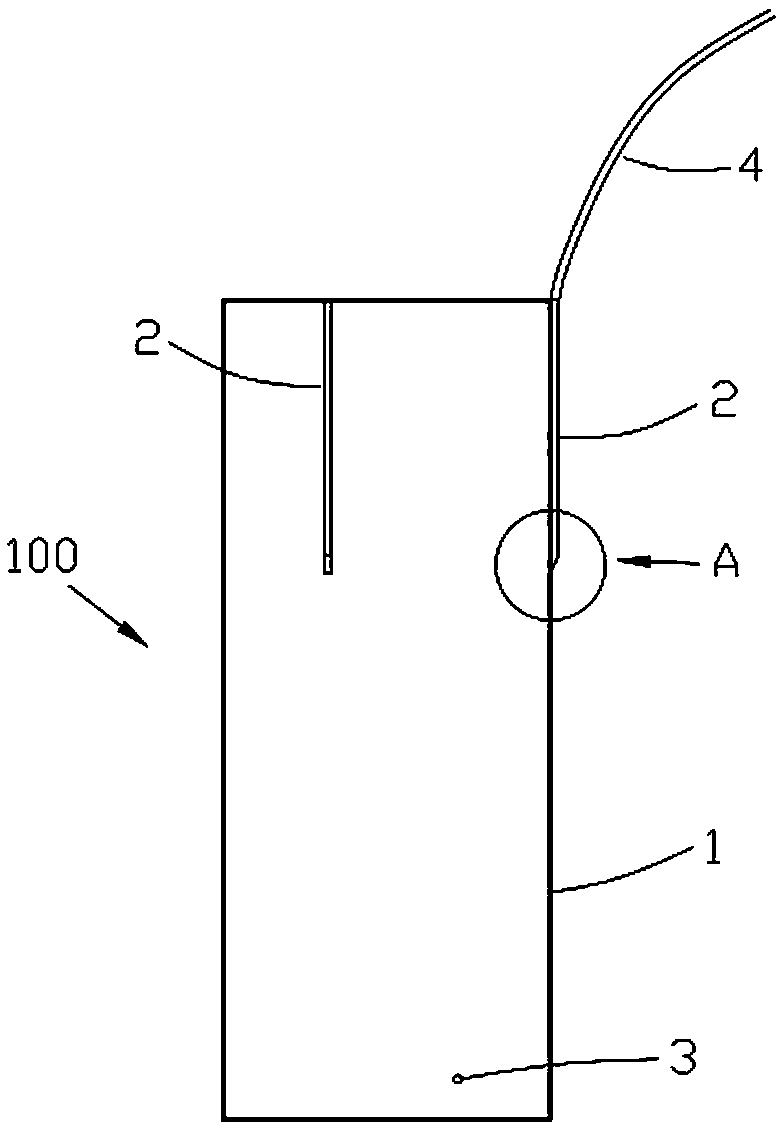

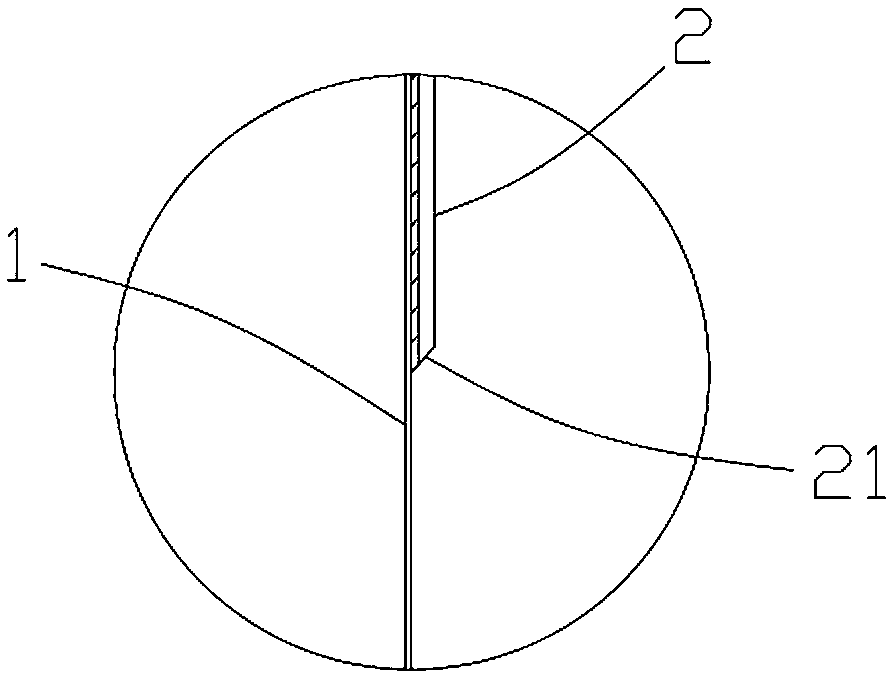

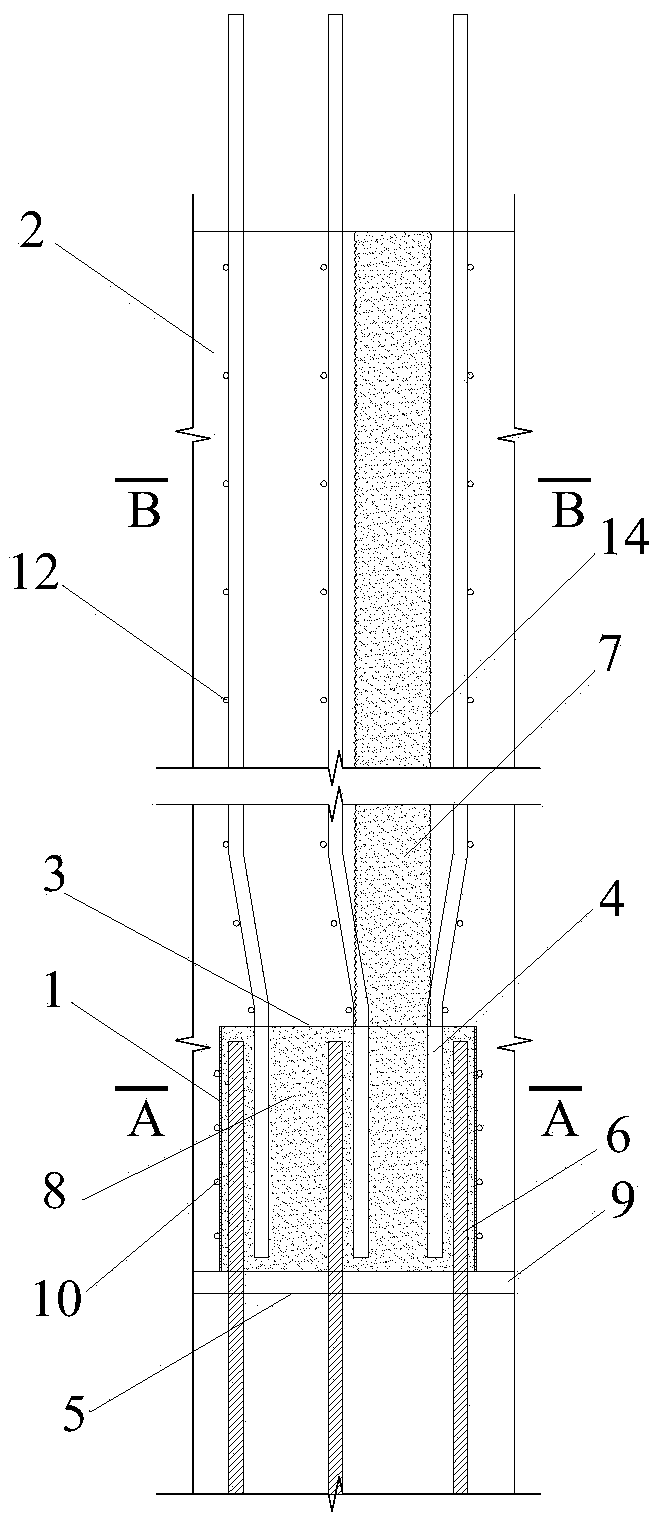

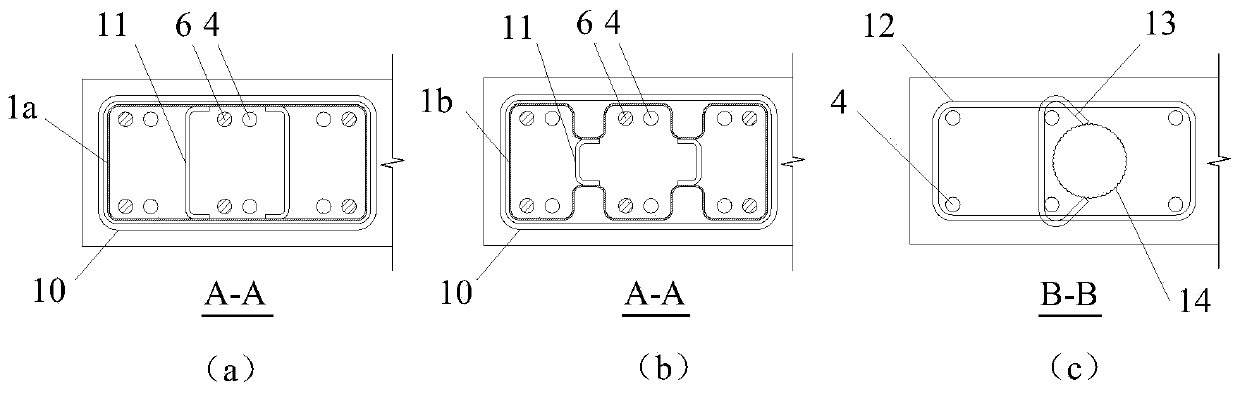

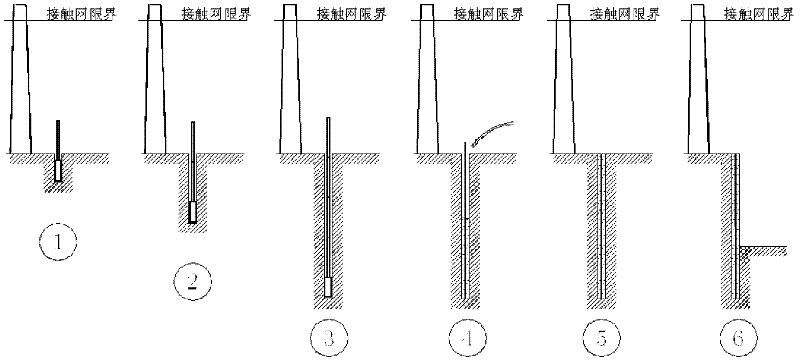

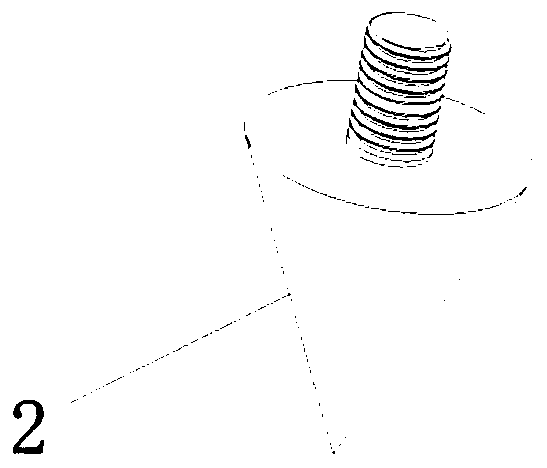

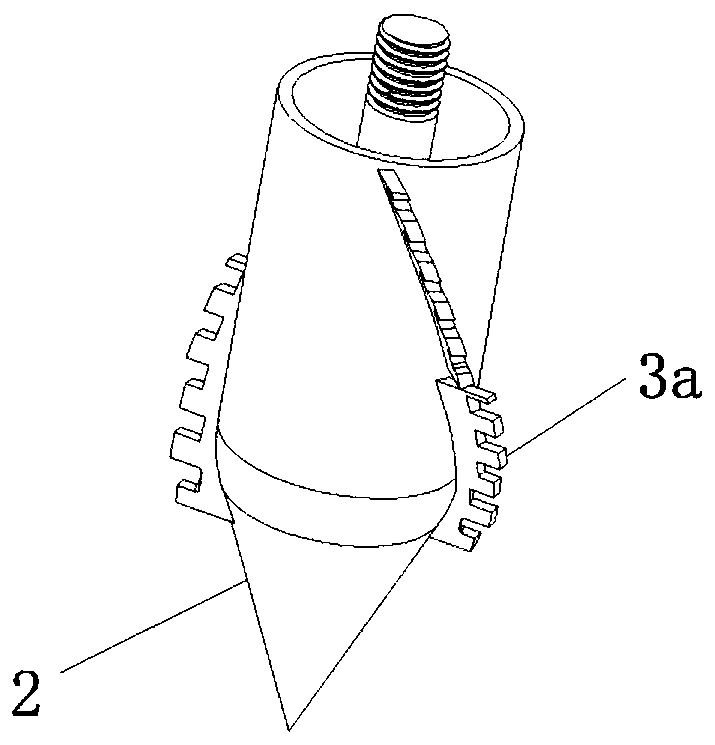

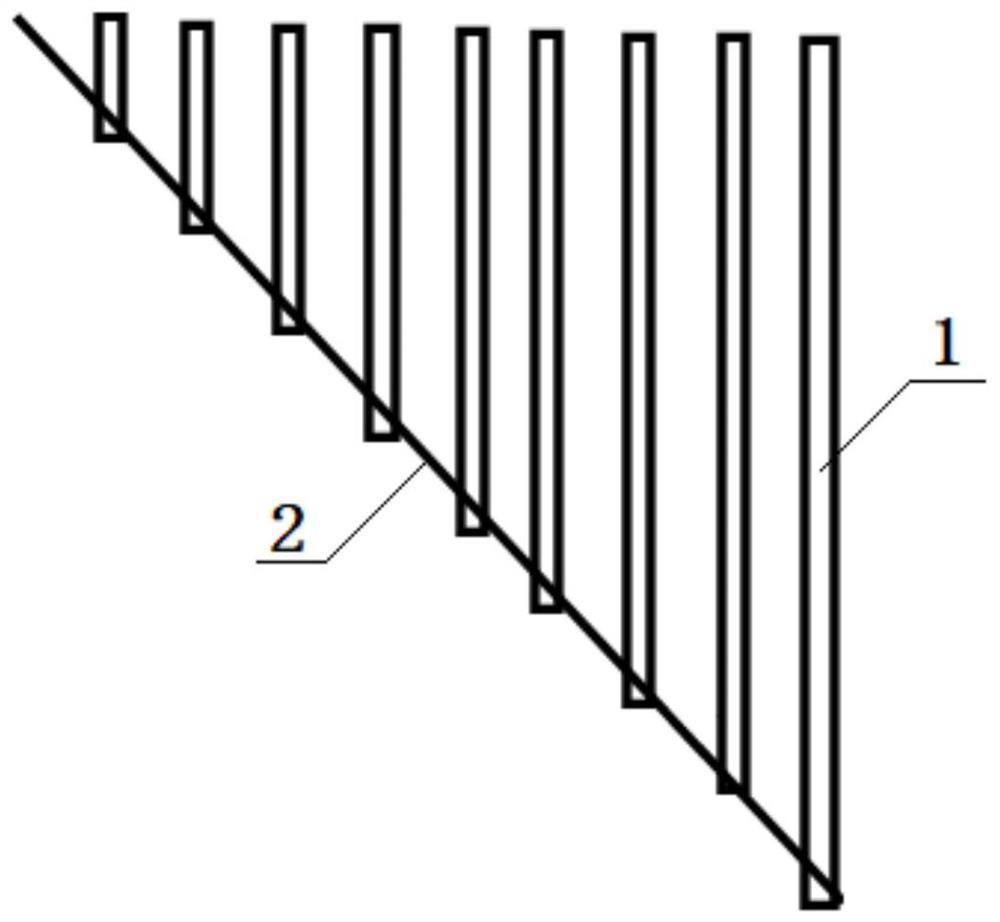

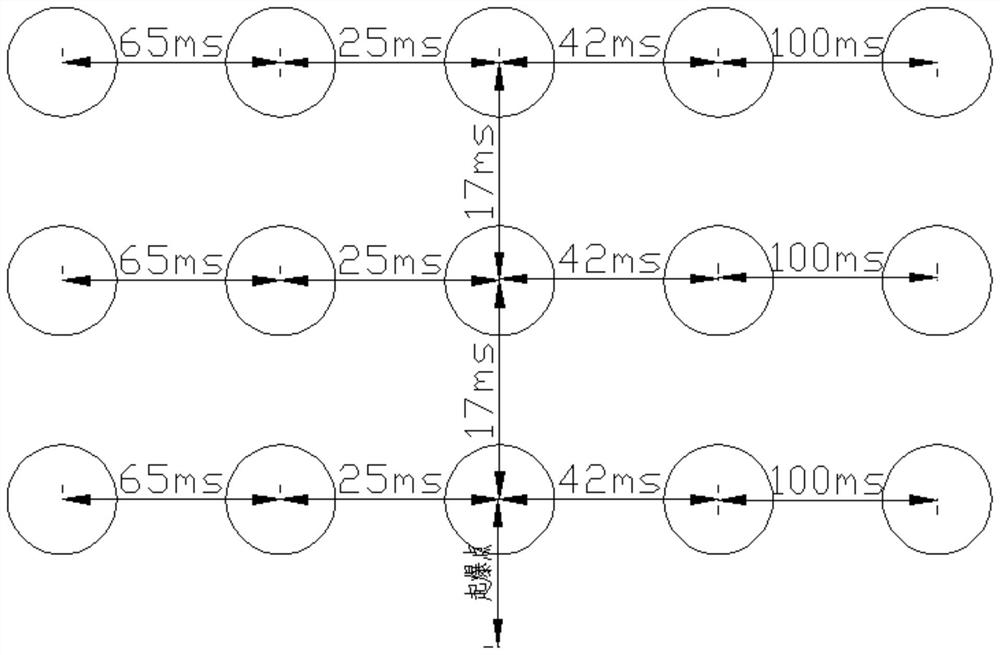

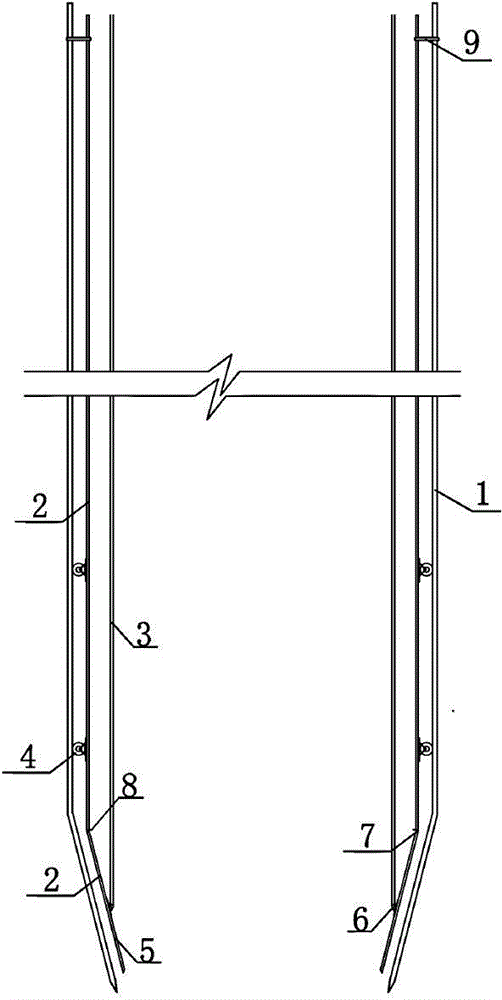

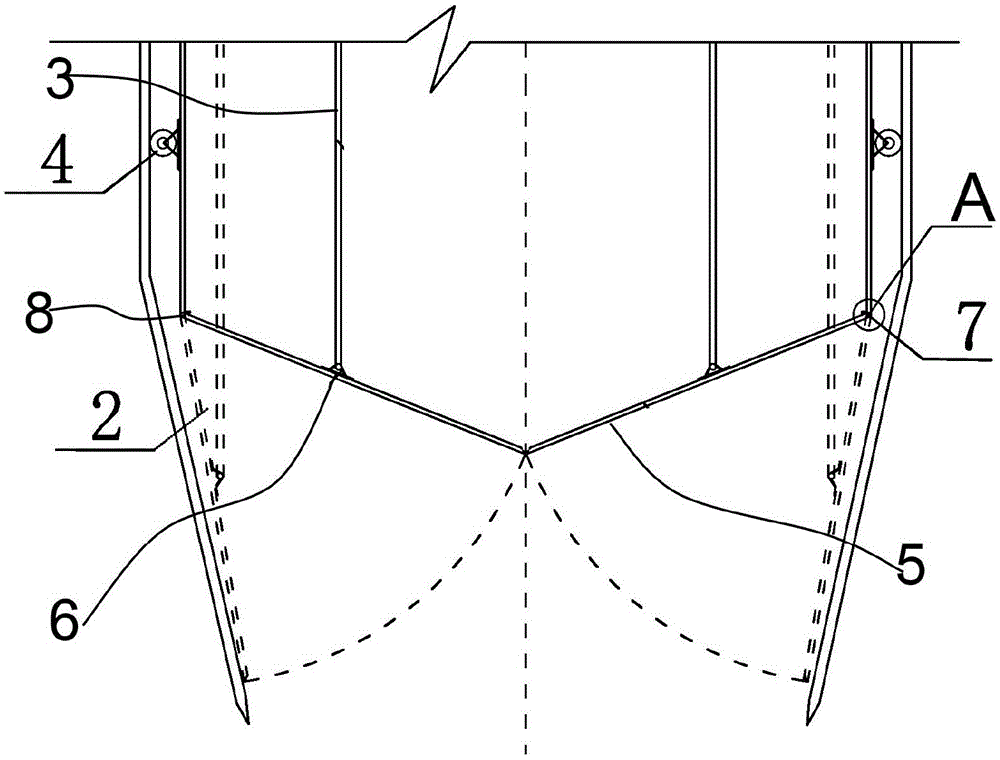

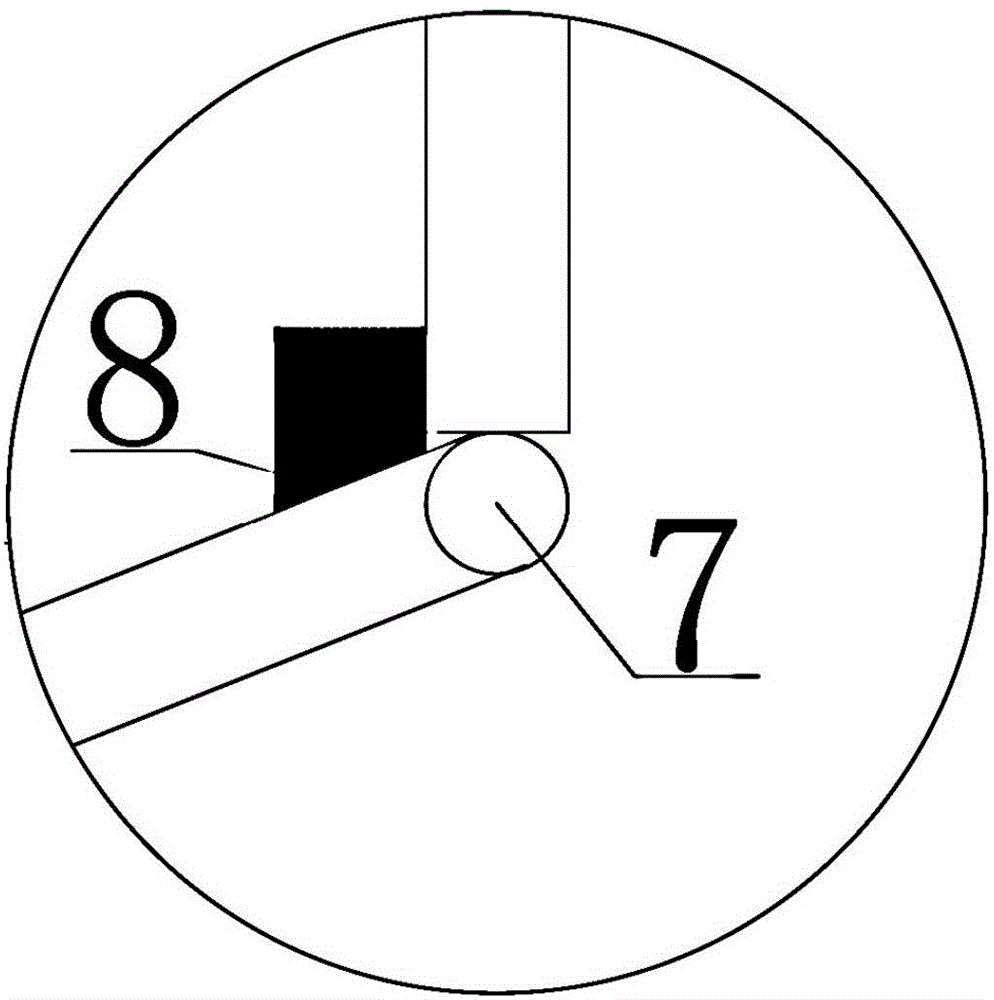

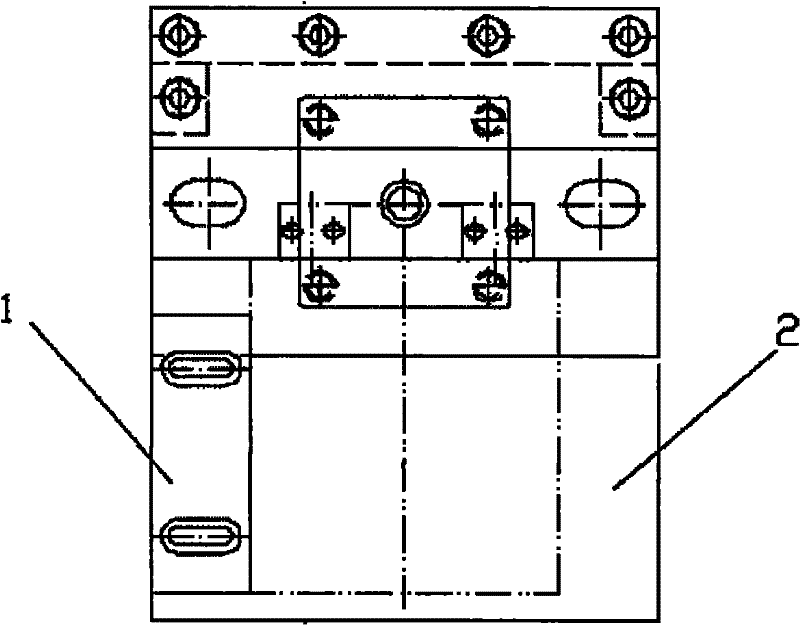

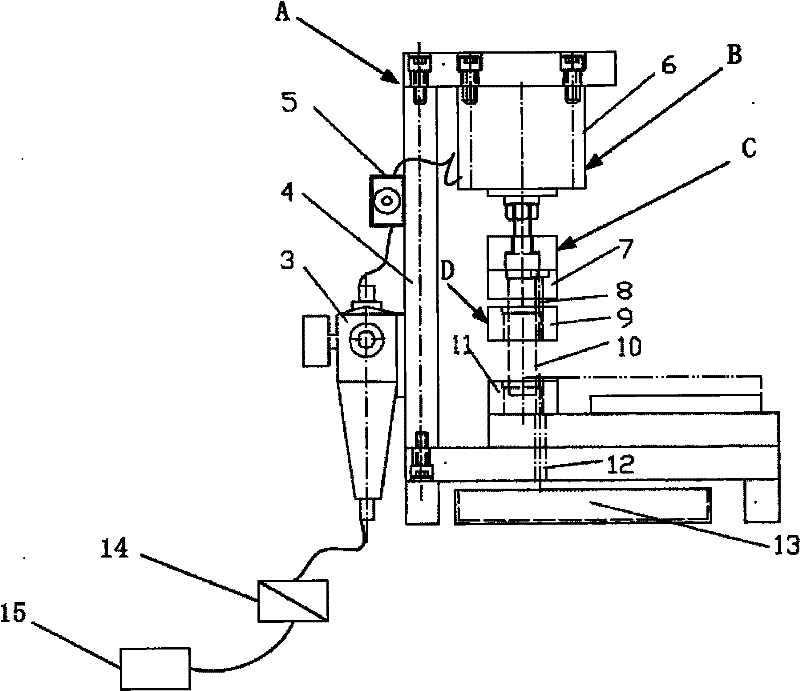

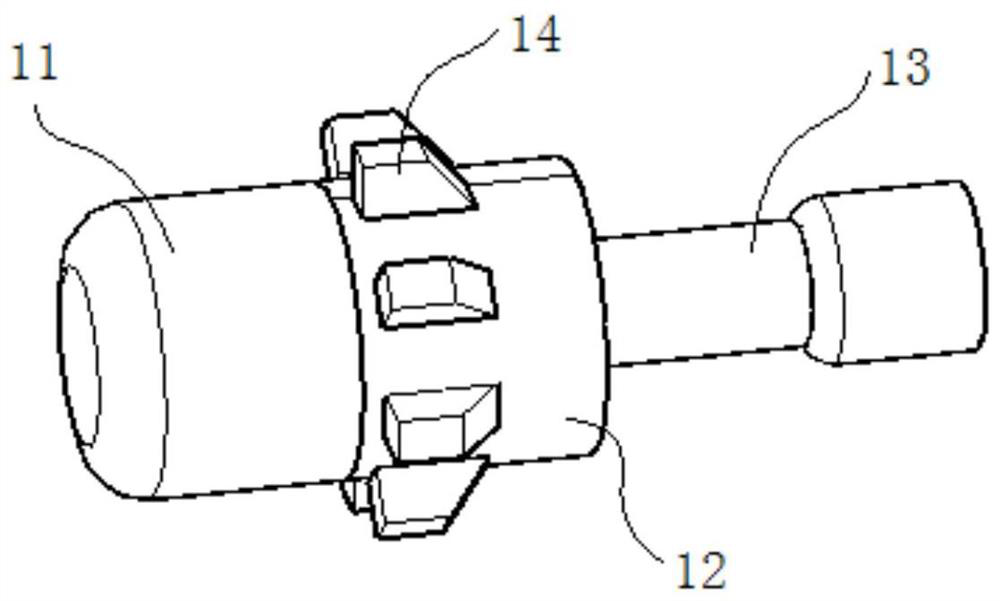

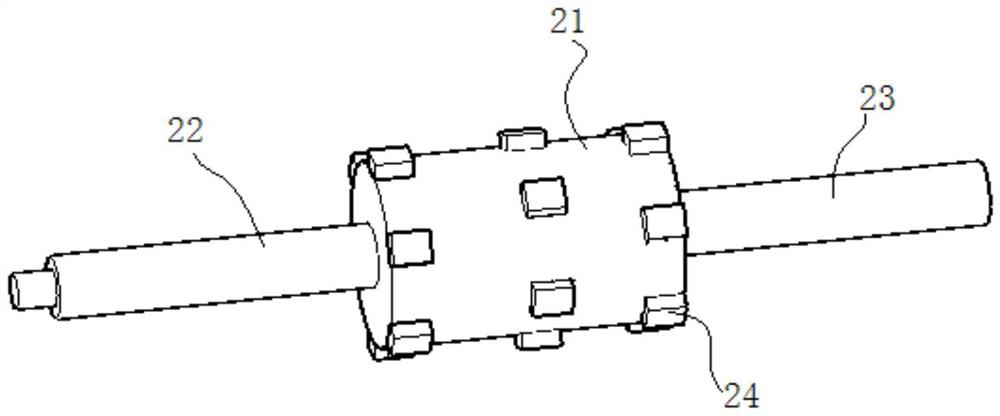

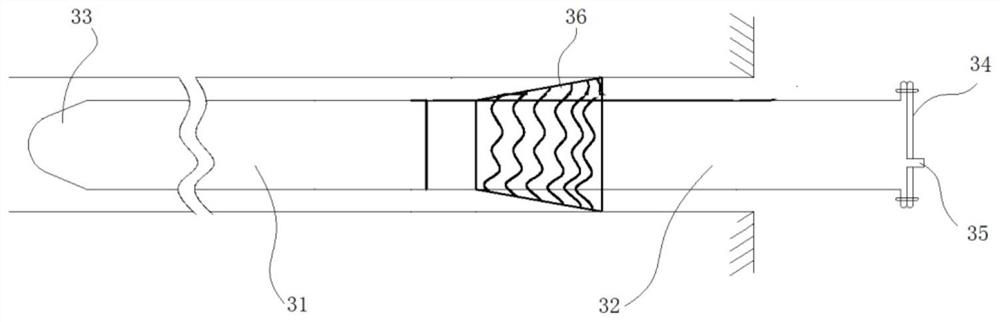

Method for producing movable core low segregation large-sized hollow steel ingot

The invention relates to a preparation technique for heavy hollow ingots of all levels between 50 tons to 300 tons, in particular to a manufacturing method for heavy hollow ingots with a movable core and low segregation. The manufacturing method is applicable to the preparation process of all heavy hollow ingots cast by adopting movable cores, including the casting of the hollow ingots of various shapes, specifications and materials; besides utilizing simulation means of computers to reasonably design a mould and a casting system for ingots, the manufacturing method mainly adopts a pore-forming technology with a movable core, an intensive cooling technology for various media at different stages, a movable core protection technology, a technology for controlling the flow of a cooling medium and the temperature of the movable core, an atomizing device for the cooling medium, an early electro slag protection and argon protection technology for molten metal and a technology for protecting the chassis from big temperature variation, thereby guaranteeing the purity of the molten metal and the operability and the stability of the casting technique, mitigating the segregation, controlling the segregation position, locating the segregation band of the hollow ingots in the middle position and increasing the utilization rate and the application range of the hollow ingots.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

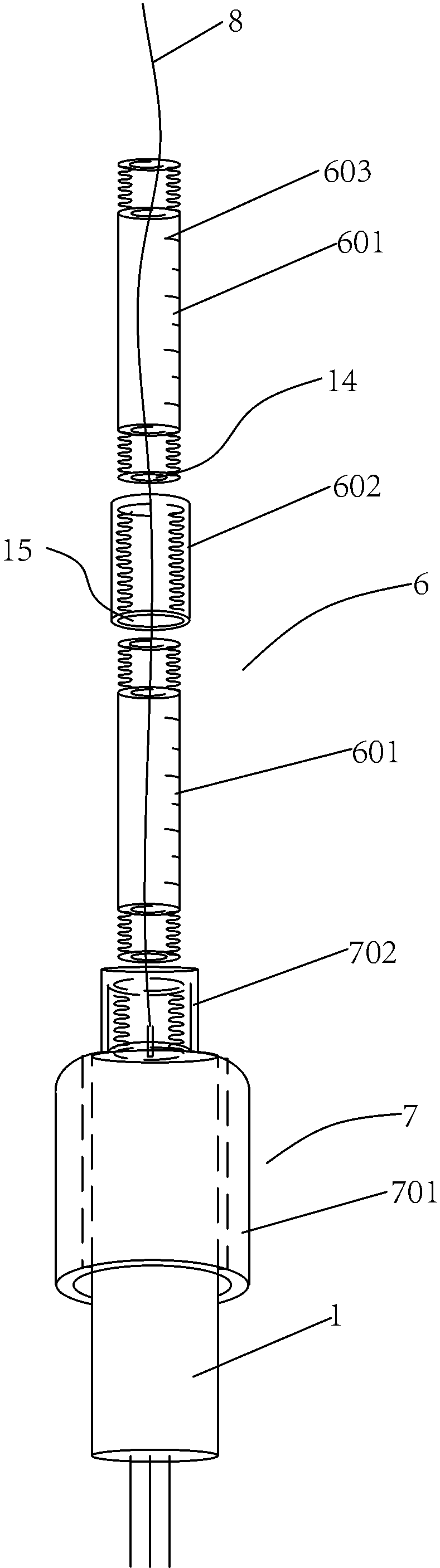

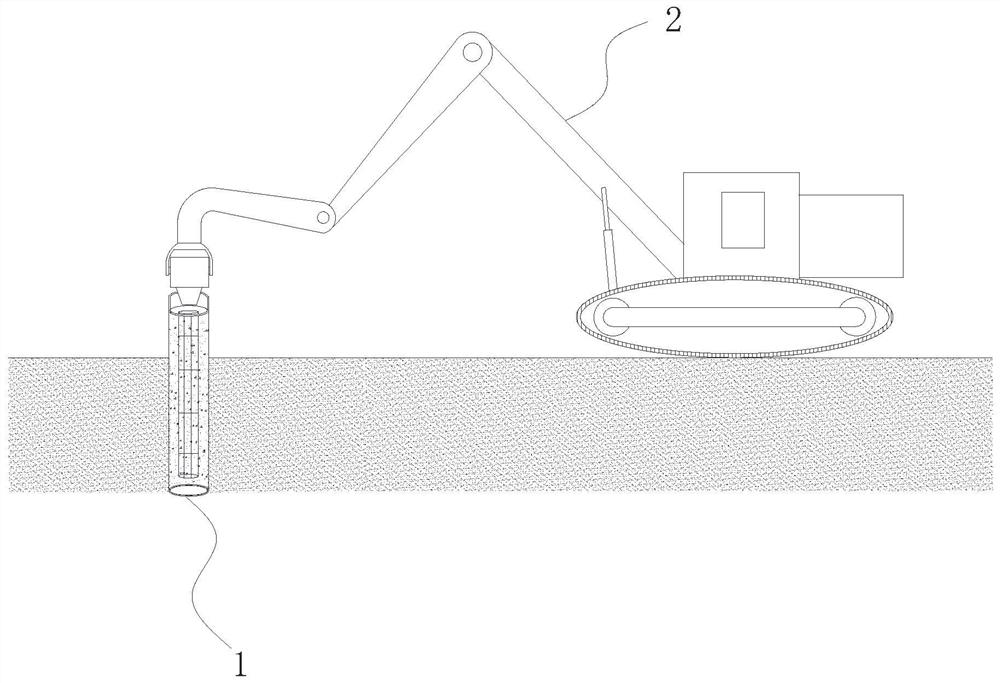

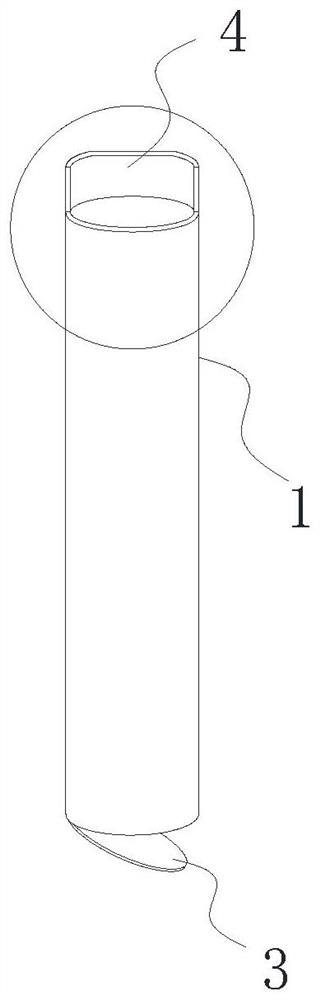

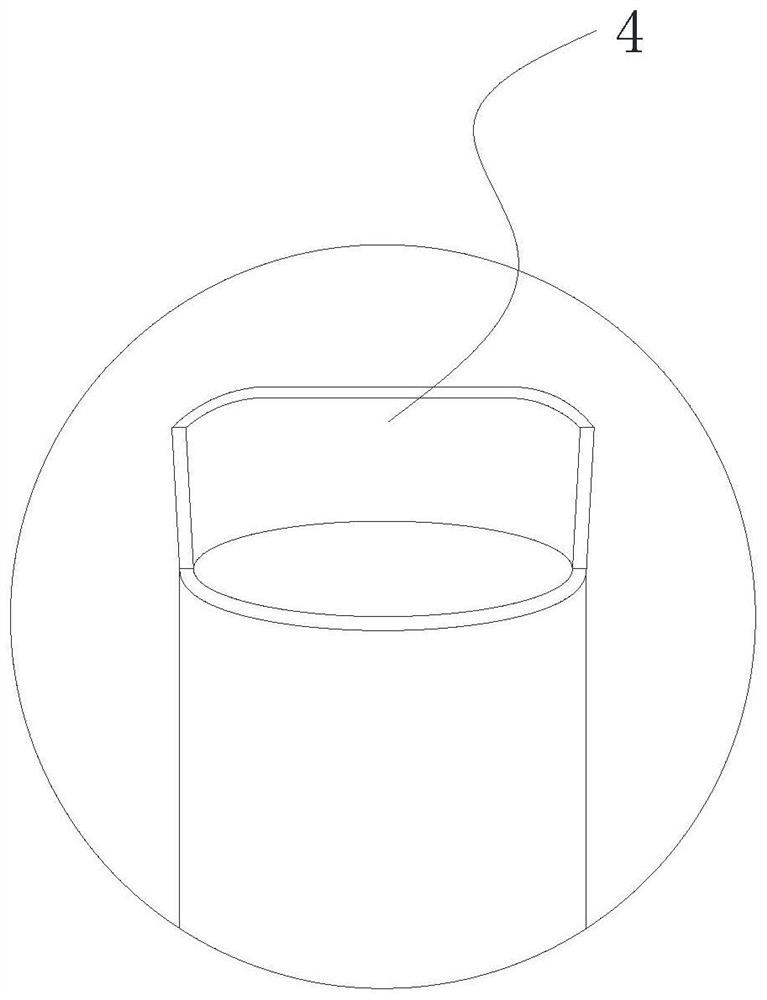

Grouting protective barrel device and pile foundation hole-forming construction method adopting same

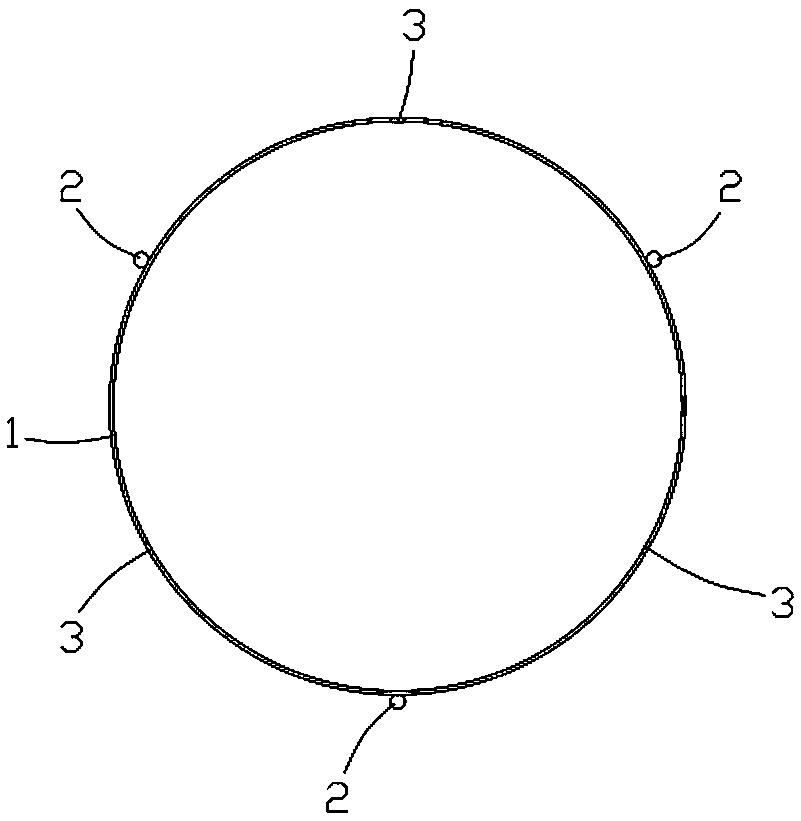

PendingCN108149682AEasy to form holesImprove hole qualityBulkheads/pilesSoil preservationDrilling machinesBuilding construction

The invention provides a grouting protective barrel device and a pile foundation hole-forming construction method adopting the same. The grouting protective barrel device comprises a barrel body. At least three grouting pipes are arranged on the outer side wall of the upper portion of the barrel body in the length direction and are arranged at equal intervals along the periphery of the barrel body. The side wall of the lower portion of the barrel body is provided with an observation hole. The bottom of the barrel body is provided with a groove blade foot. According to the grouting protective barrel device and the pile foundation hole-forming construction method adopting the same, temporary wall protection for surrounding backfill stone throwing of a drilling machine followed by the protective barrel, hole forming is easy, hole forming quality is high, safety and reliability are achieved, construction efficiency is high, convenience and safety are achieved, and cost is low.

Owner:BUCG THE EIGHTH CONSTR DEV

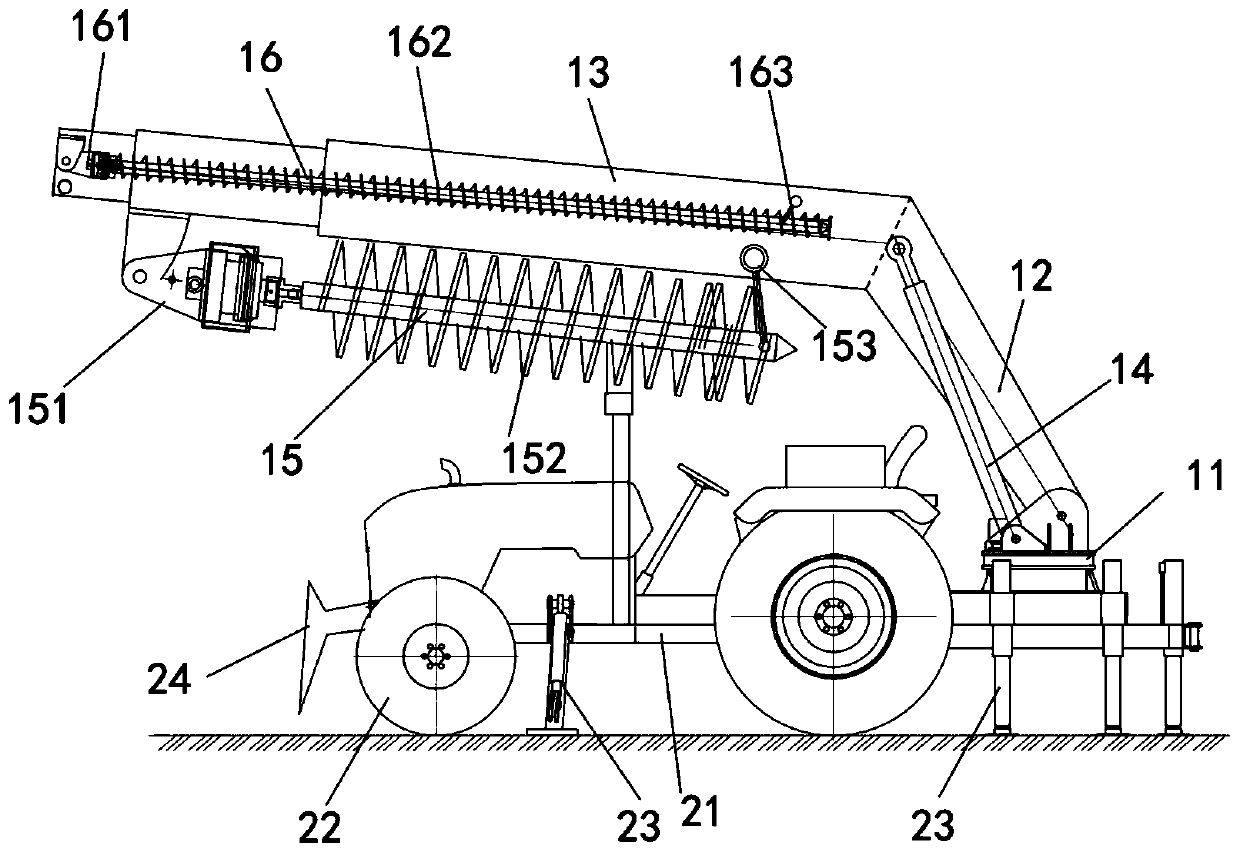

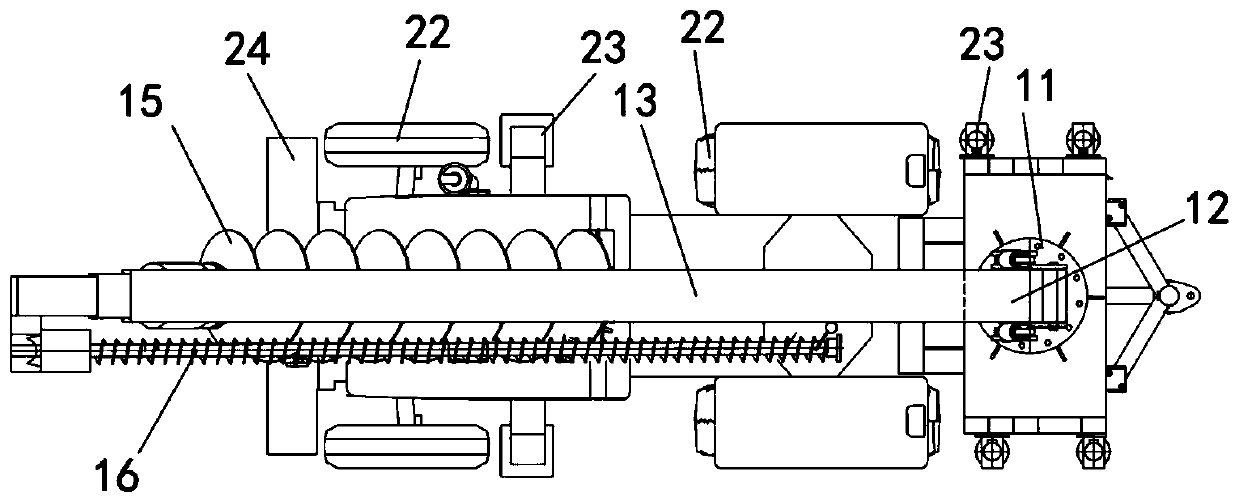

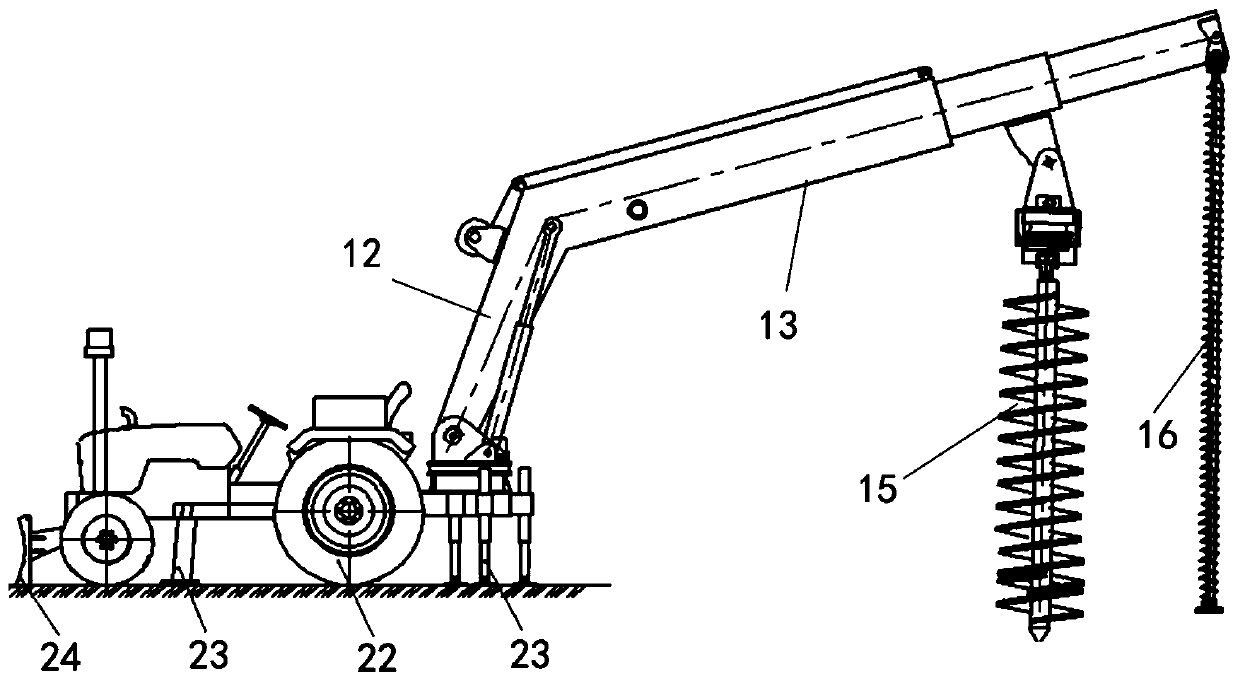

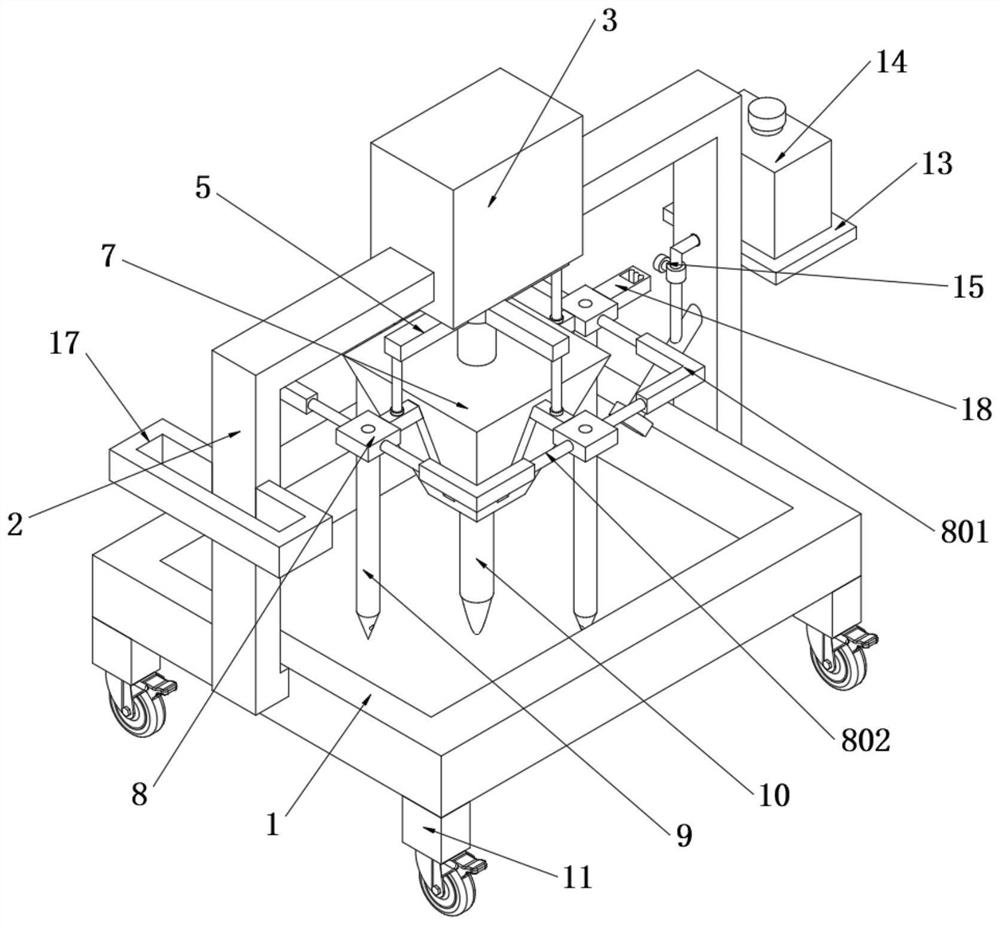

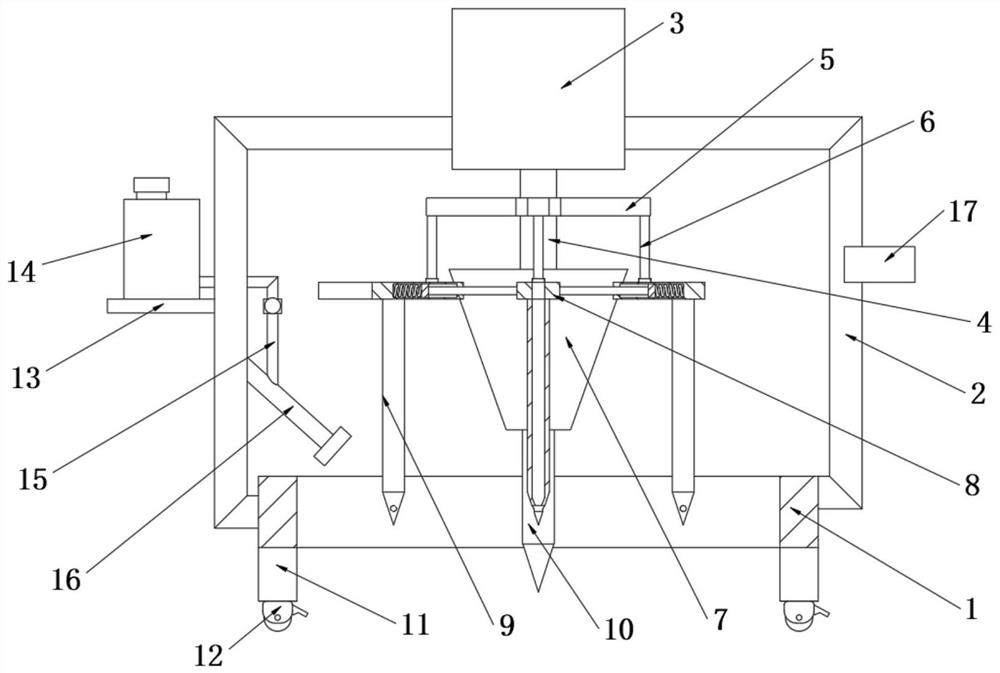

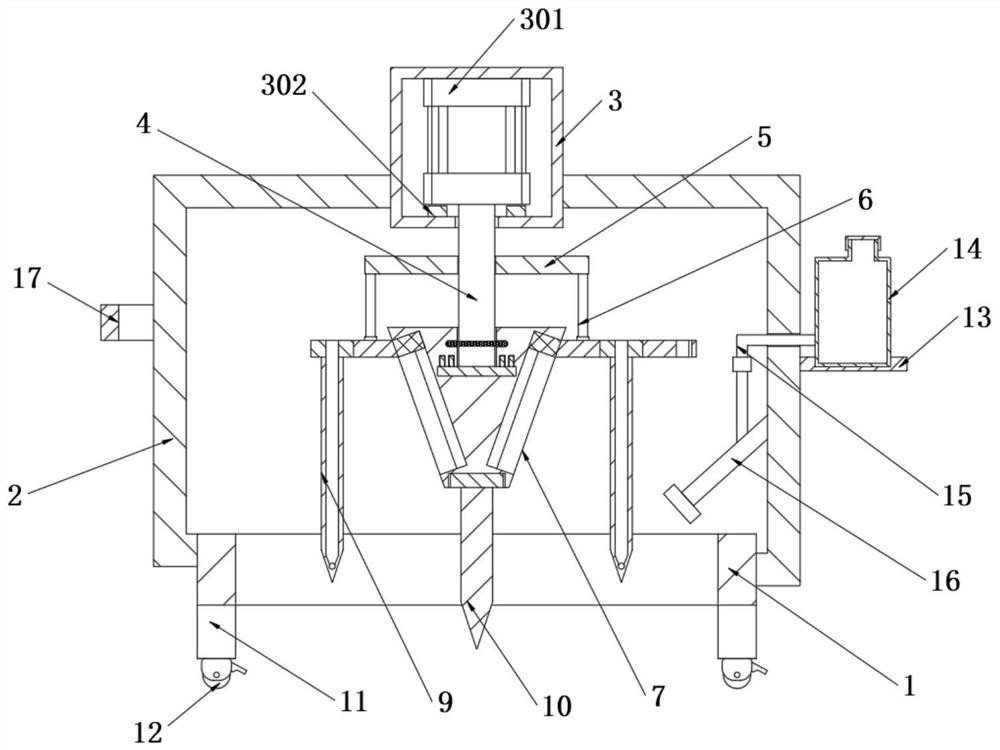

Plate type ground anchor construction machine

PendingCN109881728AImprove construction efficiencyReduce weightDrilling rodsSoil-shifting machines/dredgersArchitectural engineeringDrill

The invention relates to a plate type ground anchor construction machine. The plate type ground anchor construction machine comprises a moving module and a construction module; the construction modulecomprises a revolving support, a main arm, a telescopic arm, a hydraulic rod, a main drill rod unit and a packway drill rod unit; the revolving support is connected with the moving module; one end ofthe main arm is connected with the revolving support through a hinge, and the other end of the main arm is fixedly connected with one end of the telescopic arm; the other end of the telescopic arm isconnected with the packway drill rod unit and the main drill rod unit separately; the main arm and the telescopic arm are in obtuse angle connection; one end of the hydraulic rod is connected with the main arm and the other end of the hydraulic rod is connected with the revolving support; and the hydraulic rod is used for changing the connection angle of the main arm and the revolving support. Compared with the prior art, the plate type ground anchor construction machine has the following advantages of integrating anchor hole forming of the plate type ground anchor, packway excavation, groundanchor lifting and bulldozing functions, improving the construction efficiency and reducing the overall weight and cost of the device.

Owner:SHANGHAI POWER TRANSMISSION & TRANSFORMATION ENG CO LTD

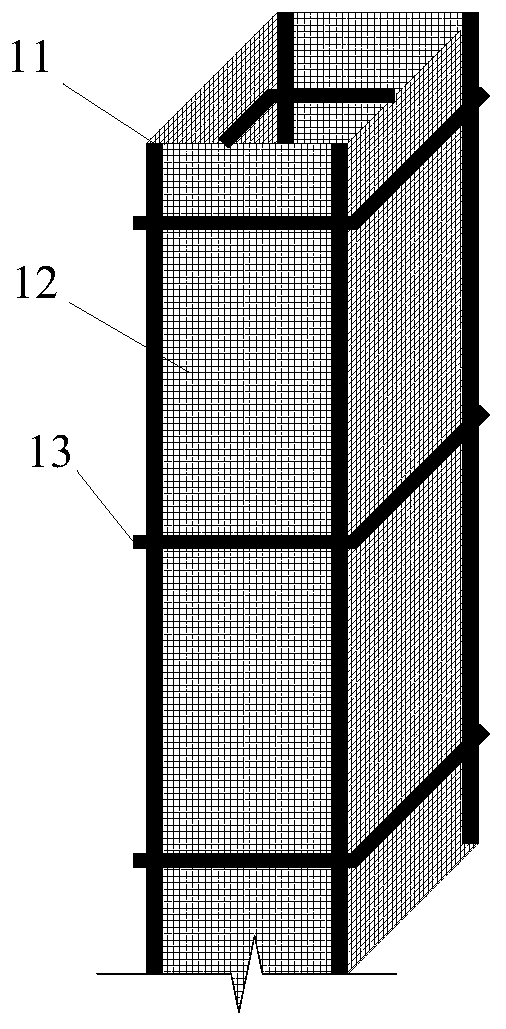

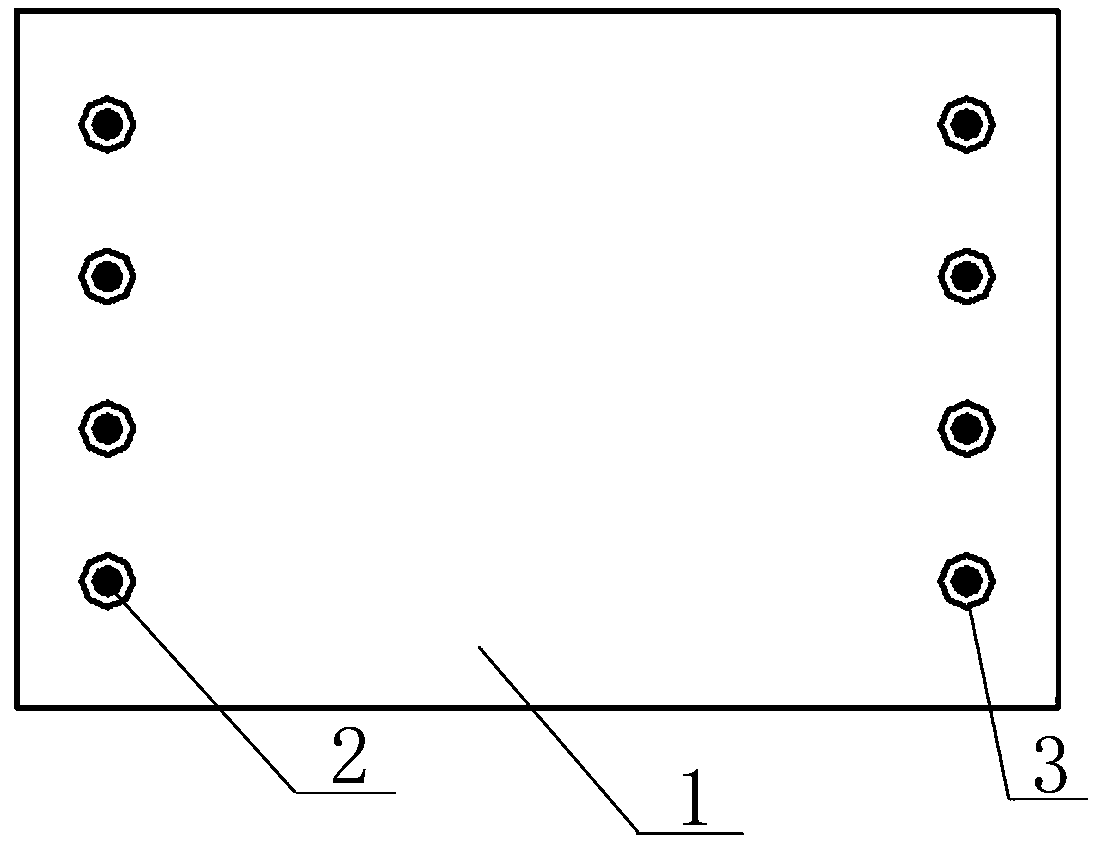

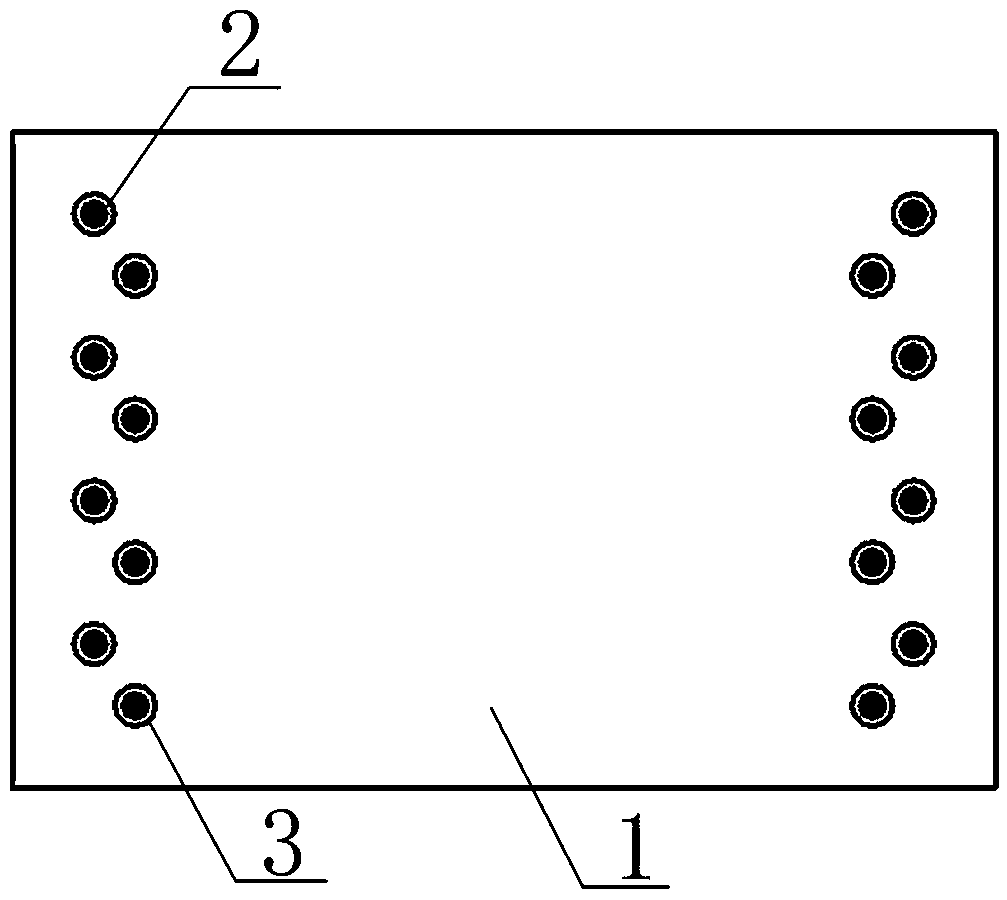

Constraining steel pipe lap joint structure for vertical prefabricated component

PendingCN111255163AFast installationAvoid One-to-One Connection IssuesBuilding reinforcementsLap jointArchitectural engineering

The invention discloses a constraining steel pipe lap joint structure for a vertical prefabricated component. The constraining steel pipe lap joint structure is mainly used for connection of longitudinal rebars of a prefabricated concrete shear wall or a column and other vertical components. The constraining steel pipe lap joint structure is as follows in specific: a constraining steel pipe is arranged at the bottom of an upper-layer prefabricated component; longitudinal ribs in the upper-layer prefabricated component are exposed to the interior of the constraining steel pipe; a lower-layer connecting rebar is inserted in the constraining steel pipe to be in lap joint with the longitudinal ribs in the upper-layer prefabricated component; then, filling material is poured in the constrainingsteel pipe through a preformed vertical through long hole in the upper-layer prefabricated component, or the filling material is filled in the constraining steel pipe through a preformed pulping holeand a slurry discharging hole in the bottom of the upper-layer prefabricated component, and lap joint of the component rebar can be realized when the strength of the filling material reaches the requirement to further meet the force transferring requirement. The constraining steel pipe lap joint structure is reasonable in stress, convenient in production and installation, easy to control in construction quality, and excellent in anti-seismic property and can solve the problems that the traditional connecting structure is difficult in installation and construction and is difficult to ensure the lap joint force transferring performance.

Owner:CABR TECH CO LTD

Hydrodynamic force motor type hard rock deep borehole drilling device

InactiveCN101319597ANot easy to damageGive full play to high-speed cutting performanceBorehole drivesEngineeringHigh pressure water

The invention discloses a water power motor type device for drilling deep holes in hard rock, which belongs to the field of drilling machines. The device comprises a drill bit, a propulsion device and a drill pipe; a micro water power motor with high-pressure water as the power is connected with a position between the drill pipe and the drill bit close to the drill bit. The water power motor goes through the inside of the drill pipe and is connected with a pressurizing water pump; a water inlet pipe in the drill pipe is communicated with the power input end of the water power motor; a through hole accessing the inside of the drill bit is arranged in a connector used to connect the power output end of the water power motor and the drill bit; the power output end of the water power motor is also provided with a water drainage hole. The device can supply near-distance power to the drill bit inside the deep holes and help the drill bit to rotate at high speed, and the drill pipe is under the stationary state; can fully display the high-speed cutting performance of the diamond drill bit; and has the advantages of good drilling capability, high linearity, no easiness of damage to the drill bit and great improvement of the drilling efficiency.

Owner:JIKAI EQUIP MFG CO LTD +1

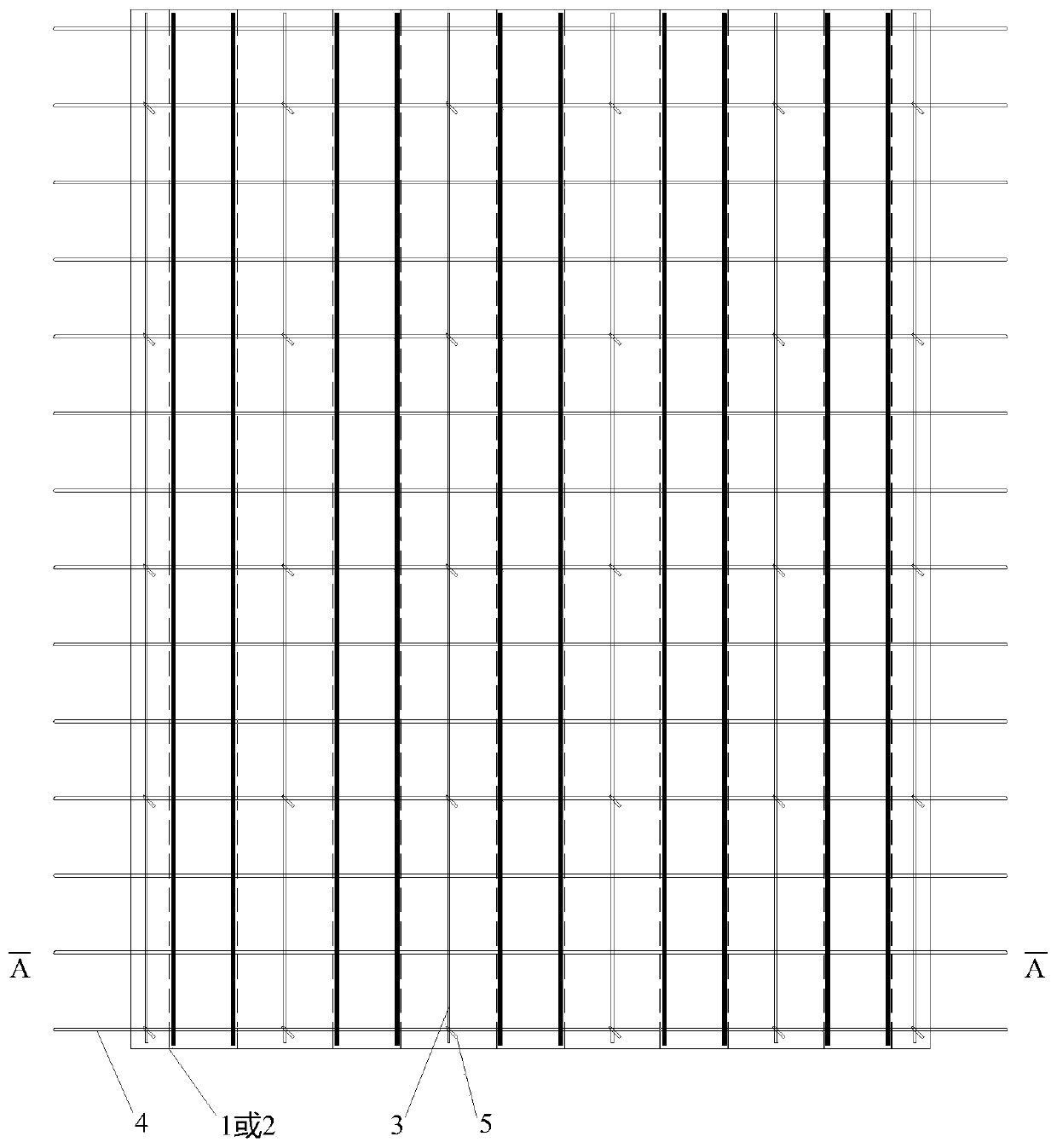

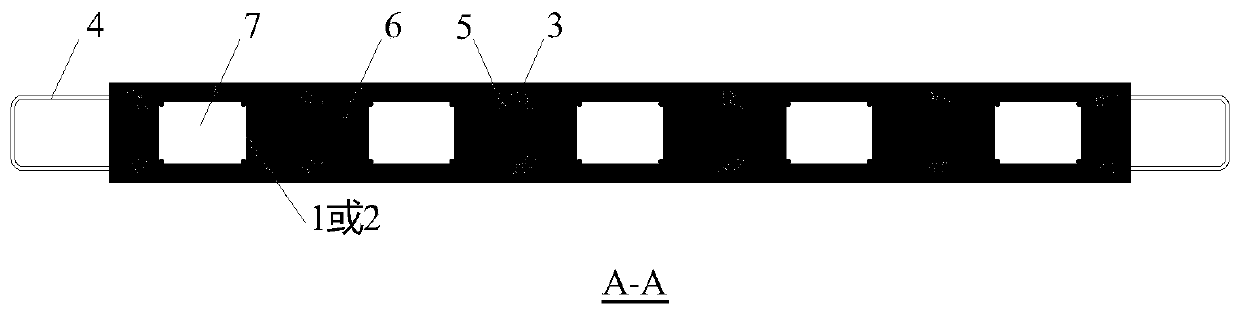

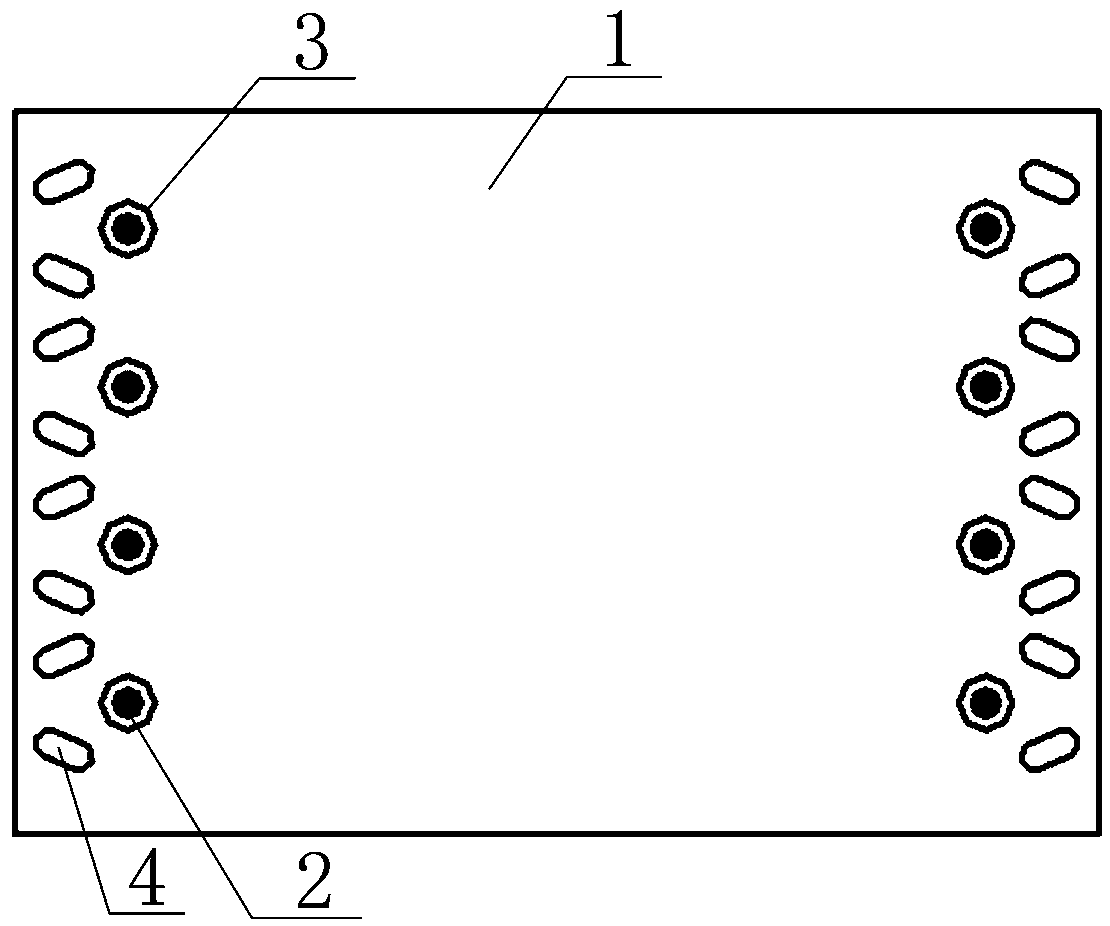

Precast wallboard molded with holes formed through steel mesh formworks

PendingCN111255121AEasy to form holesEasy installation and constructionWallsBuilding reinforcementsRebarLap joint

The invention discloses a prefabricated wallboard with holes formed through steel mesh formworks. The prefabricated wallboard is internally provided with vertical through-long holes, the holes are formed through the dismantling-free steel mesh formworks which are formed by welding longitudinal bars or angle steel, steel mesh and transverse keel during production of the wallboard, wherein the longitudinal bars or the angle steel in the steel mesh formworks serve as vertical stress reinforcing steel bars of a wall. No reinforcing steel bars stretch out of the prefabricated wallboard in the vertical direction, additional connecting reinforcing steel bars are arranged in the holes at the joint of the upper and lower layer wallboard, and concrete is poured into the holes to realize the lap joint connection of the vertical stress steel bars of the wall; and reinforcing steel bars stretch out of the prefabricated wallboard in the horizontal direction, and the same-layer adjacent wallboards are connected through a post-pouring section. The prefabricated wallboard is convenient to produce and construct, reasonable in connection structure, and capable of solving the problems that a traditional prefabricated wallboard is difficult to produce and construct, the lap joint transmission performance is difficult to guarantee, and the like.

Owner:CABR TECH CO LTD

Connecting member of prefabricated sandwiched heat-insulating wall, heat-insulating wall and construction method thereof

PendingCN108867932AAvoid formingLow thermal conductivityWallsHeat proofingFiberStructural engineering

The invention discloses a connecting member of a prefabricated sandwiched heat-insulating wall, the heat-insulating wall and a construction method thereof. The connecting member comprises a connectingplate and anchoring ribs, the connecting plate is made of a FRP material which is made of reinforced fiber and resin, thickness of the connecting plate is less than or equal to 8mm while width of thesame is greater than 40mm, holes penetrating the anchoring ribs are formed in positions, close to the edge, on two sides of the connecting plate, and the anchoring ribs are correspondingly arranged in the holes penetratingly. The technical problem that conventional connection members of the prefabricated sandwiched heat-insulating wall are big in processing difficulty and poor in anchoring performance when being applied in the heat-insulating wall.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

Construction method of reinforced concrete protection pile in loess areas

InactiveCN102444117AEasy to form holesAvoid influenceExcavationsBulkheads/pilesRebarReinforced concrete

The invention discloses a construction method of a reinforced concrete protection pile in loess areas, comprising the following steps of: (1) opening holes below the ground by means of a Luoyang shovel having a semicircular end part and a diameter of 150-170 mm; (2) when the external threads of the end part of the Luoyang shovel are in contact with the ground, connecting an extension rod with one end provided with a threaded hole and the other end provided with screw threads to the end part of the Luoyang shovel in a threaded connection manner, and continuing digging; (3) when the external threaded of the end part of the extension rod are in contact with the earth layer, connecting other extension rod and continuing digging until the hole is opened to the depth of the protection pile; (4) inserting a reinforcing steel bar having a diameter of 15-17 mm in the hole, and pouring C15 plain concrete into the hole and compacting the concrete; and (5) cutting off the reinforced concrete to expose the head, thereby completing the construction of the concrete protective pile. The construction method is applied to the range of electrified existing lines in the loess areas; the construction method effectively overcomes the disadvantageous effects of a large-sized construction machine on an existing line contact network and avoids the influence on the running of the existing lines; and the construction method is easy for construction and excellent in effect.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A method for preparing activated carbon and furfural from corn cobs

ActiveCN105174254BAvoid condensationHigh yieldOrganic chemistryCarbon compoundsActivated carbonWater vapor

The invention provides a method for preparing activated carbon and furfural by taking corncob as a raw material. The method for preparing the activated carbon and furfural by taking the corncob as the raw material comprises the following steps: 1) smashing the corncob until particle size is 15-20mm; 2) mixing the corncob with sulphuric acid solution; 3) carrying out steam stripping and hydrolysis, namely enabling steam to be contacted with the corncob for carrying out hydrolysis; 4) collecting gas during steam stripping, hydrolysis and pressure deslagging, condensing, and distilling, so as to obtain a furfural product; 5) impregnating furfural residue, namely mixing KOH solution with the furfural residue, and impregnating at room temperature; 6) drying to a free-water-less state; and 7) directly activating, namely activating the dried furfural in two stages. The method provided by the invention has the advantages that the corncob is taken as the raw material for cooperatively producing furfural and activated carbon products, so that economic benefit of furfural production can be greatly improved; high hydrolysis temperature and short hydrolysis time are adopted, so that furfural condensation is avoided during production, and yield of furfural is increased; and the furfural residue is adopted for preparing the activated carbon, so that waste residue in a furfural production process can be effectively utilized, and environmental pollution is reduced.

Owner:BEIJING FORESTRY UNIVERSITY

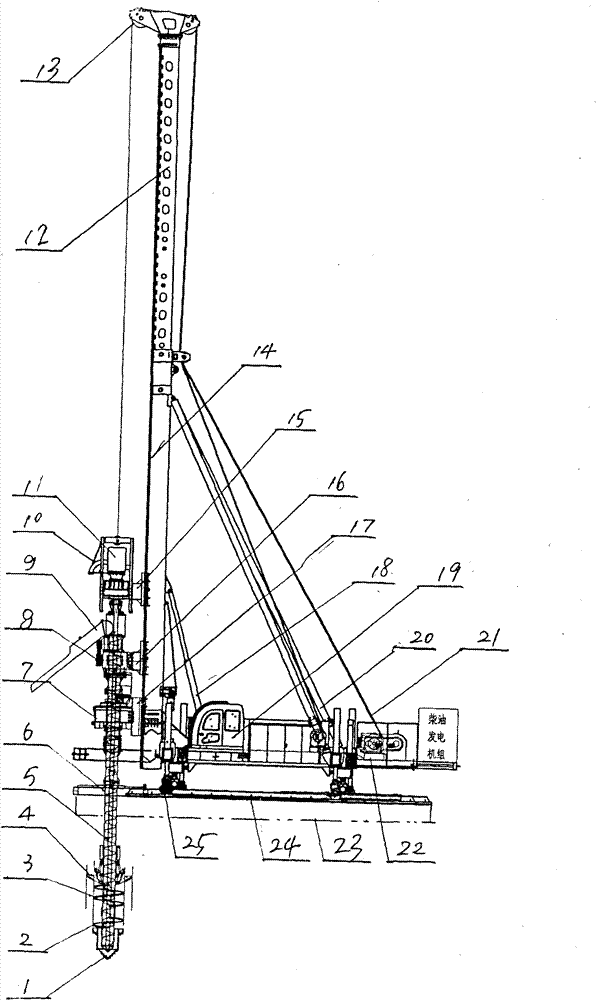

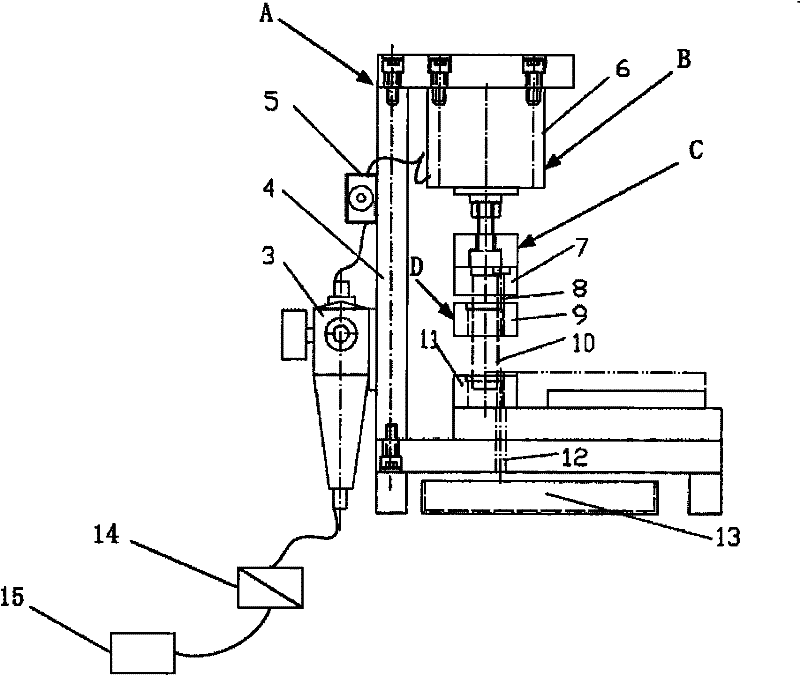

Drilling machine of coaxial double-drill large-caliber multifunctional foundation pile

InactiveCN101775959BLow construction consumptionNo pollution in the processDrilling rodsBorehole drivesEnergy consumptionPollution

The invention relates to a drilling machine of a coaxial double-drill large-caliber multifunctional foundation pile. The drilling machine is provided with a telescopic arm which is upwards upright, telescopic and foldable; the bottom end of the telescopic arm is articulated with a horizontal operating platform; the bottom of the operating platform is sequentially matched and connected with a large underpan and a rotary support through a traveling mechanism; the outer side of the telescopic arm is provided with a straight telescopic arm track; and the telescopic arm track is sequentially provided with a lifting power head slide support bracket assembled with a lifting power head mechanism, a vibratory hammer slide support bracket assembled with a vibratory hammer mechanism and a main powerhead slide support bracket assembled with a main power head mechanism from top to bottom. The invention has low construction energy consumption without pollution, easy pore-forming and consumable saving without worrying collapse, is especially suitable for the construction of a large-caliber and ultradeep pile hole and can multiply enhance the bearing capacity of an original foundation pile and enhance the work efficiency by 10-20 times.

Owner:赵园园 +1

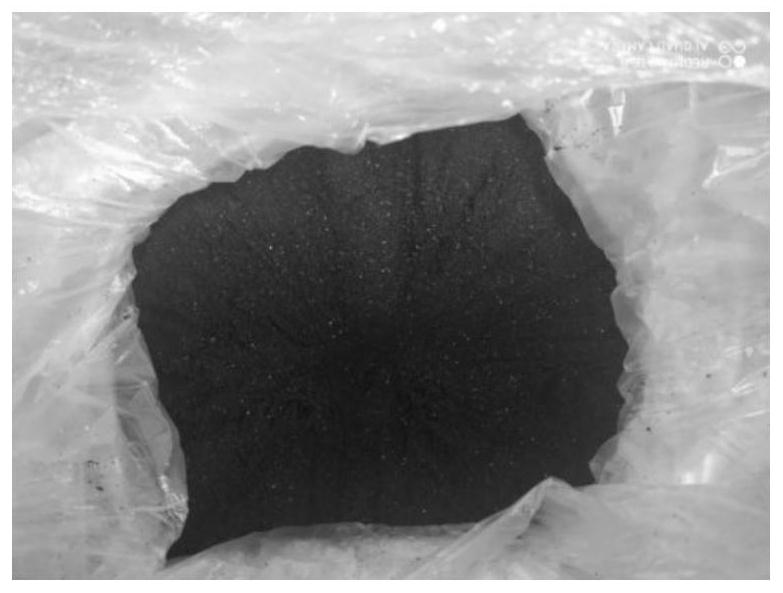

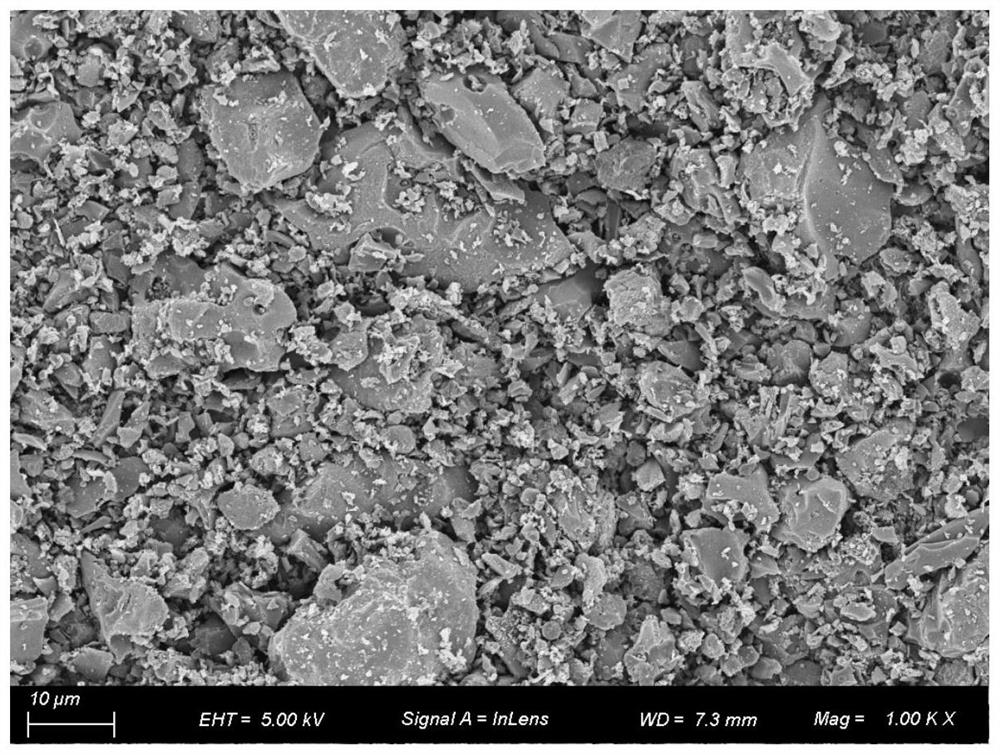

Method for preparing activated carbon by separating refined carbon from gasified slag

PendingCN114853011ALow activation reactivityNon-adhesiveCarbon compoundsEnergy inputActivated carbonSlag

The invention discloses a method for preparing activated carbon from gasified slag separated refined carbon, which comprises the following steps: uniformly mixing and stirring refined carbon powder and low-rank coal powder according to the mass ratio of 5: (0.25-1) to form mixed powder, and proportioning according to the mass ratio of the mixed powder to solid potassium hydroxide to high-temperature coal tar to water of 1: (0.02-0.05): (0.30-0.40): (0.10-0.20); preparing solid potassium hydroxide into an aqueous solution, sequentially adding the aqueous solution, high-temperature coal tar and water into the mixed powder, and uniformly mixing and kneading to form coal paste; and forming, aging, carbonizing and activating the coal paste to obtain an activated carbon product. By regulating and controlling the proportion of the refined carbon to the low-rank coal, the dosage of potassium hydroxide and the like, the prepared activated carbon product has good mesoporous distribution characteristics and is suitable for the fields of water treatment, purification, adsorption and the like.

Owner:CCTEG CHINA COAL RES INST

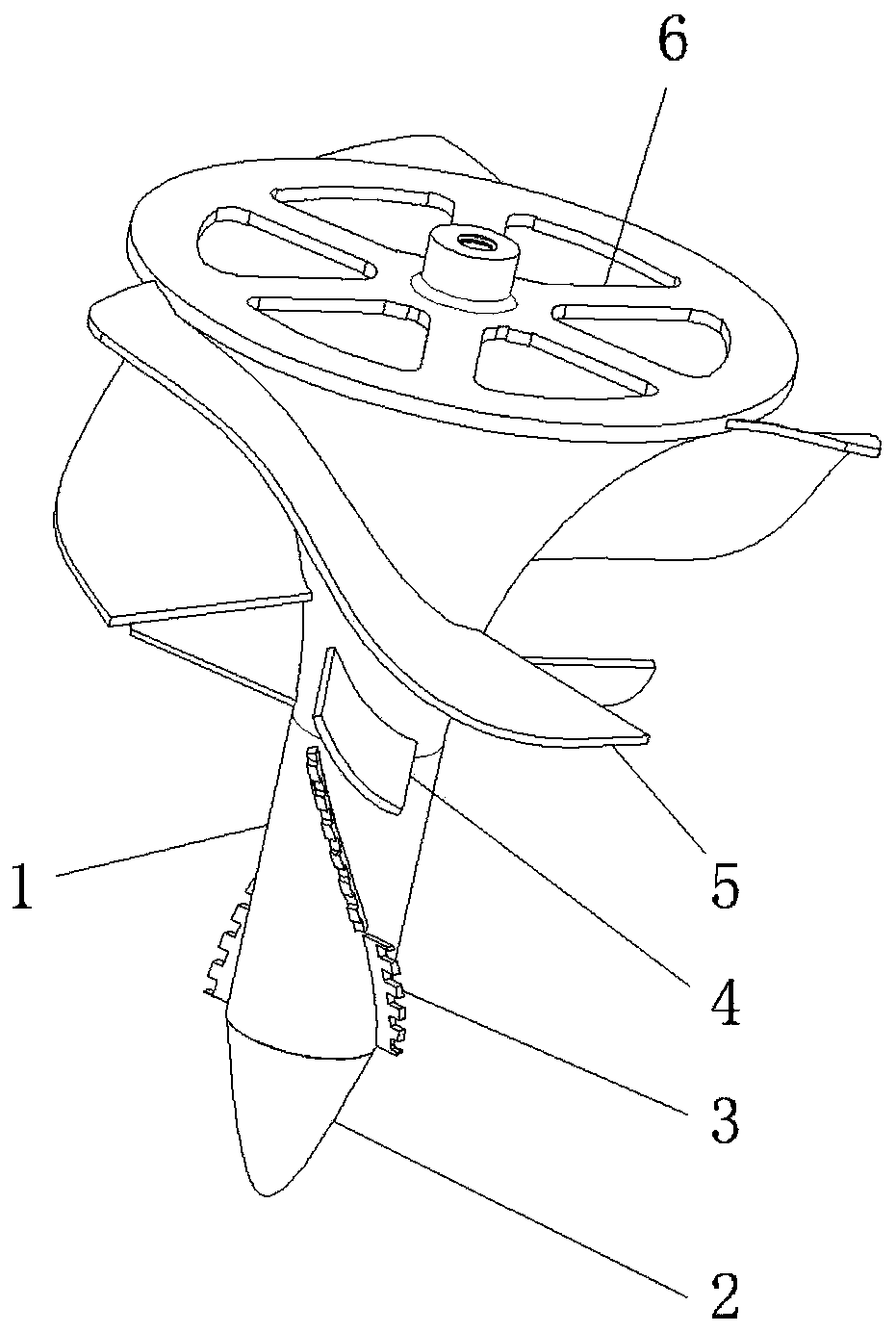

Stereoscopic curved-blade type drill assembly

InactiveCN109892065AImprove drilling effectReduce drilling difficultyPlantingFurrow making/coveringPunchingSpiral blade

The invention discloses a stereoscopic curved-blade type drill assembly. The assembly comprises a drill subassembly, wherein the drill subassembly comprises a drill rod and a drill bit which is detachably connected to the bottom of the drill rod; the bottom of the drill bit is in a conical shape with a large upper part and a small lower part; at least two groups of spiral blades are arranged on the upper and lower parts of the excircle of the drill subassembly; the outer diameters of each group of spiral blades are increased sequentially from bottom to top; each group of spiral blades comprises a plurality of spiral blades which are connected to the excircle of the drill subassembly in central symmetry. According to the structure of the drill assembly, the drill bit is adopted for preliminary punching and direction guidance at first; secondly, the two-stage spiral blades are used for sequentially expanding drilling holes; the drilling difficulty of the upper spiral blades is reduced through initial drilling of the lower spiral blades, and the drilling capability of the drill assembly is improved; the drilling holes are formed into a plurality of stair platforms through drilling ofthe spiral blades of each stage. The stair platforms can carry falling mud, so that the bottoms of the formed drilling holes are prevented from being buried by the mud for the second time, and the drilling efficiency is improved.

Owner:CHONGQING UNIV OF ARTS & SCI

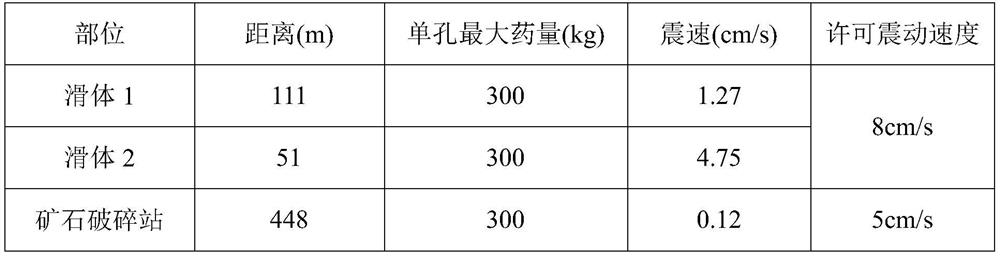

Novel horizontal ditching method for deep open pit mine

PendingCN113654424ABlasting vibration speed is smallReduce harmful effectsBlastingOpen-pit miningMining engineeringSteep slope

The invention discloses a novel horizontal ditching method for a deep open pit mine and relates to the field of mining of deep open pit mines. The defects of high construction requirements and large blasting harmful effects of a deep open pit stope with a high and steep slope and a complex drainage system in a full-section high ditching blasting mode are overcome. According to the technical scheme, the novel horizontal ditching method for the deep open pit mine comprises the steps that firstly, full-section high middle cut blasting is conducted in a clearance area at the bottom of the stope, a free face for follow-up ditching operation is formed, the clearance area is dug out after blasting, and drainage is conducted; then, a ditching area is defined, in the ditching area, the position, corresponding to the top of an access ditch, in the ditching area serves as a starting point, drilling, explosive charging and blasting are conducted on the ground from shallow to deep according to the designed slope ratio of the access ditch in the downward direction of the access ditch, then loose parts are dug away, and a slope connection way is formed; and finally, layered blasting and digging are carried out on the bottom area of the slope connection way, and the access ditch is built. The novel horizontal ditching method for the deep open pit mine is used for novel horizontal ditching of the deep open pit mine.

Owner:PANGANG GRP MINING

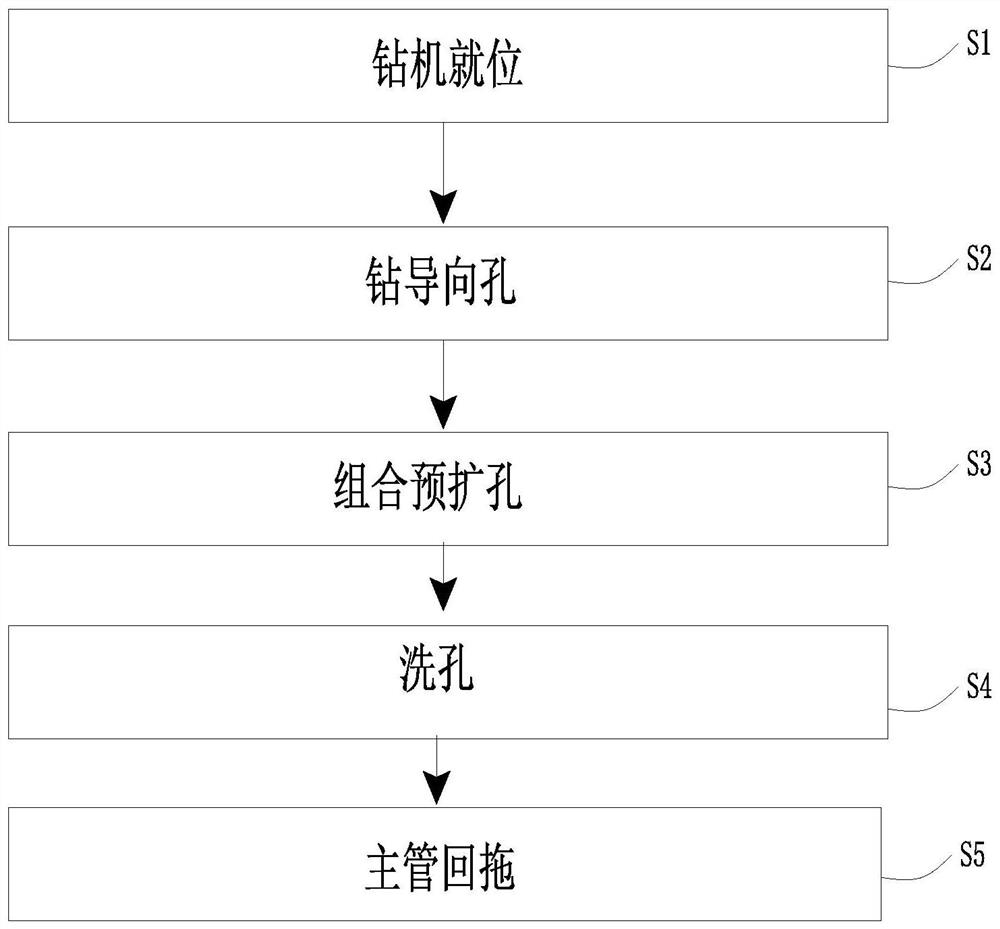

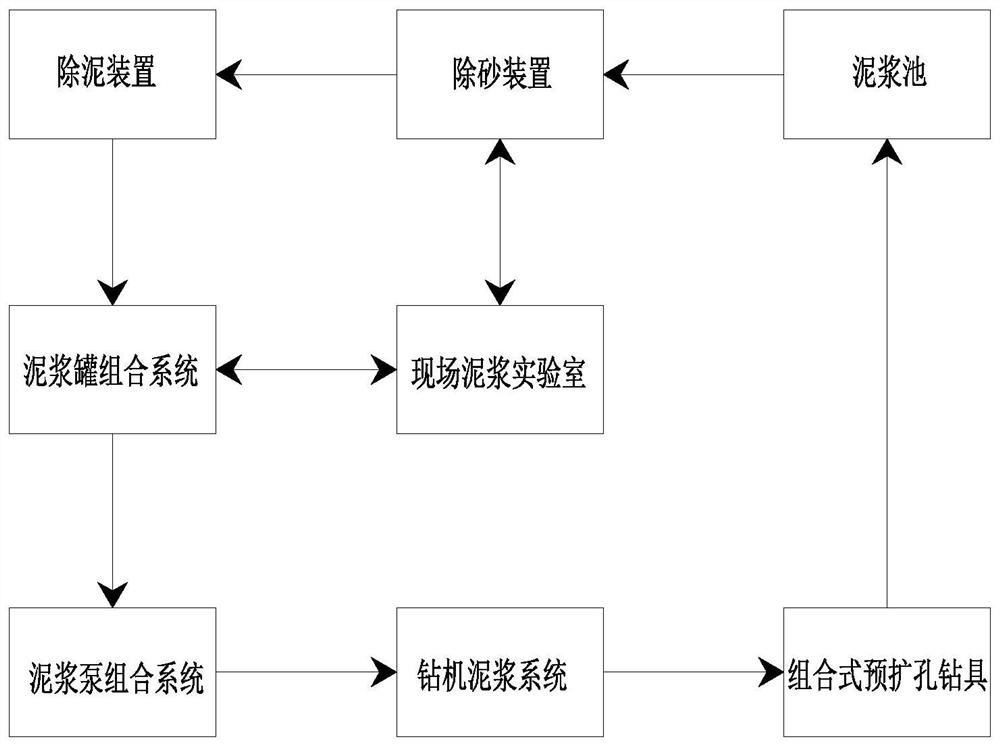

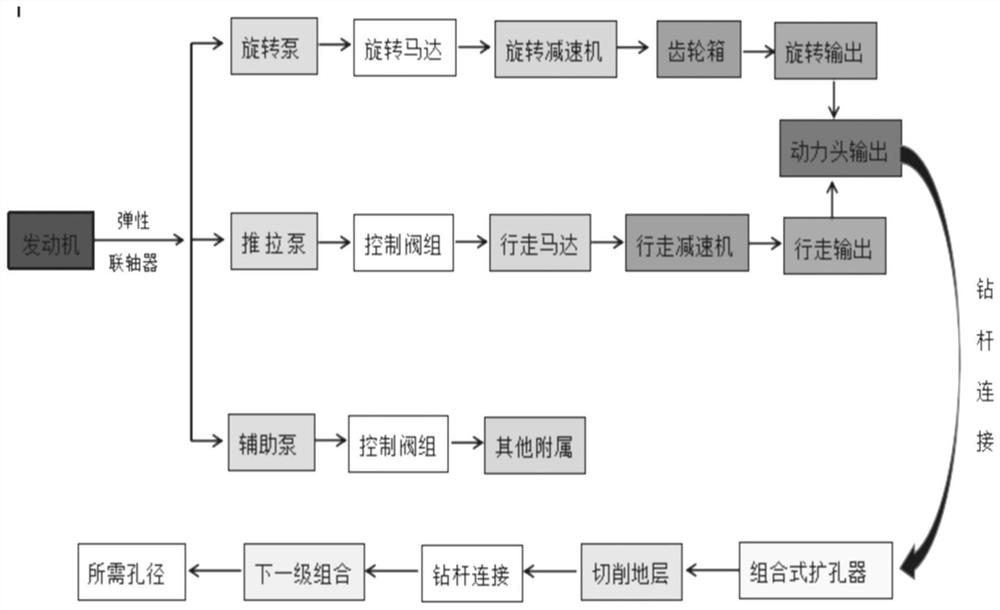

Combined type pre-reaming construction method suitable for stratum with rock hardness smaller than or equal to 30 Mpa

PendingCN113530450AHigh popularityPre-expansion high speedConstructionsDirectional drillingPilot holeClassical mechanics

The invention belongs to the technical field of combined type pre-reaming construction, and particularly relates to a combined type pre-reaming construction method suitable for a stratum with the rock hardness smaller than or equal to 30 Mpa. The combined type pre-reaming construction method comprises the following steps that S1, a drilling machine is in place; S2, a guide hole is drilled; S3, combined pre-reaming is carried out; S4, hole washing is performed; and S5, a main pipe is dragged back. Compared with a conventional step-by-step pre-reaming construction method, the method has great universality in the aspect of actual operation, and the purpose of high-speed pre-reaming is achieved; the effect is better, and the cutting capacity is 9 times that of a step-by-step pre-reaming cutting capacity; the number of times of manually applying B-type tongs for fastening is reduced, time is saved, and potential safety hazards in the operation process of personnel are reduced; and the use value and the popularization value are realized.

Owner:中石化石油工程技术服务有限公司 +1

Method for producing movable core low segregation large-sized hollow steel ingot

The invention relates to a preparation technique for heavy hollow ingots of all levels between 50 tons to 300 tons, in particular to a manufacturing method for heavy hollow ingots with a movable coreand low segregation. The manufacturing method is applicable to the preparation process of all heavy hollow ingots cast by adopting movable cores, including the casting of the hollow ingots of variousshapes, specifications and materials; besides utilizing simulation means of computers to reasonably design a mould and a casting system for ingots, the manufacturing method mainly adopts a pore-forming technology with a movable core, an intensive cooling technology for various media at different stages, a movable core protection technology, a technology for controlling the flow of a cooling mediumand the temperature of the movable core, an atomizing device for the cooling medium, an early electro slag protection and argon protection technology for molten metal and a technology for protectingthe chassis from big temperature variation, thereby guaranteeing the purity of the molten metal and the operability and the stability of the casting technique, mitigating the segregation, controllingthe segregation position, locating the segregation band of the hollow ingots in the middle position and increasing the utilization rate and the application range of the hollow ingots.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of hollow fiber membrane preparation method based on ultrasonic technology

ActiveCN104128097BEasy to form holesImprove pore structureSemi-permeable membranesPolymer resinSupersonic waves

The invention relates to a supersonic wave technology-based hollow fiber film preparation method. The preparation method comprises the following steps of S1, dissolving a polymer resin, a hydrophilc agent, a thickener, an additive and a nonsolvent in a solvent to obtain a spinning stoste, S2, carrying out deaeration treatment on the spinning stoste to obtain a spinning material liquid, S3, pressing the spinning material liquid into a spinning jet, carrying out spraying, carrying out 20-200mm air bath treatment, and stepwise feeding the sprayed materials into all levels of ultrasonic coagulation bathes for curing molding of a primary hollow fiber film, S4, treating the primary hollow fiber film by a washing tank, carrying out glycerin hole-retaining treatment, and winding the primary hollow fiber film on a wire winding wheel, and S5, cutting off the primary hollow fiber film on the wire winding wheel, tidily binding the primary hollow fiber film, putting it into a drying room and carrying out drying. The invention provides the supersonic wave technology-based hollow fiber film preparation method. The supersonic wave technology-based hollow fiber film preparation method improves hollow fiber film pore-forming efficiency, shortens spinning time and improves generation efficiency.

Owner:BEIJING E & E TECH

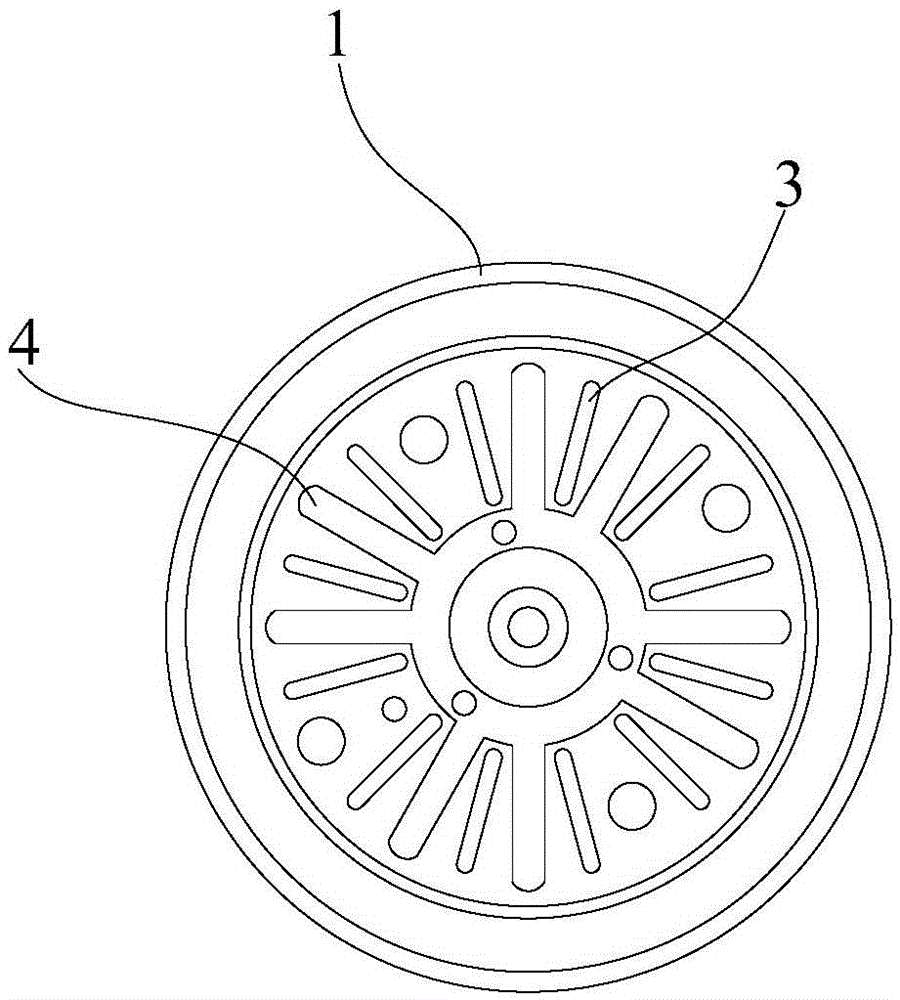

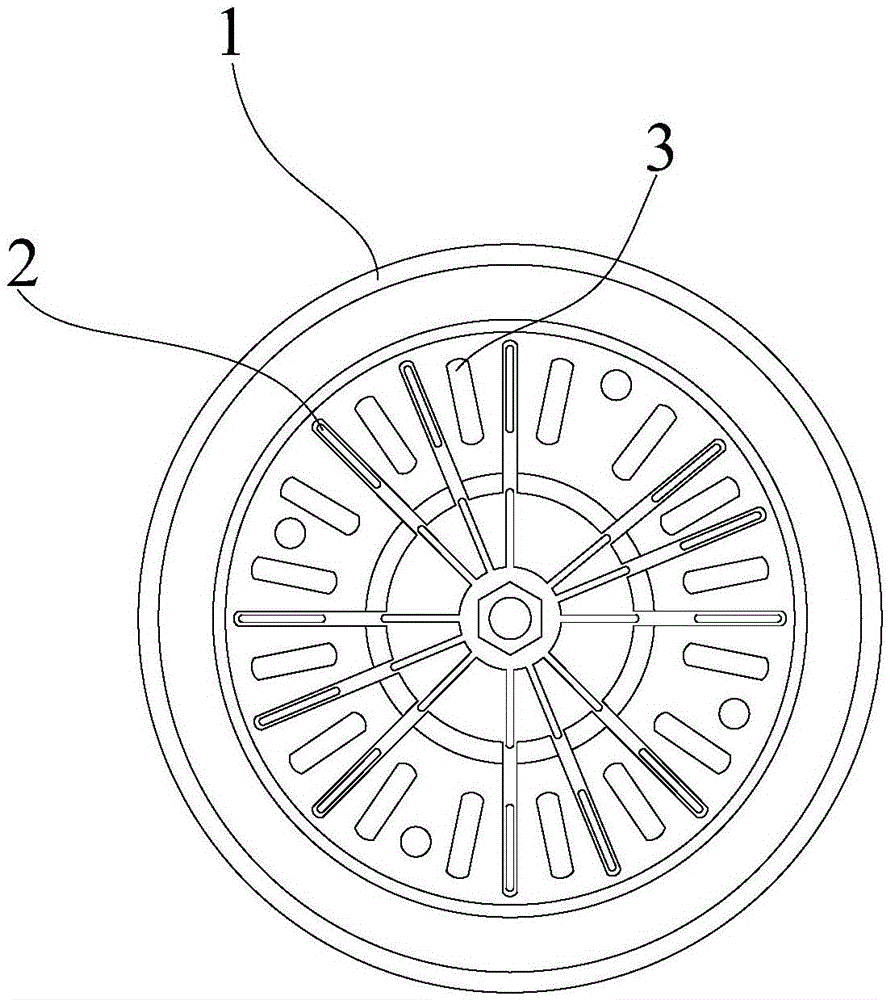

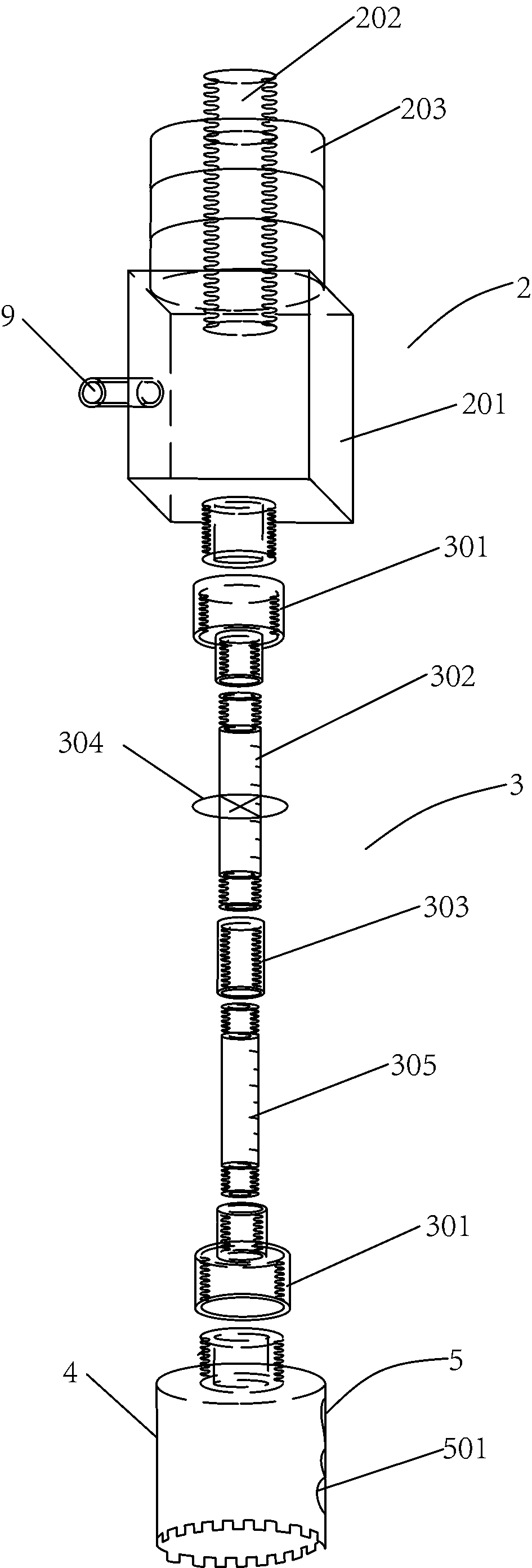

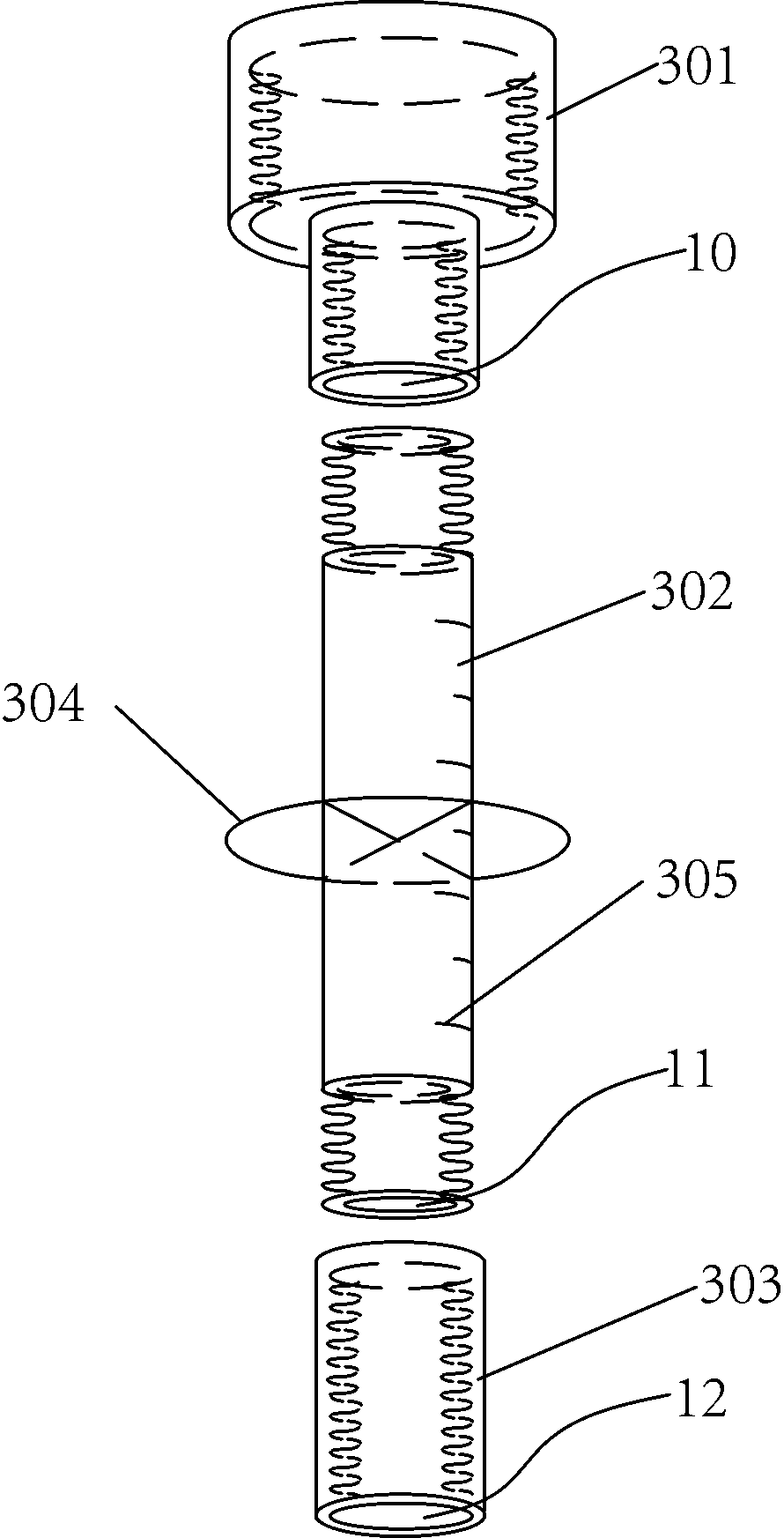

Heat dissipating device for variable frequency motor

InactiveCN105529872AEasy to installEasy to form holesCooling/ventillation arrangementImpellerElectrical and Electronics engineering

The invention provides a heat dissipating device for a variable frequency motor. The heat dissipating device comprises an impeller with an edge overturned towards one side, a first mounting hole is formed in the center of the impeller, a plurality of second mounting holes are formed around the first mounting hole, a plurality of blade mounting holes are punched in the bottom of the impeller, and a vent hole is formed between two adjacent blade mounting holes; and heat dissipating blades are fixed in the blade mounting holes. The heat dissipating device provided by the invention has the advantages that the blade mounting holes are formed conveniently, and when the blades are mounted, the blades are mounted simply.

Owner:泰信电机(苏州)有限公司

Hole-forming device and hole-forming method for water content sensor of gravel soil slope

ActiveCN107288536BSimple structureQuick assembly and disassemblyDrill bitsLiquid/gas jet drillingCrushed stoneEngineering

Owner:SHIJIAZHUANG TIEDAO UNIV

Vibrating auxiliary device for small-diameter root pile and using method of vibrating auxiliary device

The invention belongs to the technical field of river regulation, and particularly relates to a vibrating auxiliary device for a small-diameter root pile and a using method of the vibrating auxiliary device. The device comprises a pile casing placed in a preformed hole of the root pile, and the pile casing is in a hollow shape; a cover plate capable of being overturned downwards is arranged at the bottom of the pile casing, and a steel plate clamped by the vibratory pile driver is arranged at the top of the pile casing. The pile casing in the vibration auxiliary device has an extrusion effect on soil on the hole wall, the phenomena of hole collapse, hole shrinkage and the like are avoided, and it is guaranteed that the root pile is smoothly placed into the preformed hole; and the arranged cover plate which moves downwards and unidirectionally is beneficial to preventing soil from entering the vibrating auxiliary device when the vibrating auxiliary device is lowered, meanwhile, sediments at the bottom of a drill hole can be compacted, and hole cleaning measures in the grouting pile forming process are eliminated.

Owner:CHINA COAL NO 3 CONSTR GRP +1

Cast-in-situ pile casing and its construction method

ActiveCN103572756BReduce the crowding effectHarm reductionBulkheads/pilesEngineeringStructural engineering

The invention discloses a cast-in-place pile sleeve tube and a construction method of the cast-in-place pile sleeve tube. The cast-in-place pile sleeve tube comprises a first tube body, a second tube body, a plurality of valve pieces and a rope body, wherein the first tube body is hollow, openings are formed in the two ends of the first tube body, the second tube body is sleeved with the first tube body, the valve pieces are in rotatable linkage at the lower end of the second tube body, one end of the rope body is in movable linkage to the valve pieces, and the other end of the rope body extends out of the upper end of the second tube body. The construction method comprises the steps of cleaning a place, injecting the cast-in-place pile sleeve tube, closing the valve pieces through the rope body, pulling out the second tube body, placing a reinforcement cage, pouring concrete, pulling out of the first tube body and the like. According to the cast-in-place pile sleeve tube and the construction method, the soil compaction effect of a traditional cast-in-place pile can be greatly reduced, and damage caused by the soil compaction effect is reduced. Meanwhile, due to the fact that the cast-in-place pile is a soil-taking pile, the cast-in-place pile sleeve tube has the advantages that the pile sinking resistance is small, and holes are easily formed.

Owner:中铁十五局集团城市建设工程有限公司

Punching device of high-capacity dynamical lithium-ion battery lug

ActiveCN101850565BSimplified PenetrationStrong penetrating powerMetal working apparatusPunchingElectrical battery

The invention discloses a punching device of a high-capacity dynamical lithium-ion battery lug, which comprises a supporting part, and a driving part and a clamping part which are fixedly connected with the supporting part and an executing part connected with the driving part, wherein the supporting part is used for supporting the whole device; the clamping part is used for clamping the battery lug; the driving part is used for directly providing mechanical power for the executing part and driving the executing part to make linear movement, wherein a punching knife is embedded in the executing part; a through hole matched with the punching knife is respectively arranged in the corresponding clamping part and the supporting part; and the position of the through hole corresponds to that of the punching hole. The punching hole has the characteristics of reasonable structure, convenient and simple use, safe operation and small occupation area and the advantages of easy pore forming and high punching efficiency and also can reduce the potential safety hazard of the battery.

Owner:奇瑞新能源汽车股份有限公司

Construction method of super thick backfill layer pile foundation

The invention relates to a construction method for a pile foundation of an ultra-thick backfilling layer. The construction method comprises the following steps that a foundation pit for embedding of a steel pipe protective cylinder is excavated in the ultra-thick backfilling layer through a machine, and the depth of the foundation pit is more than five meters; backfilling materials contain block stone with the particle size being larger than 500 mm, and the thickness of the backfilling layer is 11 m or above; the bottom of the foundation pit is filled with a clay layer, then the steel pipe protective cylinder is arranged in the foundation pit in the vertical direction, the thickness of the clay layer is larger than 500 mm; the top end of the backfilled steel pipe protective cylinder is exposed out of the ground; clay and water are stirred to prepare slurry, and the proportion of the slurry is larger than 1.35; the prepared slurry is poured into the steel pipe protective cylinder, and the steep pipe protective cylinder is fully filled with the slurry; and the backfilling layer in the steel pipe protective cylinder is hammered through a hammering pile, and thus a hole is formed in a slurry protective wall. According to the construction method for the pile foundation of the ultra-thick backfilling layer, the hole forming quality of the pile foundation of the ultra-thick backfilling layer can be improved, hole forming of the pile foundation of the ultra-thick backfilling layer is more convenient, more efficient and rapider, accordingly the construction period can be shortened, and the construction cost is reduced.

Owner:SINOCHEM ZHOUSHAN XINGHAI CONSTR

Underground drilling and sealing tool and drainage construction method

PendingCN112282651AEasy to form holesImprove performanceDrill bitsDrilling rodsStructural engineeringCoal mine methane

The invention discloses an underground drilling and sealing tool, and relates to the technical field of coal mine gas extraction, the underground drilling and sealing tool comprises a drilling deviceand a grouting sleeve device. The drilling device comprises a guide reamer bit and a plurality of centralizers. Each centralizer comprises a centralizer body, a first drill rod and a second drill rod.One end of the guide reamer bit is in threaded connection with one end of the first drill rod. The grouting sleeve device comprises a first sleeve, a second sleeve, a guide shoe, a first flange plateand a first connecting pipe. The invention further discloses a drainage method adopting the tool. The construction method has the beneficial effects that the construction method is suitable for underground large-diameter drainage drilling hole forming, pipe descending and pipe fixing. By the adoption of the construction method, in the drilling process, the guide reamer bit drills, the centralizerstraightens the drilling track, it is guaranteed that the drilling track meets the pipe descending requirement, the protrusions on the side wall of the centralizer body can grind the unsmooth positions of the hole wall in the drilling process, and hole forming is easy.

Owner:HUAINAN MINING IND GRP

A building foundation construction device

InactiveCN112252320BEasy to slide in syncConvenient socketUsing liquid separation agentBulkheads/pilesArchitectural engineeringStructural engineering

The invention discloses a building foundation construction device, which comprises a base plate, supports are fixedly connected to both sides of the base plate, a hydraulic rod is arranged on the support, a fixing seat is arranged at the bottom of the hydraulic rod, and slide grooves are provided on the sides of the fixing seat , the inner cavity of the chute is provided with a slider, one side of the slider is provided with a bearing plate, the bottom of the bearing plate is provided with a first perforated pile, one side of the two bearing plates is provided with a slide bar, and two A bending rod is arranged between the sliding rods, a spring is arranged on one side inner wall of the sliding chamber of the bending rod, an extruding block is arranged on the spring, and a second perforated pile is arranged at the bottom of the fixing seat. The present invention utilizes the cooperation of the fixing seat, the chute, the sliding block, the connecting rod and the bearing plate to facilitate the control of the relative distance between the four first perforated piles, and utilizes the cooperation of the sliding rod, the bending rod, the spring and the extruding block , to facilitate the synchronous sliding of the four first perforated piles, improve the accuracy of the spacing, and use the cooperation of the second perforated piles and the fixing seat to socket the second perforated piles with different apertures.

Owner:鹤山市伟创工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com