Underground drilling and sealing tool and drainage construction method

A technology for sealing holes and tools, applied in drilling equipment and methods, drill bits, drill pipes, etc., can solve the problems of difficulty in drilling holes for water drainage, and the construction of drilling holes for water drainage is not recorded, so as to reduce the difficulty of drilling holes and make it easier to The effect of pore formation, retention and stabilization of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

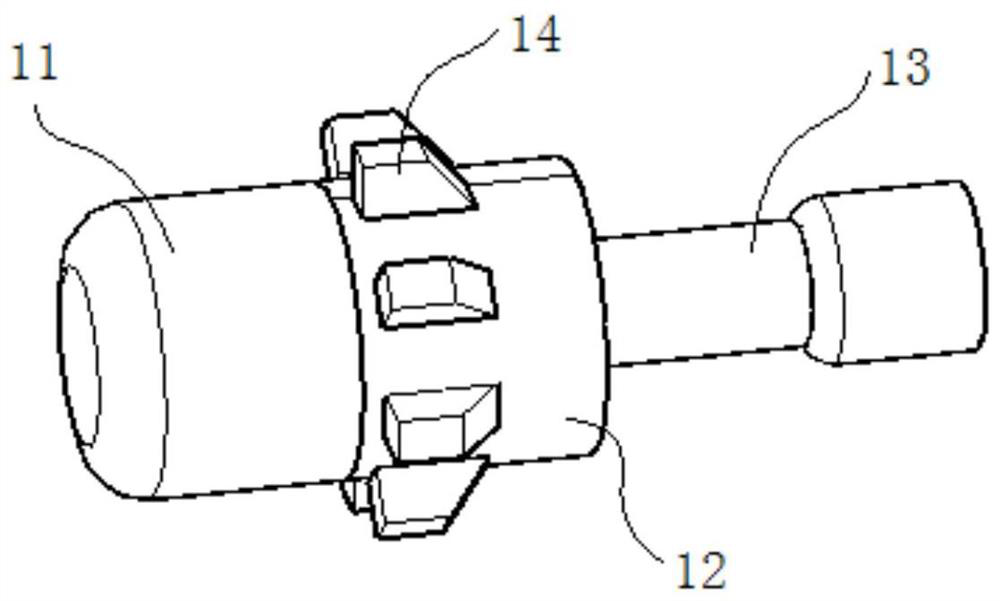

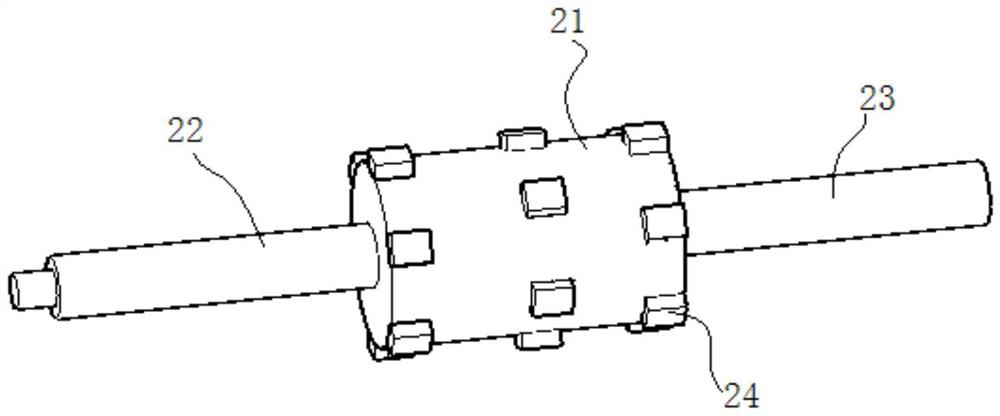

[0058] A downhole drilling and sealing tool, such as Figure 1-3 As shown, including drilling device and grouting casing device.

[0059] like figure 1 and figure 2 As shown, the drilling device includes a pilot reamer bit and a plurality of centralizers. The pilot reaming drill bit comprises the first pilot drill bit 11, the second pilot drill bit 12, connecting rod 13 and reamer 14, and the first pilot drill bit 11 and the second pilot drill bit 12 are all cylindrical, and the diameter of the first pilot drill bit 11 is the same as The diameters of the second pilot bits 12 are equal.

[0060] The center of the first pilot drill 11, the center of the second pilot drill 12, and the center of the connecting rod 13 offer coaxial through holes, and the first pilot drill 11, the second pilot drill 12 and the connecting rod 13 are communicated in sequence and coaxially arranged One end of the first pilot bit 11 is fixedly connected with one end of the second pilot bit 12 by we...

Embodiment 2

[0072] The difference between this embodiment and embodiment 1 is: as Figure 4 Shown, also comprise mud purifying device, mud purifying device comprises tank 41, settling tank 42, mud tank 43, the first suction pipe 44, the first mud pump 45 and the first row pipe 46 of mud, water tank 41 is arranged in borehole Nearby, the mud after drilling is made to flow into the water tank 41, and the specific installation position of the water tank 41 is arranged according to working conditions, and the water tank 41 is communicated with the sedimentation tank 42, and the sedimentation tank 42 is communicated with the mud tank 43, and one end of the first slurry suction pipe 44 is connected with the The mud pool 43 is connected, the other end of the slurry suction pipe is connected with the first mud pump 45 , one end of the slurry discharge pipe is connected with the first mud pump 45 , and the other end of the slurry discharge pipe is connected with an end of the second drill pipe 23 ....

Embodiment 3

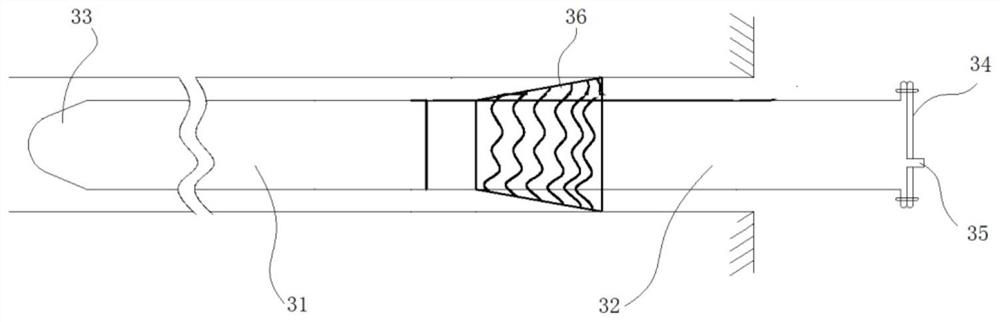

[0076] A kind of construction method that adopts the downhole drilling sealing tool in embodiment 1 to drain water downhole, comprises the following steps:

[0077] (1) Use the first drill bit: φ94mm composite sheet drill bit and Φ89mm rib drill pipe to drill to 33m, and after drilling out, inject grout under pressure.

[0078] (2) Front-guided and rear-righting step-by-step reaming: use Φ94mm to Φ153mm, Φ153mm to Φ196mm, Φ196mm to Φ248mm, Φ248mm to Φ268mm guide reaming drill bits in sequence, and adopt the method of dense first and thin later on the first 10m drill pipe near the bottom of the hole Add 5 centralizers to ensure the straightness, and ream the hole to 33m in stages. When using the Φ268mm pilot reaming bit, one centralizer is installed for the first reaming, two centralizers are added for the second reaming, and three centralizers are added for the third reaming. Cooperate with Φ89mm rib drill pipe for multiple times of sweeping. When sweeping, use a large-volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com