Vibrating auxiliary device for small-diameter root pile and using method of vibrating auxiliary device

An auxiliary device and root pile technology, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of cumbersome construction process, insufficient vibration, inconvenient hole cleaning, etc., to eliminate easy floating and reduce construction equipment The effect of using and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

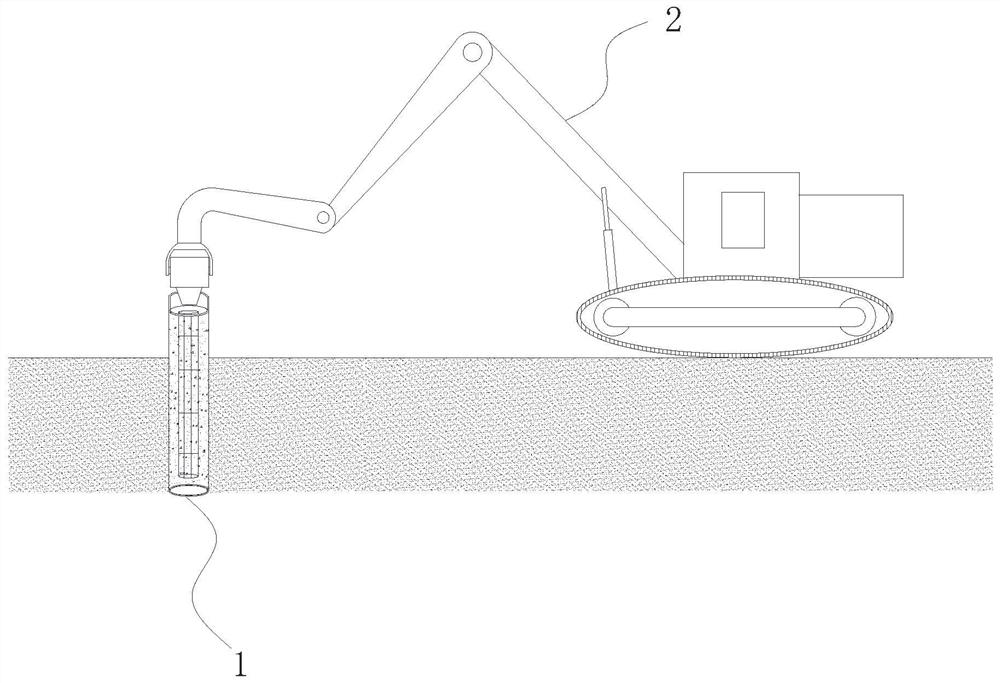

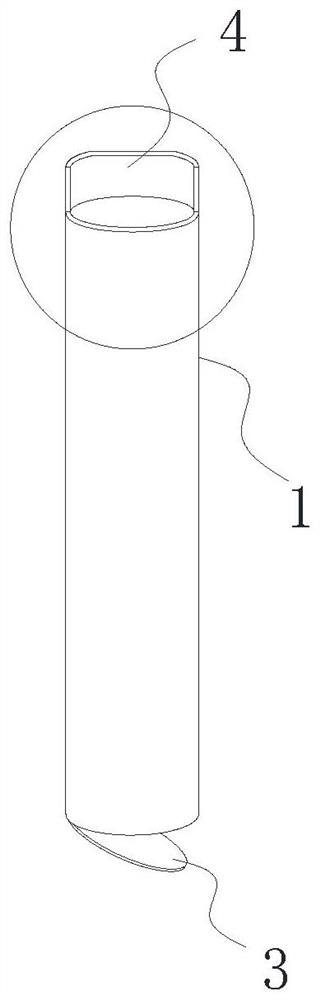

[0034] Such as Figure 1-4 As shown, a small-diameter tree root pile with a vibration auxiliary device and its use method, the device includes a casing 1 placed in the pre-formed hole of the tree root pile, the casing 1 is hollow; in order to prevent the casing 1 from being lowered When soil enters in the casing 1, the bottom of the casing 1 is provided with a cover plate 3 that can only be turned downwards, and the top of the casing 1 is provided with a steel plate 4 clamped by a vibratory pile driver 2.

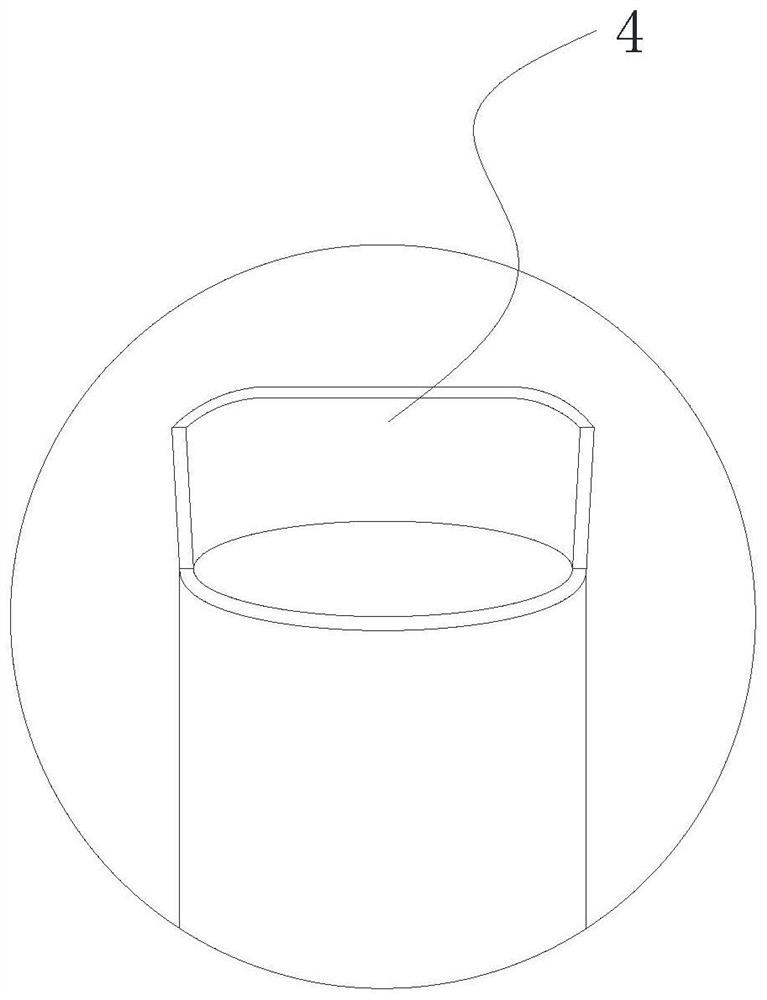

[0035] Specifically, the steel plate 4 is located on the side of the top of the casing 1, the steel plate 4 is positioned on the side of the top of the casing 1, the cross section of the bottom of the steel plate 4 is semicircular, the cross section of the top of the steel plate 4 is U-shaped, and the steel plate 4 and the The clamps of the vibratory pile driver 2 are matched and arranged. More specifically, in order to facilitate the pile driver 2 to clamp the steel plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com