Construction method of reinforced concrete protection pile in loess areas

A reinforced concrete and construction method technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of large investment and affecting the normal operation of existing lines, etc., and achieve simple hole formation, good economic and social effects, and easy construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

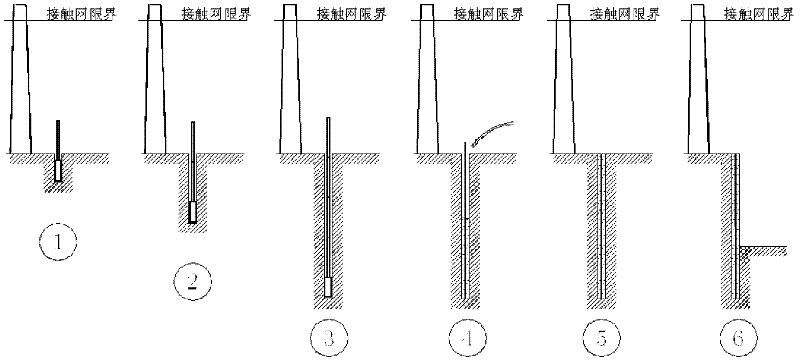

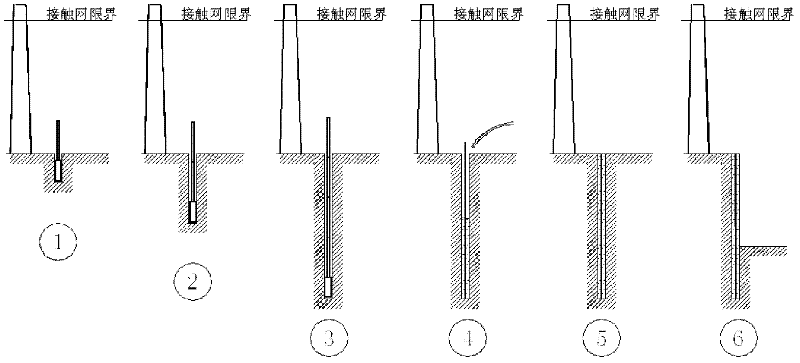

[0019] The construction method of reinforced concrete protective pile in loess area includes the following steps, see figure 1 The construction process shown:

[0020] ①. Use a Luoyang shovel with a semicircular end and a diameter of 150mm-170mm to make a hole below the construction ground. The handle end of the Luoyang shovel has an external thread;

[0021] ②. When the external thread at the end of the Luoyang shovel touches the ground, connect the extension rod with a screw hole at one end and a thread at the other end to the end of the Luoyang shovel by thread connection, and continue digging;

[0022] ③. When the external thread at the end of the extension rod touches the ground, connect another extension rod and continue digging until the hole reaches the depth of the protective pile;

[0023] ④. Insert steel bars with a diameter of 15mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com