UV-cured peelable blue gel for temporary protection of touch screen and preparation method thereof

A temporary protection, touch screen technology, applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of application limitations, affecting production efficiency, long time consumption, etc., to achieve the effect of fast film formation and improved efficiency

Inactive Publication Date: 2013-04-10

TONSAN ADHESIVES INC

View PDF1 Cites 48 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional peelable blue glue contains phthalate plasticizers that interfere with human endocrine and affect human reproductive ability, so its application is limited

Moreover, the process of curing the traditional peelable blue glue into a film is generally 120°C-150°C, 20min-60min. It takes a long time to affect production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

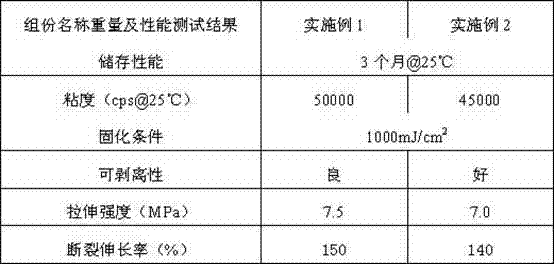

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a UV-cured peelable blue gel for temporary protection of a touch screen and a preparation method thereof. The UV-cured peelable blue gel comprises the following components of 50-70 parts of modified acrylate resin, 20-30 parts of acrylate monomer, 1.0-5.0 parts of light curing agent, 0.1-1.0 part of thixotropic agent, 0.1-5.0 parts of auxiliary and 0.1-1.0 part of pigment; and the preparation method comprises the following steps of: accurately weighing various raw materials according to a formula ratio; firstly adding the modified acrylate resin, the acrylate monomer, the light curing agent, the auxiliary and the pigment to a reaction kettle in sequence and then stirring these materials in the reaction kettle; after these materials are uniformly stirred, adding the thixotropic agent to these materials; and uniformly dispersing an obtained mixture to discharge out a material. The UV-cured peelable blue gel provided by the invention is a non-solvent and a system containing no phthalate substance and is much safer and more environment-friendly. Through the adoption of a UV curing system, the film curing and forming speed is high and the production efficiency of the touch screen is greatly increased.

Description

technical field [0001] The invention relates to a UV curing peelable blue glue and a preparation method thereof. The peelable blue glue is mainly used for temporary protection in a touch screen manufacturing process. Background technique [0002] With the rapid development of information technology and flat display technology, the application of touch screens is becoming more and more common. As large as information query systems in public places, as small as personal computers, tablet computers, and mobile phones, touch screens are closely related to our lives. During the production process of the touch screen, the glass of the touch screen needs to be temporarily protected many times by using peelable blue glue. The traditional peelable blue glue contains phthalate plasticizers that interfere with human endocrine and affect human reproductive ability, so its application is limited. Moreover, the process of curing the traditional peelable blue glue into a film is general...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D175/14C09D163/00C09D183/04C09D167/06C09D171/00C09D4/02C09D7/12

Inventor 王晓颖陈三多史伟同李守平

Owner TONSAN ADHESIVES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com